The Role of Vacuum Pumps in Novel Smart Window Technologies

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Window Tech Evolution

Smart window technology has undergone significant evolution since its inception in the 1970s. Initially, these windows relied on simple electrochromic materials that could change their opacity when an electric current was applied. However, the technology was limited by slow response times and poor durability.

In the 1990s, researchers began exploring more advanced materials and designs. This led to the development of suspended particle devices (SPD) and polymer dispersed liquid crystal (PDLC) technologies. These innovations offered faster switching times and improved control over light transmission, but still faced challenges in terms of energy efficiency and long-term stability.

The early 2000s saw a shift towards more sophisticated multi-layer designs. These incorporated various functional layers, including ion storage layers and transparent conductors, to enhance performance and durability. This period also marked the beginning of integrating smart windows with building management systems, allowing for automated control based on environmental conditions.

A significant breakthrough came in the mid-2010s with the introduction of vacuum-based smart window technologies. These systems utilized the principles of vacuum insulation to dramatically improve thermal performance. By creating a vacuum between two panes of glass, heat transfer was minimized, leading to substantial energy savings in buildings.

The role of vacuum pumps became crucial in this new generation of smart windows. High-performance vacuum pumps were required to create and maintain the necessary vacuum levels within the window structure. This innovation not only enhanced the energy efficiency of smart windows but also opened up new possibilities for dynamic control of thermal and optical properties.

Recent years have seen further advancements in vacuum-based smart window technologies. Researchers have been exploring ways to combine vacuum insulation with other smart materials, such as thermochromic and photochromic compounds. This integration aims to create windows that can respond to both temperature and light conditions autonomously, further optimizing energy performance.

The latest developments focus on improving the longevity and reliability of vacuum-based smart windows. This includes advancements in edge sealing technologies and the development of more efficient, compact vacuum pumps that can be integrated seamlessly into window frames. These innovations are crucial for the widespread adoption of vacuum-based smart windows in both residential and commercial buildings.

In the 1990s, researchers began exploring more advanced materials and designs. This led to the development of suspended particle devices (SPD) and polymer dispersed liquid crystal (PDLC) technologies. These innovations offered faster switching times and improved control over light transmission, but still faced challenges in terms of energy efficiency and long-term stability.

The early 2000s saw a shift towards more sophisticated multi-layer designs. These incorporated various functional layers, including ion storage layers and transparent conductors, to enhance performance and durability. This period also marked the beginning of integrating smart windows with building management systems, allowing for automated control based on environmental conditions.

A significant breakthrough came in the mid-2010s with the introduction of vacuum-based smart window technologies. These systems utilized the principles of vacuum insulation to dramatically improve thermal performance. By creating a vacuum between two panes of glass, heat transfer was minimized, leading to substantial energy savings in buildings.

The role of vacuum pumps became crucial in this new generation of smart windows. High-performance vacuum pumps were required to create and maintain the necessary vacuum levels within the window structure. This innovation not only enhanced the energy efficiency of smart windows but also opened up new possibilities for dynamic control of thermal and optical properties.

Recent years have seen further advancements in vacuum-based smart window technologies. Researchers have been exploring ways to combine vacuum insulation with other smart materials, such as thermochromic and photochromic compounds. This integration aims to create windows that can respond to both temperature and light conditions autonomously, further optimizing energy performance.

The latest developments focus on improving the longevity and reliability of vacuum-based smart windows. This includes advancements in edge sealing technologies and the development of more efficient, compact vacuum pumps that can be integrated seamlessly into window frames. These innovations are crucial for the widespread adoption of vacuum-based smart windows in both residential and commercial buildings.

Market Demand Analysis

The market demand for smart window technologies incorporating vacuum pumps is experiencing significant growth, driven by increasing focus on energy efficiency and sustainable building practices. As urbanization accelerates and environmental concerns intensify, there is a growing need for innovative solutions that can reduce energy consumption in buildings while enhancing occupant comfort.

