How Vacuum Pumps Support Submicron Process Technologies

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution

The evolution of vacuum pumps has played a crucial role in enabling submicron process technologies. The journey began in the early 20th century with the development of mechanical pumps, which laid the foundation for vacuum technology. These early pumps, such as rotary vane and piston pumps, were capable of achieving moderate vacuum levels but were limited in their ability to reach the ultra-high vacuum required for advanced semiconductor manufacturing.

The 1950s and 1960s saw significant advancements with the introduction of diffusion pumps. These pumps utilized the principle of momentum transfer to achieve higher vacuum levels, marking a substantial improvement over mechanical pumps. However, they were prone to oil contamination, which became a critical issue as semiconductor processes demanded increasingly cleaner environments.

The 1970s brought about a revolutionary change with the development of turbomolecular pumps. These pumps operate on the principle of imparting momentum to gas molecules through high-speed rotating blades, allowing for the achievement of much higher vacuum levels without the risk of oil contamination. This innovation was a game-changer for the semiconductor industry, enabling the production of more complex and smaller integrated circuits.

In the 1980s and 1990s, cryogenic pumps emerged as a powerful tool for achieving ultra-high vacuum conditions. By condensing gases on extremely cold surfaces, these pumps could maintain exceptionally low pressures, further supporting the advancement of submicron technologies. Concurrently, improvements in dry pumps, which operate without oil, addressed the ongoing concern of contamination in sensitive processes.

The turn of the millennium saw the rise of combination pumping systems, integrating different pump technologies to optimize vacuum performance across various pressure ranges. These hybrid systems allowed for more efficient and reliable vacuum generation, crucial for the increasingly demanding semiconductor manufacturing processes.

Recent years have witnessed the development of advanced vacuum pump designs specifically tailored for extreme ultraviolet (EUV) lithography, a key technology for producing nanometer-scale features. These pumps must handle the unique challenges of EUV systems, including the management of hydrogen gas and the need for ultra-clean environments.

Throughout this evolution, vacuum pump technology has continuously adapted to meet the stringent requirements of submicron process technologies. Improvements in materials, design, and control systems have resulted in pumps capable of achieving and maintaining the ultra-high vacuum levels necessary for cutting-edge semiconductor manufacturing. The ongoing development of vacuum pump technology remains a critical factor in pushing the boundaries of miniaturization and enabling the production of increasingly sophisticated electronic devices.

The 1950s and 1960s saw significant advancements with the introduction of diffusion pumps. These pumps utilized the principle of momentum transfer to achieve higher vacuum levels, marking a substantial improvement over mechanical pumps. However, they were prone to oil contamination, which became a critical issue as semiconductor processes demanded increasingly cleaner environments.

The 1970s brought about a revolutionary change with the development of turbomolecular pumps. These pumps operate on the principle of imparting momentum to gas molecules through high-speed rotating blades, allowing for the achievement of much higher vacuum levels without the risk of oil contamination. This innovation was a game-changer for the semiconductor industry, enabling the production of more complex and smaller integrated circuits.

In the 1980s and 1990s, cryogenic pumps emerged as a powerful tool for achieving ultra-high vacuum conditions. By condensing gases on extremely cold surfaces, these pumps could maintain exceptionally low pressures, further supporting the advancement of submicron technologies. Concurrently, improvements in dry pumps, which operate without oil, addressed the ongoing concern of contamination in sensitive processes.

The turn of the millennium saw the rise of combination pumping systems, integrating different pump technologies to optimize vacuum performance across various pressure ranges. These hybrid systems allowed for more efficient and reliable vacuum generation, crucial for the increasingly demanding semiconductor manufacturing processes.

Recent years have witnessed the development of advanced vacuum pump designs specifically tailored for extreme ultraviolet (EUV) lithography, a key technology for producing nanometer-scale features. These pumps must handle the unique challenges of EUV systems, including the management of hydrogen gas and the need for ultra-clean environments.

