How Vacuum Pumps Enhance High-Precision Nanopatterning Techniques

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Nanopatterning Background and Objectives

Vacuum pumps have played a pivotal role in the evolution of nanopatterning techniques, enabling unprecedented levels of precision and control in the fabrication of nanoscale structures. The journey of vacuum technology in nanopatterning began with the advent of electron beam lithography in the 1960s, which required high vacuum conditions to operate effectively. Since then, the symbiotic relationship between vacuum technology and nanopatterning has continued to grow, driving innovations in both fields.

The primary objective of integrating vacuum pumps into nanopatterning processes is to create an ultra-clean, controlled environment that minimizes contamination and interference during the fabrication of nanoscale features. This controlled environment is crucial for achieving the high resolution and accuracy demanded by modern nanotechnology applications, ranging from semiconductor manufacturing to advanced materials research.

As nanopatterning techniques have evolved, so too have the requirements for vacuum systems. Early vacuum pumps used in nanopatterning were primarily focused on achieving high vacuum levels. However, the focus has shifted towards creating more stable, contamination-free environments with precise pressure control. This shift has led to the development of specialized vacuum pumps designed specifically for nanopatterning applications, capable of maintaining ultra-high vacuum conditions while minimizing vibration and particle generation.

The technological trajectory of vacuum pumps in nanopatterning has been marked by several key milestones. The introduction of turbomolecular pumps in the 1970s significantly improved vacuum quality and pumping speed. The development of dry pumps in the 1980s and 1990s further enhanced cleanliness by eliminating oil contamination. More recently, the integration of advanced control systems and smart technologies has enabled real-time monitoring and adjustment of vacuum conditions, further improving process stability and reproducibility.

Looking ahead, the future of vacuum pump technology in nanopatterning is poised for continued innovation. Emerging trends include the development of more compact and energy-efficient vacuum systems, the integration of artificial intelligence for predictive maintenance and process optimization, and the exploration of novel pumping mechanisms capable of achieving even higher vacuum levels with greater precision.

The ongoing pursuit of smaller feature sizes and more complex nanostructures in fields such as quantum computing, photonics, and bioengineering is driving the demand for ever more sophisticated vacuum solutions. As such, the synergy between vacuum pump technology and nanopatterning techniques remains a critical area of research and development, promising to unlock new possibilities in nanoscale fabrication and push the boundaries of what is achievable at the atomic level.

The primary objective of integrating vacuum pumps into nanopatterning processes is to create an ultra-clean, controlled environment that minimizes contamination and interference during the fabrication of nanoscale features. This controlled environment is crucial for achieving the high resolution and accuracy demanded by modern nanotechnology applications, ranging from semiconductor manufacturing to advanced materials research.

As nanopatterning techniques have evolved, so too have the requirements for vacuum systems. Early vacuum pumps used in nanopatterning were primarily focused on achieving high vacuum levels. However, the focus has shifted towards creating more stable, contamination-free environments with precise pressure control. This shift has led to the development of specialized vacuum pumps designed specifically for nanopatterning applications, capable of maintaining ultra-high vacuum conditions while minimizing vibration and particle generation.

The technological trajectory of vacuum pumps in nanopatterning has been marked by several key milestones. The introduction of turbomolecular pumps in the 1970s significantly improved vacuum quality and pumping speed. The development of dry pumps in the 1980s and 1990s further enhanced cleanliness by eliminating oil contamination. More recently, the integration of advanced control systems and smart technologies has enabled real-time monitoring and adjustment of vacuum conditions, further improving process stability and reproducibility.

Looking ahead, the future of vacuum pump technology in nanopatterning is poised for continued innovation. Emerging trends include the development of more compact and energy-efficient vacuum systems, the integration of artificial intelligence for predictive maintenance and process optimization, and the exploration of novel pumping mechanisms capable of achieving even higher vacuum levels with greater precision.

The ongoing pursuit of smaller feature sizes and more complex nanostructures in fields such as quantum computing, photonics, and bioengineering is driving the demand for ever more sophisticated vacuum solutions. As such, the synergy between vacuum pump technology and nanopatterning techniques remains a critical area of research and development, promising to unlock new possibilities in nanoscale fabrication and push the boundaries of what is achievable at the atomic level.

