How to Utilize Cellophane in Water-Resistant Packaging?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Packaging Evolution and Objectives

Cellophane, a transparent sheet made from regenerated cellulose, has been a significant player in the packaging industry since its invention in 1908. Initially developed as a waterproof coating for tablecloths, cellophane quickly found its way into various packaging applications due to its unique properties. The evolution of cellophane in packaging has been driven by the increasing demand for sustainable, biodegradable, and water-resistant materials.

In the early stages of its development, cellophane was primarily used for food packaging due to its transparency and ability to preserve freshness. However, its inherent moisture sensitivity limited its applications in water-resistant packaging. The technological advancements in the mid-20th century led to the development of moisture-proof coatings, significantly expanding cellophane's utility in packaging applications requiring water resistance.

The objectives of utilizing cellophane in water-resistant packaging have evolved over time. Initially, the focus was on improving the material's barrier properties to enhance its water resistance. This led to the development of coated cellophane, which combined the biodegradability of cellophane with improved moisture barrier properties. As environmental concerns grew, the objectives shifted towards developing more sustainable and eco-friendly water-resistant packaging solutions.

Recent technological advancements have aimed at enhancing cellophane's water resistance while maintaining its biodegradability. This includes the development of bio-based coatings and the exploration of nanocomposite materials. The current objectives in cellophane packaging evolution focus on achieving a balance between water resistance, biodegradability, and cost-effectiveness.

Looking forward, the evolution of cellophane in water-resistant packaging is expected to be driven by several key objectives. These include improving the material's barrier properties without compromising its biodegradability, developing more efficient and sustainable production processes, and exploring novel applications in industries beyond food packaging. Additionally, there is a growing emphasis on creating cellophane-based packaging solutions that are not only water-resistant but also recyclable and compostable, aligning with the global push towards circular economy principles.

The future of cellophane in water-resistant packaging also involves integrating smart technologies. This includes the development of cellophane-based packaging with embedded sensors for monitoring product freshness and integrity, as well as exploring the potential of cellophane in active and intelligent packaging systems. These advancements aim to extend the functionality of cellophane beyond mere water resistance, positioning it as a versatile and innovative packaging material for the future.

In the early stages of its development, cellophane was primarily used for food packaging due to its transparency and ability to preserve freshness. However, its inherent moisture sensitivity limited its applications in water-resistant packaging. The technological advancements in the mid-20th century led to the development of moisture-proof coatings, significantly expanding cellophane's utility in packaging applications requiring water resistance.

The objectives of utilizing cellophane in water-resistant packaging have evolved over time. Initially, the focus was on improving the material's barrier properties to enhance its water resistance. This led to the development of coated cellophane, which combined the biodegradability of cellophane with improved moisture barrier properties. As environmental concerns grew, the objectives shifted towards developing more sustainable and eco-friendly water-resistant packaging solutions.

Recent technological advancements have aimed at enhancing cellophane's water resistance while maintaining its biodegradability. This includes the development of bio-based coatings and the exploration of nanocomposite materials. The current objectives in cellophane packaging evolution focus on achieving a balance between water resistance, biodegradability, and cost-effectiveness.

Looking forward, the evolution of cellophane in water-resistant packaging is expected to be driven by several key objectives. These include improving the material's barrier properties without compromising its biodegradability, developing more efficient and sustainable production processes, and exploring novel applications in industries beyond food packaging. Additionally, there is a growing emphasis on creating cellophane-based packaging solutions that are not only water-resistant but also recyclable and compostable, aligning with the global push towards circular economy principles.

The future of cellophane in water-resistant packaging also involves integrating smart technologies. This includes the development of cellophane-based packaging with embedded sensors for monitoring product freshness and integrity, as well as exploring the potential of cellophane in active and intelligent packaging systems. These advancements aim to extend the functionality of cellophane beyond mere water resistance, positioning it as a versatile and innovative packaging material for the future.

Market Demand for Water-Resistant Packaging

The market demand for water-resistant packaging has been steadily increasing across various industries, driven by the need for enhanced product protection and consumer convenience. This trend is particularly evident in sectors such as food and beverage, electronics, pharmaceuticals, and personal care products. The global water-resistant packaging market is experiencing significant growth, with projections indicating continued expansion in the coming years.