Throughout this evolution, vacuum pump technology has continuously adapted to meet the stringent requirements of submicron process technologies. Improvements in materials, design, and control systems have resulted in pumps capable of achieving and maintaining the ultra-high vacuum levels necessary for cutting-edge semiconductor manufacturing. The ongoing development of vacuum pump technology remains a critical factor in pushing the boundaries of miniaturization and enabling the production of increasingly sophisticated electronic devices.

Submicron Market Needs

The submicron market has experienced significant growth in recent years, driven by the increasing demand for smaller, faster, and more efficient electronic devices. This market segment encompasses a wide range of applications, including semiconductor manufacturing, nanotechnology, and advanced materials processing. As device dimensions continue to shrink, the need for precise control over manufacturing processes becomes paramount, creating a substantial market for technologies that enable submicron-scale production.

In the semiconductor industry, the push towards smaller transistor sizes and higher chip densities has been relentless. The transition from micron to submicron processes has opened up new possibilities for chip designers, allowing for increased functionality and improved performance in a smaller footprint. This trend has fueled the demand for advanced lithography systems, etching tools, and deposition equipment capable of working at the submicron scale.

Beyond semiconductors, the submicron market extends to various other sectors. In the field of nanotechnology, researchers and manufacturers require tools and processes that can manipulate and analyze materials at the molecular level. This has led to a growing market for advanced microscopy systems, nanofabrication equipment, and precision measurement tools.

The medical and biotechnology sectors have also shown increasing interest in submicron technologies. Applications such as drug delivery systems, biosensors, and lab-on-a-chip devices rely on submicron-scale features to achieve their desired functionality. This has created a demand for specialized equipment and processes that can produce these intricate structures with high precision and reliability.

In the realm of advanced materials, submicron processing techniques are enabling the development of novel materials with unique properties. From high-performance coatings to advanced composites, the ability to control material structure at the submicron scale is opening up new possibilities for material scientists and engineers.

The market needs in the submicron space are diverse and evolving. There is a constant demand for improved process control, higher throughput, and reduced defect rates. Manufacturers are seeking solutions that can maintain precise environmental conditions, including temperature, pressure, and contamination control. This has led to a growing market for advanced vacuum systems, clean room technologies, and process monitoring tools.

As the submicron market continues to expand, there is an increasing emphasis on cost-effective solutions that can scale to high-volume production. This presents both challenges and opportunities for equipment manufacturers and process developers. The ability to deliver reliable, high-performance solutions at competitive price points will be crucial for success in this rapidly evolving market.

In the semiconductor industry, the push towards smaller transistor sizes and higher chip densities has been relentless. The transition from micron to submicron processes has opened up new possibilities for chip designers, allowing for increased functionality and improved performance in a smaller footprint. This trend has fueled the demand for advanced lithography systems, etching tools, and deposition equipment capable of working at the submicron scale.

Beyond semiconductors, the submicron market extends to various other sectors. In the field of nanotechnology, researchers and manufacturers require tools and processes that can manipulate and analyze materials at the molecular level. This has led to a growing market for advanced microscopy systems, nanofabrication equipment, and precision measurement tools.

The medical and biotechnology sectors have also shown increasing interest in submicron technologies. Applications such as drug delivery systems, biosensors, and lab-on-a-chip devices rely on submicron-scale features to achieve their desired functionality. This has created a demand for specialized equipment and processes that can produce these intricate structures with high precision and reliability.

In the realm of advanced materials, submicron processing techniques are enabling the development of novel materials with unique properties. From high-performance coatings to advanced composites, the ability to control material structure at the submicron scale is opening up new possibilities for material scientists and engineers.

The market needs in the submicron space are diverse and evolving. There is a constant demand for improved process control, higher throughput, and reduced defect rates. Manufacturers are seeking solutions that can maintain precise environmental conditions, including temperature, pressure, and contamination control. This has led to a growing market for advanced vacuum systems, clean room technologies, and process monitoring tools.

