Investigating Vacuum Pump Utilization in Quantum Sensing Instruments

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Sensing Vacuum Requirements

Quantum sensing instruments rely heavily on precise vacuum conditions to maintain their delicate quantum states and ensure accurate measurements. The vacuum requirements for these instruments are stringent and play a crucial role in their performance and reliability.

In quantum sensing applications, ultra-high vacuum (UHV) conditions are often necessary to minimize interactions between the quantum system and its environment. Typical pressure ranges for quantum sensing instruments fall between 10^-9 and 10^-12 mbar, depending on the specific application and sensitivity requirements. Achieving and maintaining such low pressures demands sophisticated vacuum pump systems and careful design considerations.

The primary reasons for requiring such extreme vacuum conditions in quantum sensing instruments include reducing collisions between gas molecules and the quantum system, minimizing thermal noise, and preventing contamination of sensitive surfaces. These factors are critical for preserving quantum coherence and maintaining the integrity of the quantum states used for sensing.

Vacuum pump systems for quantum sensing instruments typically employ a combination of different pump types to achieve the desired vacuum levels. This may include roughing pumps for initial evacuation, turbomolecular pumps for reaching high vacuum, and ion pumps or cryopumps for achieving and maintaining ultra-high vacuum conditions. The selection and configuration of these pumps must be carefully optimized to meet the specific requirements of each quantum sensing application.

In addition to achieving low pressures, the stability and cleanliness of the vacuum environment are equally important. Fluctuations in pressure or the presence of contaminants can introduce noise and errors in quantum measurements. Therefore, vacuum systems for quantum sensing often incorporate advanced pressure control mechanisms, getter materials for removing residual gases, and specialized materials and coatings to minimize outgassing and contamination.

The design of vacuum chambers and components for quantum sensing instruments requires careful consideration of materials, surface treatments, and sealing techniques. Low-outgassing materials such as stainless steel, titanium, or specialized alloys are commonly used. Surface treatments like electropolishing or chemical cleaning may be employed to reduce outgassing and improve vacuum performance. High-quality vacuum seals, such as ConFlat flanges or metal seals, are essential for maintaining ultra-high vacuum conditions over extended periods.

As quantum sensing technologies continue to advance, the demands on vacuum systems are likely to become even more stringent. Future developments may include the integration of cryogenic systems with vacuum technology to achieve even lower pressures and temperatures, as well as the development of novel materials and pumping techniques specifically tailored for quantum sensing applications.

In quantum sensing applications, ultra-high vacuum (UHV) conditions are often necessary to minimize interactions between the quantum system and its environment. Typical pressure ranges for quantum sensing instruments fall between 10^-9 and 10^-12 mbar, depending on the specific application and sensitivity requirements. Achieving and maintaining such low pressures demands sophisticated vacuum pump systems and careful design considerations.

The primary reasons for requiring such extreme vacuum conditions in quantum sensing instruments include reducing collisions between gas molecules and the quantum system, minimizing thermal noise, and preventing contamination of sensitive surfaces. These factors are critical for preserving quantum coherence and maintaining the integrity of the quantum states used for sensing.

Vacuum pump systems for quantum sensing instruments typically employ a combination of different pump types to achieve the desired vacuum levels. This may include roughing pumps for initial evacuation, turbomolecular pumps for reaching high vacuum, and ion pumps or cryopumps for achieving and maintaining ultra-high vacuum conditions. The selection and configuration of these pumps must be carefully optimized to meet the specific requirements of each quantum sensing application.

In addition to achieving low pressures, the stability and cleanliness of the vacuum environment are equally important. Fluctuations in pressure or the presence of contaminants can introduce noise and errors in quantum measurements. Therefore, vacuum systems for quantum sensing often incorporate advanced pressure control mechanisms, getter materials for removing residual gases, and specialized materials and coatings to minimize outgassing and contamination.

