How to Standardize Solar Inverter Manufacturing Processes?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Inverter Tech Evolution and Objectives

Solar inverter technology has undergone significant evolution since its inception in the 1990s. Initially designed for simple DC to AC conversion, modern solar inverters have become sophisticated devices capable of grid integration, power optimization, and advanced monitoring. The primary objective in standardizing solar inverter manufacturing processes is to enhance efficiency, reliability, and cost-effectiveness while meeting increasingly stringent regulatory requirements.

The technological progression of solar inverters has been driven by the rapid growth of the solar energy sector and the need for more efficient and grid-friendly power conversion solutions. Early inverters were primarily focused on basic power conversion, but as solar installations grew in scale and complexity, inverter technology evolved to address challenges such as grid stability, power quality, and system performance optimization.

Key milestones in solar inverter technology include the introduction of maximum power point tracking (MPPT) in the early 2000s, which significantly improved energy harvest from solar panels. The development of string inverters in the mid-2000s allowed for more flexible system designs and reduced installation costs. More recently, the integration of smart features and communication capabilities has enabled remote monitoring, diagnostics, and grid support functions.

The current technological landscape is characterized by a push towards higher power densities, improved efficiency ratings exceeding 98%, and enhanced grid support capabilities. Modern inverters are expected to provide reactive power support, voltage regulation, and fault ride-through capabilities to maintain grid stability as solar penetration increases.

Looking forward, the objectives for solar inverter technology and manufacturing standardization include:

1. Improving manufacturing efficiency through automation and streamlined processes to reduce costs and increase production capacity.

2. Enhancing product reliability and longevity to meet the 25+ year lifespan expectations of solar installations.

3. Developing more compact and lightweight designs to simplify installation and reduce material costs.

4. Integrating advanced power electronics, such as wide-bandgap semiconductors, to improve efficiency and reduce thermal management requirements.

5. Implementing standardized communication protocols and interfaces to ensure seamless integration with diverse energy management systems and smart grid infrastructure.

6. Incorporating advanced diagnostic and predictive maintenance capabilities to minimize downtime and optimize performance over the inverter's lifetime.

7. Ensuring compliance with evolving grid codes and standards across different regions to facilitate global market access.

By focusing on these objectives, the solar industry aims to establish standardized manufacturing processes that can consistently produce high-quality, cost-effective inverters capable of meeting the demands of a rapidly evolving energy landscape.

The technological progression of solar inverters has been driven by the rapid growth of the solar energy sector and the need for more efficient and grid-friendly power conversion solutions. Early inverters were primarily focused on basic power conversion, but as solar installations grew in scale and complexity, inverter technology evolved to address challenges such as grid stability, power quality, and system performance optimization.

Key milestones in solar inverter technology include the introduction of maximum power point tracking (MPPT) in the early 2000s, which significantly improved energy harvest from solar panels. The development of string inverters in the mid-2000s allowed for more flexible system designs and reduced installation costs. More recently, the integration of smart features and communication capabilities has enabled remote monitoring, diagnostics, and grid support functions.

The current technological landscape is characterized by a push towards higher power densities, improved efficiency ratings exceeding 98%, and enhanced grid support capabilities. Modern inverters are expected to provide reactive power support, voltage regulation, and fault ride-through capabilities to maintain grid stability as solar penetration increases.

Looking forward, the objectives for solar inverter technology and manufacturing standardization include:

1. Improving manufacturing efficiency through automation and streamlined processes to reduce costs and increase production capacity.

2. Enhancing product reliability and longevity to meet the 25+ year lifespan expectations of solar installations.

3. Developing more compact and lightweight designs to simplify installation and reduce material costs.

4. Integrating advanced power electronics, such as wide-bandgap semiconductors, to improve efficiency and reduce thermal management requirements.

5. Implementing standardized communication protocols and interfaces to ensure seamless integration with diverse energy management systems and smart grid infrastructure.