Market Analysis for High-Precision Nanopatterning

The high-precision nanopatterning market is experiencing significant growth, driven by increasing demand for advanced semiconductor devices, nanotechnology applications, and miniaturization trends across various industries. This market segment is closely tied to the development of cutting-edge technologies in electronics, photonics, and biotechnology.

The global market for high-precision nanopatterning is projected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is primarily fueled by the semiconductor industry's continuous push for smaller, more efficient chip designs, as well as emerging applications in areas such as quantum computing and nanomedicine.

Key market drivers include the rising adoption of Internet of Things (IoT) devices, artificial intelligence, and 5G technology, all of which require advanced nanoscale components. Additionally, the increasing focus on renewable energy technologies and sustainable manufacturing processes is creating new opportunities for nanopatterning applications in solar cells and energy-efficient materials.

The Asia-Pacific region, particularly countries like China, South Korea, and Taiwan, dominates the market due to their strong presence in semiconductor manufacturing. However, North America and Europe are also significant players, with a focus on research and development in emerging nanotechnology applications.

Vacuum pump technology plays a crucial role in enabling high-precision nanopatterning techniques. The demand for advanced vacuum systems is growing in tandem with the nanopatterning market, as these pumps are essential for creating the ultra-clean, controlled environments required for nanoscale fabrication processes.

The market for vacuum pumps specifically designed for nanopatterning applications is expected to see robust growth, with a focus on developing pumps that offer higher precision, improved reliability, and reduced contamination risks. Manufacturers are investing in research and development to create innovative pump designs that can meet the increasingly stringent requirements of nanoscale manufacturing processes.

Challenges in the market include the high cost of equipment and materials, the need for specialized expertise, and concerns about environmental and health impacts of nanoparticles. However, ongoing research and development efforts are addressing these issues, paving the way for wider adoption of nanopatterning technologies across various industries.

The global market for high-precision nanopatterning is projected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is primarily fueled by the semiconductor industry's continuous push for smaller, more efficient chip designs, as well as emerging applications in areas such as quantum computing and nanomedicine.

Key market drivers include the rising adoption of Internet of Things (IoT) devices, artificial intelligence, and 5G technology, all of which require advanced nanoscale components. Additionally, the increasing focus on renewable energy technologies and sustainable manufacturing processes is creating new opportunities for nanopatterning applications in solar cells and energy-efficient materials.

The Asia-Pacific region, particularly countries like China, South Korea, and Taiwan, dominates the market due to their strong presence in semiconductor manufacturing. However, North America and Europe are also significant players, with a focus on research and development in emerging nanotechnology applications.

Vacuum pump technology plays a crucial role in enabling high-precision nanopatterning techniques. The demand for advanced vacuum systems is growing in tandem with the nanopatterning market, as these pumps are essential for creating the ultra-clean, controlled environments required for nanoscale fabrication processes.

The market for vacuum pumps specifically designed for nanopatterning applications is expected to see robust growth, with a focus on developing pumps that offer higher precision, improved reliability, and reduced contamination risks. Manufacturers are investing in research and development to create innovative pump designs that can meet the increasingly stringent requirements of nanoscale manufacturing processes.

Challenges in the market include the high cost of equipment and materials, the need for specialized expertise, and concerns about environmental and health impacts of nanoparticles. However, ongoing research and development efforts are addressing these issues, paving the way for wider adoption of nanopatterning technologies across various industries.

Current Vacuum Pump Technology in Nanopatterning

Vacuum pump technology plays a crucial role in modern nanopatterning techniques, enabling the creation of high-precision structures at the nanoscale. Current vacuum pump systems in nanopatterning applications are designed to maintain ultra-clean environments and precise pressure control, which are essential for achieving the desired level of accuracy and reproducibility in nanofabrication processes.

The most commonly used vacuum pumps in nanopatterning include turbomolecular pumps, ion pumps, and cryopumps. Turbomolecular pumps are particularly effective in achieving high vacuum levels quickly, making them ideal for processes that require rapid pump-down times. These pumps operate by imparting momentum to gas molecules, effectively "pushing" them out of the chamber.