As the submicron market continues to expand, there is an increasing emphasis on cost-effective solutions that can scale to high-volume production. This presents both challenges and opportunities for equipment manufacturers and process developers. The ability to deliver reliable, high-performance solutions at competitive price points will be crucial for success in this rapidly evolving market.

Vacuum Tech Challenges

Vacuum technology plays a crucial role in enabling submicron process technologies, particularly in semiconductor manufacturing. However, as the industry pushes towards ever-smaller feature sizes and more complex chip designs, vacuum systems face significant challenges that require innovative solutions.

One of the primary challenges is achieving and maintaining ultra-high vacuum (UHV) conditions necessary for submicron processes. As feature sizes shrink below 100 nanometers, even minute levels of contamination can severely impact device performance. This demands vacuum levels in the range of 10^-9 to 10^-11 Torr, pushing the limits of current pump technologies.

The need for faster pump-down times presents another significant hurdle. In high-volume manufacturing environments, reducing cycle times is critical for improving throughput and reducing costs. However, achieving UHV conditions quickly without compromising cleanliness or risking particle generation is a complex balancing act that requires advanced pump designs and control systems.

Particle generation within vacuum pumps themselves poses a substantial challenge. As pumps operate at high speeds and under extreme conditions, mechanical wear can produce particles that may contaminate the process chamber. Developing pump materials and designs that minimize particle generation while maintaining high performance is an ongoing area of research and development.

Energy efficiency is becoming an increasingly important consideration in vacuum technology. As fabs grow larger and more complex, the power consumption of vacuum systems can represent a significant operational cost. Improving the efficiency of vacuum pumps without sacrificing performance is a key challenge that manufacturers are actively addressing.

The integration of smart technologies and Industry 4.0 concepts into vacuum systems presents both opportunities and challenges. While advanced sensors and data analytics can improve system monitoring and predictive maintenance, implementing these technologies in high-vacuum environments without introducing new sources of contamination or reliability issues requires careful engineering.

Lastly, the handling of new process gases and byproducts in advanced semiconductor manufacturing processes poses unique challenges for vacuum systems. As new materials and deposition techniques are introduced, vacuum pumps must be capable of safely and efficiently handling a wider range of gases, some of which may be corrosive, reactive, or potentially hazardous.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, fluid dynamics, control systems, and manufacturing techniques. As the semiconductor industry continues to evolve, overcoming these vacuum technology hurdles will be critical in enabling the next generation of submicron process technologies.

One of the primary challenges is achieving and maintaining ultra-high vacuum (UHV) conditions necessary for submicron processes. As feature sizes shrink below 100 nanometers, even minute levels of contamination can severely impact device performance. This demands vacuum levels in the range of 10^-9 to 10^-11 Torr, pushing the limits of current pump technologies.

The need for faster pump-down times presents another significant hurdle. In high-volume manufacturing environments, reducing cycle times is critical for improving throughput and reducing costs. However, achieving UHV conditions quickly without compromising cleanliness or risking particle generation is a complex balancing act that requires advanced pump designs and control systems.

Particle generation within vacuum pumps themselves poses a substantial challenge. As pumps operate at high speeds and under extreme conditions, mechanical wear can produce particles that may contaminate the process chamber. Developing pump materials and designs that minimize particle generation while maintaining high performance is an ongoing area of research and development.

Energy efficiency is becoming an increasingly important consideration in vacuum technology. As fabs grow larger and more complex, the power consumption of vacuum systems can represent a significant operational cost. Improving the efficiency of vacuum pumps without sacrificing performance is a key challenge that manufacturers are actively addressing.

The integration of smart technologies and Industry 4.0 concepts into vacuum systems presents both opportunities and challenges. While advanced sensors and data analytics can improve system monitoring and predictive maintenance, implementing these technologies in high-vacuum environments without introducing new sources of contamination or reliability issues requires careful engineering.

