The Role of Vacuum Pumps in Advanced Magnetic Resonance Techniques

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MRI Vacuum Pump Evolution and Objectives

Vacuum pumps have played a crucial role in the evolution of Magnetic Resonance Imaging (MRI) technology since its inception. The development of MRI systems has been closely tied to advancements in vacuum technology, particularly in the realm of superconducting magnets. These magnets require extremely low temperatures to maintain their superconducting properties, which is achieved through the use of sophisticated vacuum systems.

The journey of vacuum pumps in MRI began in the 1970s with the introduction of the first superconducting magnets. Initially, these systems relied on relatively simple vacuum pumps to maintain the necessary insulation around the cryogenic components. As MRI technology progressed, the demands on vacuum systems increased, driving innovation in pump design and performance.

Throughout the 1980s and 1990s, significant improvements were made in vacuum pump technology specifically for MRI applications. The focus shifted towards developing pumps that could achieve higher vacuum levels while maintaining long-term reliability. This period saw the introduction of turbomolecular pumps and cryopumps, which offered superior performance in maintaining the ultra-high vacuum required for MRI systems.

The turn of the millennium brought about a new era in MRI vacuum technology. The emphasis on energy efficiency and system compactness led to the development of more sophisticated pump designs. Dry pumps, which eliminate the need for oil and reduce maintenance requirements, became increasingly popular in MRI installations. These advancements not only improved the performance of MRI systems but also reduced their environmental impact and operational costs.

In recent years, the objectives for vacuum pump technology in MRI have expanded beyond mere performance metrics. There is a growing focus on developing "smart" vacuum systems that can integrate with the overall MRI system management. These intelligent pumps can self-diagnose, predict maintenance needs, and optimize their operation based on the specific requirements of the MRI system.

Looking forward, the goals for vacuum pump technology in MRI are multifaceted. There is a push towards even higher vacuum levels to support the development of ultra-high-field MRI systems. Simultaneously, researchers are exploring ways to miniaturize vacuum components without compromising performance, which could lead to more compact and portable MRI machines. Additionally, there is an ongoing effort to improve the energy efficiency of these pumps, aligning with global sustainability initiatives.

The evolution of vacuum pump technology for MRI is expected to continue, with objectives centered around enhancing system performance, reliability, and efficiency. As MRI technology advances towards higher field strengths and more specialized applications, the role of vacuum pumps will remain critical in pushing the boundaries of magnetic resonance techniques.

The journey of vacuum pumps in MRI began in the 1970s with the introduction of the first superconducting magnets. Initially, these systems relied on relatively simple vacuum pumps to maintain the necessary insulation around the cryogenic components. As MRI technology progressed, the demands on vacuum systems increased, driving innovation in pump design and performance.

Throughout the 1980s and 1990s, significant improvements were made in vacuum pump technology specifically for MRI applications. The focus shifted towards developing pumps that could achieve higher vacuum levels while maintaining long-term reliability. This period saw the introduction of turbomolecular pumps and cryopumps, which offered superior performance in maintaining the ultra-high vacuum required for MRI systems.

The turn of the millennium brought about a new era in MRI vacuum technology. The emphasis on energy efficiency and system compactness led to the development of more sophisticated pump designs. Dry pumps, which eliminate the need for oil and reduce maintenance requirements, became increasingly popular in MRI installations. These advancements not only improved the performance of MRI systems but also reduced their environmental impact and operational costs.

In recent years, the objectives for vacuum pump technology in MRI have expanded beyond mere performance metrics. There is a growing focus on developing "smart" vacuum systems that can integrate with the overall MRI system management. These intelligent pumps can self-diagnose, predict maintenance needs, and optimize their operation based on the specific requirements of the MRI system.

Looking forward, the goals for vacuum pump technology in MRI are multifaceted. There is a push towards even higher vacuum levels to support the development of ultra-high-field MRI systems. Simultaneously, researchers are exploring ways to miniaturize vacuum components without compromising performance, which could lead to more compact and portable MRI machines. Additionally, there is an ongoing effort to improve the energy efficiency of these pumps, aligning with global sustainability initiatives.