6. Incorporating advanced diagnostic and predictive maintenance capabilities to minimize downtime and optimize performance over the inverter's lifetime.

7. Ensuring compliance with evolving grid codes and standards across different regions to facilitate global market access.

By focusing on these objectives, the solar industry aims to establish standardized manufacturing processes that can consistently produce high-quality, cost-effective inverters capable of meeting the demands of a rapidly evolving energy landscape.

Market Demand for Standardized Solar Inverters

The market demand for standardized solar inverters has been steadily increasing in recent years, driven by the rapid growth of the global solar energy sector. As solar power installations continue to expand worldwide, the need for reliable, efficient, and cost-effective inverter solutions has become paramount. Standardization in solar inverter manufacturing processes is seen as a key factor in meeting this growing demand while ensuring consistent quality and performance across the industry.

One of the primary drivers for standardized solar inverters is the push for reduced costs in solar energy systems. By implementing standardized manufacturing processes, manufacturers can achieve economies of scale, leading to lower production costs and, ultimately, more affordable solar solutions for consumers. This cost reduction is crucial for the continued adoption of solar energy, particularly in emerging markets where price sensitivity is high.

The increasing complexity of solar energy systems has also fueled the demand for standardized inverters. As solar installations become larger and more sophisticated, system integrators and installers require inverters that can seamlessly integrate with various components and comply with diverse grid requirements. Standardized manufacturing processes can help ensure that inverters meet these compatibility and compliance needs consistently, simplifying system design and installation.

Reliability and performance are critical factors driving the market demand for standardized solar inverters. End-users, from residential homeowners to large-scale solar farm operators, expect inverters to perform efficiently and reliably over extended periods. Standardized manufacturing processes can help maintain consistent quality control, reducing the likelihood of product defects and improving overall system performance and longevity.

The global nature of the solar industry has further emphasized the need for standardization. As solar projects are implemented across different countries and regions, inverters must meet various international standards and regulations. Standardized manufacturing processes can facilitate compliance with these diverse requirements, enabling manufacturers to produce inverters suitable for multiple markets and reducing barriers to international trade.

The trend towards smart grids and advanced energy management systems has also influenced the demand for standardized solar inverters. Grid operators and utilities increasingly require inverters with advanced communication and control capabilities. Standardized manufacturing processes can ensure that these features are consistently implemented across product lines, meeting the evolving needs of modern power systems.

As the solar industry matures, there is a growing emphasis on sustainability and environmental responsibility. Standardized manufacturing processes can help optimize resource utilization, reduce waste, and improve the overall environmental footprint of inverter production. This aligns with the broader goals of the renewable energy sector and appeals to environmentally conscious consumers and investors.

One of the primary drivers for standardized solar inverters is the push for reduced costs in solar energy systems. By implementing standardized manufacturing processes, manufacturers can achieve economies of scale, leading to lower production costs and, ultimately, more affordable solar solutions for consumers. This cost reduction is crucial for the continued adoption of solar energy, particularly in emerging markets where price sensitivity is high.

The increasing complexity of solar energy systems has also fueled the demand for standardized inverters. As solar installations become larger and more sophisticated, system integrators and installers require inverters that can seamlessly integrate with various components and comply with diverse grid requirements. Standardized manufacturing processes can help ensure that inverters meet these compatibility and compliance needs consistently, simplifying system design and installation.

Reliability and performance are critical factors driving the market demand for standardized solar inverters. End-users, from residential homeowners to large-scale solar farm operators, expect inverters to perform efficiently and reliably over extended periods. Standardized manufacturing processes can help maintain consistent quality control, reducing the likelihood of product defects and improving overall system performance and longevity.

The global nature of the solar industry has further emphasized the need for standardization. As solar projects are implemented across different countries and regions, inverters must meet various international standards and regulations. Standardized manufacturing processes can facilitate compliance with these diverse requirements, enabling manufacturers to produce inverters suitable for multiple markets and reducing barriers to international trade.

