How to Use Custom-Made Gels for Specialized Applications?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Custom Gel Technology Overview and Objectives

Custom-made gels have emerged as a versatile and innovative solution for a wide range of specialized applications across various industries. These tailored gel formulations offer unique properties and functionalities that can be precisely engineered to meet specific requirements in fields such as healthcare, cosmetics, electronics, and materials science.

The development of custom gel technology has been driven by the increasing demand for advanced materials with enhanced performance characteristics. Over the past few decades, significant advancements in polymer science, nanotechnology, and materials engineering have paved the way for the creation of highly specialized gel systems. These gels can be designed to exhibit specific mechanical, chemical, and physical properties, making them ideal for applications where traditional materials fall short.

The primary objective of custom gel technology is to address the limitations of conventional materials and provide tailored solutions for complex challenges. By manipulating the composition, structure, and properties of gels at the molecular level, researchers and engineers can create materials with precise functionalities. This level of control allows for the development of gels that can respond to external stimuli, deliver targeted compounds, or provide unique mechanical support in various environments.

One of the key trends in custom gel technology is the focus on smart and responsive materials. These gels can change their properties in response to environmental factors such as temperature, pH, light, or electrical stimuli. This adaptability opens up new possibilities for applications in drug delivery systems, tissue engineering, and adaptive materials for extreme conditions.

Another significant trend is the integration of nanotechnology with custom gel formulations. Nanocomposite gels, which incorporate nanoparticles or nanostructures within the gel matrix, exhibit enhanced mechanical, electrical, or optical properties. This synergy between nanotechnology and gel science has led to breakthroughs in areas such as flexible electronics, advanced sensors, and high-performance coatings.

The future of custom gel technology lies in the development of multifunctional materials that can simultaneously address multiple challenges. Researchers are exploring ways to combine different functionalities within a single gel system, creating materials that can, for example, both sense and respond to environmental changes while providing structural support.

As the field continues to evolve, the objectives of custom gel technology are expanding to include sustainability and biocompatibility. There is a growing emphasis on developing eco-friendly gel formulations using renewable resources and biodegradable components. This shift aligns with the global push towards more sustainable materials and processes across industries.

The development of custom gel technology has been driven by the increasing demand for advanced materials with enhanced performance characteristics. Over the past few decades, significant advancements in polymer science, nanotechnology, and materials engineering have paved the way for the creation of highly specialized gel systems. These gels can be designed to exhibit specific mechanical, chemical, and physical properties, making them ideal for applications where traditional materials fall short.

The primary objective of custom gel technology is to address the limitations of conventional materials and provide tailored solutions for complex challenges. By manipulating the composition, structure, and properties of gels at the molecular level, researchers and engineers can create materials with precise functionalities. This level of control allows for the development of gels that can respond to external stimuli, deliver targeted compounds, or provide unique mechanical support in various environments.

One of the key trends in custom gel technology is the focus on smart and responsive materials. These gels can change their properties in response to environmental factors such as temperature, pH, light, or electrical stimuli. This adaptability opens up new possibilities for applications in drug delivery systems, tissue engineering, and adaptive materials for extreme conditions.

Another significant trend is the integration of nanotechnology with custom gel formulations. Nanocomposite gels, which incorporate nanoparticles or nanostructures within the gel matrix, exhibit enhanced mechanical, electrical, or optical properties. This synergy between nanotechnology and gel science has led to breakthroughs in areas such as flexible electronics, advanced sensors, and high-performance coatings.

The future of custom gel technology lies in the development of multifunctional materials that can simultaneously address multiple challenges. Researchers are exploring ways to combine different functionalities within a single gel system, creating materials that can, for example, both sense and respond to environmental changes while providing structural support.

As the field continues to evolve, the objectives of custom gel technology are expanding to include sustainability and biocompatibility. There is a growing emphasis on developing eco-friendly gel formulations using renewable resources and biodegradable components. This shift aligns with the global push towards more sustainable materials and processes across industries.

Market Analysis for Specialized Gel Applications

The market for specialized gel applications has been experiencing significant growth in recent years, driven by increasing demand across various industries. Custom-made gels offer tailored solutions for specific applications, providing enhanced performance and efficiency compared to off-the-shelf alternatives. This market segment is particularly robust in sectors such as healthcare, cosmetics, electronics, and advanced materials.