The design of vacuum chambers and components for quantum sensing instruments requires careful consideration of materials, surface treatments, and sealing techniques. Low-outgassing materials such as stainless steel, titanium, or specialized alloys are commonly used. Surface treatments like electropolishing or chemical cleaning may be employed to reduce outgassing and improve vacuum performance. High-quality vacuum seals, such as ConFlat flanges or metal seals, are essential for maintaining ultra-high vacuum conditions over extended periods.

As quantum sensing technologies continue to advance, the demands on vacuum systems are likely to become even more stringent. Future developments may include the integration of cryogenic systems with vacuum technology to achieve even lower pressures and temperatures, as well as the development of novel materials and pumping techniques specifically tailored for quantum sensing applications.

Market Analysis for Quantum Sensing Instruments

The quantum sensing instruments market is experiencing rapid growth, driven by advancements in quantum technologies and increasing demand for high-precision measurements across various industries. This market segment is expected to expand significantly in the coming years, with applications ranging from healthcare and environmental monitoring to defense and aerospace.

The global quantum sensing market is projected to grow at a substantial rate, fueled by investments from both public and private sectors. Key factors contributing to this growth include the rising need for accurate and sensitive measurement tools in scientific research, the development of quantum-based navigation systems, and the potential for quantum sensors in medical diagnostics.

In the healthcare sector, quantum sensing instruments are gaining traction for their ability to detect minute changes in biological systems, potentially revolutionizing early disease detection and drug discovery processes. The environmental monitoring field is also adopting quantum sensors for their superior sensitivity in detecting pollutants and measuring atmospheric conditions.

The defense and aerospace industries are major drivers of the quantum sensing market, with applications in secure communication, submarine detection, and enhanced navigation systems. These sectors are investing heavily in quantum technologies to maintain technological superiority and enhance national security capabilities.

Geographically, North America and Europe are leading the quantum sensing instruments market, with established research institutions and tech companies driving innovation. However, Asia-Pacific is emerging as a significant player, with countries like China and Japan making substantial investments in quantum technologies.

The market for quantum sensing instruments is characterized by a mix of established tech giants and innovative startups. Major players are focusing on developing more compact, efficient, and cost-effective quantum sensors to broaden their application range and market appeal.

Challenges in the market include the high cost of quantum sensing instruments, the need for specialized expertise to operate these devices, and the current limitations in scalability. However, ongoing research and development efforts are addressing these issues, with promising advancements in miniaturization and user-friendly interfaces.

As the technology matures and becomes more accessible, new market opportunities are expected to emerge in sectors such as telecommunications, finance, and smart city infrastructure. The integration of quantum sensors with existing technologies, such as IoT devices and AI systems, is likely to create novel applications and drive further market expansion.

The global quantum sensing market is projected to grow at a substantial rate, fueled by investments from both public and private sectors. Key factors contributing to this growth include the rising need for accurate and sensitive measurement tools in scientific research, the development of quantum-based navigation systems, and the potential for quantum sensors in medical diagnostics.

In the healthcare sector, quantum sensing instruments are gaining traction for their ability to detect minute changes in biological systems, potentially revolutionizing early disease detection and drug discovery processes. The environmental monitoring field is also adopting quantum sensors for their superior sensitivity in detecting pollutants and measuring atmospheric conditions.

The defense and aerospace industries are major drivers of the quantum sensing market, with applications in secure communication, submarine detection, and enhanced navigation systems. These sectors are investing heavily in quantum technologies to maintain technological superiority and enhance national security capabilities.

Geographically, North America and Europe are leading the quantum sensing instruments market, with established research institutions and tech companies driving innovation. However, Asia-Pacific is emerging as a significant player, with countries like China and Japan making substantial investments in quantum technologies.

The market for quantum sensing instruments is characterized by a mix of established tech giants and innovative startups. Major players are focusing on developing more compact, efficient, and cost-effective quantum sensors to broaden their application range and market appeal.