The trend towards smart grids and advanced energy management systems has also influenced the demand for standardized solar inverters. Grid operators and utilities increasingly require inverters with advanced communication and control capabilities. Standardized manufacturing processes can ensure that these features are consistently implemented across product lines, meeting the evolving needs of modern power systems.

As the solar industry matures, there is a growing emphasis on sustainability and environmental responsibility. Standardized manufacturing processes can help optimize resource utilization, reduce waste, and improve the overall environmental footprint of inverter production. This aligns with the broader goals of the renewable energy sector and appeals to environmentally conscious consumers and investors.

Current Manufacturing Challenges and Constraints

The solar inverter manufacturing industry faces several significant challenges and constraints that hinder the standardization of production processes. One of the primary issues is the rapid technological advancements in solar inverter design, which necessitate frequent updates to manufacturing techniques. This constant evolution makes it difficult to establish and maintain consistent production standards across the industry.

Material sourcing and supply chain management present another major hurdle. The components used in solar inverters, such as semiconductors and specialized capacitors, often have varying specifications from different suppliers. This variability can lead to inconsistencies in the final product and complicates efforts to standardize manufacturing processes. Additionally, the global nature of the supply chain introduces complexities in terms of quality control and logistics management.

Quality control and testing procedures pose significant challenges in standardizing solar inverter production. The performance and reliability of inverters are critical for the efficiency of solar energy systems, necessitating rigorous testing protocols. However, the lack of universally accepted testing standards across different markets and regions makes it difficult to implement consistent quality control measures throughout the manufacturing process.

The diversity of solar inverter applications and customer requirements also impedes standardization efforts. Inverters for residential, commercial, and utility-scale installations often have different specifications and features, requiring manufacturers to maintain multiple production lines with varying processes. This diversity complicates the implementation of uniform manufacturing standards across all product lines.

Regulatory compliance and certification requirements vary significantly across different countries and regions. These disparities in standards and regulations force manufacturers to adapt their production processes to meet specific market requirements, further hindering the development of globally standardized manufacturing practices.

Cost pressures and market competition also play a role in constraining standardization efforts. Manufacturers often prioritize cost reduction and production efficiency over process standardization, leading to the adoption of diverse manufacturing techniques that may be more economical in the short term but less conducive to industry-wide standardization.

Lastly, the shortage of skilled labor and expertise in solar inverter manufacturing presents a significant constraint. The complexity of inverter technology requires specialized knowledge and skills, which are not always readily available. This shortage makes it challenging to implement and maintain standardized processes across different manufacturing facilities and regions.

Material sourcing and supply chain management present another major hurdle. The components used in solar inverters, such as semiconductors and specialized capacitors, often have varying specifications from different suppliers. This variability can lead to inconsistencies in the final product and complicates efforts to standardize manufacturing processes. Additionally, the global nature of the supply chain introduces complexities in terms of quality control and logistics management.

Quality control and testing procedures pose significant challenges in standardizing solar inverter production. The performance and reliability of inverters are critical for the efficiency of solar energy systems, necessitating rigorous testing protocols. However, the lack of universally accepted testing standards across different markets and regions makes it difficult to implement consistent quality control measures throughout the manufacturing process.

The diversity of solar inverter applications and customer requirements also impedes standardization efforts. Inverters for residential, commercial, and utility-scale installations often have different specifications and features, requiring manufacturers to maintain multiple production lines with varying processes. This diversity complicates the implementation of uniform manufacturing standards across all product lines.

Regulatory compliance and certification requirements vary significantly across different countries and regions. These disparities in standards and regulations force manufacturers to adapt their production processes to meet specific market requirements, further hindering the development of globally standardized manufacturing practices.

Cost pressures and market competition also play a role in constraining standardization efforts. Manufacturers often prioritize cost reduction and production efficiency over process standardization, leading to the adoption of diverse manufacturing techniques that may be more economical in the short term but less conducive to industry-wide standardization.

