How Vacuum Pumps Support Advanced Biodegradable Packaging Solutions

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution in Packaging

The evolution of vacuum pumps in packaging has been a critical factor in the development of advanced biodegradable packaging solutions. This technological progression has significantly impacted the efficiency, sustainability, and versatility of packaging processes across various industries.

In the early stages, vacuum pumps were primarily used for simple air removal in packaging, mainly to extend the shelf life of food products. As environmental concerns grew, the packaging industry began to shift towards more sustainable materials, including biodegradable options. This shift necessitated advancements in vacuum pump technology to accommodate the unique properties of these new materials.

The introduction of oil-free vacuum pumps marked a significant milestone in this evolution. These pumps eliminated the risk of oil contamination, making them ideal for use with sensitive biodegradable materials. This development allowed for the creation of cleaner, more environmentally friendly packaging processes, aligning with the growing demand for sustainable packaging solutions.

Another crucial advancement was the development of variable speed vacuum pumps. These pumps offered greater control over the vacuum level, allowing for precise adjustments based on the specific requirements of different biodegradable materials. This flexibility proved essential in handling the diverse range of eco-friendly packaging materials that emerged in the market.

The integration of smart technologies into vacuum pump systems represented a leap forward in packaging efficiency. Sensors and IoT capabilities enabled real-time monitoring and adjustment of vacuum levels, ensuring optimal performance while minimizing energy consumption. This innovation not only improved the quality of packaging but also contributed to the overall sustainability of the packaging process.

Recent years have seen the emergence of compact, high-performance vacuum pumps specifically designed for biodegradable packaging applications. These pumps offer improved energy efficiency and reduced footprint, making them ideal for modern, space-conscious packaging facilities. Their ability to maintain consistent performance with various biodegradable materials has been crucial in expanding the use of eco-friendly packaging across different product categories.

The latest frontier in vacuum pump evolution for packaging involves the development of systems that can adapt to the unique challenges posed by new biodegradable materials. These advanced pumps incorporate machine learning algorithms to optimize their performance based on the specific properties of each material, ensuring maximum efficiency and minimal waste in the packaging process.

As the packaging industry continues to prioritize sustainability, the role of vacuum pumps in supporting advanced biodegradable packaging solutions becomes increasingly vital. The ongoing evolution of this technology promises to further enhance the viability and widespread adoption of eco-friendly packaging options across global markets.

In the early stages, vacuum pumps were primarily used for simple air removal in packaging, mainly to extend the shelf life of food products. As environmental concerns grew, the packaging industry began to shift towards more sustainable materials, including biodegradable options. This shift necessitated advancements in vacuum pump technology to accommodate the unique properties of these new materials.

The introduction of oil-free vacuum pumps marked a significant milestone in this evolution. These pumps eliminated the risk of oil contamination, making them ideal for use with sensitive biodegradable materials. This development allowed for the creation of cleaner, more environmentally friendly packaging processes, aligning with the growing demand for sustainable packaging solutions.

Another crucial advancement was the development of variable speed vacuum pumps. These pumps offered greater control over the vacuum level, allowing for precise adjustments based on the specific requirements of different biodegradable materials. This flexibility proved essential in handling the diverse range of eco-friendly packaging materials that emerged in the market.

The integration of smart technologies into vacuum pump systems represented a leap forward in packaging efficiency. Sensors and IoT capabilities enabled real-time monitoring and adjustment of vacuum levels, ensuring optimal performance while minimizing energy consumption. This innovation not only improved the quality of packaging but also contributed to the overall sustainability of the packaging process.

Recent years have seen the emergence of compact, high-performance vacuum pumps specifically designed for biodegradable packaging applications. These pumps offer improved energy efficiency and reduced footprint, making them ideal for modern, space-conscious packaging facilities. Their ability to maintain consistent performance with various biodegradable materials has been crucial in expanding the use of eco-friendly packaging across different product categories.