Lastly, the handling of new process gases and byproducts in advanced semiconductor manufacturing processes poses unique challenges for vacuum systems. As new materials and deposition techniques are introduced, vacuum pumps must be capable of safely and efficiently handling a wider range of gases, some of which may be corrosive, reactive, or potentially hazardous.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, fluid dynamics, control systems, and manufacturing techniques. As the semiconductor industry continues to evolve, overcoming these vacuum technology hurdles will be critical in enabling the next generation of submicron process technologies.

Current Vacuum Solutions

01 Vacuum pump design for submicron processes

Specialized vacuum pump designs are developed to meet the requirements of submicron processes. These pumps are engineered to achieve high vacuum levels and maintain cleanliness in sensitive manufacturing environments. Features may include advanced sealing mechanisms, optimized flow paths, and materials compatible with ultra-clean processes.- Vacuum pump design for submicron processes: Specialized vacuum pump designs are developed for submicron processes, focusing on achieving high vacuum levels and maintaining cleanliness. These pumps often incorporate advanced sealing mechanisms, optimized flow paths, and materials compatible with ultra-clean environments to prevent contamination during submicron manufacturing processes.

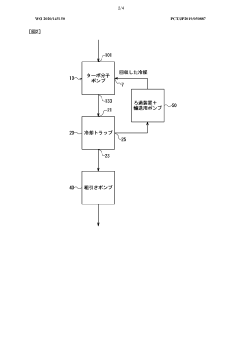

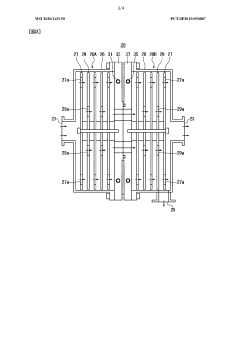

- Multi-stage vacuum systems for submicron applications: Multi-stage vacuum systems are employed in submicron processes to achieve progressively higher vacuum levels. These systems typically combine different types of pumps, such as rotary vane pumps, turbomolecular pumps, and cryopumps, to efficiently remove gases and particles across a wide pressure range, ensuring the required vacuum for submicron fabrication.

- Particle filtration in vacuum systems for submicron processes: Advanced filtration techniques are integrated into vacuum systems to remove submicron particles and prevent contamination. These may include electrostatic filters, molecular sieves, and trap designs that capture particles without impeding pump performance, ensuring the cleanliness required for submicron manufacturing environments.

- Vacuum pump control and monitoring for submicron applications: Sophisticated control and monitoring systems are implemented to maintain precise vacuum levels and detect any deviations that could affect submicron processes. These systems may include real-time pressure sensors, flow meters, and adaptive control algorithms to ensure stable and reliable vacuum conditions throughout the manufacturing process.

- Energy-efficient vacuum pumps for submicron processing: Energy-efficient vacuum pump designs are developed specifically for submicron processes, addressing the high power consumption typically associated with maintaining ultra-high vacuum levels. These pumps may incorporate advanced motor designs, optimized compression stages, and intelligent power management systems to reduce energy consumption while maintaining the required vacuum performance.

02 Multi-stage vacuum systems for submicron applications

Multi-stage vacuum systems are employed to achieve the ultra-high vacuum levels required for submicron processes. These systems typically combine different types of pumps, such as rotary vane pumps, turbomolecular pumps, and cryopumps, to progressively reduce pressure and remove contaminants at various stages of the vacuum process.Expand Specific Solutions03 Contamination control in vacuum pumps for submicron processes

Contamination control is crucial in vacuum pumps used for submicron processes. Techniques include the use of particle filters, oil-free pump designs, and specialized coatings to minimize particle generation and prevent backstreaming of pump fluids. Advanced sealing technologies and purge systems may also be implemented to maintain process purity.Expand Specific Solutions04 Vacuum pump monitoring and control systems