Ion pumps, on the other hand, are favored for their ability to maintain ultra-high vacuum conditions over extended periods. They work by ionizing gas molecules and then capturing them on a titanium surface. This pump type is especially useful in applications where contamination-free environments are critical, as they do not use any moving parts or lubricants.

Cryopumps are another essential technology in nanopatterning, particularly for processes that require extremely low pressures. These pumps operate by condensing gases onto a cold surface, effectively "freezing" them out of the chamber. Cryopumps are capable of achieving some of the lowest pressures possible, making them invaluable for certain high-precision nanopatterning techniques.

Recent advancements in vacuum pump technology have focused on improving energy efficiency, reducing pump size, and enhancing control systems. For instance, the development of magnetically levitated turbomolecular pumps has significantly reduced vibration and wear, leading to improved stability in nanopatterning processes. Additionally, the integration of smart control systems allows for more precise pressure regulation and real-time monitoring of pump performance.

Another area of innovation is in the development of hybrid pump systems that combine multiple pump technologies to optimize performance across different pressure ranges. These systems can automatically switch between different pump types as needed, providing flexibility and efficiency in complex nanopatterning processes.

The current state of vacuum pump technology also emphasizes contamination control. Advanced filtration systems and materials are being incorporated into pump designs to minimize the risk of particle contamination, which is critical in maintaining the integrity of nanoscale structures. Some pumps now feature self-cleaning mechanisms or easily replaceable components to facilitate regular maintenance without compromising the clean environment.

As nanopatterning techniques continue to evolve, demanding ever-higher levels of precision, vacuum pump manufacturers are responding with increasingly sophisticated solutions. This includes the development of pumps capable of achieving and maintaining extreme ultra-high vacuum conditions, as well as systems that offer unprecedented levels of pressure stability and uniformity across large substrate areas.

The most commonly used vacuum pumps in nanopatterning include turbomolecular pumps, ion pumps, and cryopumps. Turbomolecular pumps are particularly effective in achieving high vacuum levels quickly, making them ideal for processes that require rapid pump-down times. These pumps operate by imparting momentum to gas molecules, effectively "pushing" them out of the chamber.

Ion pumps, on the other hand, are favored for their ability to maintain ultra-high vacuum conditions over extended periods. They work by ionizing gas molecules and then capturing them on a titanium surface. This pump type is especially useful in applications where contamination-free environments are critical, as they do not use any moving parts or lubricants.

Cryopumps are another essential technology in nanopatterning, particularly for processes that require extremely low pressures. These pumps operate by condensing gases onto a cold surface, effectively "freezing" them out of the chamber. Cryopumps are capable of achieving some of the lowest pressures possible, making them invaluable for certain high-precision nanopatterning techniques.

Recent advancements in vacuum pump technology have focused on improving energy efficiency, reducing pump size, and enhancing control systems. For instance, the development of magnetically levitated turbomolecular pumps has significantly reduced vibration and wear, leading to improved stability in nanopatterning processes. Additionally, the integration of smart control systems allows for more precise pressure regulation and real-time monitoring of pump performance.

Another area of innovation is in the development of hybrid pump systems that combine multiple pump technologies to optimize performance across different pressure ranges. These systems can automatically switch between different pump types as needed, providing flexibility and efficiency in complex nanopatterning processes.

The current state of vacuum pump technology also emphasizes contamination control. Advanced filtration systems and materials are being incorporated into pump designs to minimize the risk of particle contamination, which is critical in maintaining the integrity of nanoscale structures. Some pumps now feature self-cleaning mechanisms or easily replaceable components to facilitate regular maintenance without compromising the clean environment.

As nanopatterning techniques continue to evolve, demanding ever-higher levels of precision, vacuum pump manufacturers are responding with increasingly sophisticated solutions. This includes the development of pumps capable of achieving and maintaining extreme ultra-high vacuum conditions, as well as systems that offer unprecedented levels of pressure stability and uniformity across large substrate areas.