In the healthcare industry, custom gels are widely used in drug delivery systems, wound care, and medical devices. The growing emphasis on personalized medicine and targeted therapies has fueled the demand for specialized gel formulations. These gels can be designed to control drug release rates, improve bioavailability, or enhance tissue adhesion, addressing specific patient needs and treatment requirements.

The cosmetics and personal care sector represents another major market for custom gels. Consumers are increasingly seeking products with unique textures, sensory experiences, and functional benefits. Specialized gels enable cosmetic manufacturers to create innovative formulations with improved stability, enhanced skin feel, and targeted delivery of active ingredients. This trend is particularly evident in the premium skincare and anti-aging product segments.

In the electronics industry, custom gels find applications in thermal management, encapsulation, and protection of sensitive components. As electronic devices become more compact and powerful, the need for efficient heat dissipation and environmental protection grows. Specialized thermal gels and encapsulants offer tailored solutions to address these challenges, contributing to improved product performance and reliability.

The advanced materials sector is another key driver of the custom gel market. Industries such as aerospace, automotive, and construction are increasingly adopting specialized gel materials for applications such as vibration damping, insulation, and structural reinforcement. These gels can be engineered to exhibit specific mechanical, thermal, or chemical properties, meeting the demanding requirements of high-performance applications.

Market analysis indicates that the global custom gel market is expected to continue its growth trajectory in the coming years. Factors contributing to this growth include ongoing technological advancements, increasing R&D investments, and the expanding range of applications across diverse industries. The market is characterized by a mix of established players and innovative start-ups, fostering a competitive landscape that drives continuous innovation and product development.

Geographically, North America and Europe currently lead the market for specialized gel applications, owing to their strong research infrastructure and well-established end-user industries. However, the Asia-Pacific region is emerging as a significant growth market, driven by rapid industrialization, increasing healthcare expenditure, and growing adoption of advanced materials in manufacturing sectors.

In the healthcare industry, custom gels are widely used in drug delivery systems, wound care, and medical devices. The growing emphasis on personalized medicine and targeted therapies has fueled the demand for specialized gel formulations. These gels can be designed to control drug release rates, improve bioavailability, or enhance tissue adhesion, addressing specific patient needs and treatment requirements.

The cosmetics and personal care sector represents another major market for custom gels. Consumers are increasingly seeking products with unique textures, sensory experiences, and functional benefits. Specialized gels enable cosmetic manufacturers to create innovative formulations with improved stability, enhanced skin feel, and targeted delivery of active ingredients. This trend is particularly evident in the premium skincare and anti-aging product segments.

In the electronics industry, custom gels find applications in thermal management, encapsulation, and protection of sensitive components. As electronic devices become more compact and powerful, the need for efficient heat dissipation and environmental protection grows. Specialized thermal gels and encapsulants offer tailored solutions to address these challenges, contributing to improved product performance and reliability.

The advanced materials sector is another key driver of the custom gel market. Industries such as aerospace, automotive, and construction are increasingly adopting specialized gel materials for applications such as vibration damping, insulation, and structural reinforcement. These gels can be engineered to exhibit specific mechanical, thermal, or chemical properties, meeting the demanding requirements of high-performance applications.

Market analysis indicates that the global custom gel market is expected to continue its growth trajectory in the coming years. Factors contributing to this growth include ongoing technological advancements, increasing R&D investments, and the expanding range of applications across diverse industries. The market is characterized by a mix of established players and innovative start-ups, fostering a competitive landscape that drives continuous innovation and product development.

Geographically, North America and Europe currently lead the market for specialized gel applications, owing to their strong research infrastructure and well-established end-user industries. However, the Asia-Pacific region is emerging as a significant growth market, driven by rapid industrialization, increasing healthcare expenditure, and growing adoption of advanced materials in manufacturing sectors.

Current Challenges in Custom Gel Development

The development of custom-made gels for specialized applications faces several significant challenges that researchers and manufacturers must overcome. One of the primary obstacles is achieving precise control over the gel's mechanical properties. Customizing the stiffness, elasticity, and durability of gels to match specific application requirements demands intricate formulation processes and advanced material science knowledge.

Another major challenge lies in ensuring the biocompatibility and non-toxicity of custom gels, particularly for biomedical applications. Researchers must carefully select and combine materials that not only provide the desired physical properties but also remain safe for use in biological systems. This often involves extensive testing and validation processes to meet stringent regulatory standards.