The latest frontier in vacuum pump evolution for packaging involves the development of systems that can adapt to the unique challenges posed by new biodegradable materials. These advanced pumps incorporate machine learning algorithms to optimize their performance based on the specific properties of each material, ensuring maximum efficiency and minimal waste in the packaging process.

As the packaging industry continues to prioritize sustainability, the role of vacuum pumps in supporting advanced biodegradable packaging solutions becomes increasingly vital. The ongoing evolution of this technology promises to further enhance the viability and widespread adoption of eco-friendly packaging options across global markets.

Biodegradable Packaging Market Trends

The biodegradable packaging market is experiencing significant growth and transformation, driven by increasing environmental concerns and regulatory pressures. Consumer awareness of plastic pollution and its detrimental effects on ecosystems has led to a surge in demand for sustainable packaging solutions. This shift in consumer preferences is compelling manufacturers and retailers to adopt eco-friendly alternatives, thereby fueling market expansion.

The global biodegradable packaging market is projected to grow at a robust compound annual growth rate (CAGR) over the next decade. This growth is attributed to several factors, including stringent government regulations on single-use plastics, corporate sustainability initiatives, and the rising popularity of green consumerism. Developed regions such as North America and Europe are currently leading the market, but emerging economies in Asia-Pacific are expected to witness the fastest growth due to rapid industrialization and increasing environmental consciousness.

Key trends shaping the biodegradable packaging market include the development of novel bio-based materials, such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based plastics. These materials offer improved biodegradability while maintaining the functional properties required for packaging applications. Additionally, there is a growing focus on circular economy principles, with companies investing in closed-loop recycling systems and compostable packaging solutions.

The food and beverage industry remains the largest end-user segment for biodegradable packaging, followed by healthcare and personal care products. However, new applications are emerging in sectors such as electronics and automotive, expanding the market's scope. E-commerce growth is also driving demand for sustainable packaging solutions, as online retailers seek to reduce their environmental footprint and meet consumer expectations for eco-friendly delivery options.

Technological advancements play a crucial role in market development, with innovations in material science and manufacturing processes enhancing the performance and cost-effectiveness of biodegradable packaging. Vacuum pump technology, in particular, is contributing to the production of advanced biodegradable packaging solutions by enabling precise control over material properties and processing conditions.

Challenges facing the biodegradable packaging market include higher production costs compared to conventional plastics, limited waste management infrastructure for proper disposal and composting, and the need for standardization in biodegradability claims and certifications. However, ongoing research and development efforts, coupled with economies of scale, are expected to address these challenges and further drive market growth in the coming years.

The global biodegradable packaging market is projected to grow at a robust compound annual growth rate (CAGR) over the next decade. This growth is attributed to several factors, including stringent government regulations on single-use plastics, corporate sustainability initiatives, and the rising popularity of green consumerism. Developed regions such as North America and Europe are currently leading the market, but emerging economies in Asia-Pacific are expected to witness the fastest growth due to rapid industrialization and increasing environmental consciousness.

Key trends shaping the biodegradable packaging market include the development of novel bio-based materials, such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based plastics. These materials offer improved biodegradability while maintaining the functional properties required for packaging applications. Additionally, there is a growing focus on circular economy principles, with companies investing in closed-loop recycling systems and compostable packaging solutions.

The food and beverage industry remains the largest end-user segment for biodegradable packaging, followed by healthcare and personal care products. However, new applications are emerging in sectors such as electronics and automotive, expanding the market's scope. E-commerce growth is also driving demand for sustainable packaging solutions, as online retailers seek to reduce their environmental footprint and meet consumer expectations for eco-friendly delivery options.

Technological advancements play a crucial role in market development, with innovations in material science and manufacturing processes enhancing the performance and cost-effectiveness of biodegradable packaging. Vacuum pump technology, in particular, is contributing to the production of advanced biodegradable packaging solutions by enabling precise control over material properties and processing conditions.