Existing Vacuum Pump Solutions for Nanopatterning

01 Precision control mechanisms in vacuum pumps

Advanced control mechanisms are implemented in vacuum pumps to enhance precision. These may include electronic control systems, feedback loops, and precise sensors to maintain accurate pressure levels and flow rates. Such mechanisms allow for fine-tuning of pump performance, ensuring consistent and reliable operation in high-precision applications.- Precision control systems for vacuum pumps: Advanced control systems are implemented in vacuum pumps to enhance precision. These systems may include electronic controllers, sensors, and feedback mechanisms to maintain accurate pressure levels and flow rates. Such precision control allows for better performance in applications requiring highly controlled vacuum environments.

- Innovative vacuum pump designs for improved precision: Novel vacuum pump designs are developed to achieve higher precision. These may include modifications to pump geometry, rotor designs, or sealing mechanisms. Such innovations aim to reduce fluctuations, minimize leakage, and enhance overall pump efficiency, resulting in more precise vacuum generation and maintenance.

- Integration of advanced materials in vacuum pump components: The use of advanced materials in vacuum pump components contributes to improved precision. Materials with enhanced wear resistance, thermal stability, or specific surface properties are incorporated into critical pump parts. This integration leads to better performance, longer lifespan, and more consistent vacuum levels over time.

- Precision measurement and calibration techniques for vacuum pumps: Sophisticated measurement and calibration techniques are employed to ensure vacuum pump precision. These may include high-accuracy pressure sensors, flow meters, and specialized calibration equipment. Regular calibration and precise measurement allow for maintaining and verifying the pump's performance to meet stringent precision requirements.

- Application-specific vacuum pump optimizations: Vacuum pumps are optimized for specific applications requiring high precision. This involves tailoring pump characteristics such as pumping speed, ultimate pressure, and gas handling capabilities to meet the unique demands of particular industries or processes. Such optimizations result in vacuum pumps that deliver precise performance in specialized contexts.

02 Innovative pump designs for improved precision

Novel pump designs are developed to achieve higher precision in vacuum systems. These may incorporate advanced materials, optimized geometries, or innovative sealing technologies. Such designs aim to minimize fluctuations, reduce contamination, and enhance overall pump efficiency, resulting in more precise and stable vacuum environments.Expand Specific Solutions03 Integration of smart technologies in vacuum pumps

Smart technologies, such as IoT connectivity and AI-driven algorithms, are integrated into vacuum pump systems. These technologies enable real-time monitoring, predictive maintenance, and adaptive control, leading to enhanced precision and reliability in vacuum operations. Smart pumps can self-adjust based on changing conditions, ensuring optimal performance.Expand Specific Solutions04 High-precision measurement and calibration techniques

Advanced measurement and calibration techniques are employed to ensure the precision of vacuum pumps. These may include laser-based measurements, high-accuracy pressure sensors, and sophisticated calibration procedures. Such techniques allow for precise characterization and adjustment of pump performance, critical for applications requiring extreme accuracy.Expand Specific Solutions05 Specialized vacuum pumps for ultra-high precision applications

Vacuum pumps designed specifically for ultra-high precision applications, such as semiconductor manufacturing or scientific research, are developed. These pumps may incorporate unique features like contamination-free operation, extreme stability, or the ability to achieve ultra-low pressures. They are engineered to meet the most demanding precision requirements in specialized fields.Expand Specific Solutions

Key Players in Vacuum Pump and Nanopatterning Industries

The vacuum pump technology for high-precision nanopatterning is in a mature stage of development, with a competitive landscape dominated by established players in the semiconductor and precision equipment industries. The market for this technology is substantial, driven by the growing demand for advanced microchips and nanoscale devices. Companies like ASML, Pfeiffer Vacuum, and Canon are at the forefront, leveraging their expertise in lithography and vacuum systems. The technology's maturity is evident in the involvement of major semiconductor manufacturers such as Samsung and TSMC, who rely on these advanced nanopatterning techniques for their cutting-edge chip production processes. Research institutions and universities also play a crucial role in pushing the boundaries of this technology, contributing to its ongoing refinement and application in various fields beyond semiconductors.