The evolution of vacuum pump technology for MRI is expected to continue, with objectives centered around enhancing system performance, reliability, and efficiency. As MRI technology advances towards higher field strengths and more specialized applications, the role of vacuum pumps will remain critical in pushing the boundaries of magnetic resonance techniques.

Market Demand for Advanced MRI Systems

The market demand for advanced MRI systems has been steadily increasing, driven by the growing prevalence of chronic diseases, the aging population, and the need for more accurate diagnostic tools. Magnetic Resonance Imaging (MRI) technology has become an indispensable tool in modern healthcare, offering high-resolution imaging capabilities for various medical applications.

In recent years, there has been a significant shift towards higher-field MRI systems, particularly 3T and 7T machines, which provide superior image quality and faster scan times. This trend is fueled by the demand for more detailed anatomical and functional information, especially in neuroimaging and oncology. The market for these advanced MRI systems is expected to grow substantially over the next decade.

The healthcare sector's focus on early disease detection and personalized medicine has further boosted the demand for advanced MRI systems. These systems offer enhanced capabilities in detecting subtle abnormalities and characterizing tissue properties, making them invaluable in fields such as neurology, cardiology, and oncology. The integration of artificial intelligence and machine learning algorithms with MRI technology is also driving market growth, as these advancements improve image quality, reduce scan times, and enhance diagnostic accuracy.

Emerging markets, particularly in Asia-Pacific and Latin America, are showing rapid growth in demand for advanced MRI systems. This is attributed to improving healthcare infrastructure, increasing healthcare expenditure, and rising awareness about the benefits of early diagnosis. In developed markets, the replacement of older MRI systems with more advanced models is a significant factor driving market demand.

The COVID-19 pandemic has had a mixed impact on the MRI market. While it initially caused delays in non-essential imaging procedures, it has also highlighted the importance of advanced diagnostic tools in healthcare systems. Post-pandemic, there is an anticipated surge in demand for MRI scans to address the backlog of postponed examinations and to study the long-term effects of COVID-19 on various organ systems.

Vacuum pump technology plays a crucial role in the performance and reliability of these advanced MRI systems. As MRI machines become more powerful and sophisticated, the demands on vacuum systems increase. High-performance vacuum pumps are essential for maintaining the superconducting state of the MRI magnets and ensuring consistent image quality. This has led to a parallel demand for more efficient, reliable, and quieter vacuum pump solutions tailored specifically for advanced MRI applications.

In recent years, there has been a significant shift towards higher-field MRI systems, particularly 3T and 7T machines, which provide superior image quality and faster scan times. This trend is fueled by the demand for more detailed anatomical and functional information, especially in neuroimaging and oncology. The market for these advanced MRI systems is expected to grow substantially over the next decade.

The healthcare sector's focus on early disease detection and personalized medicine has further boosted the demand for advanced MRI systems. These systems offer enhanced capabilities in detecting subtle abnormalities and characterizing tissue properties, making them invaluable in fields such as neurology, cardiology, and oncology. The integration of artificial intelligence and machine learning algorithms with MRI technology is also driving market growth, as these advancements improve image quality, reduce scan times, and enhance diagnostic accuracy.

Emerging markets, particularly in Asia-Pacific and Latin America, are showing rapid growth in demand for advanced MRI systems. This is attributed to improving healthcare infrastructure, increasing healthcare expenditure, and rising awareness about the benefits of early diagnosis. In developed markets, the replacement of older MRI systems with more advanced models is a significant factor driving market demand.

The COVID-19 pandemic has had a mixed impact on the MRI market. While it initially caused delays in non-essential imaging procedures, it has also highlighted the importance of advanced diagnostic tools in healthcare systems. Post-pandemic, there is an anticipated surge in demand for MRI scans to address the backlog of postponed examinations and to study the long-term effects of COVID-19 on various organ systems.

