Vacuum Pumps in the Production of High-Strength Glass Fibers

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glass Fiber Evolution

Glass fiber technology has undergone significant evolution since its inception in the early 20th century. The development of glass fibers can be traced back to the 1930s when Owens Corning pioneered the mass production of fiberglass. Initially, glass fibers were primarily used for insulation purposes, but their applications quickly expanded to various industries.

The 1950s and 1960s saw a rapid advancement in glass fiber technology, with the introduction of continuous filament manufacturing processes. This innovation allowed for the production of longer, stronger fibers, opening up new possibilities in reinforced plastics and composites. During this period, the use of vacuum pumps in glass fiber production began to gain traction, as manufacturers sought ways to improve fiber quality and production efficiency.

In the 1970s and 1980s, the focus shifted towards developing high-strength glass fibers. This era marked the introduction of S-glass and R-glass, which offered superior tensile strength and modulus compared to traditional E-glass. The role of vacuum pumps became increasingly critical in achieving the precise control over melting and drawing processes required for these advanced fibers.

The 1990s brought about a revolution in glass fiber manufacturing with the advent of computer-controlled production lines. This technological leap allowed for unprecedented precision in fiber diameter control and consistency. Vacuum pump technology also evolved during this time, with the introduction of more efficient and reliable pumps capable of maintaining stable vacuum levels over extended periods.

The turn of the millennium saw a growing emphasis on environmental sustainability in glass fiber production. Manufacturers began exploring ways to reduce energy consumption and emissions, leading to innovations in furnace design and raw material formulations. Vacuum pumps played a crucial role in these efforts by enabling more efficient melting processes and reducing waste.

In recent years, the focus has shifted towards developing ultra-high-strength glass fibers for specialized applications in aerospace, automotive, and wind energy sectors. Advanced vacuum pump systems have become integral to these processes, allowing for the precise control of fiber cooling rates and internal structure formation.

The latest developments in glass fiber technology include the integration of smart manufacturing principles and Industry 4.0 concepts. This involves the use of advanced sensors, data analytics, and artificial intelligence to optimize production processes in real-time. Vacuum pumps are now being equipped with smart monitoring systems, enabling predictive maintenance and further enhancing production efficiency.

Looking ahead, the evolution of glass fiber technology is expected to continue with a focus on developing fibers with even higher strength-to-weight ratios, improved chemical resistance, and enhanced thermal properties. The role of vacuum pumps in this evolution remains crucial, with ongoing research into more advanced pump designs and control systems to meet the increasingly demanding requirements of next-generation glass fibers.

The 1950s and 1960s saw a rapid advancement in glass fiber technology, with the introduction of continuous filament manufacturing processes. This innovation allowed for the production of longer, stronger fibers, opening up new possibilities in reinforced plastics and composites. During this period, the use of vacuum pumps in glass fiber production began to gain traction, as manufacturers sought ways to improve fiber quality and production efficiency.

In the 1970s and 1980s, the focus shifted towards developing high-strength glass fibers. This era marked the introduction of S-glass and R-glass, which offered superior tensile strength and modulus compared to traditional E-glass. The role of vacuum pumps became increasingly critical in achieving the precise control over melting and drawing processes required for these advanced fibers.

The 1990s brought about a revolution in glass fiber manufacturing with the advent of computer-controlled production lines. This technological leap allowed for unprecedented precision in fiber diameter control and consistency. Vacuum pump technology also evolved during this time, with the introduction of more efficient and reliable pumps capable of maintaining stable vacuum levels over extended periods.

The turn of the millennium saw a growing emphasis on environmental sustainability in glass fiber production. Manufacturers began exploring ways to reduce energy consumption and emissions, leading to innovations in furnace design and raw material formulations. Vacuum pumps played a crucial role in these efforts by enabling more efficient melting processes and reducing waste.

In recent years, the focus has shifted towards developing ultra-high-strength glass fibers for specialized applications in aerospace, automotive, and wind energy sectors. Advanced vacuum pump systems have become integral to these processes, allowing for the precise control of fiber cooling rates and internal structure formation.

The latest developments in glass fiber technology include the integration of smart manufacturing principles and Industry 4.0 concepts. This involves the use of advanced sensors, data analytics, and artificial intelligence to optimize production processes in real-time. Vacuum pumps are now being equipped with smart monitoring systems, enabling predictive maintenance and further enhancing production efficiency.