Scalability and reproducibility present additional hurdles in custom gel development. While creating small batches of specialized gels in laboratory settings may be feasible, scaling up production for commercial applications while maintaining consistent quality and performance can be problematic. Variations in raw materials, environmental conditions, and manufacturing processes can significantly impact the final product's characteristics.

The stability and shelf life of custom-made gels pose another challenge. Many specialized gels are designed for specific environmental conditions or applications, and maintaining their properties over extended periods can be difficult. Researchers must develop formulations that resist degradation, maintain their structural integrity, and preserve their functional properties throughout the intended usage period.

Achieving multifunctionality in custom gels is an ongoing challenge. As applications become more sophisticated, there is a growing demand for gels that can perform multiple functions simultaneously, such as drug delivery, sensing, and tissue engineering. Integrating these diverse functionalities into a single gel system without compromising individual performance aspects requires innovative approaches and advanced material design strategies.

The high cost associated with developing and producing custom-made gels for specialized applications is a significant barrier to widespread adoption. The extensive research, specialized equipment, and high-quality materials required often result in prohibitively expensive products, limiting their use to niche applications or high-value industries.

Lastly, the lack of standardized characterization methods for custom gels poses challenges in comparing and validating different formulations. The diverse nature of specialized gels makes it difficult to establish universal testing protocols, hindering the ability to objectively assess and compare the performance of various custom gel solutions across different applications and research groups.

Another major challenge lies in ensuring the biocompatibility and non-toxicity of custom gels, particularly for biomedical applications. Researchers must carefully select and combine materials that not only provide the desired physical properties but also remain safe for use in biological systems. This often involves extensive testing and validation processes to meet stringent regulatory standards.

Scalability and reproducibility present additional hurdles in custom gel development. While creating small batches of specialized gels in laboratory settings may be feasible, scaling up production for commercial applications while maintaining consistent quality and performance can be problematic. Variations in raw materials, environmental conditions, and manufacturing processes can significantly impact the final product's characteristics.

The stability and shelf life of custom-made gels pose another challenge. Many specialized gels are designed for specific environmental conditions or applications, and maintaining their properties over extended periods can be difficult. Researchers must develop formulations that resist degradation, maintain their structural integrity, and preserve their functional properties throughout the intended usage period.

Achieving multifunctionality in custom gels is an ongoing challenge. As applications become more sophisticated, there is a growing demand for gels that can perform multiple functions simultaneously, such as drug delivery, sensing, and tissue engineering. Integrating these diverse functionalities into a single gel system without compromising individual performance aspects requires innovative approaches and advanced material design strategies.

The high cost associated with developing and producing custom-made gels for specialized applications is a significant barrier to widespread adoption. The extensive research, specialized equipment, and high-quality materials required often result in prohibitively expensive products, limiting their use to niche applications or high-value industries.

Lastly, the lack of standardized characterization methods for custom gels poses challenges in comparing and validating different formulations. The diverse nature of specialized gels makes it difficult to establish universal testing protocols, hindering the ability to objectively assess and compare the performance of various custom gel solutions across different applications and research groups.

Existing Custom Gel Manufacturing Methods

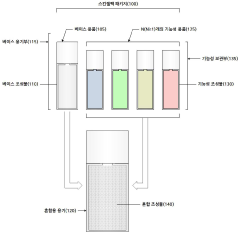

01 Customized gel formulations for specific applications

Custom-made gels can be formulated to meet specific requirements for various applications. This involves selecting appropriate ingredients, adjusting viscosity, and incorporating active compounds to achieve desired properties such as controlled release, stability, or specific therapeutic effects.- Customized gel formulations for specific applications: Custom-made gels can be formulated to meet specific requirements for various applications. This involves selecting appropriate ingredients and adjusting their concentrations to achieve desired properties such as viscosity, stability, and functionality. The formulation process may include incorporating active ingredients, modifying pH, and optimizing gel structure for targeted performance.

- Gel characterization and analysis techniques: Various analytical methods are employed to characterize custom-made gels, including rheological measurements, spectroscopic techniques, and microscopy. These techniques help assess gel properties such as structure, mechanical behavior, and chemical composition. Advanced imaging and data analysis tools may be used to evaluate gel performance and optimize formulations.

