How Vacuum Pumps Influence Microgravity Research Equipment

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech Evolution

Vacuum pump technology has undergone significant evolution since its inception, playing a crucial role in microgravity research equipment. The journey began with the invention of the first mechanical vacuum pump by Otto von Guericke in 1650, which laid the foundation for future developments. Over time, various types of vacuum pumps emerged, each addressing specific needs and overcoming limitations of previous designs.

In the early 20th century, the introduction of rotary vane pumps marked a significant milestone. These pumps offered improved efficiency and reliability, making them suitable for a wide range of applications, including early space research. The mid-20th century saw the development of turbomolecular pumps, which revolutionized high-vacuum applications by achieving much lower pressures than their predecessors.

The advent of cryogenic pumps in the 1960s further expanded the capabilities of vacuum technology. These pumps, utilizing extremely low temperatures to condense gases, proved invaluable in space simulation chambers and other microgravity research facilities. Concurrently, the development of ion pumps and getter pumps provided new methods for maintaining ultra-high vacuums, essential for sensitive microgravity experiments.

The late 20th century witnessed the refinement of existing technologies and the introduction of hybrid systems. Combination pumps, integrating multiple pump types, offered enhanced performance and versatility. This period also saw significant improvements in pump materials and designs, leading to increased durability and reduced contamination risks – critical factors in microgravity research.

Recent advancements have focused on miniaturization and energy efficiency. The development of micro-electromechanical systems (MEMS) based vacuum pumps has opened new possibilities for compact, lightweight microgravity research equipment. These innovations have been particularly beneficial for space-based experiments, where size and weight constraints are paramount.

The evolution of vacuum pump technology has been closely intertwined with advancements in microgravity research. As experiments became more sophisticated, demanding higher vacuum levels and cleaner environments, pump technology adapted to meet these needs. This symbiotic relationship has driven continuous innovation, resulting in pumps capable of achieving and maintaining the extreme conditions required for cutting-edge microgravity studies.

Looking forward, the trend towards more efficient, compact, and specialized vacuum pumps is likely to continue. Emerging technologies such as quantum vacuum pumps and advanced materials promise to push the boundaries of what is possible in microgravity research equipment. These developments will enable more precise control of microgravity environments, potentially leading to groundbreaking discoveries in fields ranging from materials science to fundamental physics.

In the early 20th century, the introduction of rotary vane pumps marked a significant milestone. These pumps offered improved efficiency and reliability, making them suitable for a wide range of applications, including early space research. The mid-20th century saw the development of turbomolecular pumps, which revolutionized high-vacuum applications by achieving much lower pressures than their predecessors.

The advent of cryogenic pumps in the 1960s further expanded the capabilities of vacuum technology. These pumps, utilizing extremely low temperatures to condense gases, proved invaluable in space simulation chambers and other microgravity research facilities. Concurrently, the development of ion pumps and getter pumps provided new methods for maintaining ultra-high vacuums, essential for sensitive microgravity experiments.

The late 20th century witnessed the refinement of existing technologies and the introduction of hybrid systems. Combination pumps, integrating multiple pump types, offered enhanced performance and versatility. This period also saw significant improvements in pump materials and designs, leading to increased durability and reduced contamination risks – critical factors in microgravity research.

Recent advancements have focused on miniaturization and energy efficiency. The development of micro-electromechanical systems (MEMS) based vacuum pumps has opened new possibilities for compact, lightweight microgravity research equipment. These innovations have been particularly beneficial for space-based experiments, where size and weight constraints are paramount.

The evolution of vacuum pump technology has been closely intertwined with advancements in microgravity research. As experiments became more sophisticated, demanding higher vacuum levels and cleaner environments, pump technology adapted to meet these needs. This symbiotic relationship has driven continuous innovation, resulting in pumps capable of achieving and maintaining the extreme conditions required for cutting-edge microgravity studies.