Lastly, the shortage of skilled labor and expertise in solar inverter manufacturing presents a significant constraint. The complexity of inverter technology requires specialized knowledge and skills, which are not always readily available. This shortage makes it challenging to implement and maintain standardized processes across different manufacturing facilities and regions.

Current Standardization Approaches

01 Manufacturing processes for solar inverter components

This category focuses on the manufacturing processes for various components of solar inverters, including power modules, circuit boards, and enclosures. It involves techniques such as automated assembly, precision machining, and quality control measures to ensure the reliability and efficiency of the inverter components.- Manufacturing processes for solar inverter components: This category focuses on the manufacturing processes of various components used in solar inverters. It includes techniques for producing semiconductor devices, circuit boards, and other essential parts. The processes may involve advanced fabrication methods, quality control measures, and optimization techniques to enhance the performance and reliability of solar inverter components.

- Assembly and integration techniques for solar inverters: This point covers the methods and techniques used in assembling and integrating various components of solar inverters. It includes processes for combining power electronics, control systems, and cooling mechanisms into a complete inverter unit. The assembly techniques may focus on improving efficiency, reducing manufacturing costs, and ensuring product durability.

- Quality control and testing procedures in solar inverter manufacturing: This category encompasses the quality control measures and testing procedures implemented during the manufacturing of solar inverters. It includes methods for inspecting components, verifying electrical performance, conducting thermal tests, and ensuring compliance with safety standards. These processes aim to maintain high product quality and reliability in solar inverter production.

- Automation and robotics in solar inverter production: This point focuses on the use of automation and robotics in the manufacturing of solar inverters. It includes the implementation of automated assembly lines, robotic systems for handling and positioning components, and computer-controlled processes for increased precision and efficiency in production. These technologies aim to improve manufacturing speed, consistency, and cost-effectiveness.

- Advanced materials and technologies in solar inverter manufacturing: This category covers the use of advanced materials and cutting-edge technologies in the production of solar inverters. It includes the incorporation of novel semiconductor materials, innovative cooling solutions, and emerging power electronics technologies. These advancements aim to improve the efficiency, reliability, and performance of solar inverters while potentially reducing manufacturing costs.

02 Integration of advanced control systems

This point covers the incorporation of advanced control systems in solar inverter manufacturing. It includes the implementation of microprocessors, digital signal processors, and smart algorithms to optimize power conversion, grid synchronization, and overall system performance. The manufacturing process involves programming and testing these control systems.Expand Specific Solutions03 Thermal management and cooling solutions

This category addresses the manufacturing processes related to thermal management and cooling solutions for solar inverters. It includes the design and production of heat sinks, cooling fans, and thermal interface materials to ensure optimal operating temperatures and enhance the longevity of the inverter components.Expand Specific Solutions04 Power electronics assembly and testing

This point focuses on the manufacturing processes for power electronics components in solar inverters. It covers the assembly of semiconductor devices, capacitors, inductors, and transformers, as well as the testing and quality assurance procedures to ensure proper functionality and reliability of the power conversion system.Expand Specific Solutions05 Modular design and scalable manufacturing

This category emphasizes the manufacturing processes that enable modular design and scalable production of solar inverters. It includes techniques for standardizing components, implementing flexible assembly lines, and utilizing advanced manufacturing technologies to accommodate different power ratings and configurations efficiently.Expand Specific Solutions