Vacuum pump technology plays a crucial role in the performance and reliability of these advanced MRI systems. As MRI machines become more powerful and sophisticated, the demands on vacuum systems increase. High-performance vacuum pumps are essential for maintaining the superconducting state of the MRI magnets and ensuring consistent image quality. This has led to a parallel demand for more efficient, reliable, and quieter vacuum pump solutions tailored specifically for advanced MRI applications.

Current Vacuum Pump Technology in MRI

Vacuum pump technology plays a crucial role in the performance and efficiency of Magnetic Resonance Imaging (MRI) systems. The current state of vacuum pump technology in MRI is characterized by a range of advanced solutions designed to meet the specific requirements of these sophisticated medical imaging devices.

One of the primary vacuum pump technologies employed in modern MRI systems is the turbomolecular pump. These pumps operate on the principle of momentum transfer, using high-speed rotating blades to impart momentum to gas molecules, directing them towards the exhaust. Turbomolecular pumps are particularly effective in achieving and maintaining the ultra-high vacuum levels required for optimal MRI performance.

Cryogenic pumps, also known as cryopumps, represent another critical technology in MRI vacuum systems. These pumps utilize extremely low temperatures to condense gases onto cold surfaces, effectively removing them from the vacuum chamber. Cryopumps are especially useful in MRI applications due to their ability to maintain a clean, hydrocarbon-free vacuum environment, which is essential for the sensitive superconducting magnets used in MRI machines.

Dry scroll pumps have gained popularity in MRI vacuum systems due to their oil-free operation. These pumps use two interleaving spiral scrolls to compress and expel gases, eliminating the risk of oil contamination in the vacuum chamber. The clean, low-maintenance operation of dry scroll pumps makes them an attractive option for MRI manufacturers seeking to enhance system reliability and reduce maintenance requirements.

Ion pumps, while less common in primary vacuum generation, play a vital role in maintaining ultra-high vacuum conditions in specific areas of MRI systems. These pumps operate by ionizing gas molecules and accelerating them into a titanium cathode, where they are trapped. Ion pumps are particularly useful for maintaining vacuum in sealed-off regions of the MRI system over extended periods.

Recent advancements in vacuum pump technology for MRI applications have focused on improving energy efficiency, reducing noise levels, and enhancing overall system integration. Manufacturers are developing smart pump systems with advanced control algorithms that optimize performance based on real-time operating conditions. These innovations contribute to more stable vacuum environments, improved image quality, and reduced operational costs for healthcare providers.

The integration of multiple pump technologies in hybrid systems is becoming increasingly common in state-of-the-art MRI installations. These hybrid solutions combine the strengths of different pump types to achieve optimal vacuum performance across various stages of operation, from initial pump-down to long-term maintenance of ultra-high vacuum conditions.

One of the primary vacuum pump technologies employed in modern MRI systems is the turbomolecular pump. These pumps operate on the principle of momentum transfer, using high-speed rotating blades to impart momentum to gas molecules, directing them towards the exhaust. Turbomolecular pumps are particularly effective in achieving and maintaining the ultra-high vacuum levels required for optimal MRI performance.

Cryogenic pumps, also known as cryopumps, represent another critical technology in MRI vacuum systems. These pumps utilize extremely low temperatures to condense gases onto cold surfaces, effectively removing them from the vacuum chamber. Cryopumps are especially useful in MRI applications due to their ability to maintain a clean, hydrocarbon-free vacuum environment, which is essential for the sensitive superconducting magnets used in MRI machines.

Dry scroll pumps have gained popularity in MRI vacuum systems due to their oil-free operation. These pumps use two interleaving spiral scrolls to compress and expel gases, eliminating the risk of oil contamination in the vacuum chamber. The clean, low-maintenance operation of dry scroll pumps makes them an attractive option for MRI manufacturers seeking to enhance system reliability and reduce maintenance requirements.

Ion pumps, while less common in primary vacuum generation, play a vital role in maintaining ultra-high vacuum conditions in specific areas of MRI systems. These pumps operate by ionizing gas molecules and accelerating them into a titanium cathode, where they are trapped. Ion pumps are particularly useful for maintaining vacuum in sealed-off regions of the MRI system over extended periods.