Challenges in the market include the high cost of quantum sensing instruments, the need for specialized expertise to operate these devices, and the current limitations in scalability. However, ongoing research and development efforts are addressing these issues, with promising advancements in miniaturization and user-friendly interfaces.

As the technology matures and becomes more accessible, new market opportunities are expected to emerge in sectors such as telecommunications, finance, and smart city infrastructure. The integration of quantum sensors with existing technologies, such as IoT devices and AI systems, is likely to create novel applications and drive further market expansion.

Vacuum Pump Technology in Quantum Sensing

Vacuum pump technology plays a crucial role in quantum sensing instruments, providing the necessary ultra-high vacuum environment for precise measurements and manipulations at the quantum level. The evolution of vacuum pump technology has been closely intertwined with advancements in quantum sensing, as researchers continually push the boundaries of what is possible in quantum experiments.

The development of vacuum pump technology for quantum sensing can be traced back to the early 20th century, with the invention of mechanical pumps. These pumps, while effective for creating low-pressure environments, were limited in their ability to achieve the ultra-high vacuum levels required for quantum experiments. The breakthrough came with the introduction of diffusion pumps in the 1920s, which could achieve much lower pressures and became a staple in quantum research laboratories.

As quantum sensing techniques became more sophisticated, the demand for even higher vacuum levels grew. This led to the development of turbomolecular pumps in the 1950s, which offered significant improvements in vacuum quality and pumping speed. These pumps quickly became essential tools in quantum sensing applications, enabling researchers to conduct experiments with unprecedented precision.

The 1980s and 1990s saw the emergence of ion pumps and cryogenic pumps, which further expanded the capabilities of vacuum systems in quantum sensing. Ion pumps, in particular, proved invaluable for maintaining stable ultra-high vacuum conditions over extended periods, a critical requirement for many quantum sensing experiments.

In recent years, the focus has shifted towards developing more compact and efficient vacuum pump systems to support the miniaturization of quantum sensing devices. This trend has led to innovations such as micro-engineered vacuum pumps and integrated vacuum systems, which are particularly relevant for portable quantum sensors and field-deployable quantum technologies.

The current state-of-the-art in vacuum pump technology for quantum sensing includes advanced combinations of turbomolecular pumps, ion pumps, and cryogenic pumps, often working in tandem to achieve and maintain the extreme vacuum levels required. These systems are capable of reaching pressures as low as 10^-12 mbar, providing an almost particle-free environment for quantum experiments.

Looking ahead, the trajectory of vacuum pump technology in quantum sensing is likely to continue towards greater integration, efficiency, and specialization. Researchers are exploring novel pumping mechanisms, such as those based on atomic and molecular interactions, which could potentially revolutionize vacuum generation and maintenance in quantum sensing instruments. Additionally, the development of smart vacuum systems that can dynamically adjust to the specific requirements of different quantum experiments is an area of active research and development.

The development of vacuum pump technology for quantum sensing can be traced back to the early 20th century, with the invention of mechanical pumps. These pumps, while effective for creating low-pressure environments, were limited in their ability to achieve the ultra-high vacuum levels required for quantum experiments. The breakthrough came with the introduction of diffusion pumps in the 1920s, which could achieve much lower pressures and became a staple in quantum research laboratories.

As quantum sensing techniques became more sophisticated, the demand for even higher vacuum levels grew. This led to the development of turbomolecular pumps in the 1950s, which offered significant improvements in vacuum quality and pumping speed. These pumps quickly became essential tools in quantum sensing applications, enabling researchers to conduct experiments with unprecedented precision.

The 1980s and 1990s saw the emergence of ion pumps and cryogenic pumps, which further expanded the capabilities of vacuum systems in quantum sensing. Ion pumps, in particular, proved invaluable for maintaining stable ultra-high vacuum conditions over extended periods, a critical requirement for many quantum sensing experiments.