In the food and beverage industry, there is a growing demand for packaging solutions that can withstand moisture and prevent contamination. This is especially crucial for products with extended shelf lives or those requiring transportation over long distances. Consumers are increasingly seeking convenient, on-the-go food options that remain fresh and protected from environmental factors, further driving the need for water-resistant packaging.

The electronics sector has also seen a surge in demand for water-resistant packaging solutions. With the proliferation of portable electronic devices and the increasing value of these products, consumers and manufacturers alike are prioritizing protection against water damage. This has led to the development of innovative packaging materials and designs that can safeguard sensitive electronic components from moisture exposure.

In the pharmaceutical industry, water-resistant packaging plays a critical role in maintaining the integrity and efficacy of medications. As regulations become more stringent and the global pharmaceutical supply chain expands, there is a growing emphasis on packaging that can protect drugs from humidity and moisture during storage and transportation.

The personal care and cosmetics industry has also contributed to the rising demand for water-resistant packaging. Products such as soaps, shampoos, and lotions require packaging that can withstand bathroom environments and prevent water ingress. Additionally, the trend towards eco-friendly and sustainable packaging solutions has led to increased interest in biodegradable water-resistant materials.

E-commerce has further fueled the demand for water-resistant packaging. As online shopping continues to grow, there is a greater need for packaging that can protect products during shipping and handling, regardless of weather conditions. This has led to innovations in both primary and secondary packaging materials that offer enhanced water resistance.

The COVID-19 pandemic has also influenced market demand, with increased focus on hygiene and product safety. Consumers are now more conscious of packaging that can protect against external contaminants, including moisture, which has further boosted the demand for water-resistant packaging solutions across various product categories.

As sustainability becomes a key concern for both consumers and businesses, there is a growing interest in water-resistant packaging materials that are also environmentally friendly. This has led to research and development efforts focused on creating biodegradable or recyclable water-resistant packaging options, aligning with global sustainability goals while meeting market demands for product protection.

In the food and beverage industry, there is a growing demand for packaging solutions that can withstand moisture and prevent contamination. This is especially crucial for products with extended shelf lives or those requiring transportation over long distances. Consumers are increasingly seeking convenient, on-the-go food options that remain fresh and protected from environmental factors, further driving the need for water-resistant packaging.

The electronics sector has also seen a surge in demand for water-resistant packaging solutions. With the proliferation of portable electronic devices and the increasing value of these products, consumers and manufacturers alike are prioritizing protection against water damage. This has led to the development of innovative packaging materials and designs that can safeguard sensitive electronic components from moisture exposure.

In the pharmaceutical industry, water-resistant packaging plays a critical role in maintaining the integrity and efficacy of medications. As regulations become more stringent and the global pharmaceutical supply chain expands, there is a growing emphasis on packaging that can protect drugs from humidity and moisture during storage and transportation.

The personal care and cosmetics industry has also contributed to the rising demand for water-resistant packaging. Products such as soaps, shampoos, and lotions require packaging that can withstand bathroom environments and prevent water ingress. Additionally, the trend towards eco-friendly and sustainable packaging solutions has led to increased interest in biodegradable water-resistant materials.

E-commerce has further fueled the demand for water-resistant packaging. As online shopping continues to grow, there is a greater need for packaging that can protect products during shipping and handling, regardless of weather conditions. This has led to innovations in both primary and secondary packaging materials that offer enhanced water resistance.

The COVID-19 pandemic has also influenced market demand, with increased focus on hygiene and product safety. Consumers are now more conscious of packaging that can protect against external contaminants, including moisture, which has further boosted the demand for water-resistant packaging solutions across various product categories.

As sustainability becomes a key concern for both consumers and businesses, there is a growing interest in water-resistant packaging materials that are also environmentally friendly. This has led to research and development efforts focused on creating biodegradable or recyclable water-resistant packaging options, aligning with global sustainability goals while meeting market demands for product protection.

Current Cellophane Technology Challenges

Despite its widespread use in packaging, cellophane faces several significant challenges when it comes to water-resistant applications. One of the primary issues is its inherent hydrophilic nature. Cellophane, being derived from cellulose, naturally absorbs moisture, which can compromise its structural integrity and barrier properties when exposed to water or high humidity environments.