Smart windows with vacuum pump technology offer a unique value proposition in this context. They provide superior insulation properties compared to traditional windows, effectively reducing heat transfer and minimizing energy loss. This translates to lower heating and cooling costs for buildings, addressing a key concern for property owners and managers in both residential and commercial sectors.

The construction industry, particularly in developed countries, is showing increased interest in these advanced window systems. As building codes become more stringent regarding energy efficiency, architects and developers are seeking cutting-edge solutions to meet these requirements. Smart windows with vacuum technology are positioned as a premium option that can significantly contribute to achieving green building certifications and improving overall building performance.

In the automotive sector, there is also a growing demand for smart window technologies. Luxury vehicle manufacturers are exploring ways to enhance passenger comfort and reduce energy consumption in electric vehicles. Vacuum-based smart windows offer potential benefits in terms of thermal management and noise reduction, aligning with the industry's push towards more efficient and comfortable transportation solutions.

The market for smart windows is expected to expand rapidly in regions with extreme climates, where energy costs for heating and cooling are substantial. Countries in Northern Europe, North America, and parts of Asia with harsh winters or hot summers are likely to be early adopters of this technology.

However, the market demand is not without challenges. The high initial cost of smart windows with vacuum pump technology remains a significant barrier to widespread adoption. Many potential customers, especially in the residential sector, may be hesitant to invest in these advanced systems despite the long-term energy savings. This suggests a need for education and awareness campaigns to highlight the benefits and return on investment of these technologies.

Additionally, the retrofit market presents a substantial opportunity. As building owners look to upgrade existing structures for improved energy efficiency, smart window technologies that can be easily integrated into existing frameworks are likely to see increased demand. This opens up possibilities for vacuum pump-based solutions that can be adapted for retrofitting applications.

Smart windows with vacuum pump technology offer a unique value proposition in this context. They provide superior insulation properties compared to traditional windows, effectively reducing heat transfer and minimizing energy loss. This translates to lower heating and cooling costs for buildings, addressing a key concern for property owners and managers in both residential and commercial sectors.

The construction industry, particularly in developed countries, is showing increased interest in these advanced window systems. As building codes become more stringent regarding energy efficiency, architects and developers are seeking cutting-edge solutions to meet these requirements. Smart windows with vacuum technology are positioned as a premium option that can significantly contribute to achieving green building certifications and improving overall building performance.

In the automotive sector, there is also a growing demand for smart window technologies. Luxury vehicle manufacturers are exploring ways to enhance passenger comfort and reduce energy consumption in electric vehicles. Vacuum-based smart windows offer potential benefits in terms of thermal management and noise reduction, aligning with the industry's push towards more efficient and comfortable transportation solutions.

The market for smart windows is expected to expand rapidly in regions with extreme climates, where energy costs for heating and cooling are substantial. Countries in Northern Europe, North America, and parts of Asia with harsh winters or hot summers are likely to be early adopters of this technology.

However, the market demand is not without challenges. The high initial cost of smart windows with vacuum pump technology remains a significant barrier to widespread adoption. Many potential customers, especially in the residential sector, may be hesitant to invest in these advanced systems despite the long-term energy savings. This suggests a need for education and awareness campaigns to highlight the benefits and return on investment of these technologies.

Additionally, the retrofit market presents a substantial opportunity. As building owners look to upgrade existing structures for improved energy efficiency, smart window technologies that can be easily integrated into existing frameworks are likely to see increased demand. This opens up possibilities for vacuum pump-based solutions that can be adapted for retrofitting applications.

Vacuum Pump Challenges

Vacuum pumps play a crucial role in the development and functionality of novel smart window technologies. However, their integration and operation present several significant challenges that need to be addressed for the successful implementation of these advanced window systems.