Looking forward, the trend towards more efficient, compact, and specialized vacuum pumps is likely to continue. Emerging technologies such as quantum vacuum pumps and advanced materials promise to push the boundaries of what is possible in microgravity research equipment. These developments will enable more precise control of microgravity environments, potentially leading to groundbreaking discoveries in fields ranging from materials science to fundamental physics.

Microgravity Research Demand

The demand for microgravity research has been steadily increasing in recent years, driven by the growing interest in space exploration and the potential for groundbreaking scientific discoveries. This surge in demand is reflected in the expanding market for microgravity research equipment, which is projected to reach significant growth in the coming years.

Microgravity research offers unique opportunities to study physical, chemical, and biological processes that are difficult or impossible to observe under Earth's gravitational conditions. This has led to a wide range of applications across various scientific disciplines, including materials science, fluid dynamics, combustion science, and biotechnology.

One of the primary drivers of microgravity research demand is the pharmaceutical industry. The ability to grow high-quality protein crystals in microgravity environments has opened new avenues for drug discovery and development. These crystals, formed without the influence of gravity, often exhibit superior structural clarity, enabling researchers to better understand protein structures and design more effective medications.

The semiconductor industry has also shown increasing interest in microgravity research. The production of ultra-pure materials and the study of fluid behavior in the absence of gravity can lead to advancements in semiconductor manufacturing processes and the development of novel electronic materials.

Space agencies and private space companies are major contributors to the growing demand for microgravity research equipment. As space missions become more frequent and ambitious, there is a pressing need for advanced research tools that can operate effectively in microgravity environments. This includes equipment for studying the effects of long-term space travel on human physiology, as well as tools for conducting experiments in materials science and fluid dynamics.

Educational institutions and research organizations are also driving demand for microgravity research equipment. The opportunity to conduct experiments in space or on parabolic flights has become more accessible, leading to an increase in academic research projects focused on microgravity phenomena.

The demand for microgravity research is not limited to space-based experiments. Ground-based facilities that simulate microgravity conditions, such as drop towers and neutral buoyancy laboratories, are also experiencing increased utilization. These facilities provide cost-effective alternatives for preliminary research and testing before conducting experiments in actual space environments.

As the commercial space industry continues to expand, there is a growing market for microgravity research services. Companies are offering platforms for conducting experiments in space, creating new opportunities for researchers and businesses to access microgravity environments. This commercialization of space research is expected to further drive the demand for specialized microgravity research equipment in the coming years.

Microgravity research offers unique opportunities to study physical, chemical, and biological processes that are difficult or impossible to observe under Earth's gravitational conditions. This has led to a wide range of applications across various scientific disciplines, including materials science, fluid dynamics, combustion science, and biotechnology.

One of the primary drivers of microgravity research demand is the pharmaceutical industry. The ability to grow high-quality protein crystals in microgravity environments has opened new avenues for drug discovery and development. These crystals, formed without the influence of gravity, often exhibit superior structural clarity, enabling researchers to better understand protein structures and design more effective medications.

The semiconductor industry has also shown increasing interest in microgravity research. The production of ultra-pure materials and the study of fluid behavior in the absence of gravity can lead to advancements in semiconductor manufacturing processes and the development of novel electronic materials.

Space agencies and private space companies are major contributors to the growing demand for microgravity research equipment. As space missions become more frequent and ambitious, there is a pressing need for advanced research tools that can operate effectively in microgravity environments. This includes equipment for studying the effects of long-term space travel on human physiology, as well as tools for conducting experiments in materials science and fluid dynamics.

Educational institutions and research organizations are also driving demand for microgravity research equipment. The opportunity to conduct experiments in space or on parabolic flights has become more accessible, leading to an increase in academic research projects focused on microgravity phenomena.

The demand for microgravity research is not limited to space-based experiments. Ground-based facilities that simulate microgravity conditions, such as drop towers and neutral buoyancy laboratories, are also experiencing increased utilization. These facilities provide cost-effective alternatives for preliminary research and testing before conducting experiments in actual space environments.