Looking ahead, the evolution of glass fiber technology is expected to continue with a focus on developing fibers with even higher strength-to-weight ratios, improved chemical resistance, and enhanced thermal properties. The role of vacuum pumps in this evolution remains crucial, with ongoing research into more advanced pump designs and control systems to meet the increasingly demanding requirements of next-generation glass fibers.

Market Demand Analysis

The market demand for vacuum pumps in the production of high-strength glass fibers has been experiencing significant growth in recent years. This surge is primarily driven by the increasing adoption of glass fiber reinforced composites across various industries, including automotive, aerospace, construction, and wind energy.

In the automotive sector, the push for lightweight materials to improve fuel efficiency and reduce emissions has led to a higher demand for glass fiber composites. This trend is expected to continue as electric vehicles gain market share, further boosting the need for high-strength glass fibers and, consequently, the vacuum pumps used in their production.

The aerospace industry has also been a major contributor to the market demand for vacuum pumps in glass fiber production. With the growing emphasis on fuel-efficient aircraft and the increasing use of composite materials in aircraft structures, the demand for high-strength glass fibers has risen substantially.

The construction industry represents another significant market for high-strength glass fibers, particularly in the production of reinforced concrete and other building materials. As urbanization continues and infrastructure projects expand globally, the demand for these materials is projected to increase, driving the need for vacuum pumps in the manufacturing process.

The wind energy sector has emerged as a rapidly growing market for high-strength glass fibers, used extensively in the production of wind turbine blades. As countries worldwide invest in renewable energy sources, the demand for larger and more efficient wind turbines has led to an increased need for high-performance glass fibers and the associated production equipment.

Market analysis indicates that the Asia-Pacific region, particularly China and India, is expected to be the fastest-growing market for vacuum pumps in glass fiber production. This growth is attributed to the rapid industrialization, infrastructure development, and increasing adoption of composite materials in these countries.

The global market for vacuum pumps in high-strength glass fiber production is influenced by factors such as technological advancements in pump design, energy efficiency requirements, and the overall growth of end-use industries. Manufacturers are focusing on developing more efficient and reliable vacuum pumps to meet the stringent requirements of glass fiber production processes.

As the demand for high-strength glass fibers continues to rise across multiple industries, the market for vacuum pumps in their production is expected to expand correspondingly. This growth presents opportunities for pump manufacturers to innovate and develop specialized solutions tailored to the unique requirements of glass fiber production, ensuring optimal performance and efficiency in this critical manufacturing process.

In the automotive sector, the push for lightweight materials to improve fuel efficiency and reduce emissions has led to a higher demand for glass fiber composites. This trend is expected to continue as electric vehicles gain market share, further boosting the need for high-strength glass fibers and, consequently, the vacuum pumps used in their production.

The aerospace industry has also been a major contributor to the market demand for vacuum pumps in glass fiber production. With the growing emphasis on fuel-efficient aircraft and the increasing use of composite materials in aircraft structures, the demand for high-strength glass fibers has risen substantially.

The construction industry represents another significant market for high-strength glass fibers, particularly in the production of reinforced concrete and other building materials. As urbanization continues and infrastructure projects expand globally, the demand for these materials is projected to increase, driving the need for vacuum pumps in the manufacturing process.

The wind energy sector has emerged as a rapidly growing market for high-strength glass fibers, used extensively in the production of wind turbine blades. As countries worldwide invest in renewable energy sources, the demand for larger and more efficient wind turbines has led to an increased need for high-performance glass fibers and the associated production equipment.

Market analysis indicates that the Asia-Pacific region, particularly China and India, is expected to be the fastest-growing market for vacuum pumps in glass fiber production. This growth is attributed to the rapid industrialization, infrastructure development, and increasing adoption of composite materials in these countries.

The global market for vacuum pumps in high-strength glass fiber production is influenced by factors such as technological advancements in pump design, energy efficiency requirements, and the overall growth of end-use industries. Manufacturers are focusing on developing more efficient and reliable vacuum pumps to meet the stringent requirements of glass fiber production processes.

As the demand for high-strength glass fibers continues to rise across multiple industries, the market for vacuum pumps in their production is expected to expand correspondingly. This growth presents opportunities for pump manufacturers to innovate and develop specialized solutions tailored to the unique requirements of glass fiber production, ensuring optimal performance and efficiency in this critical manufacturing process.