The permeability of cellophane to water vapor is another major concern. While it provides an excellent barrier against oxygen and other gases, its ability to block water vapor is limited. This characteristic can lead to moisture ingress in packaged products, potentially causing degradation or spoilage, especially in food and pharmaceutical applications where moisture control is critical.

Cellophane's mechanical properties also present challenges in water-resistant packaging. When exposed to moisture, cellophane tends to soften and lose its tensile strength. This can result in packaging failure, especially in applications where the package needs to maintain its shape and protective qualities under varying environmental conditions.

The coating process used to enhance cellophane's water resistance introduces additional complexities. Traditional coatings, such as nitrocellulose or polyvinyl alcohol, can improve water resistance to some extent but often fall short in providing long-term protection. These coatings may also affect the material's recyclability and biodegradability, which are increasingly important factors in packaging design.

Another challenge lies in the adhesion of water-resistant coatings to cellophane. The smooth surface of cellophane can make it difficult for coatings to adhere effectively, leading to potential delamination or inconsistent barrier properties across the packaging material.

The cost-effectiveness of producing water-resistant cellophane packaging is also a significant hurdle. The additional processing steps and materials required to enhance water resistance can substantially increase production costs, making it less competitive compared to synthetic alternatives like polyethylene or polypropylene films.

Furthermore, achieving consistent quality in water-resistant cellophane packaging remains a challenge. Variations in raw materials, processing conditions, and coating applications can lead to inconsistencies in the final product's water resistance properties, making quality control a critical and often difficult aspect of production.

The permeability of cellophane to water vapor is another major concern. While it provides an excellent barrier against oxygen and other gases, its ability to block water vapor is limited. This characteristic can lead to moisture ingress in packaged products, potentially causing degradation or spoilage, especially in food and pharmaceutical applications where moisture control is critical.

Cellophane's mechanical properties also present challenges in water-resistant packaging. When exposed to moisture, cellophane tends to soften and lose its tensile strength. This can result in packaging failure, especially in applications where the package needs to maintain its shape and protective qualities under varying environmental conditions.

The coating process used to enhance cellophane's water resistance introduces additional complexities. Traditional coatings, such as nitrocellulose or polyvinyl alcohol, can improve water resistance to some extent but often fall short in providing long-term protection. These coatings may also affect the material's recyclability and biodegradability, which are increasingly important factors in packaging design.

Another challenge lies in the adhesion of water-resistant coatings to cellophane. The smooth surface of cellophane can make it difficult for coatings to adhere effectively, leading to potential delamination or inconsistent barrier properties across the packaging material.

The cost-effectiveness of producing water-resistant cellophane packaging is also a significant hurdle. The additional processing steps and materials required to enhance water resistance can substantially increase production costs, making it less competitive compared to synthetic alternatives like polyethylene or polypropylene films.

Furthermore, achieving consistent quality in water-resistant cellophane packaging remains a challenge. Variations in raw materials, processing conditions, and coating applications can lead to inconsistencies in the final product's water resistance properties, making quality control a critical and often difficult aspect of production.

Existing Water-Resistant Cellophane Solutions

01 Coating techniques for water-resistant cellophane

Various coating techniques can be applied to cellophane to enhance its water resistance. These methods may include the application of hydrophobic materials, such as waxes or resins, to create a water-repellent layer on the cellophane surface. The coatings can be applied through processes like dipping, spraying, or roll coating, resulting in a more durable and water-resistant cellophane product.- Coating techniques for water-resistant cellophane: Various coating techniques can be applied to cellophane to enhance its water resistance. These methods may include the application of hydrophobic materials, polymers, or specialized coatings that form a protective barrier against moisture. The coatings can be applied through processes such as dipping, spraying, or lamination, resulting in a water-resistant cellophane suitable for packaging and other applications.

- Chemical modifications to improve cellophane water resistance: Chemical treatments can be employed to modify the molecular structure of cellophane, making it more resistant to water. These modifications may involve cross-linking agents, hydrophobic additives, or chemical reactions that alter the cellulose structure. Such treatments can significantly improve the water resistance of cellophane while maintaining its other desirable properties.

