How Vacuum Pumps Facilitate Enhanced Soil Remediation Technology

Vacuum Pump Tech Evolution

The evolution of vacuum pump technology in soil remediation has been marked by significant advancements over the past few decades. Initially, vacuum pumps were primarily used in industrial processes, but their application in environmental remediation began to gain traction in the 1980s. The early vacuum pumps used in soil remediation were often adapted from other industries and had limited efficiency and capacity.

As environmental concerns grew and regulations became stricter, there was a push for more effective soil remediation techniques. This led to the development of specialized vacuum pumps designed specifically for soil vapor extraction (SVE) and other remediation processes. These pumps were engineered to handle the unique challenges of soil remediation, such as dealing with potentially corrosive or explosive vapors and maintaining consistent suction over extended periods.

The 1990s saw a significant leap in vacuum pump technology with the introduction of rotary vane and liquid ring pumps tailored for soil remediation. These pumps offered improved performance, reliability, and the ability to handle higher flow rates. This period also marked the beginning of integrating vacuum pumps with other remediation technologies, such as air sparging and thermal desorption, enhancing overall remediation effectiveness.

In the early 2000s, the focus shifted towards energy efficiency and reduced environmental impact. This led to the development of variable frequency drive (VFD) systems for vacuum pumps, allowing for better control and energy savings. Additionally, oil-free vacuum pump technologies began to emerge, addressing concerns about potential contamination from pump lubricants.

The last decade has seen a surge in smart technologies applied to vacuum pumps in soil remediation. IoT-enabled pumps with remote monitoring and control capabilities have become increasingly common, allowing for real-time adjustments and predictive maintenance. This has significantly improved the efficiency and reliability of remediation processes.

More recently, there has been a trend towards modular and portable vacuum pump systems, making it easier to deploy remediation equipment in diverse and challenging environments. These systems often incorporate advanced filtration and vapor treatment technologies, further enhancing their effectiveness in soil remediation.

The ongoing evolution of vacuum pump technology continues to focus on improving energy efficiency, reducing noise levels, and enhancing the ability to handle complex mixtures of contaminants. Research is also being conducted on integrating renewable energy sources to power vacuum pumps, further reducing the environmental impact of remediation processes.

Soil Remediation Market Trends

The soil remediation market has been experiencing significant growth in recent years, driven by increasing environmental awareness, stringent regulations, and the need to address contaminated sites worldwide. This trend is expected to continue, with the global soil remediation market projected to expand at a compound annual growth rate (CAGR) of 7.5% from 2021 to 2028. The market size is anticipated to reach $39.4 billion by 2028, up from $25.6 billion in 2020.

Several factors are contributing to this growth trajectory. Industrialization and urbanization have led to widespread soil contamination, particularly in developing countries, creating a substantial demand for remediation services. Additionally, governments worldwide are implementing stricter environmental regulations and cleanup standards, compelling industries to invest in soil remediation technologies.

The market is witnessing a shift towards sustainable and eco-friendly remediation techniques. In-situ remediation methods, which treat contaminated soil without excavation, are gaining popularity due to their cost-effectiveness and minimal site disruption. Among these, bioremediation and phytoremediation are emerging as preferred choices for their environmental benefits and lower operational costs.

Technological advancements are playing a crucial role in shaping market trends. The integration of artificial intelligence and machine learning in soil analysis and treatment planning is enhancing the efficiency and accuracy of remediation processes. Furthermore, the development of novel remediation techniques, such as electrokinetic remediation and nanoremediation, is opening up new possibilities for treating complex contamination scenarios.

Geographically, North America dominates the soil remediation market, accounting for approximately 35% of the global market share. This is primarily due to the presence of numerous contaminated sites and stringent environmental regulations in the region. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental concerns, and government initiatives to clean up contaminated sites.

The oil and gas industry remains a significant contributor to the soil remediation market, as it often requires extensive cleanup of contaminated sites. However, other sectors such as mining, agriculture, and construction are also becoming important drivers of market growth. The increasing focus on brownfield redevelopment in urban areas is creating additional opportunities for soil remediation services.