In recent years, the focus has shifted towards developing more compact and efficient vacuum pump systems to support the miniaturization of quantum sensing devices. This trend has led to innovations such as micro-engineered vacuum pumps and integrated vacuum systems, which are particularly relevant for portable quantum sensors and field-deployable quantum technologies.

The current state-of-the-art in vacuum pump technology for quantum sensing includes advanced combinations of turbomolecular pumps, ion pumps, and cryogenic pumps, often working in tandem to achieve and maintain the extreme vacuum levels required. These systems are capable of reaching pressures as low as 10^-12 mbar, providing an almost particle-free environment for quantum experiments.

Looking ahead, the trajectory of vacuum pump technology in quantum sensing is likely to continue towards greater integration, efficiency, and specialization. Researchers are exploring novel pumping mechanisms, such as those based on atomic and molecular interactions, which could potentially revolutionize vacuum generation and maintenance in quantum sensing instruments. Additionally, the development of smart vacuum systems that can dynamically adjust to the specific requirements of different quantum experiments is an area of active research and development.

Current Vacuum Solutions for Quantum Sensing

01 Improved vacuum pump designs

Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include modifications to rotor configurations, sealing mechanisms, or the integration of advanced materials to optimize pump operation.- Improved vacuum pump designs: Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include modifications to rotor configurations, sealing mechanisms, or the integration of advanced materials to optimize pump operation.

- Energy-efficient vacuum pump systems: Development of energy-efficient vacuum pump systems focuses on reducing power consumption while maintaining high performance. These systems may incorporate variable speed drives, intelligent control algorithms, or heat recovery mechanisms to minimize energy usage and operational costs.

- Vacuum pump cooling and lubrication: Advancements in cooling and lubrication systems for vacuum pumps aim to improve reliability and extend operational life. These innovations may include novel cooling methods, advanced lubricant formulations, or integrated temperature management systems to prevent overheating and reduce wear.

- Multi-stage vacuum pump configurations: Multi-stage vacuum pump designs combine different pump types or stages to achieve higher vacuum levels or improved pumping speeds. These configurations may integrate various pump technologies, such as rotary vane, scroll, or turbomolecular pumps, to optimize performance across a wide range of pressure conditions.

- Vacuum pump control and monitoring systems: Advanced control and monitoring systems for vacuum pumps enhance operational efficiency and facilitate predictive maintenance. These systems may incorporate sensors, data analytics, and remote monitoring capabilities to optimize pump performance, detect potential issues, and reduce downtime.

02 Vacuum pump control systems

Advanced control systems for vacuum pumps focus on optimizing operation, energy efficiency, and performance. These systems may incorporate sensors, microprocessors, and algorithms to adjust pump parameters based on real-time conditions and requirements.Expand Specific Solutions03 Specialized vacuum pumps for specific applications

Vacuum pumps designed for particular industries or applications, such as semiconductor manufacturing, medical devices, or food processing. These pumps may have unique features or materials to meet specific requirements like cleanliness, chemical resistance, or precision control.Expand Specific Solutions04 Energy-efficient vacuum pump technologies

Innovations focused on reducing energy consumption in vacuum pumps, including the use of variable speed drives, regenerative designs, or heat recovery systems. These technologies aim to minimize operational costs and environmental impact while maintaining performance.Expand Specific Solutions05 Maintenance and monitoring systems for vacuum pumps

Development of systems and methods for predictive maintenance, condition monitoring, and diagnostics of vacuum pumps. These may include sensors, data analysis tools, and remote monitoring capabilities to optimize pump performance and reduce downtime.Expand Specific Solutions