Challenges facing the biodegradable packaging market include higher production costs compared to conventional plastics, limited waste management infrastructure for proper disposal and composting, and the need for standardization in biodegradability claims and certifications. However, ongoing research and development efforts, coupled with economies of scale, are expected to address these challenges and further drive market growth in the coming years.

Vacuum Technology Challenges

Vacuum technology plays a crucial role in advanced biodegradable packaging solutions, but it also faces several significant challenges. One of the primary issues is maintaining consistent vacuum levels across different packaging materials. Biodegradable materials often have varying porosity and permeability, which can affect the efficiency of vacuum sealing processes. This inconsistency can lead to compromised package integrity and reduced shelf life for the packaged products.

Another challenge lies in the energy consumption of vacuum pumps. As sustainability becomes increasingly important in packaging industries, there is a growing need for more energy-efficient vacuum systems. Current vacuum pump technologies often require substantial power input, which can offset the environmental benefits of using biodegradable packaging materials. Developing pumps with improved energy efficiency while maintaining high performance is a key area of focus for researchers and engineers in this field.

The compatibility between vacuum pump materials and biodegradable packaging substances presents another hurdle. Some biodegradable materials may release gases or particles during the vacuum process that can potentially damage pump components or contaminate the system. This necessitates the development of more robust and resistant pump materials, as well as advanced filtration systems to protect the vacuum equipment.

Scalability is also a significant challenge in vacuum technology for biodegradable packaging. While vacuum systems may work effectively on a small scale or in laboratory settings, adapting these technologies for high-volume industrial production can be problematic. Issues such as maintaining uniform vacuum distribution across large packaging areas and ensuring consistent sealing quality at high speeds need to be addressed.

Furthermore, the cost of implementing advanced vacuum technologies in biodegradable packaging production lines remains a barrier for many manufacturers. The initial investment in specialized vacuum equipment, along with ongoing maintenance and potential modifications to existing production processes, can be substantial. This economic factor often slows down the adoption of new vacuum technologies in the biodegradable packaging sector.

Lastly, there is the challenge of integrating vacuum technology with other aspects of biodegradable packaging production. This includes synchronizing vacuum processes with material handling systems, ensuring compatibility with various packaging shapes and sizes, and incorporating vacuum technology into automated production lines. Achieving seamless integration while maintaining the integrity of the biodegradable materials throughout the packaging process requires ongoing research and development efforts.

Another challenge lies in the energy consumption of vacuum pumps. As sustainability becomes increasingly important in packaging industries, there is a growing need for more energy-efficient vacuum systems. Current vacuum pump technologies often require substantial power input, which can offset the environmental benefits of using biodegradable packaging materials. Developing pumps with improved energy efficiency while maintaining high performance is a key area of focus for researchers and engineers in this field.

The compatibility between vacuum pump materials and biodegradable packaging substances presents another hurdle. Some biodegradable materials may release gases or particles during the vacuum process that can potentially damage pump components or contaminate the system. This necessitates the development of more robust and resistant pump materials, as well as advanced filtration systems to protect the vacuum equipment.

Scalability is also a significant challenge in vacuum technology for biodegradable packaging. While vacuum systems may work effectively on a small scale or in laboratory settings, adapting these technologies for high-volume industrial production can be problematic. Issues such as maintaining uniform vacuum distribution across large packaging areas and ensuring consistent sealing quality at high speeds need to be addressed.

Furthermore, the cost of implementing advanced vacuum technologies in biodegradable packaging production lines remains a barrier for many manufacturers. The initial investment in specialized vacuum equipment, along with ongoing maintenance and potential modifications to existing production processes, can be substantial. This economic factor often slows down the adoption of new vacuum technologies in the biodegradable packaging sector.

Lastly, there is the challenge of integrating vacuum technology with other aspects of biodegradable packaging production. This includes synchronizing vacuum processes with material handling systems, ensuring compatibility with various packaging shapes and sizes, and incorporating vacuum technology into automated production lines. Achieving seamless integration while maintaining the integrity of the biodegradable materials throughout the packaging process requires ongoing research and development efforts.