- Smart and responsive gel systems: Custom-made gels can be designed to respond to external stimuli such as temperature, pH, or light. These smart gel systems can change their properties or release encapsulated substances in response to specific triggers. Applications include drug delivery, sensors, and adaptive materials for various industries.

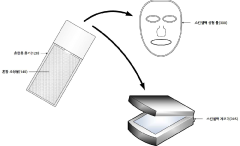

- Gel-based materials for biomedical applications: Custom-made gels are widely used in biomedical applications, including tissue engineering, wound healing, and drug delivery. These gels can be tailored to mimic natural tissue properties, promote cell growth, or provide controlled release of therapeutic agents. Biocompatibility and degradation characteristics are crucial considerations in designing these materials.

- Manufacturing processes for custom-made gels: Various manufacturing processes are employed to produce custom-made gels, including chemical crosslinking, physical gelation, and advanced techniques such as 3D printing. These processes can be optimized to control gel properties, ensure batch-to-batch consistency, and scale up production for commercial applications. Quality control measures are implemented to maintain desired gel characteristics.

02 Advanced manufacturing techniques for custom gels

Innovative manufacturing processes are employed to produce custom-made gels with precise specifications. These may include 3D printing, microfluidic techniques, or specialized mixing methods to ensure uniform distribution of ingredients and desired gel properties.Expand Specific Solutions03 Characterization and analysis of custom-made gels

Sophisticated analytical techniques are used to characterize and evaluate custom-made gels. This includes rheological measurements, spectroscopic analysis, and microscopy to assess gel structure, composition, and performance attributes.Expand Specific Solutions04 Smart and responsive custom-made gels

Development of smart gels that respond to external stimuli such as temperature, pH, or light. These custom-made gels can change their properties or release active ingredients in response to specific environmental conditions, making them suitable for targeted drug delivery or sensing applications.Expand Specific Solutions05 Computational modeling and design of custom gels

Utilization of computational methods and machine learning algorithms to design and optimize custom-made gels. This approach allows for predicting gel properties, simulating performance, and streamlining the development process for tailored gel formulations.Expand Specific Solutions

Key Players in Specialized Gel Industry

The market for custom-made gels in specialized applications is in a growth phase, driven by increasing demand across various industries. The global market size for specialized gels is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is advancing rapidly, with companies like BASF Corp., Croda International Plc, and Momentive Performance Materials Inc. leading innovation in gel formulations. These industry leaders are investing heavily in R&D to develop advanced, application-specific gels. Emerging players such as Dimension Inx Corp. are also contributing to technological advancements, particularly in biomedical applications. The competitive landscape is characterized by a mix of established chemical companies and specialized startups, indicating a maturing but still dynamic market.

BASF Corp.

Technical Solution: BASF Corp. has developed a range of custom-made gels for specialized applications, focusing on their Rheomax® ETD technology. This innovative solution utilizes tailored polymers to create gels with specific rheological properties. The technology allows for precise control over gel formation, stability, and responsiveness to external stimuli such as temperature or pH changes[1]. BASF's approach involves synthesizing polymers with carefully designed molecular structures that can self-assemble into three-dimensional networks in aqueous environments. These networks can be fine-tuned to exhibit desired characteristics such as shear-thinning behavior, rapid recovery after deformation, or controlled release of active ingredients[2].

Strengths: Highly customizable gel properties, wide range of industrial applications, and strong R&D capabilities. Weaknesses: Potentially higher production costs due to specialized formulations and limited scalability for some niche applications.

Croda International Plc

Technical Solution: Croda International Plc has developed a platform for custom-made gels called EcoSense™ Gelmakers. This technology focuses on creating sustainable, naturally derived gelling agents for various specialized applications. The EcoSense™ Gelmakers utilize a combination of plant-based polymers and proprietary processing techniques to produce gels with tailored properties. Croda's approach involves selecting specific biopolymers and modifying them through controlled crosslinking and functionalization processes. This allows for the creation of gels with adjustable viscosity, stability, and sensory characteristics[3]. The company has also invested in developing smart gels that respond to environmental triggers, such as temperature or ionic strength, enabling applications in controlled release systems and smart materials[4].

Strengths: Focus on sustainability and natural ingredients, versatile application range, and strong market presence in personal care and pharmaceuticals. Weaknesses: Potential limitations in extreme industrial conditions and higher costs compared to some synthetic alternatives.