Recent advancements in vacuum pump technology for MRI applications have focused on improving energy efficiency, reducing noise levels, and enhancing overall system integration. Manufacturers are developing smart pump systems with advanced control algorithms that optimize performance based on real-time operating conditions. These innovations contribute to more stable vacuum environments, improved image quality, and reduced operational costs for healthcare providers.

The integration of multiple pump technologies in hybrid systems is becoming increasingly common in state-of-the-art MRI installations. These hybrid solutions combine the strengths of different pump types to achieve optimal vacuum performance across various stages of operation, from initial pump-down to long-term maintenance of ultra-high vacuum conditions.

Existing Vacuum Solutions for MRI Applications

01 Improvements in vacuum pump design

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, innovative sealing mechanisms, and optimized fluid flow paths. Such enhancements contribute to increased vacuum levels, reduced power consumption, and improved overall pump reliability.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping capacity, reduced power consumption, and improved reliability in vacuum systems.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high vacuum levels, and minimize particle contamination. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.

- Historical developments in vacuum pump technology: The evolution of vacuum pump technology spans several decades, with numerous innovations contributing to improved performance and functionality. Historical patents showcase early designs and concepts that laid the foundation for modern vacuum pumps, including advancements in rotary, reciprocating, and diffusion pump technologies.

- Integration of vacuum pumps in automotive systems: Vacuum pumps have found applications in various automotive systems, including brake boosters, emission control systems, and turbochargers. Specialized designs have been developed to meet the specific requirements of these applications, focusing on compact size, durability, and integration with other vehicle components.

- Energy-efficient vacuum pump solutions: Recent innovations in vacuum pump technology have focused on improving energy efficiency and reducing environmental impact. These advancements include the development of variable speed drives, heat recovery systems, and intelligent control algorithms. Such features allow for optimized pump operation, reduced power consumption, and lower operating costs in industrial applications.

02 Application-specific vacuum pump configurations

Vacuum pumps have been developed for specific applications, such as semiconductor manufacturing, medical devices, and industrial processes. These specialized configurations may incorporate features like contamination control, precise pressure regulation, or compatibility with specific gases or environments. Such tailored designs ensure optimal performance in their intended applications.Expand Specific Solutions03 Integration of vacuum pumps with other systems

Vacuum pumps have been integrated with other systems to create more comprehensive solutions. This integration may involve combining pumps with pressure sensors, control systems, or other process equipment. Such integrated systems can offer improved automation, monitoring, and overall process efficiency in various industrial and scientific applications.Expand Specific Solutions04 Novel vacuum generation mechanisms

Innovative approaches to vacuum generation have been developed, moving beyond traditional mechanical pumping methods. These may include the use of advanced materials, electromagnetic principles, or novel physical phenomena to create and maintain vacuum conditions. Such novel mechanisms can potentially offer advantages in terms of size, efficiency, or specific performance characteristics.Expand Specific Solutions05 Vacuum pump maintenance and reliability enhancements

Efforts have been made to improve the maintenance aspects and overall reliability of vacuum pumps. This includes the development of self-diagnostic systems, easy-to-service designs, and the use of more durable materials or coatings. These enhancements aim to reduce downtime, extend pump lifespan, and minimize the total cost of ownership for vacuum pump systems.Expand Specific Solutions

Key Players in MRI Vacuum Pump Industry

The vacuum pump market for advanced magnetic resonance techniques is in a growth phase, driven by increasing demand in semiconductor manufacturing, medical imaging, and scientific research. The market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is mature but continuously evolving, with companies like Edwards Ltd., Pfeiffer Vacuum GmbH, and Leybold AG leading in innovation. These firms, along with others such as Agilent Technologies and MKS, Inc., are pushing the boundaries of vacuum pump efficiency, reliability, and precision for high-performance applications. The competitive landscape is characterized by a mix of established players and specialized manufacturers, with a focus on developing more compact, energy-efficient, and application-specific vacuum solutions for advanced magnetic resonance systems.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced turbomolecular pumps specifically designed for magnetic resonance applications. Their GXS dry screw vacuum pumps provide high pumping speeds up to 3400 m3/h and ultimate pressures down to 5 x 10-4 mbar[1]. These pumps utilize a unique screw rotor design that minimizes vibration and noise, critical for sensitive MRI environments. Edwards has also introduced intelligent pump controllers that optimize vacuum performance and energy efficiency through adaptive algorithms[2]. Their pumps incorporate corrosion-resistant materials and coatings to handle aggressive gases used in some MR applications. Edwards' latest turbomolecular pumps achieve pumping speeds over 3000 L/s with a compact footprint, enabling integration into space-constrained MRI systems[3].