Current Vacuum Solutions

01 Rotary vacuum pump designs

Various designs of rotary vacuum pumps have been developed to improve efficiency and performance. These designs may include modifications to rotor configurations, sealing mechanisms, and fluid flow paths within the pump. Rotary vacuum pumps are widely used in industrial applications due to their ability to create high vacuum levels.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps tailored for semiconductor manufacturing processes have been developed. These pumps are designed to handle specific gases and particles encountered in semiconductor fabrication, ensuring high purity and preventing contamination. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.

- Energy-efficient vacuum pump systems: Innovations in vacuum pump technology have focused on improving energy efficiency. These developments include the use of variable speed drives, intelligent control systems, and heat recovery mechanisms. Such advancements result in reduced power consumption, lower operating costs, and improved environmental sustainability.

- Multi-stage vacuum pump configurations: Multi-stage vacuum pump designs have been created to achieve higher vacuum levels and improved pumping efficiency. These configurations typically combine different pump types or multiple pumping stages in series. This approach allows for better gas handling capabilities and the ability to reach lower ultimate pressures.

- Vacuum pump monitoring and control systems: Advanced monitoring and control systems have been integrated into vacuum pump designs. These systems incorporate sensors, data analytics, and automation technologies to optimize pump performance, predict maintenance needs, and ensure consistent operation. Such features contribute to improved reliability, reduced downtime, and enhanced overall system efficiency.

02 Improvements in reciprocating vacuum pumps

Advancements in reciprocating vacuum pump technology focus on enhancing piston designs, valve systems, and overall pump construction. These improvements aim to increase pumping capacity, reduce maintenance requirements, and extend the operational life of the pumps. Reciprocating vacuum pumps are commonly used in applications requiring high vacuum levels.Expand Specific Solutions03 Vacuum pump control systems

Modern vacuum pumps incorporate sophisticated control systems to optimize performance and energy efficiency. These systems may include sensors, variable speed drives, and intelligent algorithms to adjust pump operation based on demand. Advanced control systems help maintain precise vacuum levels and reduce energy consumption in various industrial processes.Expand Specific Solutions04 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps designed specifically for semiconductor manufacturing processes have been developed to meet the stringent cleanliness and performance requirements of the industry. These pumps often incorporate advanced materials, contamination control features, and precise vacuum level control to support various semiconductor fabrication steps.Expand Specific Solutions05 Vacuum pump noise reduction techniques

Various methods have been developed to reduce noise levels in vacuum pumps, improving their suitability for noise-sensitive environments. These techniques may include acoustic enclosures, vibration isolation systems, and redesigned internal components to minimize noise generation. Noise reduction is particularly important in applications where vacuum pumps are used in close proximity to personnel or sensitive equipment.Expand Specific Solutions

Key Vacuum Pump Manufacturers

The vacuum pump market for advanced biodegradable packaging solutions is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding as more industries adopt sustainable packaging practices. Technologically, the field is advancing rapidly, with companies like Pfeiffer Vacuum GmbH and Ateliers Busch SA leading innovation in vacuum pump design for packaging applications. These firms, along with others such as LEYBOLD AG and Nantong Pengshu Vacuum Equipment Manufacturing Co., Ltd., are developing more efficient and specialized vacuum solutions to meet the unique requirements of biodegradable materials. The competition is intensifying as both established players and new entrants strive to capture market share in this promising sector.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum has developed advanced vacuum solutions specifically tailored for biodegradable packaging production. Their HiPace turbopumps with hybrid bearings offer high pumping speeds and compression ratios, crucial for maintaining the controlled atmosphere required in biodegradable film extrusion processes[1]. The company's ACP multi-stage roots pumps provide oil-free and low-maintenance operation, ensuring contamination-free packaging production[2]. Pfeiffer's smart vacuum systems integrate Industry 4.0 features, allowing real-time monitoring and optimization of vacuum levels throughout the packaging manufacturing process, resulting in improved product quality and reduced waste[3].