Innovative Approaches in Gel Customization

Gel, in particular for use in a wound treatment agent

PatentInactiveUS20150056304A1

Innovation

- A gel formulation using an electrochemically activated aqueous common salt solution with a conductivity of at most 12 mS/cm, combined with an inorganic silicate thickener like lithium magnesium sodium silicate, which retains microbiocidal efficacy and provides long-term stability.

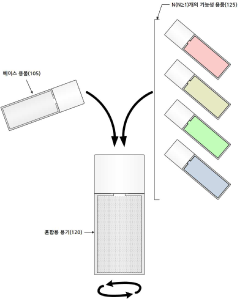

Mixed Non-liquefied Skin Gel Pack for Manufacturing by Customer

PatentPendingKR1020220149839A

Innovation

- Customizable skin gel pack that allows users to mix base composition with functional compositions in real-time.

- Non-liquid storage state of base and functional compositions that can be liquefied with water at specific temperatures.

- Ability to mix multiple functional compositions (up to N) with the base composition for personalized skincare benefits.

Regulatory Considerations for Custom Gels

The regulatory landscape for custom-made gels in specialized applications is complex and multifaceted, requiring careful consideration throughout the development and implementation process. Manufacturers and end-users must navigate a web of regulations that vary depending on the intended use, composition, and application of the gel.

For medical and pharmaceutical applications, custom gels often fall under the purview of regulatory bodies such as the FDA in the United States or the EMA in Europe. These agencies typically require extensive documentation, including safety data, efficacy studies, and quality control measures. The classification of the gel as a medical device, drug, or combination product can significantly impact the regulatory pathway and requirements.

In cosmetic applications, custom gels may be subject to less stringent regulations, but still require compliance with safety standards and ingredient disclosure requirements. The EU Cosmetics Regulation and the FDA's cosmetic regulations provide frameworks for ensuring product safety and proper labeling.

For industrial and research applications, custom gels may need to adhere to environmental and workplace safety regulations. This includes compliance with REACH in the EU or TSCA in the US for chemical substances, as well as adherence to occupational safety standards set by agencies like OSHA.

Biocompatibility and toxicity testing are critical aspects of regulatory compliance for custom gels, especially those intended for direct contact with human tissues or the environment. Standards such as ISO 10993 for biocompatibility evaluation of medical devices often apply and may require extensive in vitro and in vivo testing.

Quality management systems play a crucial role in regulatory compliance. Manufacturers of custom gels for specialized applications often need to implement and maintain robust quality systems, such as those outlined in ISO 13485 for medical devices or Good Manufacturing Practices (GMP) for pharmaceutical products.

Intellectual property considerations are also intertwined with regulatory aspects. Patented formulations or processes used in custom gels may influence the regulatory strategy, particularly in terms of disclosure requirements and market exclusivity.

As the field of custom gels continues to evolve, regulatory frameworks are adapting to keep pace. Emerging technologies, such as 3D-printed gels or smart responsive materials, may require new regulatory approaches. Manufacturers and researchers must stay informed about these developments to ensure ongoing compliance and market access.

For medical and pharmaceutical applications, custom gels often fall under the purview of regulatory bodies such as the FDA in the United States or the EMA in Europe. These agencies typically require extensive documentation, including safety data, efficacy studies, and quality control measures. The classification of the gel as a medical device, drug, or combination product can significantly impact the regulatory pathway and requirements.

In cosmetic applications, custom gels may be subject to less stringent regulations, but still require compliance with safety standards and ingredient disclosure requirements. The EU Cosmetics Regulation and the FDA's cosmetic regulations provide frameworks for ensuring product safety and proper labeling.

For industrial and research applications, custom gels may need to adhere to environmental and workplace safety regulations. This includes compliance with REACH in the EU or TSCA in the US for chemical substances, as well as adherence to occupational safety standards set by agencies like OSHA.

Biocompatibility and toxicity testing are critical aspects of regulatory compliance for custom gels, especially those intended for direct contact with human tissues or the environment. Standards such as ISO 10993 for biocompatibility evaluation of medical devices often apply and may require extensive in vitro and in vivo testing.