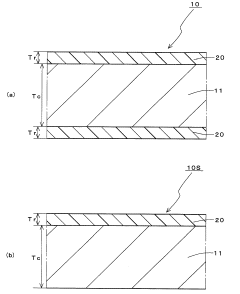

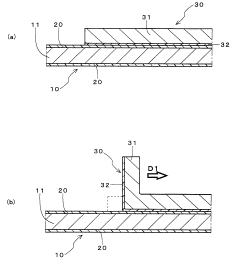

- Composite materials incorporating cellophane for water resistance: Cellophane can be combined with other materials to create composite structures with enhanced water resistance. These composites may involve layering cellophane with water-resistant films, incorporating it into laminates, or blending it with other polymers. The resulting materials benefit from cellophane's properties while achieving improved water resistance.

- Nanotechnology applications for water-resistant cellophane: Nanotechnology offers innovative approaches to improving cellophane's water resistance. This may include the incorporation of nanoparticles, nanocoatings, or nanostructured materials that can significantly enhance the water-repellent properties of cellophane. These nano-scale modifications can provide superior water resistance without compromising the material's transparency or flexibility.

- Biodegradable water-resistant cellophane alternatives: Research into environmentally friendly alternatives to traditional cellophane has led to the development of biodegradable materials with water-resistant properties. These materials may be derived from renewable resources and modified to achieve water resistance while maintaining biodegradability. Such innovations address the growing demand for sustainable packaging solutions that offer both water resistance and eco-friendliness.

02 Chemical modifications to improve cellophane water resistance

Chemical treatments can be employed to modify the molecular structure of cellophane, making it inherently more water-resistant. These modifications may involve cross-linking cellulose chains, grafting hydrophobic groups onto the cellulose backbone, or incorporating water-repellent additives during the manufacturing process. Such chemical alterations can significantly enhance the water resistance of cellophane without compromising its other desirable properties.Expand Specific Solutions03 Multilayer structures for water-resistant cellophane

Developing multilayer structures that incorporate cellophane can improve its water resistance. This approach involves combining cellophane with other water-resistant materials, such as polyethylene or polypropylene, to create a composite structure. The additional layers provide a barrier against water while maintaining the beneficial properties of cellophane, resulting in a more versatile and water-resistant product.Expand Specific Solutions04 Nanotechnology applications for cellophane water resistance

Nanotechnology offers innovative solutions for enhancing the water resistance of cellophane. This may include incorporating nanoparticles or nanocoatings that create a superhydrophobic surface on the cellophane. These nano-scale modifications can significantly improve water repellency while maintaining the transparency and flexibility of the cellophane, opening up new possibilities for its use in various applications.Expand Specific Solutions05 Biodegradable additives for water-resistant cellophane

Research into biodegradable additives that can enhance the water resistance of cellophane while maintaining its eco-friendly nature is ongoing. These additives may be derived from natural sources or designed to be compatible with the cellulose-based structure of cellophane. By incorporating such additives, it is possible to create water-resistant cellophane products that remain environmentally friendly and biodegradable.Expand Specific Solutions

Innovative Cellophane Coating Technologies

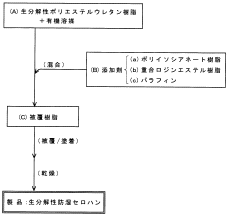

Biodegradable damp-proof cellophane

PatentInactiveJP2006231870A

Innovation

- A coating comprising a decomposable polyester urethane resin, polyisocyanate resin, polymerized rosin ester resin, and paraffin is applied to cellophane, forming a moisture-proof layer without the need for anchoring agents or press molding, enhancing adhesion and moisture resistance while allowing heat-sealing.

Base material for forming a cellulose packaging material and the use thereof

PatentWO2024164057A1

Innovation

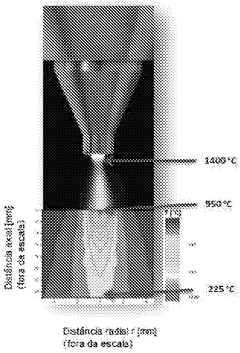

- A base material composed of 98% to 99% cellulose and 1% to 2% inert silicon-based material, featuring a plasma-pre-treated cellulosic substrate, a nanofibrillated cellulose film layer for gas barrier, and an atmospheric plasma-coated inner layer for liquid barrier, ensuring waterproof and recyclable packaging.