Strengths: High-performance pumps tailored for packaging industry, contamination-free operation, smart monitoring capabilities. Weaknesses: Potentially higher initial investment compared to conventional vacuum systems.

Ateliers Busch SA

Technical Solution: Busch has innovated with their COBRA NX screw vacuum pumps, specifically designed for the extrusion of biodegradable plastics. These dry screw vacuum pumps operate without oil, eliminating the risk of contamination in food-grade packaging production[4]. The COBRA NX series offers variable speed control, allowing manufacturers to adjust vacuum levels precisely according to different biodegradable materials' requirements. Busch's R 5 rotary vane vacuum pumps, equipped with oxygen-compatible seals, support the production of high-barrier biodegradable films that require oxygen-free environments during manufacturing[5].

Strengths: Oil-free operation ideal for food packaging, flexible vacuum control for various materials. Weaknesses: May require specialized maintenance due to advanced technology.

Innovative Vacuum Pump Designs

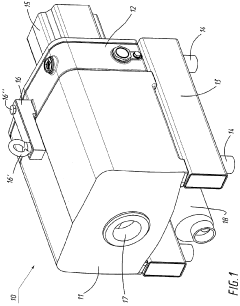

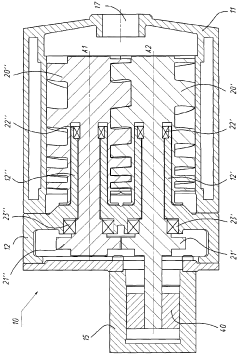

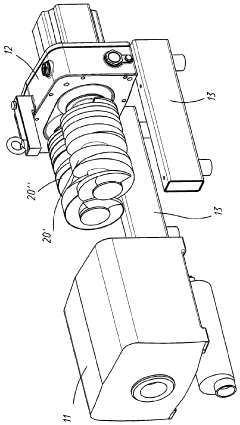

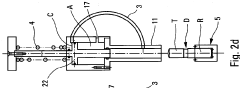

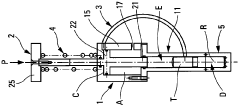

Vacuum pump for applications in vacuum packaging machines

PatentWO2012076204A2

Innovation

- A compact, dry screw-type vacuum pump design with parallel cylindrical chambers, cantilevered motor, and easy-access rotor support, eliminating the need for oil and allowing for efficient cleaning and maintenance without specialized personnel, featuring a horizontal axis configuration for reduced size and improved flow efficiency.

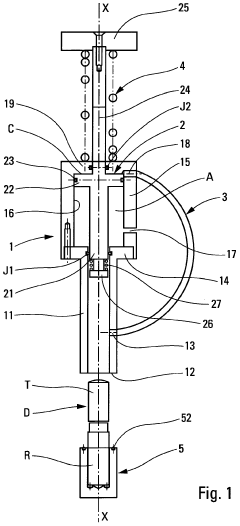

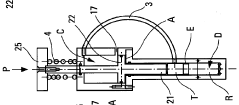

Vacuum packaging assembly and method

PatentWO2011023895A1

Innovation

- A packaging assembly that generates a vacuum or depression inside a sealed enclosure using a movable conditioning element and piston, which varies the volume of the chamber to create a vacuum without the need for a vacuum pump, allowing for light, partial, or high vacuum conditions.

Environmental Impact Assessment

The environmental impact assessment of vacuum pumps in advanced biodegradable packaging solutions reveals a complex interplay of positive and negative effects. On the positive side, vacuum pumps contribute significantly to the development and production of biodegradable packaging materials, which are inherently more environmentally friendly than traditional plastic alternatives. By enabling the creation of airtight seals and facilitating the removal of air from packaging, vacuum pumps help extend the shelf life of products, reducing food waste and the associated environmental burden.

Furthermore, the use of vacuum technology in packaging processes often leads to a reduction in overall material usage. This is achieved through more efficient packaging designs and the ability to create thinner, yet equally effective, barrier layers. The decreased material consumption translates to reduced resource extraction, energy use, and waste generation throughout the supply chain.