As the commercial space industry continues to expand, there is a growing market for microgravity research services. Companies are offering platforms for conducting experiments in space, creating new opportunities for researchers and businesses to access microgravity environments. This commercialization of space research is expected to further drive the demand for specialized microgravity research equipment in the coming years.

Vacuum Pump Challenges

Vacuum pumps play a crucial role in microgravity research equipment, yet they face several significant challenges that impact their performance and reliability. One of the primary issues is the maintenance of consistent vacuum levels in microgravity environments. The absence of gravity affects fluid dynamics and gas behavior, making it difficult for traditional pump designs to operate efficiently. This challenge is particularly evident in space-based laboratories where even minor fluctuations in vacuum quality can compromise experimental results.

Another major hurdle is the size and weight constraints imposed on vacuum pumps for space applications. Microgravity research equipment often needs to be compact and lightweight to minimize launch costs and conserve valuable space on spacecraft. This requirement puts pressure on engineers to develop miniaturized pump systems without sacrificing performance or durability. The trade-off between size reduction and maintaining adequate pumping capacity remains a significant technical challenge.

Power consumption is also a critical concern for vacuum pumps in microgravity research. Space missions have limited energy resources, and every watt of power must be carefully allocated. Developing energy-efficient pump systems that can operate reliably for extended periods is essential. This challenge is compounded by the need for pumps to function across a wide range of temperatures and pressures encountered in space environments.

Reliability and longevity present another set of challenges for vacuum pumps in microgravity research. The harsh conditions of space, including radiation exposure and extreme temperature fluctuations, can accelerate wear and tear on pump components. Designing pumps that can withstand these conditions while maintaining consistent performance over long durations is crucial for the success of extended microgravity experiments.

The absence of convection in microgravity environments also poses unique challenges for heat dissipation in vacuum pumps. Overheating can lead to performance degradation and premature failure. Engineers must develop innovative cooling solutions that do not rely on gravity-dependent mechanisms, further complicating pump design and operation.

Contamination control is another critical challenge for vacuum pumps in microgravity research. The pumps must maintain ultra-clean environments for sensitive experiments while preventing the backstreaming of pump oils or other contaminants. This requirement necessitates the development of specialized sealing and filtration systems that can function effectively in the absence of gravity.

Lastly, the serviceability of vacuum pumps in space presents a significant challenge. Unlike Earth-based laboratories, repairing or replacing pump components in orbit is extremely difficult and costly. This limitation puts additional pressure on designers to create highly reliable systems that can operate for extended periods without maintenance, while also incorporating modular designs that facilitate potential in-space servicing or replacement.

Another major hurdle is the size and weight constraints imposed on vacuum pumps for space applications. Microgravity research equipment often needs to be compact and lightweight to minimize launch costs and conserve valuable space on spacecraft. This requirement puts pressure on engineers to develop miniaturized pump systems without sacrificing performance or durability. The trade-off between size reduction and maintaining adequate pumping capacity remains a significant technical challenge.

Power consumption is also a critical concern for vacuum pumps in microgravity research. Space missions have limited energy resources, and every watt of power must be carefully allocated. Developing energy-efficient pump systems that can operate reliably for extended periods is essential. This challenge is compounded by the need for pumps to function across a wide range of temperatures and pressures encountered in space environments.

Reliability and longevity present another set of challenges for vacuum pumps in microgravity research. The harsh conditions of space, including radiation exposure and extreme temperature fluctuations, can accelerate wear and tear on pump components. Designing pumps that can withstand these conditions while maintaining consistent performance over long durations is crucial for the success of extended microgravity experiments.

The absence of convection in microgravity environments also poses unique challenges for heat dissipation in vacuum pumps. Overheating can lead to performance degradation and premature failure. Engineers must develop innovative cooling solutions that do not rely on gravity-dependent mechanisms, further complicating pump design and operation.

Contamination control is another critical challenge for vacuum pumps in microgravity research. The pumps must maintain ultra-clean environments for sensitive experiments while preventing the backstreaming of pump oils or other contaminants. This requirement necessitates the development of specialized sealing and filtration systems that can function effectively in the absence of gravity.