Vacuum Pump Challenges

The production of high-strength glass fibers presents several significant challenges for vacuum pump systems. One of the primary issues is the extreme operating conditions within the glass fiber production process. The high temperatures required for melting and drawing glass fibers, often exceeding 1,000°C, can lead to thermal stress on vacuum pump components. This thermal load can cause premature wear, reduced efficiency, and potential failure of pump parts, necessitating frequent maintenance and replacements.

Another critical challenge is the presence of fine glass particles and vapors in the production environment. These particles can infiltrate the vacuum system, causing abrasion and erosion of pump internals. Over time, this leads to decreased pump performance and potential contamination of the glass fiber product. The accumulation of glass particles can also result in clogging of filters and other components, further reducing system efficiency and increasing maintenance requirements.

Corrosion is a significant concern in vacuum pump systems used in glass fiber production. The presence of chemical additives used in the glass formulation, combined with high temperatures and moisture, can create a corrosive environment. This corrosion can affect seals, bearings, and other critical pump components, leading to leaks, reduced vacuum performance, and increased downtime for repairs.

The need for consistent and precise vacuum levels throughout the production process poses another challenge. Fluctuations in vacuum can affect the quality and uniformity of the glass fibers produced. Maintaining stable vacuum conditions becomes increasingly difficult as production scales up, requiring sophisticated control systems and potentially multiple pump configurations to ensure optimal performance across various stages of the manufacturing process.

Energy efficiency is an ongoing challenge in vacuum pump applications for glass fiber production. The continuous operation of these systems consumes significant amounts of energy, impacting production costs and environmental footprint. Balancing the need for high-performance vacuum with energy conservation goals requires innovative pump designs and control strategies.

Lastly, the demand for increased production speeds and higher-quality glass fibers puts additional strain on vacuum pump systems. As manufacturers seek to improve output and fiber properties, vacuum pumps must evolve to handle higher throughput rates while maintaining or improving vacuum quality. This challenge drives the need for continuous innovation in pump technology, materials, and system design to meet the evolving demands of the glass fiber industry.

Another critical challenge is the presence of fine glass particles and vapors in the production environment. These particles can infiltrate the vacuum system, causing abrasion and erosion of pump internals. Over time, this leads to decreased pump performance and potential contamination of the glass fiber product. The accumulation of glass particles can also result in clogging of filters and other components, further reducing system efficiency and increasing maintenance requirements.

Corrosion is a significant concern in vacuum pump systems used in glass fiber production. The presence of chemical additives used in the glass formulation, combined with high temperatures and moisture, can create a corrosive environment. This corrosion can affect seals, bearings, and other critical pump components, leading to leaks, reduced vacuum performance, and increased downtime for repairs.

The need for consistent and precise vacuum levels throughout the production process poses another challenge. Fluctuations in vacuum can affect the quality and uniformity of the glass fibers produced. Maintaining stable vacuum conditions becomes increasingly difficult as production scales up, requiring sophisticated control systems and potentially multiple pump configurations to ensure optimal performance across various stages of the manufacturing process.

Energy efficiency is an ongoing challenge in vacuum pump applications for glass fiber production. The continuous operation of these systems consumes significant amounts of energy, impacting production costs and environmental footprint. Balancing the need for high-performance vacuum with energy conservation goals requires innovative pump designs and control strategies.

Lastly, the demand for increased production speeds and higher-quality glass fibers puts additional strain on vacuum pump systems. As manufacturers seek to improve output and fiber properties, vacuum pumps must evolve to handle higher throughput rates while maintaining or improving vacuum quality. This challenge drives the need for continuous innovation in pump technology, materials, and system design to meet the evolving demands of the glass fiber industry.

Current Vacuum Solutions

01 Improvements in vacuum pump design

Various advancements have been made in vacuum pump design to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.- Rotary vacuum pump designs: Various designs of rotary vacuum pumps have been developed to improve efficiency and performance. These designs may include specific rotor configurations, sealing mechanisms, and lubrication systems to enhance vacuum generation and maintain consistent operation.

- Reciprocating vacuum pump innovations: Advancements in reciprocating vacuum pump technology focus on improving piston designs, valve systems, and cylinder arrangements. These innovations aim to increase pumping capacity, reduce wear, and enhance overall reliability in various industrial applications.