ASML Netherlands BV

Technical Solution: ASML's advanced vacuum pump technology is integral to their EUV lithography systems, which are crucial for high-precision nanopatterning. Their systems utilize multi-stage vacuum pumps to maintain ultra-clean environments necessary for EUV light propagation. ASML's latest EUV systems incorporate advanced turbomolecular pumps capable of achieving pressures as low as 10^-7 Pa [1]. This ultra-high vacuum environment is essential for minimizing particle contamination and ensuring the accuracy of nanoscale patterns. ASML has also developed innovative vacuum chamber designs that optimize gas flow dynamics, reducing pump-down times and improving overall system efficiency [3].

Strengths: Unparalleled expertise in EUV lithography, cutting-edge vacuum technology integration, and ability to achieve ultra-high vacuum levels. Weaknesses: High system complexity and cost, limited to high-end semiconductor manufacturing.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum specializes in high-performance vacuum solutions for nanopatterning applications. Their HiPace turbomolecular pumps, designed specifically for semiconductor manufacturing, can achieve ultimate pressures below 10^-10 mbar [2]. For nanopatterning processes, Pfeiffer has developed multi-stage pump systems that combine turbomolecular pumps with dry backing pumps, ensuring contamination-free environments. Their ACP series of multi-stage roots pumps provides high pumping speeds of up to 2700 m³/h, crucial for rapid evacuation of process chambers [4]. Pfeiffer's vacuum solutions also incorporate advanced control systems that allow for precise pressure regulation, essential for maintaining consistent nanopatterning results.

Strengths: Wide range of specialized vacuum solutions, high pumping speeds, and advanced pressure control capabilities. Weaknesses: Primarily focused on vacuum technology, may lack integration with other nanopatterning components.

Core Innovations in Vacuum-Enhanced Nanopatterning

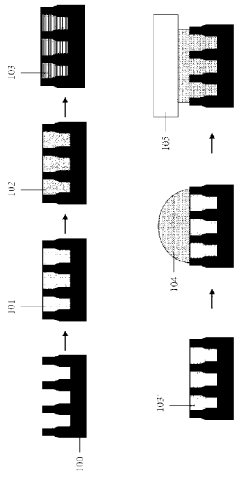

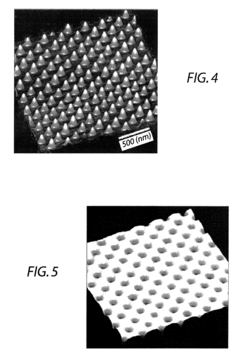

Method of insertion into nanopores of polymer precursor using vacuum effect and method for precision duplication of nanopattern using same

PatentWO2010041873A2

Innovation

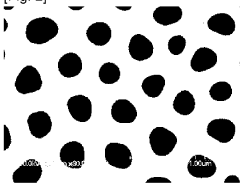

- A method utilizing a vacuum effect with ammonia gas to fill micropores in a mold, followed by solvent exchange with water and other solvents, to effectively insert a viscous fluid into nanometer-level pores, ensuring precise replication of patterns regardless of surface affinity, and using aluminum anodic oxidation technology to create controlled nanometer-level microstructures.

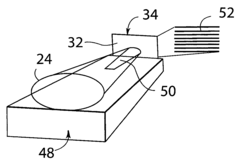

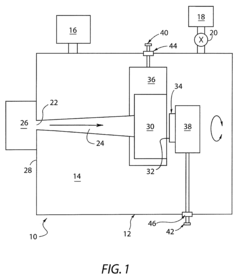

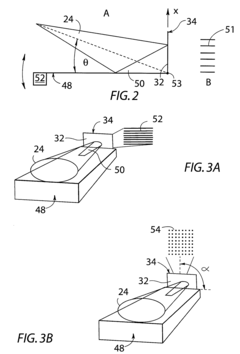

Nanometer-scale lithography using extreme ultraviolet/soft x-ray laser interferometry

PatentInactiveUS7705332B2

Innovation

- A compact apparatus using pulsed EUV/SXR laser radiation with a wavelength between 1 nm and 100 nm is employed to generate interference patterns on a photoresist surface within a vacuum chamber, enabling nanometer-scale lithographic patterning through the Lloyd's mirror configuration and multiple exposure techniques.