Strengths: High pumping speeds, low ultimate pressures, and vibration reduction for MRI compatibility. Intelligent controls for optimized performance. Weaknesses: Higher cost compared to conventional pumps. May require specialized maintenance.

LEYBOLD AG

Technical Solution: LEYBOLD AG has pioneered oil-free vacuum solutions for magnetic resonance imaging. Their SCROLLVAC series of dry scroll pumps offers pumping speeds from 5 to 60 m3/h with ultimate pressures below 10-2 mbar[4]. These pumps utilize a unique orbiting scroll mechanism that provides pulse-free, low-vibration operation ideal for MRI environments. LEYBOLD has also developed specialized fore-vacuum pumps like the DRYVAC, which can achieve pressures down to 10-3 mbar while handling high gas loads[5]. Their latest innovation is the TURBOLAB core, an integrated pumping system combining a turbomolecular pump with a suitable backing pump, providing a turnkey vacuum solution for MRI manufacturers. LEYBOLD's pumps incorporate advanced bearing technology and intelligent controllers to maximize uptime and minimize maintenance requirements[6].

Strengths: Oil-free operation, low vibration, and integrated solutions for MRI systems. Robust design for long service intervals. Weaknesses: Limited pumping speed range compared to some competitors. Higher initial cost for advanced models.

Innovative Vacuum Pump Designs for MRI

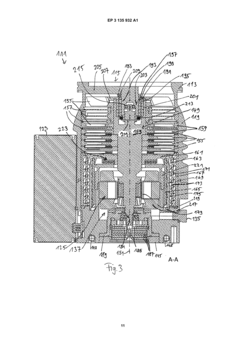

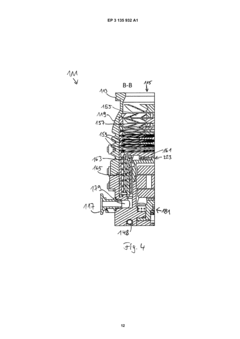

Vacuum pump and permanent magnet bearing

PatentActiveEP3135932A1

Innovation

- The design of the permanent magnet bearing involves ring magnets with specific axial and radial dimensions, where the axial height of the outer and inner ring magnets is between 3 to 5 times the gap width, and the radial width is less than or equal to 1.5 times the height, optimizing the bearing rigidity for improved rotor support.

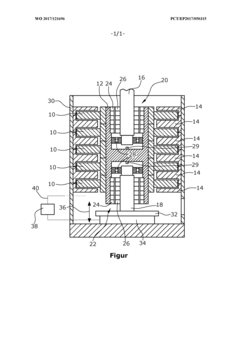

Vacuum pump having axially moveable bearing with permanent magnets

PatentWO2017121696A1

Innovation

- The vacuum pump employs a design with two non-contact permanent magnet bearings, where an actuator device axially displaces a stationary magnetic element to adjust the position of the rotating magnetic element, eliminating the need for additional magnetic coils and reducing radial destabilization, and optionally includes a second bearing element like a roller or permanent magnet bearing for force balance.

MRI Safety and Vacuum Pump Integration

The integration of vacuum pumps in MRI systems is crucial for maintaining a safe and efficient operating environment. Vacuum technology plays a vital role in ensuring the proper functioning of the superconducting magnet, which is the core component of an MRI machine. The superconducting coils within the magnet require extremely low temperatures to operate, typically around -269°C (-452°F), which is achieved through the use of liquid helium as a coolant.