- Vacuum pump control and monitoring systems: Modern vacuum pumps incorporate sophisticated control and monitoring systems to optimize performance and energy efficiency. These systems may include sensors, electronic controllers, and software algorithms to adjust pump operation based on demand and environmental conditions.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps designed specifically for semiconductor manufacturing processes have been developed to meet the stringent requirements of clean room environments. These pumps often feature advanced materials, contamination control measures, and precise pressure regulation capabilities.

- Historical developments in vacuum pump technology: The evolution of vacuum pump technology can be traced through various historical patents, showcasing early innovations and fundamental design principles. These developments have laid the foundation for modern vacuum pump systems and continue to influence current research and development efforts.

02 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high cleanliness levels, and provide stable vacuum conditions. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.Expand Specific Solutions03 Integration of vacuum pumps in larger systems

Vacuum pumps are increasingly being integrated into larger systems for various applications. This integration involves designing compact pump units, developing control interfaces for seamless operation with other components, and optimizing energy efficiency. Such integrated systems find applications in fields like analytical instruments, industrial automation, and environmental monitoring.Expand Specific Solutions04 Historical developments in vacuum pump technology

The evolution of vacuum pump technology spans several decades, with significant milestones in pump design and operation. Historical patents reveal the progression from early mechanical designs to more sophisticated electromagnetic and fluid-based systems. These developments have led to the diverse range of vacuum pumps available today, catering to various industrial and scientific applications.Expand Specific Solutions05 Novel vacuum pump mechanisms and principles

Innovative vacuum pump mechanisms and operating principles have been introduced to address specific challenges or improve performance in certain applications. These may include new approaches to gas displacement, novel rotor designs, or the use of advanced materials. Such innovations aim to achieve higher vacuum levels, reduce power consumption, or enhance pump longevity in demanding environments.Expand Specific Solutions

Industry Leaders

The vacuum pump market for high-strength glass fiber production is in a mature growth stage, with a significant global market size driven by increasing demand for lightweight and durable materials across various industries. The technology has reached a high level of maturity, with established players like Edwards Vacuum, Pfeiffer Vacuum, and Leybold dominating the market. These companies offer advanced vacuum solutions tailored for the glass fiber industry, focusing on efficiency, reliability, and precision. Emerging players such as Jiangsu Huangchao Vacuum Glass Technology are also entering the market, potentially bringing innovative approaches to vacuum technology for glass fiber production.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed the HiPace turbomolecular pumps, which are particularly suitable for high-vacuum applications in glass fiber production. These pumps utilize advanced rotor designs and magnetic bearings to achieve high pumping speeds and compression ratios[2]. Pfeiffer's pumps incorporate holographic balancing technology, reducing vibration and improving overall system stability during the glass fiber drawing process[4]. The company has also introduced smart pump controllers that allow for real-time monitoring and adjustment of vacuum levels, crucial for maintaining consistent fiber quality. Their pumps feature a modular design, enabling easy maintenance and reducing downtime in production environments[6].

Strengths: High pumping speeds, low vibration, and smart control capabilities. Weaknesses: May require specialized maintenance and potentially higher initial investment.

Edwards Vacuum LLC

Technical Solution: Edwards Vacuum LLC has developed advanced vacuum pump technologies specifically tailored for the production of high-strength glass fibers. Their GXS dry screw vacuum pumps offer high performance in demanding glass fiber manufacturing environments[1]. These pumps utilize a unique screw mechanism that provides consistent vacuum levels while handling the challenging byproducts of glass fiber production. Edwards has also implemented intelligent control systems that optimize pump performance based on process conditions, resulting in up to 50% energy savings compared to traditional pumps[3]. Additionally, their pumps incorporate advanced sealing technologies to prevent contamination and extend maintenance intervals[5].

Strengths: High performance in demanding environments, energy efficiency, and extended maintenance intervals. Weaknesses: Potentially higher initial cost compared to simpler pump designs.

Key Vacuum Innovations

Vacuum pump

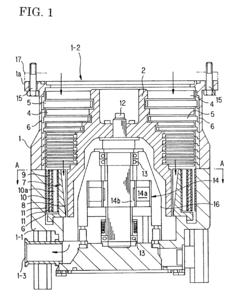

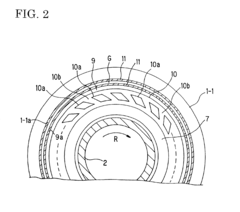

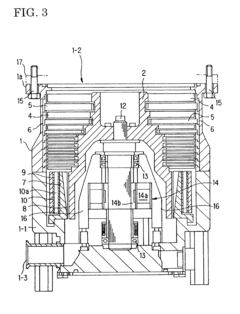

PatentInactiveUS6814536B2

Innovation

- A vacuum pump design featuring a rigid ring positioned outside the screw stator to absorb and dissipate the shock load, combined with a buffer member and low-frictional surfaces to reduce frictional forces, preventing the transfer of damaging torque to the process chamber.