One of the primary challenges is the miniaturization of vacuum pumps while maintaining their efficiency. Smart windows require compact designs to fit within standard window frames, necessitating the development of smaller, yet powerful vacuum pumps. This reduction in size often leads to compromises in pumping capacity and overall performance, which can affect the window's ability to maintain the required vacuum levels for optimal functionality.

The energy consumption of vacuum pumps is another major concern. Smart windows are designed to enhance energy efficiency in buildings, but the continuous operation of vacuum pumps can potentially offset these energy savings. Developing low-power vacuum pumps that can maintain the necessary vacuum levels without significant energy expenditure is a critical challenge that researchers and engineers must overcome.

Durability and longevity of vacuum pumps in smart window applications pose additional challenges. These pumps need to operate reliably over extended periods, often in varying environmental conditions. Factors such as temperature fluctuations, humidity, and exposure to UV radiation can impact the performance and lifespan of vacuum pumps, necessitating the development of robust designs and materials that can withstand these conditions without degradation.

Noise reduction is another significant challenge in the integration of vacuum pumps into smart windows. Traditional vacuum pumps can generate considerable noise during operation, which is unacceptable in residential or office environments. Developing silent or near-silent vacuum pump technologies is essential for the widespread adoption of smart window systems in various settings.

Maintenance and serviceability of vacuum pumps in smart windows present logistical challenges. Unlike standalone vacuum systems, pumps integrated into windows are not easily accessible for routine maintenance or repairs. This necessitates the development of highly reliable, low-maintenance pump designs or innovative approaches to pump replacement and servicing without compromising the window's integrity.

Cost-effectiveness is a crucial factor that poses a significant challenge in the widespread adoption of smart windows with integrated vacuum pumps. The addition of sophisticated vacuum technology substantially increases the overall cost of smart windows, potentially limiting their market penetration. Developing cost-effective manufacturing processes and materials for vacuum pumps while maintaining their performance is essential for making smart windows economically viable for large-scale implementation.

One of the primary challenges is the miniaturization of vacuum pumps while maintaining their efficiency. Smart windows require compact designs to fit within standard window frames, necessitating the development of smaller, yet powerful vacuum pumps. This reduction in size often leads to compromises in pumping capacity and overall performance, which can affect the window's ability to maintain the required vacuum levels for optimal functionality.

The energy consumption of vacuum pumps is another major concern. Smart windows are designed to enhance energy efficiency in buildings, but the continuous operation of vacuum pumps can potentially offset these energy savings. Developing low-power vacuum pumps that can maintain the necessary vacuum levels without significant energy expenditure is a critical challenge that researchers and engineers must overcome.

Durability and longevity of vacuum pumps in smart window applications pose additional challenges. These pumps need to operate reliably over extended periods, often in varying environmental conditions. Factors such as temperature fluctuations, humidity, and exposure to UV radiation can impact the performance and lifespan of vacuum pumps, necessitating the development of robust designs and materials that can withstand these conditions without degradation.

Noise reduction is another significant challenge in the integration of vacuum pumps into smart windows. Traditional vacuum pumps can generate considerable noise during operation, which is unacceptable in residential or office environments. Developing silent or near-silent vacuum pump technologies is essential for the widespread adoption of smart window systems in various settings.

Maintenance and serviceability of vacuum pumps in smart windows present logistical challenges. Unlike standalone vacuum systems, pumps integrated into windows are not easily accessible for routine maintenance or repairs. This necessitates the development of highly reliable, low-maintenance pump designs or innovative approaches to pump replacement and servicing without compromising the window's integrity.

Cost-effectiveness is a crucial factor that poses a significant challenge in the widespread adoption of smart windows with integrated vacuum pumps. The addition of sophisticated vacuum technology substantially increases the overall cost of smart windows, potentially limiting their market penetration. Developing cost-effective manufacturing processes and materials for vacuum pumps while maintaining their performance is essential for making smart windows economically viable for large-scale implementation.