Sophisticated monitoring and control systems are integrated into vacuum pumps for submicron processes. These systems may include pressure sensors, temperature monitors, and flow controllers to ensure optimal pump performance and process stability. Real-time data analysis and predictive maintenance features can help maintain consistent vacuum levels and prevent process interruptions.Expand Specific Solutions05 Energy-efficient vacuum pumps for submicron applications

Energy-efficient vacuum pump designs are developed for submicron processes to reduce power consumption and operating costs. These pumps may incorporate variable speed drives, regenerative technologies, and optimized motor designs. Advanced control algorithms can adjust pump performance based on process demands, further improving energy efficiency.Expand Specific Solutions

Key Vacuum Pump Makers

The vacuum pump industry supporting submicron process technologies is in a mature growth phase, characterized by a competitive landscape dominated by established players. The global market size for vacuum pumps in semiconductor manufacturing is substantial, driven by the increasing demand for advanced microchips. Technologically, the field is highly sophisticated, with companies like Edwards Ltd., Applied Materials, Inc., and Pfeiffer Vacuum GmbH leading innovation. These firms, along with others such as Tokyo Electron Ltd. and ULVAC, Inc., are continually pushing the boundaries of vacuum technology to meet the exacting requirements of submicron processes. The industry also sees participation from research institutions like the Korea Research Institute of Standards & Science, contributing to the overall technological advancement in this critical semiconductor manufacturing sector.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for submicron process technologies. Their iXH series dry pumps utilize a unique tapered screw design that provides high pumping speeds and ultimate pressures down to 3 x 10^-3 mbar[1]. The pumps incorporate advanced temperature management systems to handle high gas loads and particulates common in submicron processes. Edwards has also introduced their GXS dry screw pump range, which offers increased robustness and reliability for demanding semiconductor applications[2]. These pumps feature a novel motor cooling system and optimized screw profiles to enhance performance in submicron environments.

Strengths: High pumping efficiency, advanced temperature management, and robust design for semiconductor applications. Weaknesses: May have higher initial costs compared to traditional pump technologies.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed integrated vacuum solutions for their semiconductor manufacturing equipment, crucial for submicron process technologies. Their Endura platform incorporates high-performance vacuum pumps and advanced pressure control systems to maintain ultra-clean environments necessary for submicron fabrication[3]. The company's PVD (Physical Vapor Deposition) systems utilize specialized vacuum pumps to achieve base pressures as low as 5 x 10^-9 Torr, enabling precise thin film deposition at the nanoscale[4]. Applied Materials has also introduced vacuum-integrated metrology tools that allow in-situ measurements without breaking vacuum, enhancing process control and reducing contamination risks in submicron manufacturing.

Strengths: Integrated vacuum solutions tailored for specific semiconductor processes, advanced process control capabilities. Weaknesses: Solutions may be limited to Applied Materials' own equipment ecosystem.

Innovative Pump Designs

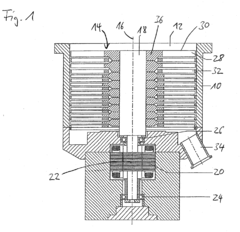

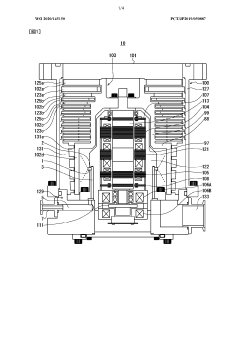

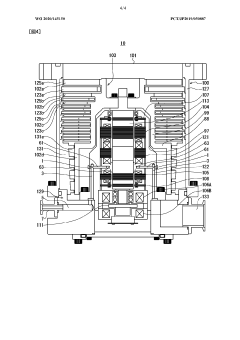

Vacuum pump

PatentActiveEP2740943A3

Innovation

- Incorporating nanoparticles, such as carbon nanotubes, into metal components like rotor disks to enhance mechanical and thermal resistance, maintaining metallic properties while increasing strength and heat resistance, allowing for reliable operation with high gas loads and flow rates.