Key Players in Solar Inverter Manufacturing

The solar inverter manufacturing industry is in a mature growth phase, characterized by a competitive landscape with established players and emerging innovators. The global market size for solar inverters is projected to reach significant volumes, driven by increasing solar energy adoption worldwide. Technological maturity varies among companies, with industry leaders like Huawei Digital Power, Enphase Energy, and SMA Solar Technology demonstrating advanced capabilities in inverter design and production. Emerging players such as JA Solar and Delta Electronics are also making strides in standardizing manufacturing processes. The focus is shifting towards improving efficiency, reliability, and cost-effectiveness through automation and quality control measures. As the industry evolves, collaboration between established manufacturers and research institutions is becoming crucial for driving innovation and standardization in solar inverter production.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei has developed a standardized manufacturing process for solar inverters that incorporates advanced automation and intelligent quality control. Their approach includes the use of AI-driven robotic assembly lines, which can adapt to different inverter models[1]. They have also implemented a digital twin system for real-time monitoring and optimization of the production process[2]. Huawei's standardization efforts extend to component selection, with a focus on using high-quality, pre-tested parts to ensure consistency across production batches[3]. Additionally, they have developed a modular design for their inverters, which allows for easier assembly and customization while maintaining standardized core components[4].

Strengths: High level of automation, consistent quality, and scalable production. Weaknesses: High initial investment costs and potential over-reliance on proprietary technology.

Enphase Energy, Inc.

Technical Solution: Enphase Energy has pioneered a microinverter-based approach to solar inverter manufacturing, which inherently lends itself to standardization. Their process involves producing large volumes of identical microinverters, each capable of converting DC to AC for individual solar panels[5]. The company employs advanced semiconductor manufacturing techniques, including automated testing and calibration for each unit[6]. Enphase has also implemented a comprehensive quality management system that includes in-line testing at multiple stages of production, ensuring consistent performance across all units[7]. Their standardization efforts extend to firmware, with over-the-air update capabilities allowing for uniform functionality improvements across deployed inverters[8].

Strengths: Highly scalable production, consistent quality across large volumes, and easier field upgrades. Weaknesses: Limited flexibility for custom solutions and potentially higher per-watt costs for large installations.

Core Innovations in Manufacturing Standardization

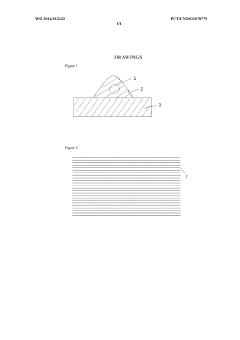

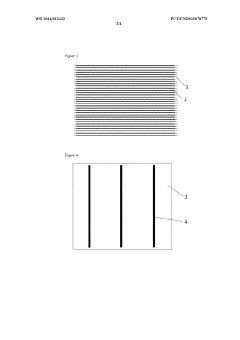

Front-side electrode structure of solar cell sheet and fabrication method therefor

PatentWO2014012432A1

Innovation

- Conductive wire is used to wrap conductive paste and is pasted on the solar cell. Combined with drying and sintering processes, an efficient electrode structure is formed, which avoids the defects of screen printing and reduces the use of conductive paste.

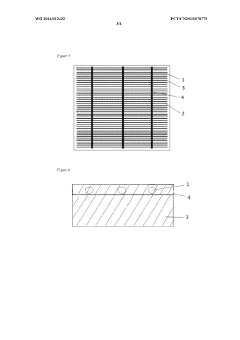

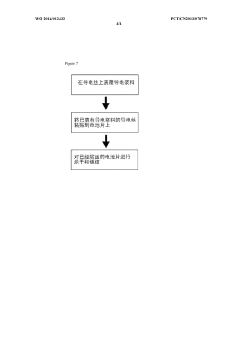

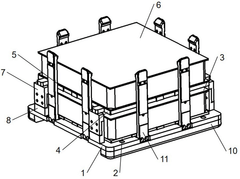

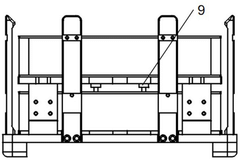

Electric injection double-layer material box

PatentActiveCN221885069U

Innovation

- An electric injection double-layer material box is designed, including a bottom plate, a movable plate, a cover plate, a support component, a middle partition plate, a conductive component and a gear rod. By placing the battery sheets in layers and using the conductive components to achieve current conduction, the battery can be avoided. The support assembly and cover plate provide protection, and the gear lever prevents lateral falling.