High strength glass composition and fibers

PatentActiveUS9783454B2

Innovation

- Developing glass compositions with specific oxide ratios (SiO2, Al2O3, MgO, CaO, Na2O, and residual transition metal oxides) that allow for low melting and fiberizing temperatures, suitable for refractory-lined furnaces, while maintaining high strength and modulus characteristics.

Energy Efficiency Impact

The energy efficiency impact of vacuum pumps in the production of high-strength glass fibers is a critical consideration for manufacturers seeking to optimize their processes and reduce operational costs. Vacuum pumps play a crucial role in maintaining the necessary low-pressure environment during the fiber drawing process, which directly affects the quality and strength of the resulting glass fibers.

In recent years, there has been a growing emphasis on improving the energy efficiency of vacuum pumps used in glass fiber production. Traditional oil-sealed rotary vane pumps, while effective, are known for their high energy consumption and maintenance requirements. This has led to the development and adoption of more energy-efficient alternatives, such as dry screw pumps and multi-stage root pumps.

These newer pump technologies offer significant energy savings compared to their predecessors. For instance, dry screw pumps can reduce energy consumption by up to 50% in some applications, while also eliminating the need for oil changes and disposal. This not only lowers operational costs but also contributes to a more environmentally friendly production process.

The impact of energy-efficient vacuum pumps extends beyond direct electricity savings. By reducing the heat generated during operation, these pumps can also decrease the cooling requirements for the production facility. This cascading effect further enhances overall energy efficiency and can lead to substantial reductions in a plant's carbon footprint.

Moreover, the improved reliability and reduced maintenance needs of modern vacuum pumps contribute to increased uptime and productivity. This indirectly impacts energy efficiency by allowing manufacturers to produce more glass fibers with the same or less energy input, effectively improving the energy-to-output ratio of the entire production line.

As the glass fiber industry continues to grow, driven by demand from sectors such as construction, automotive, and wind energy, the cumulative energy savings from widespread adoption of efficient vacuum pump technologies could be substantial. This not only benefits individual manufacturers but also contributes to broader industry-wide sustainability goals and compliance with increasingly stringent energy efficiency regulations.

Looking ahead, ongoing research and development in vacuum pump technology promise even greater energy efficiency gains. Innovations such as variable speed drives, advanced control systems, and novel pump designs are expected to further optimize energy consumption in high-strength glass fiber production, paving the way for more sustainable manufacturing practices in the future.

In recent years, there has been a growing emphasis on improving the energy efficiency of vacuum pumps used in glass fiber production. Traditional oil-sealed rotary vane pumps, while effective, are known for their high energy consumption and maintenance requirements. This has led to the development and adoption of more energy-efficient alternatives, such as dry screw pumps and multi-stage root pumps.

These newer pump technologies offer significant energy savings compared to their predecessors. For instance, dry screw pumps can reduce energy consumption by up to 50% in some applications, while also eliminating the need for oil changes and disposal. This not only lowers operational costs but also contributes to a more environmentally friendly production process.

The impact of energy-efficient vacuum pumps extends beyond direct electricity savings. By reducing the heat generated during operation, these pumps can also decrease the cooling requirements for the production facility. This cascading effect further enhances overall energy efficiency and can lead to substantial reductions in a plant's carbon footprint.

Moreover, the improved reliability and reduced maintenance needs of modern vacuum pumps contribute to increased uptime and productivity. This indirectly impacts energy efficiency by allowing manufacturers to produce more glass fibers with the same or less energy input, effectively improving the energy-to-output ratio of the entire production line.

As the glass fiber industry continues to grow, driven by demand from sectors such as construction, automotive, and wind energy, the cumulative energy savings from widespread adoption of efficient vacuum pump technologies could be substantial. This not only benefits individual manufacturers but also contributes to broader industry-wide sustainability goals and compliance with increasingly stringent energy efficiency regulations.

