How Vacuum Pumps Enhance Microfluidic Device Fabrication

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech in Microfluidics: Background and Objectives

Vacuum pump technology has played a pivotal role in the evolution of microfluidic device fabrication, revolutionizing the field of microfluidics and enabling unprecedented advancements in various scientific and industrial applications. The integration of vacuum pumps in microfluidic device manufacturing processes has significantly enhanced the precision, efficiency, and overall quality of these miniaturized systems.

The development of microfluidic devices can be traced back to the 1990s, with the advent of micro-electromechanical systems (MEMS) and lab-on-a-chip technologies. As the demand for more sophisticated and compact analytical tools grew, so did the need for improved fabrication techniques. Vacuum pump technology emerged as a crucial component in addressing the challenges associated with microfluidic device production.

The primary objective of incorporating vacuum pumps in microfluidic device fabrication is to achieve precise control over the microenvironment during the manufacturing process. By creating a controlled vacuum environment, manufacturers can manipulate materials at the microscale with unprecedented accuracy, enabling the creation of intricate channel networks, valves, and other microstructures essential for microfluidic functionality.

One of the key advantages of vacuum pump technology in this context is its ability to remove air bubbles and contaminants from the microfluidic channels during the fabrication process. This is crucial for ensuring the reliability and reproducibility of microfluidic devices, as even minute impurities can significantly impact their performance. The vacuum environment also facilitates the uniform distribution of materials, such as polymers used in soft lithography techniques, resulting in more consistent and higher-quality devices.

Furthermore, vacuum pumps have enabled the development of advanced bonding techniques for microfluidic device assembly. By creating a vacuum between layers of materials, manufacturers can achieve stronger and more reliable bonds, essential for preventing leaks and ensuring the long-term stability of microfluidic devices. This has been particularly beneficial in the production of multi-layer devices with complex architectures.

The integration of vacuum pump technology has also opened up new possibilities in terms of material selection for microfluidic device fabrication. By allowing for the manipulation of a wider range of materials under controlled conditions, vacuum pumps have expanded the design space for microfluidic devices, enabling the use of novel materials with unique properties tailored to specific applications.

As the field of microfluidics continues to evolve, the role of vacuum pump technology is expected to grow even more significant. Future developments aim to further enhance the precision and efficiency of microfluidic device fabrication, with a focus on scalability and automation. The ongoing refinement of vacuum pump technology will likely lead to the production of even more sophisticated and high-performance microfluidic devices, capable of addressing complex challenges in fields such as healthcare, environmental monitoring, and chemical synthesis.

The development of microfluidic devices can be traced back to the 1990s, with the advent of micro-electromechanical systems (MEMS) and lab-on-a-chip technologies. As the demand for more sophisticated and compact analytical tools grew, so did the need for improved fabrication techniques. Vacuum pump technology emerged as a crucial component in addressing the challenges associated with microfluidic device production.

The primary objective of incorporating vacuum pumps in microfluidic device fabrication is to achieve precise control over the microenvironment during the manufacturing process. By creating a controlled vacuum environment, manufacturers can manipulate materials at the microscale with unprecedented accuracy, enabling the creation of intricate channel networks, valves, and other microstructures essential for microfluidic functionality.

One of the key advantages of vacuum pump technology in this context is its ability to remove air bubbles and contaminants from the microfluidic channels during the fabrication process. This is crucial for ensuring the reliability and reproducibility of microfluidic devices, as even minute impurities can significantly impact their performance. The vacuum environment also facilitates the uniform distribution of materials, such as polymers used in soft lithography techniques, resulting in more consistent and higher-quality devices.

Furthermore, vacuum pumps have enabled the development of advanced bonding techniques for microfluidic device assembly. By creating a vacuum between layers of materials, manufacturers can achieve stronger and more reliable bonds, essential for preventing leaks and ensuring the long-term stability of microfluidic devices. This has been particularly beneficial in the production of multi-layer devices with complex architectures.

The integration of vacuum pump technology has also opened up new possibilities in terms of material selection for microfluidic device fabrication. By allowing for the manipulation of a wider range of materials under controlled conditions, vacuum pumps have expanded the design space for microfluidic devices, enabling the use of novel materials with unique properties tailored to specific applications.

As the field of microfluidics continues to evolve, the role of vacuum pump technology is expected to grow even more significant. Future developments aim to further enhance the precision and efficiency of microfluidic device fabrication, with a focus on scalability and automation. The ongoing refinement of vacuum pump technology will likely lead to the production of even more sophisticated and high-performance microfluidic devices, capable of addressing complex challenges in fields such as healthcare, environmental monitoring, and chemical synthesis.

Market Analysis for Microfluidic Device Fabrication

The microfluidic device fabrication market has experienced significant growth in recent years, driven by increasing demand for point-of-care diagnostics, drug discovery applications, and personalized medicine. The global market for microfluidic devices is projected to reach $32.7 billion by 2026, growing at a CAGR of 18.4% from 2021 to 2026. This robust growth is attributed to the rising adoption of microfluidic technologies in various industries, including healthcare, pharmaceuticals, and life sciences.