As the market evolves, there is a growing emphasis on developing cost-effective and time-efficient remediation solutions. This trend is particularly relevant for small and medium-sized contaminated sites, which often have limited budgets for cleanup activities. Consequently, there is a rising demand for innovative technologies that can deliver effective remediation results while minimizing costs and project durations.

Vacuum Pump Challenges

Vacuum pumps play a crucial role in enhancing soil remediation technology, but they face several significant challenges that can impact their effectiveness and efficiency. One of the primary issues is the potential for clogging and fouling of pump components due to the presence of soil particles, contaminants, and moisture in the extracted vapors. This can lead to reduced performance, increased maintenance requirements, and shortened equipment lifespan.

Another challenge is maintaining consistent vacuum levels across the treatment area, especially in heterogeneous soil conditions. Variations in soil permeability and moisture content can create preferential flow paths, leading to uneven contaminant extraction and reduced overall remediation efficiency. This issue is particularly pronounced in large-scale remediation projects where maintaining uniform vacuum distribution becomes increasingly complex.

The energy consumption of vacuum pumps is a significant concern, especially for long-term remediation projects. High-power requirements not only increase operational costs but also contribute to the carbon footprint of the remediation process. Balancing energy efficiency with the need for effective contaminant extraction remains a persistent challenge for engineers and environmental specialists.

Vacuum pump noise and vibration can pose problems, particularly in urban or sensitive environments. Mitigating these issues often requires additional engineering solutions, such as sound enclosures or vibration dampening systems, which can increase project costs and complexity.

The corrosive nature of some extracted vapors presents another challenge for vacuum pump systems. Exposure to acidic or reactive compounds can accelerate wear on pump components, necessitating the use of specialized materials or protective coatings. This not only increases equipment costs but also requires more frequent maintenance and replacement of parts.

Scaling vacuum pump systems for different project sizes and contaminant types is another significant challenge. Remediation projects can vary widely in scope, from small localized contaminations to large industrial sites. Designing flexible and modular vacuum systems that can be easily adapted to different project requirements while maintaining optimal performance is an ongoing area of development in the field.

Lastly, the integration of vacuum pumps with other remediation technologies, such as thermal treatment or chemical oxidation, presents both opportunities and challenges. While combined approaches can enhance overall remediation effectiveness, they also introduce additional complexity in system design, operation, and control. Balancing the requirements of different treatment methods with the capabilities of vacuum extraction systems requires careful engineering and ongoing optimization.

Current Vacuum-Assisted Methods

01 Vacuum-assisted soil remediation systems

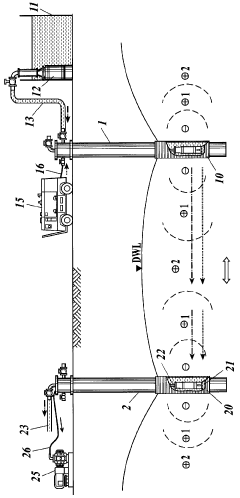

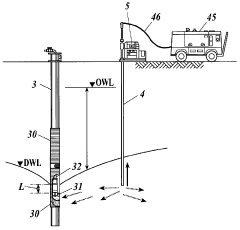

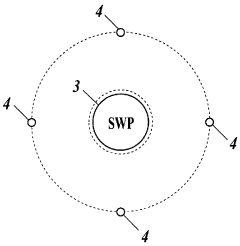

These systems use vacuum pumps to extract contaminants from soil. The vacuum creates a pressure gradient that draws volatile organic compounds and other pollutants out of the soil. This method is particularly effective for removing volatile and semi-volatile organic compounds from contaminated sites.- Vacuum-assisted soil remediation systems: These systems use vacuum pumps to extract contaminants from soil. The vacuum creates a pressure gradient that draws volatile compounds and soil vapors through extraction wells. This method is effective for removing various organic pollutants and can be combined with other treatment technologies for enhanced remediation.

- Multi-phase extraction for soil and groundwater cleanup: This technique employs vacuum pumps to simultaneously extract contaminated groundwater, separate phase liquids, and soil vapors. It's particularly useful for sites with complex contamination profiles, allowing for the removal of both dissolved and vapor-phase contaminants in a single process.