Environmental Impact of Cellophane Packaging

The environmental impact of cellophane packaging is a critical consideration in the context of water-resistant packaging solutions. Cellophane, a biodegradable material derived from cellulose, offers both advantages and challenges in terms of its ecological footprint.

One of the primary environmental benefits of cellophane is its biodegradability. Unlike many synthetic plastics, cellophane can decompose naturally in the environment, reducing long-term pollution concerns. This characteristic aligns with growing consumer demand for more sustainable packaging options and helps companies meet increasingly stringent environmental regulations.

However, the production process of cellophane raises some environmental concerns. The manufacturing of cellophane involves the use of chemicals such as carbon disulfide and sodium hydroxide, which can have negative impacts on air and water quality if not properly managed. Additionally, the energy-intensive nature of cellophane production contributes to its carbon footprint.

When considering water-resistant cellophane packaging, additional factors come into play. The application of water-resistant coatings or treatments may reduce the biodegradability of the material, potentially offsetting some of its environmental benefits. The type and composition of these coatings can significantly influence the overall environmental impact of the packaging solution.

In terms of waste management, cellophane presents both opportunities and challenges. While it can be composted under proper conditions, many municipal waste systems are not equipped to handle cellophane effectively. This can lead to cellophane ending up in landfills or contaminating recycling streams, diminishing its potential environmental advantages.

The water resistance of cellophane packaging also affects its end-of-life environmental impact. While improved water resistance can extend the shelf life of products and reduce food waste, it may also hinder the natural decomposition process of the cellophane, potentially leading to longer persistence in the environment.

From a lifecycle perspective, the environmental impact of cellophane packaging must be evaluated holistically. This includes considering raw material sourcing, manufacturing processes, transportation, use phase, and end-of-life disposal. Comparative studies with alternative packaging materials are essential to determine the overall environmental preferability of cellophane in specific applications.

As the packaging industry continues to evolve, ongoing research and development efforts are focused on enhancing the environmental performance of cellophane. This includes exploring more sustainable production methods, improving the compatibility of water-resistant coatings with biodegradation, and developing better end-of-life management strategies for cellophane packaging.

One of the primary environmental benefits of cellophane is its biodegradability. Unlike many synthetic plastics, cellophane can decompose naturally in the environment, reducing long-term pollution concerns. This characteristic aligns with growing consumer demand for more sustainable packaging options and helps companies meet increasingly stringent environmental regulations.

However, the production process of cellophane raises some environmental concerns. The manufacturing of cellophane involves the use of chemicals such as carbon disulfide and sodium hydroxide, which can have negative impacts on air and water quality if not properly managed. Additionally, the energy-intensive nature of cellophane production contributes to its carbon footprint.

When considering water-resistant cellophane packaging, additional factors come into play. The application of water-resistant coatings or treatments may reduce the biodegradability of the material, potentially offsetting some of its environmental benefits. The type and composition of these coatings can significantly influence the overall environmental impact of the packaging solution.

In terms of waste management, cellophane presents both opportunities and challenges. While it can be composted under proper conditions, many municipal waste systems are not equipped to handle cellophane effectively. This can lead to cellophane ending up in landfills or contaminating recycling streams, diminishing its potential environmental advantages.

The water resistance of cellophane packaging also affects its end-of-life environmental impact. While improved water resistance can extend the shelf life of products and reduce food waste, it may also hinder the natural decomposition process of the cellophane, potentially leading to longer persistence in the environment.

From a lifecycle perspective, the environmental impact of cellophane packaging must be evaluated holistically. This includes considering raw material sourcing, manufacturing processes, transportation, use phase, and end-of-life disposal. Comparative studies with alternative packaging materials are essential to determine the overall environmental preferability of cellophane in specific applications.

As the packaging industry continues to evolve, ongoing research and development efforts are focused on enhancing the environmental performance of cellophane. This includes exploring more sustainable production methods, improving the compatibility of water-resistant coatings with biodegradation, and developing better end-of-life management strategies for cellophane packaging.