Key Vacuum Pump Manufacturers and Quantum Instrument Makers

The quantum sensing instruments market is in its early growth stage, characterized by rapid technological advancements and increasing applications across various industries. The market size is expanding, driven by growing demand for high-precision measurement tools in fields such as healthcare, defense, and telecommunications. While the technology is still evolving, companies like Edwards Ltd., Pfeiffer Vacuum GmbH, and Applied Materials, Inc. are at the forefront of vacuum pump development for quantum sensing applications. These firms are investing heavily in R&D to improve pump efficiency and reliability, crucial for maintaining the ultra-high vacuum environments required in quantum sensing instruments. The competitive landscape is intensifying as both established players and innovative startups vie for market share in this promising sector.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for quantum sensing instruments. Their approach focuses on ultra-high vacuum (UHV) systems that can achieve pressures as low as 10^-12 mbar [1]. These pumps utilize a combination of turbomolecular and ion pumping techniques to create and maintain the extreme vacuum conditions required for sensitive quantum measurements. Edwards' pumps incorporate advanced materials and coatings to minimize outgassing and contamination, ensuring the purity of the vacuum environment. They have also implemented intelligent control systems that can dynamically adjust pumping speeds and pressures to optimize performance for different quantum sensing applications [3].

Strengths: Expertise in UHV systems, advanced materials for contamination control, and intelligent pump control. Weaknesses: High cost of specialized equipment, potential complexity in operation and maintenance for non-expert users.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed a range of vacuum solutions specifically designed for quantum sensing instruments. Their approach includes the use of hybrid pumping systems that combine turbomolecular pumps with backing pumps to achieve high vacuum levels quickly and efficiently. Pfeiffer's pumps feature advanced rotor designs that minimize vibration, which is crucial for maintaining the stability of quantum sensors [2]. They have also implemented innovative sealing technologies to prevent leaks and maintain vacuum integrity over extended periods. Pfeiffer's pumps are equipped with smart monitoring systems that provide real-time data on pump performance and vacuum quality, allowing for predictive maintenance and optimization of quantum sensing experiments [4].

Strengths: Low-vibration pump designs, smart monitoring systems, and efficient hybrid pumping technology. Weaknesses: May require specialized training for optimal use, potentially higher initial investment compared to standard vacuum systems.

Innovative Vacuum Technologies for Quantum Instruments

Vacuum pump

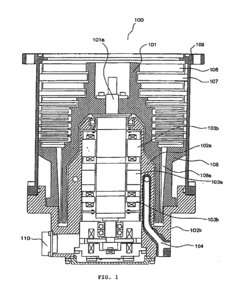

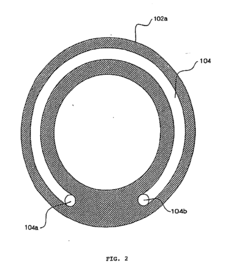

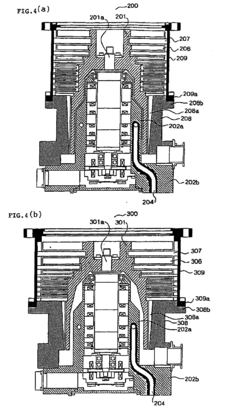

PatentInactiveEP2228539A2

Innovation

- A vacuum pump design with a cooling water pipe buried in the stator column, allowing for localized cooling of the electrical equipment section and common component usage across different sizes and shapes, reducing overheating risks and manufacturing costs.

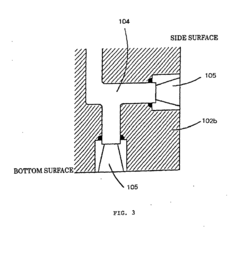

Vacuum pump

PatentWO2011058339A2

Innovation

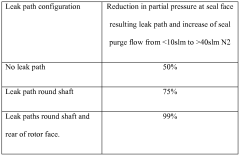

- An additional leakage path is created away from the seal arrangement to divert back-leaked gas, reducing contact with the seal lip and prolonging its life without significantly increasing nitrogen flow rates, utilizing annular grooves in the rotor, transverse wall, or shaft to provide a less restrictive flow path for gas.

