Vacuum Pumps in the Synthesis of High-Performance Glass Ceramics

Vacuum Pump Tech Evolution

The evolution of vacuum pump technology in the context of high-performance glass ceramics synthesis has been marked by significant advancements over the past decades. Initially, basic mechanical pumps were employed to create low-pressure environments for material processing. These early pumps, while effective for rudimentary applications, lacked the precision and efficiency required for advanced ceramic production.

As the demand for higher-quality glass ceramics grew, the 1960s and 1970s saw the introduction of oil-sealed rotary vane pumps. These pumps offered improved vacuum levels and greater reliability, enabling more controlled synthesis processes. However, the potential for oil contamination remained a concern in high-purity applications.

The 1980s brought about a revolution with the development of oil-free dry pumps. These pumps, utilizing scroll and diaphragm technologies, eliminated the risk of oil contamination and provided cleaner vacuum environments. This innovation was particularly crucial for the synthesis of optical glass ceramics, where purity is paramount.

In the 1990s, turbomolecular pumps gained prominence in glass ceramic synthesis. These high-speed pumps could achieve ultra-high vacuum levels, allowing for more precise control over the material composition and structure. The integration of turbomolecular pumps with backing pumps created powerful vacuum systems capable of maintaining stable low-pressure environments for extended periods.

The turn of the millennium saw the advent of magnetically levitated turbo pumps, which offered even higher pumping speeds and lower vibration. This technology proved invaluable for the production of large-scale glass ceramic components with exceptional uniformity and performance characteristics.

Recent years have witnessed the rise of smart vacuum systems, incorporating advanced sensors and control algorithms. These systems can dynamically adjust pumping parameters based on real-time process conditions, optimizing energy efficiency and product quality. The integration of Industry 4.0 principles has further enhanced the capabilities of vacuum pumps in glass ceramic synthesis, enabling remote monitoring and predictive maintenance.

Looking ahead, the future of vacuum pump technology in high-performance glass ceramics synthesis is likely to focus on further improvements in energy efficiency, miniaturization, and integration with other process technologies. Emerging trends include the development of hybrid pump systems that combine multiple pumping mechanisms for optimal performance across different pressure ranges, as well as the exploration of novel materials and designs to enhance pump durability and reduce maintenance requirements.

Glass Ceramics Market Demand

The glass ceramics market has been experiencing significant growth in recent years, driven by the increasing demand for high-performance materials in various industries. The global glass ceramics market size was valued at USD 1.6 billion in 2020 and is projected to reach USD 2.5 billion by 2027, growing at a CAGR of 6.8% during the forecast period.

One of the key factors contributing to the market demand for glass ceramics is their exceptional combination of properties, including high strength, low thermal expansion, excellent chemical resistance, and biocompatibility. These characteristics make glass ceramics ideal for applications in industries such as aerospace, electronics, healthcare, and construction.

In the aerospace sector, glass ceramics are increasingly being used in the manufacturing of components for aircraft engines, missile systems, and satellite mirrors due to their ability to withstand extreme temperatures and maintain dimensional stability. The growing investments in space exploration and satellite technology are expected to further boost the demand for high-performance glass ceramics in this sector.

The electronics industry is another major driver of glass ceramics market demand. With the rapid advancement of 5G technology and the Internet of Things (IoT), there is a growing need for materials that can provide excellent dielectric properties and thermal management in electronic devices. Glass ceramics are being utilized in the production of substrates for integrated circuits, microwave devices, and high-frequency applications.

In the healthcare sector, glass ceramics have gained significant traction in dental and orthopedic applications. The biocompatibility and aesthetic properties of glass ceramics make them an attractive choice for dental implants, crowns, and bridges. Additionally, their use in bone grafts and tissue engineering scaffolds is expanding, driven by the growing aging population and increasing demand for advanced medical treatments.

The construction industry is also contributing to the rising demand for glass ceramics. These materials are being used in the production of cooktops, fireplace windows, and architectural panels due to their thermal shock resistance and aesthetic appeal. The trend towards energy-efficient buildings and sustainable construction practices is expected to further drive the adoption of glass ceramics in this sector.