Current Vacuum Solutions

01 Improvements in vacuum pump design

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability.- Rotary vacuum pump designs: Various rotary vacuum pump designs have been developed to improve efficiency and performance. These include innovations in rotor configurations, sealing mechanisms, and chamber designs to enhance suction power and reduce friction. Some designs focus on compact arrangements for specific applications, while others aim to optimize flow characteristics and minimize wear.

- Vacuum pump control systems: Advanced control systems have been implemented in vacuum pumps to improve their operation and efficiency. These systems may include electronic controllers, sensors, and actuators to regulate pump speed, pressure, and other parameters. Some designs incorporate adaptive control algorithms to optimize performance based on changing conditions or specific process requirements.

- Vacuum pump sealing technologies: Innovations in sealing technologies for vacuum pumps have been developed to enhance performance and reliability. These may include advanced materials for seals, improved seal designs, and novel sealing mechanisms. Some designs focus on reducing friction and wear, while others aim to minimize leakage and maintain high vacuum levels under various operating conditions.

- Multi-stage vacuum pump systems: Multi-stage vacuum pump systems have been designed to achieve higher vacuum levels and improved efficiency. These systems may combine different types of pumps in series or parallel configurations to optimize performance across a wide range of pressure conditions. Some designs focus on compact arrangements for specific applications, while others aim to provide versatile solutions for various industrial processes.

- Vacuum pump cooling and lubrication systems: Advancements in cooling and lubrication systems for vacuum pumps have been developed to enhance performance and longevity. These may include innovative cooling mechanisms, such as liquid cooling or heat dissipation designs, as well as improved lubrication methods to reduce friction and wear. Some designs focus on minimizing contamination risks in sensitive applications, while others aim to optimize energy efficiency and reduce maintenance requirements.

02 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high cleanliness levels, and provide stable vacuum conditions. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.Expand Specific Solutions03 Energy-efficient vacuum pump systems

Innovations in vacuum pump technology have focused on improving energy efficiency. These developments include the use of variable speed drives, optimized motor designs, and intelligent control systems. Such advancements result in reduced power consumption, lower operating costs, and improved environmental sustainability.Expand Specific Solutions04 Multi-stage vacuum pump configurations

Multi-stage vacuum pump designs have been created to achieve higher vacuum levels and improved pumping performance. These configurations typically combine different pump types or multiple pumping stages in series. This approach allows for more efficient gas removal across a wide pressure range and can result in faster pump-down times and lower ultimate pressures.Expand Specific Solutions05 Vacuum pump monitoring and control systems

Advanced monitoring and control systems have been developed for vacuum pumps to enhance their performance and reliability. These systems may include sensors for temperature, pressure, and vibration monitoring, as well as intelligent control algorithms for optimizing pump operation. Such features enable predictive maintenance, remote monitoring, and automatic adjustment of pump parameters for optimal performance.Expand Specific Solutions

Key Industry Players

The market for smart window technologies incorporating vacuum pumps is in a nascent stage, with significant growth potential as energy efficiency and smart building solutions gain traction. The global smart glass market is projected to reach $8.35 billion by 2023, with a CAGR of 16.6%. Key players like View Operating Corp., SAGE Electrochromics, and Guardian Glass LLC are driving innovation in this space. The technology is still evolving, with companies like SKY Technology Development Co., Ltd. CAS and Pfeiffer Vacuum SAS contributing to vacuum pump advancements. Research institutions such as Zhejiang University and Rensselaer Polytechnic Institute are also playing crucial roles in developing novel smart window technologies, indicating a collaborative ecosystem between industry and academia.

Guardian Glass LLC

Technical Solution: Guardian Glass LLC has developed a range of smart glass products that incorporate vacuum technology in their production. Their dynamic glazing solutions use vacuum-deposited coatings to create electrochromic windows that can change tint on demand. The vacuum pumps used in their manufacturing process are crucial for creating the high-quality, multi-layer coatings required for electrochromic functionality[7]. Guardian's smart windows can reduce solar heat gain by up to 90% when fully tinted, significantly impacting building energy efficiency[8]. The company's vacuum-based production methods allow for precise control over the thickness and composition of the electrochromic layers, ensuring consistent performance across large glass surfaces. Guardian's technology also includes vacuum-insulated glazing units, which use vacuum pumps to create a near-vacuum between glass panes, dramatically improving thermal insulation properties.