Regulatory Compliance for Food Packaging

Regulatory compliance is a critical aspect of utilizing cellophane in water-resistant food packaging. The use of cellophane must adhere to strict guidelines set by various regulatory bodies to ensure consumer safety and environmental protection.

In the United States, the Food and Drug Administration (FDA) regulates food packaging materials under the Federal Food, Drug, and Cosmetic Act. Cellophane used in food packaging must comply with FDA regulations, particularly 21 CFR 177.1200, which outlines specific requirements for cellophane intended for food contact. This regulation covers the composition, manufacturing processes, and permissible additives for cellophane used in food packaging applications.

The European Union has its own set of regulations governing food contact materials, including Regulation (EC) No 1935/2004. This framework ensures that materials used in food packaging do not transfer harmful substances to food in quantities that could endanger human health. For cellophane to be used in water-resistant food packaging within the EU, it must comply with these regulations and undergo appropriate testing to demonstrate its safety.

In addition to food safety regulations, environmental considerations play a significant role in regulatory compliance for cellophane packaging. Many countries have implemented regulations to address the environmental impact of packaging materials. For instance, the EU Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging waste, including cellophane-based materials.

Water-resistant cellophane packaging must also comply with regulations related to chemical substances used in its production. The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU requires manufacturers to register and assess the safety of chemical substances used in packaging materials, including those that impart water-resistant properties to cellophane.

Manufacturers must consider biodegradability and compostability standards when developing water-resistant cellophane packaging. In the EU, the EN 13432 standard sets requirements for packaging recoverable through composting and biodegradation. Compliance with such standards may be necessary for cellophane packaging to be marketed as environmentally friendly or biodegradable.

To ensure regulatory compliance, manufacturers must implement rigorous quality control measures and maintain detailed documentation of their production processes and material compositions. Regular testing and certification by accredited laboratories are essential to demonstrate ongoing compliance with applicable regulations.

As regulations evolve to address emerging concerns about food safety and environmental impact, manufacturers must stay informed about changes in regulatory requirements across different markets. This may involve participating in industry associations, engaging with regulatory bodies, and continuously updating their compliance strategies to meet new standards and guidelines for water-resistant cellophane packaging in the food industry.

In the United States, the Food and Drug Administration (FDA) regulates food packaging materials under the Federal Food, Drug, and Cosmetic Act. Cellophane used in food packaging must comply with FDA regulations, particularly 21 CFR 177.1200, which outlines specific requirements for cellophane intended for food contact. This regulation covers the composition, manufacturing processes, and permissible additives for cellophane used in food packaging applications.

The European Union has its own set of regulations governing food contact materials, including Regulation (EC) No 1935/2004. This framework ensures that materials used in food packaging do not transfer harmful substances to food in quantities that could endanger human health. For cellophane to be used in water-resistant food packaging within the EU, it must comply with these regulations and undergo appropriate testing to demonstrate its safety.

In addition to food safety regulations, environmental considerations play a significant role in regulatory compliance for cellophane packaging. Many countries have implemented regulations to address the environmental impact of packaging materials. For instance, the EU Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging waste, including cellophane-based materials.

Water-resistant cellophane packaging must also comply with regulations related to chemical substances used in its production. The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU requires manufacturers to register and assess the safety of chemical substances used in packaging materials, including those that impart water-resistant properties to cellophane.

Manufacturers must consider biodegradability and compostability standards when developing water-resistant cellophane packaging. In the EU, the EN 13432 standard sets requirements for packaging recoverable through composting and biodegradation. Compliance with such standards may be necessary for cellophane packaging to be marketed as environmentally friendly or biodegradable.

To ensure regulatory compliance, manufacturers must implement rigorous quality control measures and maintain detailed documentation of their production processes and material compositions. Regular testing and certification by accredited laboratories are essential to demonstrate ongoing compliance with applicable regulations.

As regulations evolve to address emerging concerns about food safety and environmental impact, manufacturers must stay informed about changes in regulatory requirements across different markets. This may involve participating in industry associations, engaging with regulatory bodies, and continuously updating their compliance strategies to meet new standards and guidelines for water-resistant cellophane packaging in the food industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!