Vacuum pumps are essential in creating and maintaining the insulation necessary to prevent heat transfer and preserve the cryogenic conditions within the magnet. The vacuum jacket surrounding the helium vessel acts as a thermal barrier, significantly reducing heat ingress and minimizing helium boil-off. This not only ensures the longevity of the helium supply but also contributes to the overall safety and reliability of the MRI system.

In terms of safety, vacuum pumps play a critical role in managing helium levels and preventing potential hazards associated with rapid helium boil-off, known as a quench. During a quench, the sudden loss of superconductivity can lead to a rapid expansion of helium gas, posing risks to both equipment and personnel. Properly integrated vacuum systems help mitigate these risks by maintaining the integrity of the cryogenic environment and providing controlled pathways for helium venting in emergency situations.

The integration of vacuum pumps also contributes to the overall efficiency and cost-effectiveness of MRI operations. By minimizing helium loss, healthcare facilities can reduce the frequency and cost of helium refills, which can be a significant operational expense. Additionally, advanced vacuum technologies have enabled the development of zero boil-off systems, further enhancing the sustainability and economic viability of MRI installations.

From a technical standpoint, the integration of vacuum pumps in MRI systems requires careful consideration of materials and design. Components used in the vacuum system must be non-magnetic to prevent interference with the magnetic field. Furthermore, the pumps must operate quietly to maintain a comfortable environment for patients undergoing scans. Innovations in vacuum pump technology, such as the use of oil-free and magnetically shielded designs, have addressed these challenges and improved the overall performance and reliability of MRI systems.

As MRI technology continues to advance, the role of vacuum pumps in ensuring safety and efficiency becomes increasingly important. Future developments may focus on further improving vacuum insulation techniques, enhancing the reliability of zero boil-off systems, and developing more compact and energy-efficient vacuum solutions for next-generation MRI machines.

Vacuum pumps are essential in creating and maintaining the insulation necessary to prevent heat transfer and preserve the cryogenic conditions within the magnet. The vacuum jacket surrounding the helium vessel acts as a thermal barrier, significantly reducing heat ingress and minimizing helium boil-off. This not only ensures the longevity of the helium supply but also contributes to the overall safety and reliability of the MRI system.

In terms of safety, vacuum pumps play a critical role in managing helium levels and preventing potential hazards associated with rapid helium boil-off, known as a quench. During a quench, the sudden loss of superconductivity can lead to a rapid expansion of helium gas, posing risks to both equipment and personnel. Properly integrated vacuum systems help mitigate these risks by maintaining the integrity of the cryogenic environment and providing controlled pathways for helium venting in emergency situations.

The integration of vacuum pumps also contributes to the overall efficiency and cost-effectiveness of MRI operations. By minimizing helium loss, healthcare facilities can reduce the frequency and cost of helium refills, which can be a significant operational expense. Additionally, advanced vacuum technologies have enabled the development of zero boil-off systems, further enhancing the sustainability and economic viability of MRI installations.

From a technical standpoint, the integration of vacuum pumps in MRI systems requires careful consideration of materials and design. Components used in the vacuum system must be non-magnetic to prevent interference with the magnetic field. Furthermore, the pumps must operate quietly to maintain a comfortable environment for patients undergoing scans. Innovations in vacuum pump technology, such as the use of oil-free and magnetically shielded designs, have addressed these challenges and improved the overall performance and reliability of MRI systems.

As MRI technology continues to advance, the role of vacuum pumps in ensuring safety and efficiency becomes increasingly important. Future developments may focus on further improving vacuum insulation techniques, enhancing the reliability of zero boil-off systems, and developing more compact and energy-efficient vacuum solutions for next-generation MRI machines.

Environmental Impact of MRI Vacuum Systems

The environmental impact of MRI vacuum systems is a critical consideration in the development and operation of advanced magnetic resonance techniques. These systems, while essential for maintaining the superconducting state of MRI magnets, have several environmental implications that warrant careful examination.