Quality management systems play a crucial role in regulatory compliance. Manufacturers of custom gels for specialized applications often need to implement and maintain robust quality systems, such as those outlined in ISO 13485 for medical devices or Good Manufacturing Practices (GMP) for pharmaceutical products.

Intellectual property considerations are also intertwined with regulatory aspects. Patented formulations or processes used in custom gels may influence the regulatory strategy, particularly in terms of disclosure requirements and market exclusivity.

As the field of custom gels continues to evolve, regulatory frameworks are adapting to keep pace. Emerging technologies, such as 3D-printed gels or smart responsive materials, may require new regulatory approaches. Manufacturers and researchers must stay informed about these developments to ensure ongoing compliance and market access.

Environmental Impact of Gel Production

The production of custom-made gels for specialized applications has significant environmental implications that warrant careful consideration. The manufacturing process often involves the use of various chemicals, solvents, and raw materials, which can have both direct and indirect environmental impacts. One of the primary concerns is the potential release of harmful substances into the environment during production. Many gel formulations require synthetic polymers, cross-linking agents, and additives that may be toxic or non-biodegradable.

Water consumption is another critical factor in gel production. The synthesis and purification of gel components typically require substantial amounts of water, which can strain local water resources, especially in water-scarce regions. Additionally, the wastewater generated during production may contain residual chemicals and contaminants that require proper treatment before discharge to prevent water pollution.

Energy usage in gel manufacturing processes contributes to the overall carbon footprint of the industry. The production of raw materials, operation of manufacturing equipment, and maintenance of controlled environments for gel synthesis all demand significant energy inputs. This energy consumption, particularly if derived from non-renewable sources, can lead to increased greenhouse gas emissions and contribute to climate change.

The disposal of gel products and production waste presents another environmental challenge. Many specialized gels are designed for single-use applications, leading to a considerable amount of post-consumer waste. If not properly managed, these discarded gels can accumulate in landfills or natural environments, potentially leaching chemicals into soil and water systems. Furthermore, the production process itself generates waste materials that may require special handling and disposal procedures to minimize environmental harm.

To mitigate these environmental impacts, the gel industry is increasingly focusing on sustainable production methods. This includes the development of bio-based and biodegradable gel materials, implementation of closed-loop manufacturing systems to reduce waste and resource consumption, and adoption of green chemistry principles to minimize the use of hazardous substances. Additionally, efforts are being made to improve energy efficiency in production facilities and to transition towards renewable energy sources.

Regulatory frameworks and industry standards play a crucial role in addressing the environmental impact of gel production. Many countries have implemented strict regulations governing the use and disposal of chemicals, emissions control, and waste management in industrial processes. Compliance with these regulations not only helps to protect the environment but also drives innovation in cleaner production technologies and more sustainable gel formulations.

Water consumption is another critical factor in gel production. The synthesis and purification of gel components typically require substantial amounts of water, which can strain local water resources, especially in water-scarce regions. Additionally, the wastewater generated during production may contain residual chemicals and contaminants that require proper treatment before discharge to prevent water pollution.

Energy usage in gel manufacturing processes contributes to the overall carbon footprint of the industry. The production of raw materials, operation of manufacturing equipment, and maintenance of controlled environments for gel synthesis all demand significant energy inputs. This energy consumption, particularly if derived from non-renewable sources, can lead to increased greenhouse gas emissions and contribute to climate change.

The disposal of gel products and production waste presents another environmental challenge. Many specialized gels are designed for single-use applications, leading to a considerable amount of post-consumer waste. If not properly managed, these discarded gels can accumulate in landfills or natural environments, potentially leaching chemicals into soil and water systems. Furthermore, the production process itself generates waste materials that may require special handling and disposal procedures to minimize environmental harm.

To mitigate these environmental impacts, the gel industry is increasingly focusing on sustainable production methods. This includes the development of bio-based and biodegradable gel materials, implementation of closed-loop manufacturing systems to reduce waste and resource consumption, and adoption of green chemistry principles to minimize the use of hazardous substances. Additionally, efforts are being made to improve energy efficiency in production facilities and to transition towards renewable energy sources.

Regulatory frameworks and industry standards play a crucial role in addressing the environmental impact of gel production. Many countries have implemented strict regulations governing the use and disposal of chemicals, emissions control, and waste management in industrial processes. Compliance with these regulations not only helps to protect the environment but also drives innovation in cleaner production technologies and more sustainable gel formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!