However, the environmental impact of vacuum pumps themselves must be considered. The production of these devices involves the use of various materials, including metals and plastics, which have their own environmental footprints. Additionally, the operation of vacuum pumps requires energy, typically in the form of electricity. Depending on the energy source, this could contribute to greenhouse gas emissions and other environmental concerns associated with power generation.

The disposal of vacuum pumps at the end of their lifecycle also presents environmental challenges. While many components can be recycled, certain parts may require special handling or disposal procedures. This aspect underscores the importance of designing vacuum pumps with recyclability and ease of disassembly in mind to minimize their end-of-life environmental impact.

When assessing the overall environmental impact, it's crucial to consider the entire lifecycle of both the vacuum pumps and the biodegradable packaging they help produce. While the pumps themselves may have some negative environmental aspects, their role in enabling more sustainable packaging solutions generally results in a net positive impact. The reduction in non-biodegradable plastic waste, decreased food spoilage, and more efficient use of packaging materials collectively outweigh the environmental costs associated with the pumps' production and operation.

To further improve the environmental profile of vacuum pump usage in biodegradable packaging, several strategies can be employed. These include developing more energy-efficient pump designs, utilizing renewable energy sources for pump operation, and implementing closed-loop recycling systems for pump components. Additionally, optimizing packaging processes to minimize vacuum pump usage while maintaining product quality can help reduce the overall environmental footprint of packaging operations.

Furthermore, the use of vacuum technology in packaging processes often leads to a reduction in overall material usage. This is achieved through more efficient packaging designs and the ability to create thinner, yet equally effective, barrier layers. The decreased material consumption translates to reduced resource extraction, energy use, and waste generation throughout the supply chain.

However, the environmental impact of vacuum pumps themselves must be considered. The production of these devices involves the use of various materials, including metals and plastics, which have their own environmental footprints. Additionally, the operation of vacuum pumps requires energy, typically in the form of electricity. Depending on the energy source, this could contribute to greenhouse gas emissions and other environmental concerns associated with power generation.

The disposal of vacuum pumps at the end of their lifecycle also presents environmental challenges. While many components can be recycled, certain parts may require special handling or disposal procedures. This aspect underscores the importance of designing vacuum pumps with recyclability and ease of disassembly in mind to minimize their end-of-life environmental impact.

When assessing the overall environmental impact, it's crucial to consider the entire lifecycle of both the vacuum pumps and the biodegradable packaging they help produce. While the pumps themselves may have some negative environmental aspects, their role in enabling more sustainable packaging solutions generally results in a net positive impact. The reduction in non-biodegradable plastic waste, decreased food spoilage, and more efficient use of packaging materials collectively outweigh the environmental costs associated with the pumps' production and operation.

To further improve the environmental profile of vacuum pump usage in biodegradable packaging, several strategies can be employed. These include developing more energy-efficient pump designs, utilizing renewable energy sources for pump operation, and implementing closed-loop recycling systems for pump components. Additionally, optimizing packaging processes to minimize vacuum pump usage while maintaining product quality can help reduce the overall environmental footprint of packaging operations.

Regulatory Framework for Packaging

The regulatory framework for packaging plays a crucial role in shaping the development and adoption of advanced biodegradable packaging solutions supported by vacuum pump technology. As environmental concerns continue to drive policy changes, governments and international organizations are implementing stricter regulations to reduce packaging waste and promote sustainable practices.

In the European Union, the Packaging and Packaging Waste Directive (PPWD) sets targets for recycling and recovery of packaging materials. This directive has been recently updated to include specific provisions for biodegradable packaging, encouraging the use of materials that can decompose naturally without harming the environment. The EU's Circular Economy Action Plan further reinforces these efforts by promoting eco-design principles and extended producer responsibility.