Vacuum pump

PatentWO2020145150A1

Innovation

- A vacuum pump design featuring a magnetic bearing system with liquid cooling, where liquid is injected to cool the rotor blades and shaft, and a vaporization-based cooling mechanism that efficiently manages heat dissipation, allowing continuous high-volume gas exhaust while preventing overheating.

Cleanroom Integration

Vacuum pumps play a crucial role in supporting submicron process technologies within cleanroom environments. The integration of these pumps into cleanroom systems requires careful consideration of several factors to maintain the ultra-clean conditions necessary for submicron manufacturing processes.

Cleanroom design and construction must account for the specific requirements of vacuum pump integration. This includes dedicated spaces for pump installation that are isolated from the main cleanroom area to prevent contamination. These spaces often feature separate ventilation systems and airlock entrances to maintain cleanliness levels.

The selection of vacuum pumps for cleanroom integration is critical. Oil-free dry pumps are typically preferred due to their lower risk of contamination. These pumps use advanced sealing technologies and materials that minimize particle generation and outgassing, which is essential for maintaining the integrity of submicron processes.

Vacuum pump exhaust management is a key aspect of cleanroom integration. Exhaust systems must be designed to prevent backflow of contaminants and ensure proper removal of process gases. This often involves the use of specialized exhaust scrubbers and filters to capture potentially harmful particles and chemicals before they are released into the environment.

Vibration isolation is another important consideration in cleanroom vacuum pump integration. Submicron processes are highly sensitive to vibrations, which can affect the precision of manufacturing equipment. Vacuum pumps are typically installed on vibration-dampening mounts or in separate rooms with vibration-isolating foundations to minimize their impact on sensitive processes.

Cleanroom vacuum systems often incorporate multiple pumps working in parallel or series configurations to meet the high vacuum requirements of submicron processes. This redundancy also allows for maintenance of individual pumps without disrupting ongoing operations, ensuring continuous cleanroom functionality.

The control and monitoring of vacuum pumps in cleanroom environments are typically integrated into the overall cleanroom management system. This integration allows for real-time monitoring of pump performance, pressure levels, and potential contamination risks. Advanced control systems can automatically adjust pump operation to maintain optimal vacuum levels and respond to process changes or potential issues.

Cleanroom design and construction must account for the specific requirements of vacuum pump integration. This includes dedicated spaces for pump installation that are isolated from the main cleanroom area to prevent contamination. These spaces often feature separate ventilation systems and airlock entrances to maintain cleanliness levels.

The selection of vacuum pumps for cleanroom integration is critical. Oil-free dry pumps are typically preferred due to their lower risk of contamination. These pumps use advanced sealing technologies and materials that minimize particle generation and outgassing, which is essential for maintaining the integrity of submicron processes.

Vacuum pump exhaust management is a key aspect of cleanroom integration. Exhaust systems must be designed to prevent backflow of contaminants and ensure proper removal of process gases. This often involves the use of specialized exhaust scrubbers and filters to capture potentially harmful particles and chemicals before they are released into the environment.

Vibration isolation is another important consideration in cleanroom vacuum pump integration. Submicron processes are highly sensitive to vibrations, which can affect the precision of manufacturing equipment. Vacuum pumps are typically installed on vibration-dampening mounts or in separate rooms with vibration-isolating foundations to minimize their impact on sensitive processes.

Cleanroom vacuum systems often incorporate multiple pumps working in parallel or series configurations to meet the high vacuum requirements of submicron processes. This redundancy also allows for maintenance of individual pumps without disrupting ongoing operations, ensuring continuous cleanroom functionality.

The control and monitoring of vacuum pumps in cleanroom environments are typically integrated into the overall cleanroom management system. This integration allows for real-time monitoring of pump performance, pressure levels, and potential contamination risks. Advanced control systems can automatically adjust pump operation to maintain optimal vacuum levels and respond to process changes or potential issues.