Strengths: Wide range of smart glass products, high-performance thermal insulation, and scalability for large architectural projects. Weaknesses: Higher production costs and potential for seal failure in vacuum-insulated units.

View Operating Corp.

Technical Solution: View Operating Corp. has developed a dynamic glass technology that incorporates vacuum pumps in its production process. Their smart windows use a proprietary electrochromic coating that changes opacity in response to electrical signals. The vacuum pumps are essential in the sputtering process used to deposit the nanolayers of electrochromic material onto the glass[3]. View's technology allows for automatic tinting based on external conditions, using AI and machine learning algorithms to optimize light and heat management. Their smart windows can reduce HVAC energy consumption by up to 20% and lighting energy usage by up to 18%[4]. The vacuum pumps used in manufacturing ensure the precise layering required for the electrochromic effect, contributing to the durability and performance of the final product.

Strengths: Advanced AI-driven tinting control, significant energy savings, and improved occupant comfort. Weaknesses: Complex installation process and potential for software glitches.

Innovative Pump Designs

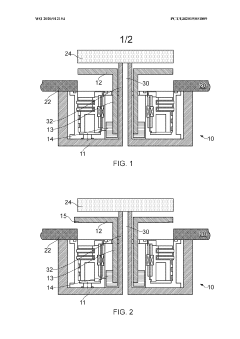

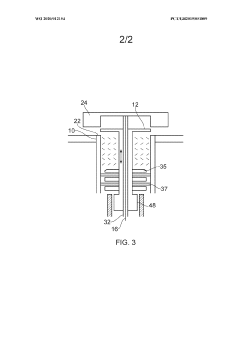

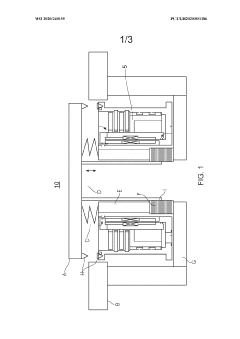

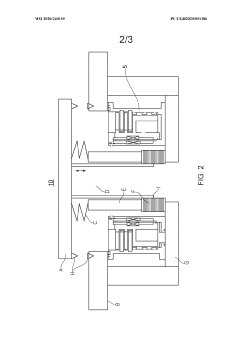

Vacuum pump with through channel and vacuum chamber

PatentWO2020012154A1

Innovation

- A vacuum pump design featuring a rotor, stator, and a controllable valve plate with an axial passage for central substrate mounting and power connections, allowing for uniform gas flow and fast pressure control, along with the option of magnetic levitation for rotor positioning and actuator-controlled axial movement of the valve plate to optimize inlet conductance.

Vacuum assembly and vacuum pump with an axial through passage

PatentWO2020240155A1

Innovation

- A vacuum pump with a hollow shaft defining an axial passage that extends through the pump, allowing the cathode plate to be powered and sealed without disrupting gas flow, eliminating the need for a poppet valve and reducing hardware requirements by using a movable cathode plate for sealing and power supply access.

Energy Efficiency Impact

The integration of vacuum pumps in novel smart window technologies has a significant impact on energy efficiency in buildings. These advanced windows utilize vacuum-insulated glazing units, which consist of two glass panes separated by a vacuum-sealed space. The role of vacuum pumps in this technology is crucial for creating and maintaining the vacuum between the glass panes, thereby dramatically reducing heat transfer and improving overall energy performance.