Lastly, the serviceability of vacuum pumps in space presents a significant challenge. Unlike Earth-based laboratories, repairing or replacing pump components in orbit is extremely difficult and costly. This limitation puts additional pressure on designers to create highly reliable systems that can operate for extended periods without maintenance, while also incorporating modular designs that facilitate potential in-space servicing or replacement.

Current Vacuum Solutions

01 Vacuum pump design improvements

Advancements in vacuum pump design focus on enhancing efficiency, reducing noise, and improving overall performance. These improvements may include modifications to rotor configurations, sealing mechanisms, and materials used in construction. Such design enhancements contribute to better vacuum generation and maintenance across various applications.- Vacuum pump design improvements: Advancements in vacuum pump design focus on enhancing efficiency, reducing noise, and improving overall performance. These improvements may include modifications to rotor configurations, sealing mechanisms, and materials used in construction. Such enhancements contribute to better vacuum generation and maintenance across various applications.

- Vacuum pump applications in semiconductor manufacturing: Vacuum pumps play a crucial role in semiconductor manufacturing processes, including etching, deposition, and ion implantation. The influence of vacuum pumps in this field extends to maintaining clean environments, controlling process pressures, and enabling precise material handling. Specialized pump designs cater to the unique requirements of semiconductor fabrication.

- Energy efficiency and environmental impact: Innovations in vacuum pump technology aim to reduce energy consumption and minimize environmental impact. This includes the development of more efficient motors, improved heat management systems, and the use of environmentally friendly materials and lubricants. These advancements contribute to lower operating costs and reduced carbon footprints in industrial applications.

- Vacuum pump control and monitoring systems: Advanced control and monitoring systems enhance the performance and reliability of vacuum pumps. These systems may include sensors for pressure, temperature, and flow rate monitoring, as well as intelligent control algorithms for optimizing pump operation. Integration with industrial automation systems allows for remote monitoring and predictive maintenance.

- Specialized vacuum pumps for specific industries: Vacuum pumps are tailored for specific industries such as food processing, pharmaceutical manufacturing, and aerospace. These specialized pumps address unique requirements like handling corrosive gases, maintaining sterile environments, or operating in extreme conditions. The influence of vacuum pumps in these industries extends to product quality, process efficiency, and regulatory compliance.

02 Vacuum pump applications in semiconductor manufacturing

Vacuum pumps play a crucial role in semiconductor manufacturing processes, including etching, deposition, and ion implantation. The influence of vacuum pumps in this field extends to maintaining clean environments, controlling process pressures, and enabling precise material handling. Specialized vacuum pump designs cater to the unique requirements of semiconductor fabrication.Expand Specific Solutions03 Energy efficiency and environmental impact

Innovations in vacuum pump technology aim to reduce energy consumption and minimize environmental impact. This includes the development of more efficient motors, improved heat management systems, and the use of environmentally friendly materials. These advancements contribute to lower operating costs and reduced carbon footprints in industrial applications.Expand Specific Solutions04 Vacuum pump control and monitoring systems

Advanced control and monitoring systems enhance the performance and reliability of vacuum pumps. These systems may include sensors for pressure, temperature, and flow rate monitoring, as well as intelligent control algorithms for optimizing pump operation. Integration with industrial automation systems allows for improved process control and predictive maintenance.Expand Specific Solutions05 Vacuum pump influence on material properties

The use of vacuum pumps can significantly influence material properties in various processes, such as heat treatment, coating, and drying. By controlling the pressure environment, vacuum pumps enable precise manipulation of material characteristics, including density, porosity, and surface properties. This influence extends to applications in metallurgy, food processing, and pharmaceutical manufacturing.Expand Specific Solutions