Environmental Impact of Vacuum Pump Technologies

The environmental impact of vacuum pump technologies in high-precision nanopatterning techniques is a critical consideration as these processes become more prevalent in advanced manufacturing. Vacuum pumps play a crucial role in creating the controlled environments necessary for nanoscale fabrication, but their operation can have significant environmental implications.

Energy consumption is a primary concern when assessing the environmental footprint of vacuum pump systems. High-performance pumps required for nanopatterning often demand substantial electrical power, contributing to increased energy usage and associated greenhouse gas emissions. The continuous operation of these pumps in cleanroom environments further amplifies their energy requirements, necessitating efficient power management strategies and the exploration of more energy-efficient pump designs.

Waste generation is another environmental aspect to consider. Vacuum pumps used in nanopatterning may produce oil mist or particulate matter, which requires proper filtration and disposal. The use of oil-sealed pumps, while effective for certain applications, can lead to contamination issues and the need for regular oil changes, resulting in hazardous waste that must be managed carefully to prevent environmental pollution.

Water consumption is also a factor, particularly in cooling systems for high-capacity pumps. The demand for temperature-controlled environments in nanopatterning processes often necessitates water-cooled vacuum systems, potentially straining local water resources and requiring treatment of heated effluent water.

Noise pollution from vacuum pumps can impact the work environment and surrounding areas, potentially affecting wildlife and human health. While this may seem less significant compared to other environmental concerns, it is an important consideration in urban or sensitive ecological settings where nanofabrication facilities may be located.

The materials used in vacuum pump construction and maintenance also have environmental implications. Many pumps contain rare earth elements or specialized alloys, the mining and processing of which can have substantial environmental impacts. Additionally, the disposal or recycling of pump components at the end of their lifecycle presents challenges in terms of resource recovery and waste management.

To mitigate these environmental impacts, researchers and manufacturers are exploring several avenues. The development of dry pump technologies that eliminate the need for oil reduces both contamination risks and hazardous waste generation. Advances in pump efficiency and the integration of smart control systems are helping to optimize energy consumption. Furthermore, the adoption of lifecycle assessment approaches in pump design and manufacturing is promoting more sustainable practices throughout the industry.

As nanopatterning techniques continue to evolve, the environmental impact of supporting technologies like vacuum pumps must be carefully managed. Balancing the need for high-precision environments with environmental sustainability will be crucial for the long-term viability and acceptance of these advanced manufacturing processes.

Energy consumption is a primary concern when assessing the environmental footprint of vacuum pump systems. High-performance pumps required for nanopatterning often demand substantial electrical power, contributing to increased energy usage and associated greenhouse gas emissions. The continuous operation of these pumps in cleanroom environments further amplifies their energy requirements, necessitating efficient power management strategies and the exploration of more energy-efficient pump designs.

Waste generation is another environmental aspect to consider. Vacuum pumps used in nanopatterning may produce oil mist or particulate matter, which requires proper filtration and disposal. The use of oil-sealed pumps, while effective for certain applications, can lead to contamination issues and the need for regular oil changes, resulting in hazardous waste that must be managed carefully to prevent environmental pollution.

Water consumption is also a factor, particularly in cooling systems for high-capacity pumps. The demand for temperature-controlled environments in nanopatterning processes often necessitates water-cooled vacuum systems, potentially straining local water resources and requiring treatment of heated effluent water.

Noise pollution from vacuum pumps can impact the work environment and surrounding areas, potentially affecting wildlife and human health. While this may seem less significant compared to other environmental concerns, it is an important consideration in urban or sensitive ecological settings where nanofabrication facilities may be located.

The materials used in vacuum pump construction and maintenance also have environmental implications. Many pumps contain rare earth elements or specialized alloys, the mining and processing of which can have substantial environmental impacts. Additionally, the disposal or recycling of pump components at the end of their lifecycle presents challenges in terms of resource recovery and waste management.

To mitigate these environmental impacts, researchers and manufacturers are exploring several avenues. The development of dry pump technologies that eliminate the need for oil reduces both contamination risks and hazardous waste generation. Advances in pump efficiency and the integration of smart control systems are helping to optimize energy consumption. Furthermore, the adoption of lifecycle assessment approaches in pump design and manufacturing is promoting more sustainable practices throughout the industry.