Quality Control and Testing Protocols

Quality control and testing protocols are crucial components in standardizing solar inverter manufacturing processes. These protocols ensure that each inverter meets the required specifications and performs reliably in various operating conditions. A comprehensive quality control system typically involves multiple stages of inspection and testing throughout the production process.

The first step in establishing effective quality control is implementing incoming material inspection. This involves thorough testing of components and materials used in inverter production, such as semiconductors, capacitors, and circuit boards. By verifying the quality of input materials, manufacturers can prevent defects from propagating through the production line.

During the assembly process, in-line quality checks are essential. These may include visual inspections, automated optical inspections (AOI), and functional tests at various stages of production. Such checks help identify and rectify issues early in the manufacturing process, reducing the likelihood of defects in the final product.

Once assembly is complete, each inverter undergoes a series of rigorous tests. These typically include insulation resistance tests, ground continuity tests, and load tests to ensure electrical safety and performance. Additionally, environmental stress screening (ESS) may be employed to simulate various operating conditions and identify potential weaknesses in the inverter's design or construction.

Efficiency testing is another critical aspect of quality control for solar inverters. This involves measuring the inverter's ability to convert DC power from solar panels into AC power for grid use or local consumption. Standardized test procedures, such as those outlined in IEC 61683, are often used to ensure consistent and comparable results across different manufacturers and models.

To maintain consistency in quality control, it is essential to implement standardized test procedures and documentation. This includes detailed test plans, checklists, and reporting formats that ensure all necessary tests are performed and results are properly recorded. Automated test equipment and data logging systems can further enhance the accuracy and efficiency of these processes.

Regular calibration of test equipment is vital to maintain the accuracy and reliability of quality control measures. This involves periodic verification and adjustment of measurement instruments against traceable standards to ensure they continue to provide accurate results over time.

Finally, implementing a robust system for tracking and analyzing quality data is crucial for continuous improvement. This may involve statistical process control (SPC) techniques to monitor trends in production quality and identify areas for improvement. By analyzing this data, manufacturers can refine their processes, update test protocols, and ultimately enhance the overall quality and reliability of their solar inverters.

The first step in establishing effective quality control is implementing incoming material inspection. This involves thorough testing of components and materials used in inverter production, such as semiconductors, capacitors, and circuit boards. By verifying the quality of input materials, manufacturers can prevent defects from propagating through the production line.

During the assembly process, in-line quality checks are essential. These may include visual inspections, automated optical inspections (AOI), and functional tests at various stages of production. Such checks help identify and rectify issues early in the manufacturing process, reducing the likelihood of defects in the final product.

Once assembly is complete, each inverter undergoes a series of rigorous tests. These typically include insulation resistance tests, ground continuity tests, and load tests to ensure electrical safety and performance. Additionally, environmental stress screening (ESS) may be employed to simulate various operating conditions and identify potential weaknesses in the inverter's design or construction.

Efficiency testing is another critical aspect of quality control for solar inverters. This involves measuring the inverter's ability to convert DC power from solar panels into AC power for grid use or local consumption. Standardized test procedures, such as those outlined in IEC 61683, are often used to ensure consistent and comparable results across different manufacturers and models.

To maintain consistency in quality control, it is essential to implement standardized test procedures and documentation. This includes detailed test plans, checklists, and reporting formats that ensure all necessary tests are performed and results are properly recorded. Automated test equipment and data logging systems can further enhance the accuracy and efficiency of these processes.

Regular calibration of test equipment is vital to maintain the accuracy and reliability of quality control measures. This involves periodic verification and adjustment of measurement instruments against traceable standards to ensure they continue to provide accurate results over time.

Finally, implementing a robust system for tracking and analyzing quality data is crucial for continuous improvement. This may involve statistical process control (SPC) techniques to monitor trends in production quality and identify areas for improvement. By analyzing this data, manufacturers can refine their processes, update test protocols, and ultimately enhance the overall quality and reliability of their solar inverters.