The healthcare sector remains the largest end-user segment for microfluidic devices, accounting for over 40% of the market share. The increasing prevalence of chronic diseases and the need for rapid, accurate diagnostic tools are driving the demand for microfluidic-based point-of-care testing devices. Additionally, the pharmaceutical industry is leveraging microfluidic technologies for drug discovery and development processes, contributing to market expansion.

Geographically, North America dominates the microfluidic device fabrication market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its advanced healthcare infrastructure and substantial investments in research and development. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by increasing healthcare expenditure and growing awareness of personalized medicine.

The market landscape is characterized by the presence of both established players and innovative start-ups. Key market players include Danaher Corporation, Thermo Fisher Scientific, and Bio-Rad Laboratories, among others. These companies are focusing on strategic collaborations, mergers, and acquisitions to strengthen their market position and expand their product portfolios.

The integration of vacuum pump technology in microfluidic device fabrication is emerging as a significant trend in the market. Vacuum pumps enhance the precision and efficiency of microfluidic device production, enabling the creation of more complex and sophisticated designs. This technological advancement is expected to drive market growth further by improving product quality and reducing manufacturing costs.

Despite the positive outlook, the market faces challenges such as high initial investment costs and the need for skilled personnel to operate advanced microfluidic systems. However, ongoing technological advancements and increasing research activities in the field are expected to address these challenges and create new opportunities for market expansion.

The healthcare sector remains the largest end-user segment for microfluidic devices, accounting for over 40% of the market share. The increasing prevalence of chronic diseases and the need for rapid, accurate diagnostic tools are driving the demand for microfluidic-based point-of-care testing devices. Additionally, the pharmaceutical industry is leveraging microfluidic technologies for drug discovery and development processes, contributing to market expansion.

Geographically, North America dominates the microfluidic device fabrication market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its advanced healthcare infrastructure and substantial investments in research and development. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by increasing healthcare expenditure and growing awareness of personalized medicine.

The market landscape is characterized by the presence of both established players and innovative start-ups. Key market players include Danaher Corporation, Thermo Fisher Scientific, and Bio-Rad Laboratories, among others. These companies are focusing on strategic collaborations, mergers, and acquisitions to strengthen their market position and expand their product portfolios.

The integration of vacuum pump technology in microfluidic device fabrication is emerging as a significant trend in the market. Vacuum pumps enhance the precision and efficiency of microfluidic device production, enabling the creation of more complex and sophisticated designs. This technological advancement is expected to drive market growth further by improving product quality and reducing manufacturing costs.

Despite the positive outlook, the market faces challenges such as high initial investment costs and the need for skilled personnel to operate advanced microfluidic systems. However, ongoing technological advancements and increasing research activities in the field are expected to address these challenges and create new opportunities for market expansion.

Current Challenges in Microfluidic Manufacturing

Despite significant advancements in microfluidic device fabrication, several challenges persist in the manufacturing process. One of the primary issues is achieving consistent and precise control over the microfluidic channels' dimensions and geometries. The miniature scale of these devices demands extremely high precision, often at the sub-micron level, which pushes the limits of current manufacturing techniques.

Material selection and compatibility present another significant challenge. The materials used must be chemically inert, optically transparent, and biocompatible for many applications. Additionally, they need to withstand the fabrication process without deformation or degradation. Finding materials that meet all these criteria while remaining cost-effective for large-scale production is an ongoing challenge.

Bonding and sealing of microfluidic devices continue to be problematic. The need for leak-free, strong bonds between layers without altering the channel geometries or introducing contaminants is crucial. Current bonding methods, such as thermal bonding or adhesive bonding, can sometimes lead to channel deformation or introduce unwanted substances into the microfluidic system.

Integration of functional components, such as sensors, actuators, and electrodes, into microfluidic devices remains a complex task. These components often require different fabrication processes, making their seamless integration challenging. The need for precise alignment and maintaining the functionality of these components during the fabrication process adds another layer of complexity.

Scalability and mass production of microfluidic devices pose significant challenges. While prototyping and small-scale production have become more accessible, transitioning to high-volume manufacturing while maintaining quality and consistency is difficult. The intricate nature of microfluidic devices often requires specialized equipment and processes that are not easily scalable.

Surface modification and functionalization of microfluidic channels present another hurdle. Controlling the surface properties is crucial for many applications, such as preventing non-specific adsorption or promoting specific interactions. Achieving uniform and stable surface modifications within the confined spaces of microfluidic channels remains challenging.

Lastly, the development of standardized fabrication protocols and quality control measures for microfluidic devices is an ongoing challenge. The lack of industry-wide standards makes it difficult to ensure reproducibility and reliability across different manufacturing facilities and batches. Establishing robust quality control methods that can effectively detect defects in these miniature devices is essential for widespread adoption in critical applications.