Cryogenic Integration in Quantum Sensing Vacuum Systems

The integration of cryogenic systems in quantum sensing vacuum environments represents a critical advancement in the field of quantum technology. This synergy between ultra-low temperatures and high vacuum conditions creates an ideal environment for quantum sensors to operate with unprecedented precision and sensitivity. Cryogenic integration in these systems typically involves the use of specialized materials and components that can withstand extreme cold while maintaining vacuum integrity.

One of the primary challenges in cryogenic integration is the selection of appropriate materials that exhibit low outgassing properties at cryogenic temperatures. Common materials used in vacuum systems, such as certain plastics and elastomers, may become brittle or release trapped gases when cooled to extremely low temperatures. This necessitates the use of specially engineered materials, such as cryogenic-grade stainless steel, copper, and certain ceramics, which maintain their structural integrity and vacuum-compatible properties at temperatures approaching absolute zero.

The design of cryogenic vacuum chambers for quantum sensing applications requires careful consideration of thermal management. Heat shields and multi-layer insulation (MLI) are often employed to minimize radiative heat transfer between the cryogenic components and the surrounding environment. Additionally, the implementation of efficient thermal anchoring techniques ensures proper cooling of critical components while minimizing heat loads on the cryogenic system.

Vacuum pumps used in cryogenic quantum sensing systems must be capable of operating effectively at low temperatures. Cryopumps, which utilize extremely cold surfaces to condense and trap gases, are particularly well-suited for these applications. These pumps can achieve ultra-high vacuum levels and maintain them over extended periods, which is crucial for many quantum sensing experiments.

The integration of cryogenic and vacuum technologies also extends to the sensor instrumentation itself. Quantum sensors, such as superconducting quantum interference devices (SQUIDs) or nitrogen-vacancy (NV) centers in diamond, often require operation at cryogenic temperatures to achieve optimal performance. This necessitates the development of specialized cryogenic feedthroughs and wiring solutions that can transmit signals between the cold sensor environment and room-temperature electronics while minimizing heat leakage.

Advancements in cryogenic integration for quantum sensing vacuum systems have led to the development of compact, closed-cycle cryocoolers that can achieve and maintain the required low temperatures without the need for liquid cryogens. These systems offer increased operational flexibility and reduced maintenance requirements, making quantum sensing technologies more accessible for a wider range of applications.

One of the primary challenges in cryogenic integration is the selection of appropriate materials that exhibit low outgassing properties at cryogenic temperatures. Common materials used in vacuum systems, such as certain plastics and elastomers, may become brittle or release trapped gases when cooled to extremely low temperatures. This necessitates the use of specially engineered materials, such as cryogenic-grade stainless steel, copper, and certain ceramics, which maintain their structural integrity and vacuum-compatible properties at temperatures approaching absolute zero.

The design of cryogenic vacuum chambers for quantum sensing applications requires careful consideration of thermal management. Heat shields and multi-layer insulation (MLI) are often employed to minimize radiative heat transfer between the cryogenic components and the surrounding environment. Additionally, the implementation of efficient thermal anchoring techniques ensures proper cooling of critical components while minimizing heat loads on the cryogenic system.

Vacuum pumps used in cryogenic quantum sensing systems must be capable of operating effectively at low temperatures. Cryopumps, which utilize extremely cold surfaces to condense and trap gases, are particularly well-suited for these applications. These pumps can achieve ultra-high vacuum levels and maintain them over extended periods, which is crucial for many quantum sensing experiments.

The integration of cryogenic and vacuum technologies also extends to the sensor instrumentation itself. Quantum sensors, such as superconducting quantum interference devices (SQUIDs) or nitrogen-vacancy (NV) centers in diamond, often require operation at cryogenic temperatures to achieve optimal performance. This necessitates the development of specialized cryogenic feedthroughs and wiring solutions that can transmit signals between the cold sensor environment and room-temperature electronics while minimizing heat leakage.

Advancements in cryogenic integration for quantum sensing vacuum systems have led to the development of compact, closed-cycle cryocoolers that can achieve and maintain the required low temperatures without the need for liquid cryogens. These systems offer increased operational flexibility and reduced maintenance requirements, making quantum sensing technologies more accessible for a wider range of applications.