The vacuum created by these pumps effectively eliminates conduction and convection heat transfer mechanisms, leaving only radiation as the primary means of heat exchange. This results in exceptional thermal insulation properties, with U-values as low as 0.1 W/m²K, significantly outperforming traditional double or triple-glazed windows. Such high-performance insulation translates to substantial energy savings in both heating and cooling applications across various climate zones.

In cold climates, vacuum-insulated smart windows minimize heat loss from building interiors, reducing the energy demand for heating systems. Conversely, in hot climates, these windows prevent unwanted heat gain, decreasing the cooling load on air conditioning systems. This bi-directional insulation capability makes vacuum-pumped smart windows an versatile solution for improving energy efficiency in diverse environmental conditions.

The energy-saving potential of these windows extends beyond their insulation properties. By incorporating electrochromic or thermochromic materials, smart windows can dynamically adjust their optical properties in response to environmental conditions or user preferences. This adaptive behavior allows for optimal management of solar heat gain and natural light transmission, further reducing reliance on artificial lighting and HVAC systems.

Moreover, the improved thermal performance of vacuum-insulated smart windows contributes to enhanced occupant comfort by eliminating cold or hot spots near window surfaces. This reduction in temperature differentials within living spaces can lead to more efficient use of heating and cooling systems, as thermostats can be set to more moderate temperatures without compromising comfort.

The long-term energy efficiency impact of vacuum-pumped smart windows is also noteworthy. With proper maintenance of the vacuum seal, these windows can maintain their high-performance characteristics over extended periods, ensuring consistent energy savings throughout the building's lifecycle. This durability factor enhances the overall return on investment and makes vacuum-insulated smart windows an attractive option for both new construction and retrofitting projects aimed at improving building energy efficiency.

The vacuum created by these pumps effectively eliminates conduction and convection heat transfer mechanisms, leaving only radiation as the primary means of heat exchange. This results in exceptional thermal insulation properties, with U-values as low as 0.1 W/m²K, significantly outperforming traditional double or triple-glazed windows. Such high-performance insulation translates to substantial energy savings in both heating and cooling applications across various climate zones.

In cold climates, vacuum-insulated smart windows minimize heat loss from building interiors, reducing the energy demand for heating systems. Conversely, in hot climates, these windows prevent unwanted heat gain, decreasing the cooling load on air conditioning systems. This bi-directional insulation capability makes vacuum-pumped smart windows an versatile solution for improving energy efficiency in diverse environmental conditions.

The energy-saving potential of these windows extends beyond their insulation properties. By incorporating electrochromic or thermochromic materials, smart windows can dynamically adjust their optical properties in response to environmental conditions or user preferences. This adaptive behavior allows for optimal management of solar heat gain and natural light transmission, further reducing reliance on artificial lighting and HVAC systems.

Moreover, the improved thermal performance of vacuum-insulated smart windows contributes to enhanced occupant comfort by eliminating cold or hot spots near window surfaces. This reduction in temperature differentials within living spaces can lead to more efficient use of heating and cooling systems, as thermostats can be set to more moderate temperatures without compromising comfort.

The long-term energy efficiency impact of vacuum-pumped smart windows is also noteworthy. With proper maintenance of the vacuum seal, these windows can maintain their high-performance characteristics over extended periods, ensuring consistent energy savings throughout the building's lifecycle. This durability factor enhances the overall return on investment and makes vacuum-insulated smart windows an attractive option for both new construction and retrofitting projects aimed at improving building energy efficiency.

Manufacturing Processes

The manufacturing processes for novel smart window technologies incorporating vacuum pumps are critical to ensuring the efficiency, reliability, and scalability of these advanced systems. The integration of vacuum pumps into smart windows requires precise engineering and specialized production techniques to maintain the necessary vacuum levels within the window units.

The process typically begins with the fabrication of the glass panes, which are carefully cleaned and prepared to ensure a pristine surface. These panes are then coated with specialized materials, such as low-emissivity coatings or electrochromic layers, depending on the specific smart window technology being implemented. The coatings are applied using advanced deposition techniques, such as magnetron sputtering or chemical vapor deposition, to ensure uniform coverage and optimal performance.