As nanopatterning techniques continue to evolve, the environmental impact of supporting technologies like vacuum pumps must be carefully managed. Balancing the need for high-precision environments with environmental sustainability will be crucial for the long-term viability and acceptance of these advanced manufacturing processes.

Scalability Challenges in Nanopatterning Processes

Scalability remains a significant challenge in nanopatterning processes, particularly as the demand for larger-scale production and more complex nanostructures continues to grow. One of the primary obstacles is maintaining consistent pattern quality and precision across larger substrate areas. As the patterning area expands, it becomes increasingly difficult to ensure uniform exposure, etching, or deposition across the entire surface.

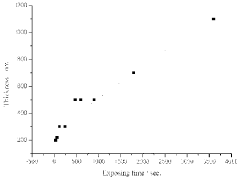

Another scalability issue lies in the throughput of nanopatterning techniques. Many high-precision methods, such as electron beam lithography, are inherently slow due to their serial nature. This limitation becomes more pronounced when attempting to scale up production, as the time required to pattern larger areas increases dramatically. Consequently, there is a constant trade-off between pattern resolution and production speed.

Material constraints also pose challenges to scalability. Some nanopatterning techniques require specialized substrates or resist materials, which may be expensive or difficult to produce in large quantities. Additionally, the properties of these materials may change or degrade when scaled up, affecting the overall quality and consistency of the nanopatterns.

Equipment scaling presents another hurdle. Many nanopatterning tools, such as those used in extreme ultraviolet lithography, are highly complex and expensive. Scaling up production often requires multiple machines, leading to significant capital investments and potential synchronization issues between different units.

Environmental control becomes increasingly critical as the scale of nanopatterning processes grows. Larger production areas are more susceptible to variations in temperature, humidity, and particulate contamination. Maintaining the necessary level of cleanliness and environmental stability across larger spaces presents both technical and logistical challenges.

Vacuum systems, while crucial for many nanopatterning techniques, also face scalability issues. Larger chambers require more powerful pumps and longer pump-down times, potentially reducing overall throughput. Achieving and maintaining uniform vacuum conditions across larger volumes can be challenging, potentially leading to inconsistencies in the nanopatterning process.

Addressing these scalability challenges requires a multifaceted approach, combining advancements in materials science, equipment design, and process control. Innovations in parallel processing techniques, such as nanoimprint lithography, offer promising solutions for increasing throughput. Similarly, developments in large-area electron beam lithography systems aim to overcome the speed limitations of traditional e-beam methods.

Another scalability issue lies in the throughput of nanopatterning techniques. Many high-precision methods, such as electron beam lithography, are inherently slow due to their serial nature. This limitation becomes more pronounced when attempting to scale up production, as the time required to pattern larger areas increases dramatically. Consequently, there is a constant trade-off between pattern resolution and production speed.

Material constraints also pose challenges to scalability. Some nanopatterning techniques require specialized substrates or resist materials, which may be expensive or difficult to produce in large quantities. Additionally, the properties of these materials may change or degrade when scaled up, affecting the overall quality and consistency of the nanopatterns.

Equipment scaling presents another hurdle. Many nanopatterning tools, such as those used in extreme ultraviolet lithography, are highly complex and expensive. Scaling up production often requires multiple machines, leading to significant capital investments and potential synchronization issues between different units.

Environmental control becomes increasingly critical as the scale of nanopatterning processes grows. Larger production areas are more susceptible to variations in temperature, humidity, and particulate contamination. Maintaining the necessary level of cleanliness and environmental stability across larger spaces presents both technical and logistical challenges.

Vacuum systems, while crucial for many nanopatterning techniques, also face scalability issues. Larger chambers require more powerful pumps and longer pump-down times, potentially reducing overall throughput. Achieving and maintaining uniform vacuum conditions across larger volumes can be challenging, potentially leading to inconsistencies in the nanopatterning process.

Addressing these scalability challenges requires a multifaceted approach, combining advancements in materials science, equipment design, and process control. Innovations in parallel processing techniques, such as nanoimprint lithography, offer promising solutions for increasing throughput. Similarly, developments in large-area electron beam lithography systems aim to overcome the speed limitations of traditional e-beam methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!