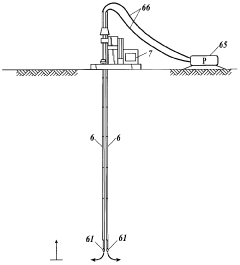

- In-situ thermal desorption with vacuum extraction: This method combines soil heating with vacuum extraction to remove contaminants. Heat is applied to the soil to increase the volatility of pollutants, while vacuum pumps extract the vaporized contaminants. This approach is effective for treating soils contaminated with semi-volatile and non-volatile organic compounds.

- Portable vacuum-based soil remediation equipment: Portable systems incorporating vacuum pumps for on-site soil remediation have been developed. These units can be easily transported to contaminated sites, allowing for flexible and cost-effective treatment of smaller areas or for use in remote locations where large-scale equipment is impractical.

- Integration of vacuum pumps with bioremediation processes: This approach combines vacuum extraction with biological treatment methods. Vacuum pumps are used to create aerobic conditions in the soil, stimulating microbial activity and enhancing the biodegradation of contaminants. This integrated method can be particularly effective for treating petroleum hydrocarbons and other biodegradable pollutants.

02 Multi-phase extraction for soil and groundwater remediation

This technique combines vacuum extraction with groundwater pumping to simultaneously remove contaminants from both soil and groundwater. The vacuum pump creates a negative pressure to extract soil vapors, while also lowering the water table to expose more contaminated soil to air flow.Expand Specific Solutions03 In-situ thermal desorption with vacuum extraction

This method involves heating the contaminated soil in place and using vacuum pumps to extract the vaporized contaminants. The heat increases the volatility of pollutants, making them easier to remove through vacuum extraction. This approach is effective for treating a wide range of organic contaminants.Expand Specific Solutions04 Portable vacuum-based soil remediation equipment

These are mobile units that incorporate vacuum pumps for on-site soil remediation. They can be easily transported to different contaminated sites, offering flexibility in treatment locations. These units often include filtration systems to clean the extracted vapors before release.Expand Specific Solutions05 Vacuum-enhanced bioremediation for soil treatment

This approach combines vacuum extraction with bioremediation techniques. The vacuum system is used to create aerobic conditions in the soil, promoting the growth of microorganisms that can break down contaminants. It may also involve the injection of nutrients or oxygen to further enhance microbial activity.Expand Specific Solutions

Innovative Vacuum Technologies

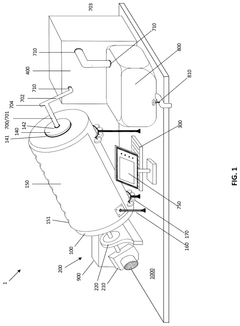

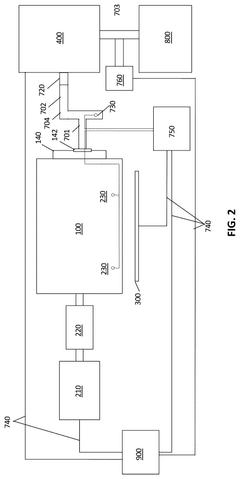

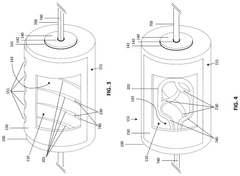

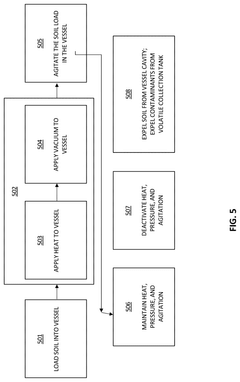

- A system comprising a vessel with an agitation source, a heat source, and a vacuum pump that applies heat, pressure, and agitation to the contaminated soil to volatilize contaminants, which are then removed using a vacuum pump and collected in a separate tank.

- The method involves installing two wells at a predetermined interval, where one well supplies water and air to the ground through a strainer, and the other well uses a vacuum pump to suck up water and air, creating a negative pressure effect that improves permeability and reduces well loss, while small wells with air pressure are used to create water paths and enhance apparent hydraulic conductivity.

Environmental Regulations

Environmental regulations play a crucial role in shaping the landscape of soil remediation technologies, including those utilizing vacuum pumps. These regulations are designed to protect human health and the environment by setting standards for soil quality and remediation processes. In the context of vacuum pump-enhanced soil remediation, regulatory frameworks often dictate the acceptable levels of contaminants in soil, the methods used for remediation, and the disposal of extracted pollutants.