Geographically, Asia Pacific is anticipated to be the fastest-growing market for glass ceramics, driven by rapid industrialization, increasing investments in infrastructure development, and the growing electronics manufacturing sector in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with a strong presence of aerospace and healthcare industries driving demand for high-performance glass ceramics.

Vacuum Tech Challenges

The synthesis of high-performance glass ceramics presents several significant vacuum technology challenges. One of the primary issues is maintaining a consistent and high-quality vacuum environment throughout the entire production process. This is crucial for ensuring the purity and structural integrity of the final product. Contamination from atmospheric gases or other impurities can severely compromise the material properties of the glass ceramics, leading to defects, reduced strength, and poor optical characteristics.

Another major challenge lies in the precise control of pressure during different stages of synthesis. The formation of glass ceramics often involves complex phase transitions and crystallization processes, which are highly sensitive to pressure conditions. Vacuum pumps must be capable of providing stable and adjustable vacuum levels to accommodate these varying requirements. This demands sophisticated pump control systems and real-time monitoring capabilities.

The high temperatures involved in glass ceramic synthesis pose additional challenges for vacuum technology. Vacuum pumps and associated components must be able to withstand and operate efficiently under elevated temperature conditions. This necessitates the use of specialized materials and cooling systems to prevent degradation of pump performance or failure of vacuum seals.

Scaling up production from laboratory to industrial levels introduces further complications. Large-scale vacuum systems for glass ceramic synthesis must maintain uniform vacuum conditions across sizeable production chambers. This requires careful design of vacuum distribution networks and the implementation of multiple pump arrays to ensure even pressure distribution and rapid response to fluctuations.

Energy efficiency is another significant concern in vacuum technology for glass ceramic production. The continuous operation of high-capacity vacuum pumps consumes substantial amounts of energy. Developing more efficient pump designs and implementing intelligent control strategies to optimize pump operation based on process requirements are ongoing challenges in this field.

Lastly, the integration of vacuum technology with other aspects of glass ceramic synthesis, such as temperature control and material handling systems, presents complex engineering challenges. Ensuring seamless coordination between these various subsystems is critical for achieving consistent product quality and process efficiency. This requires advanced automation and control systems capable of managing multiple process parameters simultaneously while maintaining the integrity of the vacuum environment.

Current Vacuum Solutions

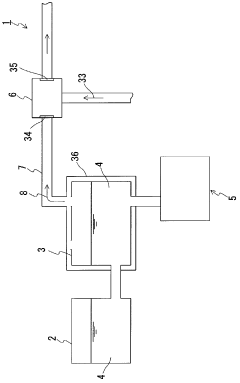

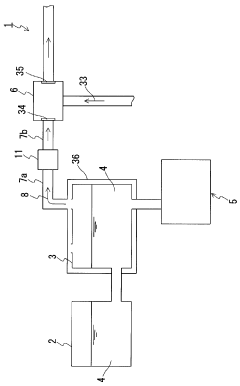

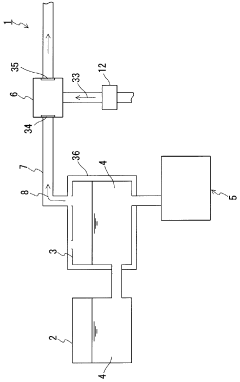

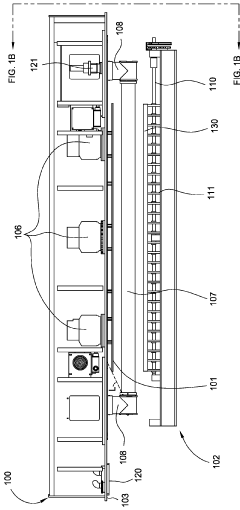

01 Improvements in vacuum pump design

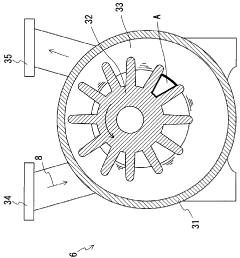

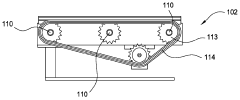

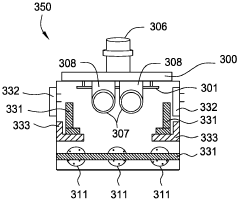

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.