Key Vacuum Pump Manufacturers

The vacuum pump industry for microgravity research equipment is in a mature stage, with established players like Edwards Ltd., Pfeiffer Vacuum GmbH, and Agilent Technologies dominating the market. The global market size for vacuum pumps in research applications is estimated to be in the billions, driven by increasing investments in space exploration and microgravity experiments. Technologically, companies like Edwards Vacuum LLC and Applied Materials, Inc. are at the forefront, continuously improving pump efficiency and precision for microgravity environments. Research institutions such as MIT and Korea Research Institute of Standards & Science collaborate with these companies to advance vacuum technology for space applications, ensuring a steady pipeline of innovations in this specialized field.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pumps specifically designed for microgravity research equipment. Their GXS dry screw vacuum pumps offer high pumping speeds and ultimate pressures, crucial for maintaining stable microgravity environments. These pumps utilize a unique screw mechanism that minimizes vibration and oil contamination, essential for sensitive microgravity experiments [1]. Edwards has also introduced the nEXT turbomolecular pump series, which provides ultra-high vacuum levels with minimal power consumption, enabling long-duration microgravity research missions [2]. The company's vacuum pumps incorporate intelligent control systems that can adapt to varying pressure conditions, ensuring consistent performance in fluctuating microgravity environments [3].

Strengths: High pumping efficiency, low vibration, and contamination-free operation. Weaknesses: Higher initial cost compared to traditional pumps, may require specialized maintenance.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed the HiPace turbomolecular pump series, specifically optimized for microgravity research applications. These pumps feature a hybrid bearing system combining ceramic ball bearings and permanent magnetic bearings, which significantly reduces mechanical wear and vibration, critical for maintaining stable microgravity conditions [1]. The company's OnTool Booster pumps provide rapid pump-down times, essential for cyclic microgravity experiments. Pfeiffer has also introduced the ACP multi-stage Roots pumps, which offer high pumping speeds at low pressures, ideal for simulating various microgravity environments [2]. Their vacuum pumps incorporate advanced rotor designs that minimize heat generation, crucial for temperature-sensitive microgravity research equipment [3].

Strengths: High reliability, low maintenance requirements, and precise pressure control. Weaknesses: Relatively high power consumption, which may be a constraint in space-based applications.

Innovative Vacuum Designs

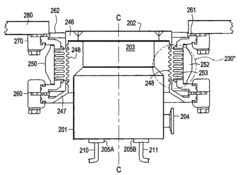

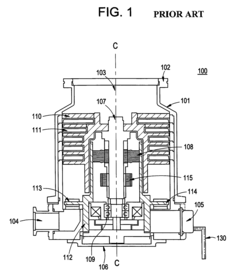

Vibration damper with nested turbo molecular pump

PatentInactiveUS7300261B2

Innovation

- A nested vibration damping arrangement is implemented, where a flexible bellow damper surrounds a major portion of the turbo pump, providing effective damping with a direct connection to the vacuum chamber inlet port, reducing the size and cost of the pump while maintaining high throughput and low vibration.

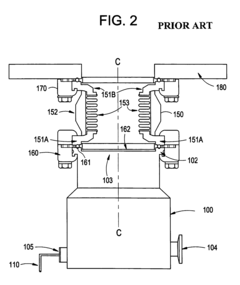

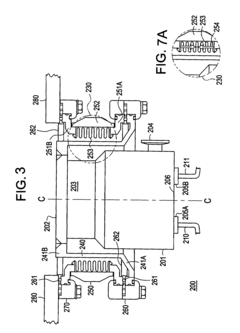

Method for operating an assembly with vacuum pump and assembly with a vacuum pump

PatentInactiveEP2003342A3

Innovation

- A method and arrangement that utilize a magnetic bearing with a switching means to reduce pre-magnetization during quiet operation phases, allowing for lower bias current usage, which minimizes mechanical vibrations by adjusting the pre-magnetization current based on rotor deflection and installation position, ensuring sufficient force to support the rotor's weight while reducing vibration transmission.

Space Agency Collaborations

Space agency collaborations play a crucial role in advancing microgravity research equipment, particularly in the development and application of vacuum pump technologies. These partnerships foster innovation, knowledge sharing, and resource optimization across international boundaries, leading to significant advancements in space exploration and scientific research.