Looking ahead, ongoing research and development in vacuum pump technology promise even greater energy efficiency gains. Innovations such as variable speed drives, advanced control systems, and novel pump designs are expected to further optimize energy consumption in high-strength glass fiber production, paving the way for more sustainable manufacturing practices in the future.

Environmental Regulations

Environmental regulations play a crucial role in shaping the production processes of high-strength glass fibers, particularly concerning the use of vacuum pumps. These regulations aim to minimize the environmental impact of manufacturing operations and ensure sustainable practices in the industry.

One of the primary concerns addressed by environmental regulations is the emission of volatile organic compounds (VOCs) during the glass fiber production process. Vacuum pumps, which are essential for maintaining the required pressure levels, can potentially contribute to VOC emissions if not properly managed. Regulatory bodies have established strict limits on VOC emissions, necessitating the implementation of advanced filtration systems and exhaust treatment technologies in conjunction with vacuum pump operations.

Energy efficiency is another key focus of environmental regulations affecting vacuum pump usage in glass fiber production. Many jurisdictions have implemented energy consumption standards that require manufacturers to adopt more efficient vacuum pump technologies. This has led to the development of variable speed drives and intelligent control systems that optimize pump performance based on real-time production demands, resulting in significant energy savings and reduced carbon footprints.

Water conservation is also a critical aspect of environmental regulations impacting vacuum pump operations. The cooling systems associated with vacuum pumps often require substantial water usage. Regulatory frameworks now mandate the implementation of closed-loop cooling systems and water recycling technologies to minimize freshwater consumption and reduce wastewater discharge.

Noise pollution is an additional environmental concern addressed by regulations in the context of vacuum pump usage. Many jurisdictions have established noise level limits for industrial operations, including glass fiber production facilities. This has prompted manufacturers to invest in noise reduction technologies such as acoustic enclosures and vibration dampening systems for their vacuum pump installations.

The disposal of waste materials generated during the production process, including those associated with vacuum pump maintenance, is subject to stringent environmental regulations. Proper handling, storage, and disposal of lubricants, filters, and other consumables used in vacuum pump systems are mandated to prevent soil and groundwater contamination.

As environmental regulations continue to evolve, manufacturers of high-strength glass fibers are increasingly adopting lifecycle assessment approaches to evaluate and minimize the environmental impact of their production processes, including vacuum pump operations. This holistic approach considers factors such as raw material sourcing, energy consumption, emissions, and end-of-life disposal, driving innovation in vacuum pump design and integration within the broader production ecosystem.

One of the primary concerns addressed by environmental regulations is the emission of volatile organic compounds (VOCs) during the glass fiber production process. Vacuum pumps, which are essential for maintaining the required pressure levels, can potentially contribute to VOC emissions if not properly managed. Regulatory bodies have established strict limits on VOC emissions, necessitating the implementation of advanced filtration systems and exhaust treatment technologies in conjunction with vacuum pump operations.

Energy efficiency is another key focus of environmental regulations affecting vacuum pump usage in glass fiber production. Many jurisdictions have implemented energy consumption standards that require manufacturers to adopt more efficient vacuum pump technologies. This has led to the development of variable speed drives and intelligent control systems that optimize pump performance based on real-time production demands, resulting in significant energy savings and reduced carbon footprints.

Water conservation is also a critical aspect of environmental regulations impacting vacuum pump operations. The cooling systems associated with vacuum pumps often require substantial water usage. Regulatory frameworks now mandate the implementation of closed-loop cooling systems and water recycling technologies to minimize freshwater consumption and reduce wastewater discharge.

Noise pollution is an additional environmental concern addressed by regulations in the context of vacuum pump usage. Many jurisdictions have established noise level limits for industrial operations, including glass fiber production facilities. This has prompted manufacturers to invest in noise reduction technologies such as acoustic enclosures and vibration dampening systems for their vacuum pump installations.

The disposal of waste materials generated during the production process, including those associated with vacuum pump maintenance, is subject to stringent environmental regulations. Proper handling, storage, and disposal of lubricants, filters, and other consumables used in vacuum pump systems are mandated to prevent soil and groundwater contamination.

As environmental regulations continue to evolve, manufacturers of high-strength glass fibers are increasingly adopting lifecycle assessment approaches to evaluate and minimize the environmental impact of their production processes, including vacuum pump operations. This holistic approach considers factors such as raw material sourcing, energy consumption, emissions, and end-of-life disposal, driving innovation in vacuum pump design and integration within the broader production ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!