- Vacuum pump applications in semiconductor manufacturing: Vacuum pumps play a crucial role in semiconductor manufacturing processes. Specialized pump designs have been developed to meet the stringent requirements of clean room environments and ultra-high vacuum conditions. These pumps are optimized for handling process gases, maintaining contamination-free environments, and supporting various stages of semiconductor fabrication.

- Historical developments in vacuum pump technology: The evolution of vacuum pump technology spans several decades, with numerous innovations contributing to improved performance and functionality. Historical patents showcase early designs and concepts that laid the foundation for modern vacuum pumps. These developments include advancements in mechanical pumps, diffusion pumps, and other vacuum-generating mechanisms.

- Vacuum pump control and monitoring systems: Advanced control and monitoring systems have been developed to optimize vacuum pump operation. These systems incorporate sensors, electronic controllers, and software algorithms to regulate pump speed, monitor vacuum levels, and manage overall system performance. Such innovations contribute to improved energy efficiency, reduced maintenance requirements, and enhanced process control in various industrial applications.

- Specialized vacuum pump designs for specific applications: Various specialized vacuum pump designs have been created to address the unique requirements of specific industries and applications. These include pumps optimized for medical devices, food packaging, aerospace testing, and scientific research. Such tailored designs incorporate features to handle specific gas compositions, achieve ultra-high vacuums, or operate in challenging environments.

02 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high cleanliness levels, and provide stable vacuum conditions. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.Expand Specific Solutions03 Energy-efficient vacuum pump systems

Innovations in vacuum pump technology have focused on improving energy efficiency. These developments include the use of variable speed drives, optimized motor designs, and intelligent control systems. Such advancements result in reduced power consumption, lower operating costs, and improved environmental sustainability of vacuum pump operations.Expand Specific Solutions04 Multi-stage vacuum pump configurations

Multi-stage vacuum pump designs have been created to achieve higher vacuum levels and improved pumping efficiency. These configurations typically combine different pump types or multiple pumping stages in series. This approach allows for better gas handling capabilities, wider operating pressure ranges, and enhanced overall system performance.Expand Specific Solutions05 Vacuum pump maintenance and monitoring systems

Advanced maintenance and monitoring systems have been developed for vacuum pumps to ensure optimal performance and longevity. These systems may include real-time condition monitoring, predictive maintenance algorithms, and remote diagnostics capabilities. Such innovations help reduce downtime, optimize maintenance schedules, and improve the overall reliability of vacuum pump operations.Expand Specific Solutions

Key Vacuum Pump Manufacturers

The vacuum pump market for high-performance glass ceramics synthesis is in a growth phase, driven by increasing demand for advanced materials in various industries. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is moderately mature but continues to evolve. Key players like Edwards Vacuum, Pfeiffer Vacuum, and BÜCHI Labortechnik are leading innovation, focusing on improving pump efficiency, reducing energy consumption, and enhancing process control. Emerging companies such as Mammoth Biosciences are also entering the market with novel approaches, potentially disrupting traditional vacuum technologies. The competitive landscape is characterized by a mix of established manufacturers and innovative startups, with increasing emphasis on R&D to meet the growing demands of high-performance glass ceramic production.

Edwards Vacuum LLC

SCHOTT AG

Innovative Vacuum Designs

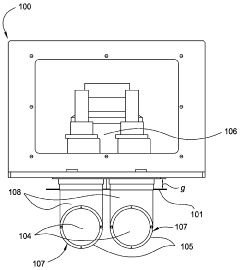

- A glass manufacturing apparatus employing a liquid ring pump to decompress the vacuum clarification section, which effectively reduces air bubbles by using a sealing liquid to suck and discharge gases, minimizing equipment complexity and preventing contamination damage.

- A pump baffle is placed between the sputter targets and the vacuum pump ports, creating a gap and overhang to prevent direct line of sight, manufactured from a planar metal sheet with sufficient thickness, and attached to the chamber lid, ensuring no direct path for sputtered material to reach the pumps, while maintaining a gap to minimize pumping non-uniformities.