In the United States, the Food and Drug Administration (FDA) regulates food packaging materials, including biodegradable options. The FDA's focus on ensuring food safety has led to stringent requirements for packaging materials that come into contact with food products. This regulatory landscape has prompted manufacturers to develop innovative biodegradable packaging solutions that meet both safety and environmental standards.

The United Nations Environment Programme (UNEP) has also been instrumental in shaping global packaging regulations. Through initiatives like the Global Partnership on Marine Litter, UNEP encourages countries to adopt policies that reduce plastic pollution, indirectly promoting the use of biodegradable packaging alternatives.

Many countries have implemented or are considering implementing taxes on non-biodegradable packaging materials. For instance, the UK's Plastic Packaging Tax incentivizes the use of recycled plastic content in packaging, indirectly boosting the market for biodegradable alternatives. Similar measures are being considered in other nations, creating a global trend towards more sustainable packaging solutions.

The regulatory framework also extends to labeling requirements for biodegradable packaging. Standards such as ASTM D6400 and EN 13432 provide guidelines for certifying compostable plastics, ensuring that consumers can make informed choices about the environmental impact of their purchases. These standards often require specific testing protocols, where vacuum pump technology plays a crucial role in simulating environmental conditions and measuring degradation rates.

As regulations evolve, they are increasingly focusing on the entire lifecycle of packaging materials. This holistic approach considers not only the end-of-life disposal but also the production processes involved. Vacuum pump technology, known for its energy efficiency and precision in manufacturing processes, aligns well with these regulatory trends towards more sustainable production methods.

The interplay between regulations and technological innovation in the packaging industry is creating new opportunities for vacuum pump applications. As manufacturers strive to meet stringent environmental standards while maintaining product quality and safety, the demand for advanced vacuum solutions in the production and testing of biodegradable packaging is likely to grow significantly in the coming years.

In the European Union, the Packaging and Packaging Waste Directive (PPWD) sets targets for recycling and recovery of packaging materials. This directive has been recently updated to include specific provisions for biodegradable packaging, encouraging the use of materials that can decompose naturally without harming the environment. The EU's Circular Economy Action Plan further reinforces these efforts by promoting eco-design principles and extended producer responsibility.

In the United States, the Food and Drug Administration (FDA) regulates food packaging materials, including biodegradable options. The FDA's focus on ensuring food safety has led to stringent requirements for packaging materials that come into contact with food products. This regulatory landscape has prompted manufacturers to develop innovative biodegradable packaging solutions that meet both safety and environmental standards.

The United Nations Environment Programme (UNEP) has also been instrumental in shaping global packaging regulations. Through initiatives like the Global Partnership on Marine Litter, UNEP encourages countries to adopt policies that reduce plastic pollution, indirectly promoting the use of biodegradable packaging alternatives.

Many countries have implemented or are considering implementing taxes on non-biodegradable packaging materials. For instance, the UK's Plastic Packaging Tax incentivizes the use of recycled plastic content in packaging, indirectly boosting the market for biodegradable alternatives. Similar measures are being considered in other nations, creating a global trend towards more sustainable packaging solutions.

The regulatory framework also extends to labeling requirements for biodegradable packaging. Standards such as ASTM D6400 and EN 13432 provide guidelines for certifying compostable plastics, ensuring that consumers can make informed choices about the environmental impact of their purchases. These standards often require specific testing protocols, where vacuum pump technology plays a crucial role in simulating environmental conditions and measuring degradation rates.

As regulations evolve, they are increasingly focusing on the entire lifecycle of packaging materials. This holistic approach considers not only the end-of-life disposal but also the production processes involved. Vacuum pump technology, known for its energy efficiency and precision in manufacturing processes, aligns well with these regulatory trends towards more sustainable production methods.

The interplay between regulations and technological innovation in the packaging industry is creating new opportunities for vacuum pump applications. As manufacturers strive to meet stringent environmental standards while maintaining product quality and safety, the demand for advanced vacuum solutions in the production and testing of biodegradable packaging is likely to grow significantly in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!