One of the primary environmental concerns associated with MRI vacuum systems is energy consumption. The continuous operation of vacuum pumps requires a significant amount of electricity, contributing to the overall energy footprint of healthcare facilities. This increased energy demand not only impacts operational costs but also indirectly contributes to greenhouse gas emissions, depending on the source of electricity generation.

The use of cryogens, particularly liquid helium, in MRI systems also poses environmental challenges. While the vacuum systems help maintain the cryogenic environment, the production and transportation of liquid helium have their own environmental impacts. Helium is a non-renewable resource, and its extraction and processing can lead to greenhouse gas emissions and other environmental disturbances.

Noise pollution is another environmental factor to consider. Vacuum pumps, especially older models, can generate significant noise levels, potentially affecting both patients and healthcare staff. This acoustic impact extends beyond the immediate vicinity of the MRI suite and may contribute to overall environmental noise in healthcare settings.

The disposal and replacement of vacuum pump components also have environmental implications. As these systems require regular maintenance and occasional part replacements, the proper disposal of used components, which may contain lubricants or other potentially harmful materials, is crucial to prevent soil and water contamination.

On a positive note, advancements in vacuum pump technology are addressing some of these environmental concerns. The development of more energy-efficient pumps and the implementation of zero boil-off technologies in MRI systems are reducing energy consumption and the need for frequent cryogen replenishment. These innovations not only lower operational costs but also minimize the environmental impact of MRI facilities.

Furthermore, the longevity and reliability of modern vacuum systems contribute to the overall sustainability of MRI technology. By ensuring the stable operation of MRI machines over extended periods, these systems reduce the need for frequent equipment replacements, thereby minimizing the environmental impact associated with manufacturing and disposing of large medical devices.

In conclusion, while MRI vacuum systems play a crucial role in enabling advanced magnetic resonance techniques, their environmental impact is multifaceted. Balancing the benefits of these essential medical technologies with environmental considerations remains an ongoing challenge for manufacturers and healthcare providers alike. Continued research and development in this area are vital for further reducing the environmental footprint of MRI technology.

One of the primary environmental concerns associated with MRI vacuum systems is energy consumption. The continuous operation of vacuum pumps requires a significant amount of electricity, contributing to the overall energy footprint of healthcare facilities. This increased energy demand not only impacts operational costs but also indirectly contributes to greenhouse gas emissions, depending on the source of electricity generation.

The use of cryogens, particularly liquid helium, in MRI systems also poses environmental challenges. While the vacuum systems help maintain the cryogenic environment, the production and transportation of liquid helium have their own environmental impacts. Helium is a non-renewable resource, and its extraction and processing can lead to greenhouse gas emissions and other environmental disturbances.

Noise pollution is another environmental factor to consider. Vacuum pumps, especially older models, can generate significant noise levels, potentially affecting both patients and healthcare staff. This acoustic impact extends beyond the immediate vicinity of the MRI suite and may contribute to overall environmental noise in healthcare settings.

The disposal and replacement of vacuum pump components also have environmental implications. As these systems require regular maintenance and occasional part replacements, the proper disposal of used components, which may contain lubricants or other potentially harmful materials, is crucial to prevent soil and water contamination.

On a positive note, advancements in vacuum pump technology are addressing some of these environmental concerns. The development of more energy-efficient pumps and the implementation of zero boil-off technologies in MRI systems are reducing energy consumption and the need for frequent cryogen replenishment. These innovations not only lower operational costs but also minimize the environmental impact of MRI facilities.

Furthermore, the longevity and reliability of modern vacuum systems contribute to the overall sustainability of MRI technology. By ensuring the stable operation of MRI machines over extended periods, these systems reduce the need for frequent equipment replacements, thereby minimizing the environmental impact associated with manufacturing and disposing of large medical devices.

In conclusion, while MRI vacuum systems play a crucial role in enabling advanced magnetic resonance techniques, their environmental impact is multifaceted. Balancing the benefits of these essential medical technologies with environmental considerations remains an ongoing challenge for manufacturers and healthcare providers alike. Continued research and development in this area are vital for further reducing the environmental footprint of MRI technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!