Once the glass panes are prepared, the assembly of the window unit commences. Spacers are precisely positioned between the panes to create the required gap for the vacuum cavity. These spacers are typically made of materials with low thermal conductivity to minimize heat transfer. The edges of the window unit are then sealed using high-performance sealants that can withstand the pressure differential and maintain the vacuum integrity over extended periods.

The critical step in the manufacturing process involves the creation and maintenance of the vacuum within the window unit. This is where vacuum pumps play a crucial role. Specialized vacuum pumps, often turbomolecular or ion pumps, are used to evacuate the air from the cavity between the glass panes. The pumping process must be carefully controlled to achieve the desired vacuum level without compromising the structural integrity of the window unit.

To ensure long-term vacuum retention, getter materials are often incorporated into the window design. These materials are strategically placed within the vacuum cavity to absorb any residual gases or those that may permeate through the seals over time. The activation of these getter materials is typically done during the final stages of the manufacturing process.

Quality control measures are implemented throughout the production process, with particular attention paid to vacuum integrity testing. Advanced leak detection systems and pressure monitoring equipment are employed to verify that each window unit meets the stringent vacuum requirements. Any units failing to meet the specified standards are either reworked or discarded.

The final stages of manufacturing involve the integration of smart control systems, such as sensors and actuators, that enable the window to respond to environmental conditions or user inputs. These components must be carefully integrated to maintain the vacuum seal while providing the desired functionality.

As the technology evolves, manufacturers are continually refining their processes to improve efficiency and reduce costs. Automation and robotics are increasingly being employed to enhance precision and consistency in the production of smart vacuum windows. Additionally, research into new materials and sealing technologies is ongoing, aiming to further improve the performance and longevity of these advanced window systems.

The process typically begins with the fabrication of the glass panes, which are carefully cleaned and prepared to ensure a pristine surface. These panes are then coated with specialized materials, such as low-emissivity coatings or electrochromic layers, depending on the specific smart window technology being implemented. The coatings are applied using advanced deposition techniques, such as magnetron sputtering or chemical vapor deposition, to ensure uniform coverage and optimal performance.

Once the glass panes are prepared, the assembly of the window unit commences. Spacers are precisely positioned between the panes to create the required gap for the vacuum cavity. These spacers are typically made of materials with low thermal conductivity to minimize heat transfer. The edges of the window unit are then sealed using high-performance sealants that can withstand the pressure differential and maintain the vacuum integrity over extended periods.

The critical step in the manufacturing process involves the creation and maintenance of the vacuum within the window unit. This is where vacuum pumps play a crucial role. Specialized vacuum pumps, often turbomolecular or ion pumps, are used to evacuate the air from the cavity between the glass panes. The pumping process must be carefully controlled to achieve the desired vacuum level without compromising the structural integrity of the window unit.

To ensure long-term vacuum retention, getter materials are often incorporated into the window design. These materials are strategically placed within the vacuum cavity to absorb any residual gases or those that may permeate through the seals over time. The activation of these getter materials is typically done during the final stages of the manufacturing process.

Quality control measures are implemented throughout the production process, with particular attention paid to vacuum integrity testing. Advanced leak detection systems and pressure monitoring equipment are employed to verify that each window unit meets the stringent vacuum requirements. Any units failing to meet the specified standards are either reworked or discarded.

The final stages of manufacturing involve the integration of smart control systems, such as sensors and actuators, that enable the window to respond to environmental conditions or user inputs. These components must be carefully integrated to maintain the vacuum seal while providing the desired functionality.

As the technology evolves, manufacturers are continually refining their processes to improve efficiency and reduce costs. Automation and robotics are increasingly being employed to enhance precision and consistency in the production of smart vacuum windows. Additionally, research into new materials and sealing technologies is ongoing, aiming to further improve the performance and longevity of these advanced window systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!