Energy Efficiency Focus

Energy efficiency has become a critical focus in the development and application of vacuum pumps for submicron process technologies. As semiconductor manufacturing processes continue to shrink to nanometer scales, the demand for more precise and efficient vacuum systems has intensified. Vacuum pumps play a crucial role in maintaining the ultra-clean environments required for these advanced processes, but they also consume significant amounts of energy.

Recent advancements in vacuum pump technology have led to substantial improvements in energy efficiency. Manufacturers are now developing pumps with optimized designs that reduce power consumption while maintaining or even improving performance. These innovations include the use of advanced materials, improved rotor designs, and more efficient motor systems.

One key area of focus has been the development of variable speed drives for vacuum pumps. These systems allow the pump to adjust its speed and power consumption based on the actual process requirements, rather than running at full capacity continuously. This adaptive approach can lead to energy savings of up to 50% in some applications, significantly reducing operational costs and environmental impact.

Another important trend is the integration of smart control systems and IoT technologies into vacuum pump systems. These advanced control systems can monitor pump performance in real-time, optimize operating parameters, and predict maintenance needs. By ensuring that pumps are always operating at peak efficiency and avoiding unnecessary downtime, these smart systems further contribute to overall energy efficiency.

Heat recovery systems are also being implemented to harness the waste heat generated by vacuum pumps. This recovered energy can be used for other processes within the manufacturing facility, such as heating or preheating process gases, further improving the overall energy efficiency of the production line.

Manufacturers are increasingly focusing on the total cost of ownership (TCO) of vacuum pump systems, which includes both initial investment and long-term operational costs. Energy efficiency plays a significant role in reducing TCO, making it a key selling point for new vacuum pump technologies. As a result, there is a growing market demand for energy-efficient vacuum solutions, driving further innovation in this area.

The push for energy efficiency in vacuum pumps aligns with broader sustainability goals in the semiconductor industry. As companies strive to reduce their carbon footprint and meet stringent environmental regulations, the adoption of energy-efficient vacuum technologies becomes increasingly important. This trend is likely to continue, with ongoing research and development efforts focused on further improving the energy efficiency of vacuum pumps for submicron process technologies.

Recent advancements in vacuum pump technology have led to substantial improvements in energy efficiency. Manufacturers are now developing pumps with optimized designs that reduce power consumption while maintaining or even improving performance. These innovations include the use of advanced materials, improved rotor designs, and more efficient motor systems.

One key area of focus has been the development of variable speed drives for vacuum pumps. These systems allow the pump to adjust its speed and power consumption based on the actual process requirements, rather than running at full capacity continuously. This adaptive approach can lead to energy savings of up to 50% in some applications, significantly reducing operational costs and environmental impact.

Another important trend is the integration of smart control systems and IoT technologies into vacuum pump systems. These advanced control systems can monitor pump performance in real-time, optimize operating parameters, and predict maintenance needs. By ensuring that pumps are always operating at peak efficiency and avoiding unnecessary downtime, these smart systems further contribute to overall energy efficiency.

Heat recovery systems are also being implemented to harness the waste heat generated by vacuum pumps. This recovered energy can be used for other processes within the manufacturing facility, such as heating or preheating process gases, further improving the overall energy efficiency of the production line.

Manufacturers are increasingly focusing on the total cost of ownership (TCO) of vacuum pump systems, which includes both initial investment and long-term operational costs. Energy efficiency plays a significant role in reducing TCO, making it a key selling point for new vacuum pump technologies. As a result, there is a growing market demand for energy-efficient vacuum solutions, driving further innovation in this area.

The push for energy efficiency in vacuum pumps aligns with broader sustainability goals in the semiconductor industry. As companies strive to reduce their carbon footprint and meet stringent environmental regulations, the adoption of energy-efficient vacuum technologies becomes increasingly important. This trend is likely to continue, with ongoing research and development efforts focused on further improving the energy efficiency of vacuum pumps for submicron process technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!