Quantum Sensing Vacuum Standards and Certifications

The development of quantum sensing instruments has led to increasingly stringent requirements for vacuum environments, necessitating the establishment of comprehensive standards and certifications. These standards ensure the reliability, consistency, and comparability of quantum sensing measurements across different laboratories and applications.

International organizations, such as the International Organization for Standardization (ISO) and the National Institute of Standards and Technology (NIST), have been at the forefront of developing vacuum standards applicable to quantum sensing. The ISO 3529 series, for instance, provides guidelines for pressure measurements in the range relevant to many quantum sensing applications.

Specific to quantum sensing, vacuum standards often focus on ultra-high vacuum (UHV) and extreme-high vacuum (XHV) conditions. These standards typically define acceptable pressure ranges, outgassing rates, and leak rates for various components used in quantum sensing instruments. They also outline procedures for vacuum system bakeout, residual gas analysis, and long-term stability measurements.

Certification processes for vacuum systems in quantum sensing instruments often involve rigorous testing and documentation. This includes verifying the performance of vacuum pumps, gauges, and other components under various operating conditions. Manufacturers of quantum sensing equipment must demonstrate compliance with these standards to ensure their products meet the exacting requirements of the scientific community.

One critical aspect of vacuum standards for quantum sensing is the characterization of background noise and interference sources. This includes specifications for electromagnetic shielding, vibration isolation, and thermal stability, all of which can significantly impact the performance of quantum sensors operating in vacuum environments.

Traceability to primary vacuum standards is another key consideration. National metrology institutes maintain primary vacuum standards, which serve as reference points for calibrating secondary standards and commercial vacuum gauges. This traceability chain ensures that vacuum measurements in quantum sensing applications are consistent and comparable across different facilities and countries.

As quantum sensing technology continues to advance, vacuum standards and certifications are evolving to keep pace. New standards are being developed to address emerging challenges, such as the need for even lower pressures, improved cleanliness, and enhanced long-term stability in vacuum systems. These standards will play a crucial role in enabling the next generation of quantum sensing instruments and applications.

International organizations, such as the International Organization for Standardization (ISO) and the National Institute of Standards and Technology (NIST), have been at the forefront of developing vacuum standards applicable to quantum sensing. The ISO 3529 series, for instance, provides guidelines for pressure measurements in the range relevant to many quantum sensing applications.

Specific to quantum sensing, vacuum standards often focus on ultra-high vacuum (UHV) and extreme-high vacuum (XHV) conditions. These standards typically define acceptable pressure ranges, outgassing rates, and leak rates for various components used in quantum sensing instruments. They also outline procedures for vacuum system bakeout, residual gas analysis, and long-term stability measurements.

Certification processes for vacuum systems in quantum sensing instruments often involve rigorous testing and documentation. This includes verifying the performance of vacuum pumps, gauges, and other components under various operating conditions. Manufacturers of quantum sensing equipment must demonstrate compliance with these standards to ensure their products meet the exacting requirements of the scientific community.

One critical aspect of vacuum standards for quantum sensing is the characterization of background noise and interference sources. This includes specifications for electromagnetic shielding, vibration isolation, and thermal stability, all of which can significantly impact the performance of quantum sensors operating in vacuum environments.

Traceability to primary vacuum standards is another key consideration. National metrology institutes maintain primary vacuum standards, which serve as reference points for calibrating secondary standards and commercial vacuum gauges. This traceability chain ensures that vacuum measurements in quantum sensing applications are consistent and comparable across different facilities and countries.

As quantum sensing technology continues to advance, vacuum standards and certifications are evolving to keep pace. New standards are being developed to address emerging challenges, such as the need for even lower pressures, improved cleanliness, and enhanced long-term stability in vacuum systems. These standards will play a crucial role in enabling the next generation of quantum sensing instruments and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!