NASA and ESA have been at the forefront of such collaborations, jointly developing advanced vacuum pump systems for use in microgravity environments. Their combined efforts have resulted in more efficient and reliable equipment, capable of maintaining precise vacuum conditions essential for various experiments conducted on the International Space Station (ISS).

The Russian space agency, Roscosmos, has also contributed significantly to this field through its collaboration with other agencies. Their expertise in long-duration space missions has provided valuable insights into the long-term performance and maintenance of vacuum pumps in microgravity conditions. This knowledge has been instrumental in designing more durable and sustainable systems for future deep space missions.

JAXA, the Japanese space agency, has focused on miniaturization and energy efficiency in vacuum pump technology. Through partnerships with NASA and ESA, JAXA has developed compact, low-power consumption vacuum pumps that are particularly suited for small satellite missions and cubesats. These innovations have expanded the possibilities for conducting microgravity research on a broader scale.

The Chinese National Space Administration (CNSA) has recently emerged as a significant player in space agency collaborations. Their contributions to vacuum pump technology, particularly in the development of novel materials resistant to degradation in space environments, have garnered interest from other agencies. Collaborative projects between CNSA and international partners are expected to yield new advancements in vacuum pump reliability and longevity.

Interagency collaborations have also led to the establishment of standardized protocols for vacuum pump operation and maintenance in microgravity. These shared guidelines ensure compatibility and interoperability of equipment across different space platforms, facilitating more seamless international cooperation in space research.

The impact of these collaborations extends beyond technical advancements. They have fostered a global community of researchers and engineers dedicated to solving the unique challenges posed by microgravity environments. Regular conferences, workshops, and exchange programs organized by these space agencies have accelerated the pace of innovation and knowledge dissemination in the field of vacuum pump technology for space applications.

As space exploration continues to evolve, these collaborative efforts are expected to intensify. Future joint missions, such as those planned for lunar and Martian exploration, will heavily rely on the collective expertise gained through these partnerships in developing robust and efficient vacuum pump systems capable of operating in diverse extraterrestrial environments.

NASA and ESA have been at the forefront of such collaborations, jointly developing advanced vacuum pump systems for use in microgravity environments. Their combined efforts have resulted in more efficient and reliable equipment, capable of maintaining precise vacuum conditions essential for various experiments conducted on the International Space Station (ISS).

The Russian space agency, Roscosmos, has also contributed significantly to this field through its collaboration with other agencies. Their expertise in long-duration space missions has provided valuable insights into the long-term performance and maintenance of vacuum pumps in microgravity conditions. This knowledge has been instrumental in designing more durable and sustainable systems for future deep space missions.

JAXA, the Japanese space agency, has focused on miniaturization and energy efficiency in vacuum pump technology. Through partnerships with NASA and ESA, JAXA has developed compact, low-power consumption vacuum pumps that are particularly suited for small satellite missions and cubesats. These innovations have expanded the possibilities for conducting microgravity research on a broader scale.

The Chinese National Space Administration (CNSA) has recently emerged as a significant player in space agency collaborations. Their contributions to vacuum pump technology, particularly in the development of novel materials resistant to degradation in space environments, have garnered interest from other agencies. Collaborative projects between CNSA and international partners are expected to yield new advancements in vacuum pump reliability and longevity.

Interagency collaborations have also led to the establishment of standardized protocols for vacuum pump operation and maintenance in microgravity. These shared guidelines ensure compatibility and interoperability of equipment across different space platforms, facilitating more seamless international cooperation in space research.

The impact of these collaborations extends beyond technical advancements. They have fostered a global community of researchers and engineers dedicated to solving the unique challenges posed by microgravity environments. Regular conferences, workshops, and exchange programs organized by these space agencies have accelerated the pace of innovation and knowledge dissemination in the field of vacuum pump technology for space applications.