Many countries have established comprehensive environmental protection agencies that oversee soil remediation efforts. For instance, the United States Environmental Protection Agency (EPA) has set forth guidelines under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), also known as Superfund. These regulations provide a framework for identifying, assessing, and cleaning up contaminated sites, often involving advanced technologies such as vacuum-enhanced remediation.

The implementation of vacuum pump technologies in soil remediation must adhere to specific regulatory requirements. These may include obtaining necessary permits, conducting environmental impact assessments, and ensuring that the remediation process does not cause further harm to the environment. Regulations often mandate regular monitoring and reporting of soil and groundwater quality during and after the remediation process to verify its effectiveness and compliance with established standards.

In Europe, the European Union's Environmental Liability Directive (ELD) sets the framework for soil protection and remediation. This directive emphasizes the "polluter pays" principle and encourages the use of innovative technologies, including vacuum-enhanced methods, to achieve efficient and cost-effective soil cleanup. Member states are required to implement these directives into their national legislation, leading to a harmonized approach across the EU.

Regulatory bodies also focus on the proper handling and disposal of contaminants extracted during the remediation process. Vacuum pump systems often extract a mixture of soil vapors, liquids, and sometimes solid particles, which may contain hazardous substances. Strict guidelines govern the treatment, storage, and disposal of these extracted materials to prevent secondary contamination and ensure environmental safety.

As environmental awareness grows and scientific understanding of soil contamination improves, regulations continue to evolve. This dynamic regulatory landscape drives innovation in soil remediation technologies, pushing for more efficient, less invasive, and environmentally friendly methods. Vacuum pump-enhanced soil remediation technologies must adapt to these changing regulations, often leading to improvements in pump design, extraction efficiency, and overall system performance.

Cost-Benefit Analysis

The implementation of vacuum pump technology in soil remediation processes offers significant cost-benefit advantages over traditional methods. Initial investment costs for vacuum pump systems are typically higher than conventional remediation techniques. However, the long-term operational efficiency and effectiveness of vacuum-enhanced remediation often result in substantial cost savings and improved outcomes.

Vacuum pumps accelerate the soil remediation process by creating negative pressure gradients that facilitate the extraction of contaminants. This increased efficiency translates to shorter project timelines, reducing overall labor costs and minimizing site disruption. The expedited cleanup process also allows for quicker land redevelopment, potentially generating faster returns on investment for property owners.

Energy consumption is a key factor in the cost-benefit analysis of vacuum pump systems. While these pumps require electricity to operate, their targeted approach often results in lower overall energy usage compared to more extensive excavation or chemical treatment methods. The precise control offered by vacuum systems allows for optimized energy utilization, focusing remediation efforts on specific contaminated areas.

Maintenance costs for vacuum pump systems are generally moderate, with routine servicing and occasional part replacements necessary to ensure optimal performance. However, these costs are often offset by the reduced need for consumables and chemicals associated with alternative remediation techniques. The durability and reliability of modern vacuum pumps contribute to extended operational lifespans, further enhancing their long-term cost-effectiveness.

Environmental benefits of vacuum-enhanced soil remediation also factor into the cost-benefit equation. The technology's ability to minimize site disturbance and reduce the volume of contaminated soil requiring off-site disposal can lead to significant cost savings in transportation and landfill fees. Additionally, the reduced environmental impact may result in fewer regulatory compliance issues and associated costs.

The versatility of vacuum pump systems in addressing various contaminants and soil types adds to their cost-benefit profile. This adaptability often eliminates the need for multiple specialized remediation techniques, potentially reducing equipment and training costs for remediation companies. The ability to tackle a wide range of pollutants with a single system enhances operational efficiency and project management.

In conclusion, while the initial capital expenditure for vacuum pump systems in soil remediation may be higher, the long-term benefits often outweigh the costs. Factors such as accelerated cleanup times, reduced energy consumption, lower maintenance requirements, and environmental advantages contribute to a favorable cost-benefit analysis for this technology in many soil remediation scenarios.