Energy Efficiency in Pumps

Energy efficiency in vacuum pumps plays a crucial role in the synthesis of high-performance glass ceramics. As the demand for advanced materials continues to grow, optimizing the energy consumption of vacuum pumps becomes increasingly important for both economic and environmental reasons. Vacuum pumps are essential in creating the controlled atmosphere required for the precise synthesis of glass ceramics, but they can be significant energy consumers in the production process.

Recent advancements in pump design have led to substantial improvements in energy efficiency. Modern vacuum pumps incorporate features such as variable speed drives, which allow the pump to adjust its operation based on the specific vacuum requirements of different stages in the glass ceramic synthesis process. This dynamic adjustment capability ensures that energy is not wasted by running pumps at full capacity when lower vacuum levels are sufficient.

Another key development in energy-efficient vacuum pumps is the use of advanced materials and coatings. These innovations reduce friction and heat generation within the pump mechanism, leading to lower energy losses and improved overall efficiency. Additionally, some manufacturers have introduced intelligent control systems that optimize pump performance by continuously monitoring and adjusting operational parameters, further reducing energy consumption.

Heat recovery systems have also been integrated into some vacuum pump designs, allowing the heat generated during operation to be captured and repurposed. This recovered energy can be used for other processes in the glass ceramic production facility, such as preheating raw materials or maintaining optimal temperatures in annealing ovens, thereby reducing the overall energy footprint of the manufacturing process.

The implementation of dry vacuum pumps in glass ceramic synthesis has shown promising results in terms of energy efficiency. Unlike traditional oil-sealed pumps, dry pumps eliminate the need for oil changes and reduce the risk of contamination, while also consuming less energy due to their more streamlined design and reduced internal friction.

Furthermore, the adoption of Industry 4.0 principles in vacuum pump systems has led to the development of smart, connected pumps that can be remotely monitored and controlled. This connectivity allows for predictive maintenance, reducing downtime and ensuring that pumps operate at peak efficiency throughout their lifecycle. It also enables better integration with other systems in the glass ceramic production line, optimizing overall energy use across the entire manufacturing process.

Material Compatibility Issues

Material compatibility is a critical consideration in the use of vacuum pumps for the synthesis of high-performance glass ceramics. The interaction between the pump components and the materials involved in the glass ceramic production process can significantly impact both the pump's performance and the quality of the final product.

Vacuum pumps used in this application are exposed to a variety of potentially corrosive or abrasive substances. These may include volatile precursors, reactive gases, and fine particulates generated during the synthesis process. The pump's internal components, such as seals, gaskets, and lubricants, must be carefully selected to withstand these challenging conditions without degradation or contamination of the glass ceramic material.

Stainless steel is often the material of choice for pump bodies and rotors due to its excellent corrosion resistance and durability. However, even stainless steel can be susceptible to certain aggressive chemicals used in glass ceramic synthesis. In such cases, specialized coatings or more exotic alloys may be necessary to ensure long-term reliability.

Elastomeric materials used in seals and O-rings require particular attention. Fluoroelastomers, such as Viton, are commonly employed for their chemical resistance, but they may not be suitable for all process chemistries. In some instances, perfluoroelastomers like Kalrez might be necessary, despite their higher cost, to prevent premature seal failure and maintain vacuum integrity.

The choice of pump lubricants is another critical factor. Traditional hydrocarbon-based oils can break down under high temperatures or when exposed to certain chemicals, leading to pump failure and potential contamination of the glass ceramic product. Synthetic lubricants, such as perfluoropolyether (PFPE) oils, offer superior chemical stability and are often preferred in these demanding applications.

Consideration must also be given to the potential for backstreaming, where pump oil vapors can migrate into the process chamber. This can be particularly problematic in the synthesis of high-performance glass ceramics, where even trace contaminants can significantly affect the material properties. The use of oil-free pump technologies, such as dry screw or scroll pumps, may be necessary to eliminate this risk entirely.

The vacuum pump's exhaust system must also be designed with material compatibility in mind. Corrosion-resistant piping and appropriate filtration systems are essential to prevent the release of harmful substances and to protect downstream equipment from damage.