As space exploration continues to evolve, these collaborative efforts are expected to intensify. Future joint missions, such as those planned for lunar and Martian exploration, will heavily rely on the collective expertise gained through these partnerships in developing robust and efficient vacuum pump systems capable of operating in diverse extraterrestrial environments.

Vacuum Pump Reliability

Vacuum pump reliability is a critical factor in the performance and effectiveness of microgravity research equipment. The consistent and stable operation of vacuum pumps directly impacts the quality of experimental results and the overall success of microgravity studies. In space-based research facilities, the reliability of vacuum pumps becomes even more crucial due to the limited opportunities for maintenance and repair.

The primary challenge in ensuring vacuum pump reliability lies in the harsh operating conditions encountered in microgravity environments. These conditions include extreme temperature fluctuations, radiation exposure, and the absence of gravity itself. Vacuum pumps must be designed and manufactured to withstand these challenges while maintaining consistent performance over extended periods.

To address these reliability concerns, manufacturers have developed specialized vacuum pumps for microgravity applications. These pumps often incorporate advanced materials and design features to enhance durability and longevity. For instance, the use of corrosion-resistant alloys and ceramic components helps mitigate the effects of harsh environmental conditions.

Redundancy is another key strategy employed to improve vacuum pump reliability in microgravity research equipment. By incorporating multiple pumps or backup systems, researchers can ensure continuous operation even in the event of a single pump failure. This approach is particularly important for long-duration experiments or missions where equipment downtime could compromise valuable research opportunities.

Predictive maintenance techniques have also been developed to enhance vacuum pump reliability. These methods utilize sensors and data analytics to monitor pump performance in real-time, allowing for early detection of potential issues. By identifying and addressing problems before they lead to failure, researchers can minimize disruptions to their experiments and extend the operational life of their equipment.

The reliability of vacuum pumps in microgravity research equipment is closely tied to their power consumption and heat generation. Efficient pump designs that minimize energy use and heat output not only contribute to overall system reliability but also reduce the strain on limited power resources in space-based laboratories.

Ongoing research and development efforts are focused on further improving vacuum pump reliability for microgravity applications. These efforts include the exploration of novel pump designs, such as magnetically levitated turbomolecular pumps, which offer reduced mechanical wear and improved longevity. Additionally, advancements in materials science are being leveraged to develop more resilient components capable of withstanding the rigors of space-based operation.

The primary challenge in ensuring vacuum pump reliability lies in the harsh operating conditions encountered in microgravity environments. These conditions include extreme temperature fluctuations, radiation exposure, and the absence of gravity itself. Vacuum pumps must be designed and manufactured to withstand these challenges while maintaining consistent performance over extended periods.

To address these reliability concerns, manufacturers have developed specialized vacuum pumps for microgravity applications. These pumps often incorporate advanced materials and design features to enhance durability and longevity. For instance, the use of corrosion-resistant alloys and ceramic components helps mitigate the effects of harsh environmental conditions.

Redundancy is another key strategy employed to improve vacuum pump reliability in microgravity research equipment. By incorporating multiple pumps or backup systems, researchers can ensure continuous operation even in the event of a single pump failure. This approach is particularly important for long-duration experiments or missions where equipment downtime could compromise valuable research opportunities.

Predictive maintenance techniques have also been developed to enhance vacuum pump reliability. These methods utilize sensors and data analytics to monitor pump performance in real-time, allowing for early detection of potential issues. By identifying and addressing problems before they lead to failure, researchers can minimize disruptions to their experiments and extend the operational life of their equipment.

The reliability of vacuum pumps in microgravity research equipment is closely tied to their power consumption and heat generation. Efficient pump designs that minimize energy use and heat output not only contribute to overall system reliability but also reduce the strain on limited power resources in space-based laboratories.

Ongoing research and development efforts are focused on further improving vacuum pump reliability for microgravity applications. These efforts include the exploration of novel pump designs, such as magnetically levitated turbomolecular pumps, which offer reduced mechanical wear and improved longevity. Additionally, advancements in materials science are being leveraged to develop more resilient components capable of withstanding the rigors of space-based operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!