Sustainability in Solar Inverter Production

Sustainability in solar inverter production has become a critical focus as the renewable energy sector continues to expand. The manufacturing processes for solar inverters present significant opportunities for environmental improvement and resource efficiency. One key area of focus is the reduction of energy consumption during production. Manufacturers are implementing energy-efficient machinery and optimizing production line layouts to minimize energy waste. Additionally, the use of renewable energy sources to power manufacturing facilities is gaining traction, with some companies installing on-site solar arrays to offset their carbon footprint.

Material selection and waste reduction are also crucial aspects of sustainable inverter production. Manufacturers are increasingly opting for recyclable and eco-friendly materials in their components, reducing the environmental impact of end-of-life disposal. Advanced manufacturing techniques, such as 3D printing for certain parts, are being explored to minimize material waste and improve production efficiency. Furthermore, the implementation of lean manufacturing principles helps to streamline processes and reduce overall resource consumption.

Water conservation is another important consideration in sustainable inverter production. Manufacturers are adopting closed-loop water systems and water-efficient cleaning processes to minimize water usage and reduce wastewater generation. Some facilities are also implementing rainwater harvesting systems to supplement their water supply, further reducing their environmental impact.

The concept of a circular economy is gaining prominence in solar inverter production. This approach emphasizes the importance of designing products for easy disassembly and recycling at the end of their lifecycle. Manufacturers are developing modular designs that allow for easier repairs and component replacements, extending the lifespan of inverters and reducing electronic waste.

Supply chain sustainability is also a key focus area. Inverter manufacturers are increasingly scrutinizing their suppliers' environmental practices and seeking partnerships with those who demonstrate a commitment to sustainability. This includes considerations such as transportation efficiency, packaging reduction, and the use of locally sourced materials where possible to minimize the carbon footprint associated with logistics.

Lastly, the integration of smart manufacturing technologies and Industry 4.0 principles is enhancing sustainability in solar inverter production. Advanced data analytics and IoT sensors are being used to optimize energy consumption, predict maintenance needs, and improve overall production efficiency. These technologies not only contribute to sustainability goals but also enhance product quality and reduce manufacturing costs, demonstrating that environmental responsibility and economic viability can go hand in hand in the solar inverter industry.

Material selection and waste reduction are also crucial aspects of sustainable inverter production. Manufacturers are increasingly opting for recyclable and eco-friendly materials in their components, reducing the environmental impact of end-of-life disposal. Advanced manufacturing techniques, such as 3D printing for certain parts, are being explored to minimize material waste and improve production efficiency. Furthermore, the implementation of lean manufacturing principles helps to streamline processes and reduce overall resource consumption.

Water conservation is another important consideration in sustainable inverter production. Manufacturers are adopting closed-loop water systems and water-efficient cleaning processes to minimize water usage and reduce wastewater generation. Some facilities are also implementing rainwater harvesting systems to supplement their water supply, further reducing their environmental impact.

The concept of a circular economy is gaining prominence in solar inverter production. This approach emphasizes the importance of designing products for easy disassembly and recycling at the end of their lifecycle. Manufacturers are developing modular designs that allow for easier repairs and component replacements, extending the lifespan of inverters and reducing electronic waste.

Supply chain sustainability is also a key focus area. Inverter manufacturers are increasingly scrutinizing their suppliers' environmental practices and seeking partnerships with those who demonstrate a commitment to sustainability. This includes considerations such as transportation efficiency, packaging reduction, and the use of locally sourced materials where possible to minimize the carbon footprint associated with logistics.

Lastly, the integration of smart manufacturing technologies and Industry 4.0 principles is enhancing sustainability in solar inverter production. Advanced data analytics and IoT sensors are being used to optimize energy consumption, predict maintenance needs, and improve overall production efficiency. These technologies not only contribute to sustainability goals but also enhance product quality and reduce manufacturing costs, demonstrating that environmental responsibility and economic viability can go hand in hand in the solar inverter industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!