Material selection and compatibility present another significant challenge. The materials used must be chemically inert, optically transparent, and biocompatible for many applications. Additionally, they need to withstand the fabrication process without deformation or degradation. Finding materials that meet all these criteria while remaining cost-effective for large-scale production is an ongoing challenge.

Bonding and sealing of microfluidic devices continue to be problematic. The need for leak-free, strong bonds between layers without altering the channel geometries or introducing contaminants is crucial. Current bonding methods, such as thermal bonding or adhesive bonding, can sometimes lead to channel deformation or introduce unwanted substances into the microfluidic system.

Integration of functional components, such as sensors, actuators, and electrodes, into microfluidic devices remains a complex task. These components often require different fabrication processes, making their seamless integration challenging. The need for precise alignment and maintaining the functionality of these components during the fabrication process adds another layer of complexity.

Scalability and mass production of microfluidic devices pose significant challenges. While prototyping and small-scale production have become more accessible, transitioning to high-volume manufacturing while maintaining quality and consistency is difficult. The intricate nature of microfluidic devices often requires specialized equipment and processes that are not easily scalable.

Surface modification and functionalization of microfluidic channels present another hurdle. Controlling the surface properties is crucial for many applications, such as preventing non-specific adsorption or promoting specific interactions. Achieving uniform and stable surface modifications within the confined spaces of microfluidic channels remains challenging.

Lastly, the development of standardized fabrication protocols and quality control measures for microfluidic devices is an ongoing challenge. The lack of industry-wide standards makes it difficult to ensure reproducibility and reliability across different manufacturing facilities and batches. Establishing robust quality control methods that can effectively detect defects in these miniature devices is essential for widespread adoption in critical applications.

Existing Vacuum-Based Solutions for Microfluidic Fabrication

01 Improved pump design and efficiency

Enhancements in vacuum pump design focus on improving overall efficiency and performance. This includes optimizing impeller geometry, reducing internal friction, and enhancing sealing mechanisms. Advanced materials and manufacturing techniques are employed to create more durable and efficient pump components.- Improved pump design and efficiency: Enhancements in vacuum pump design focus on improving overall efficiency and performance. This includes optimizing impeller geometry, reducing internal friction, and enhancing sealing mechanisms. Advanced materials and manufacturing techniques are employed to create more durable and efficient pump components.

- Multi-stage vacuum pump systems: Multi-stage vacuum pump configurations are developed to achieve higher vacuum levels and improved pumping speeds. These systems combine different pump types or multiple stages of the same pump type to optimize performance across a wide range of pressure conditions.

- Integration of smart technologies: Vacuum pumps are enhanced with smart technologies, including sensors, IoT connectivity, and advanced control systems. These features enable real-time monitoring, predictive maintenance, and automated operation, improving overall system reliability and efficiency.

- Energy-efficient and environmentally friendly solutions: Developments in vacuum pump technology focus on reducing energy consumption and environmental impact. This includes the use of variable speed drives, heat recovery systems, and eco-friendly lubricants. Some designs also incorporate noise reduction features for improved workplace conditions.

- Application-specific vacuum pump enhancements: Vacuum pumps are tailored for specific applications, such as semiconductor manufacturing, medical devices, or food packaging. These enhancements may include specialized materials for corrosion resistance, contamination control features, or compact designs for integration into larger systems.

02 Multi-stage vacuum pump systems

Multi-stage vacuum pump configurations are developed to achieve higher vacuum levels and improved pumping speeds. These systems combine different pump types or multiple pumps in series to optimize performance across various pressure ranges. This approach allows for more efficient and effective vacuum generation in diverse applications.Expand Specific Solutions03 Integration of smart technologies

Vacuum pumps are enhanced with smart technologies, including sensors, IoT connectivity, and advanced control systems. These features enable real-time monitoring, predictive maintenance, and automated operation adjustments. Smart integration improves pump reliability, efficiency, and overall system performance.Expand Specific Solutions04 Energy-efficient and environmentally friendly solutions

Developments in vacuum pump technology focus on reducing energy consumption and environmental impact. This includes the use of variable speed drives, energy recovery systems, and eco-friendly materials. These enhancements aim to minimize power usage, reduce carbon footprint, and improve overall sustainability.Expand Specific Solutions05 Application-specific vacuum pump enhancements

Vacuum pumps are tailored for specific applications, such as semiconductor manufacturing, medical devices, or industrial processes. These enhancements may include specialized coatings, contamination control features, or adaptations for handling specific gases or particulates. Application-specific designs optimize pump performance and longevity in challenging environments.Expand Specific Solutions

Key Players in Vacuum Pump and Microfluidic Industries

The vacuum pump market for microfluidic device fabrication is in a growth phase, driven by increasing demand for precise fluid control in various applications. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is advancing rapidly, with companies like Edwards Ltd. and Edwards Vacuum LLC leading in pump innovation. Academic institutions such as MIT and Caltech are contributing to research and development, pushing the boundaries of microfluidic technologies. The industry is seeing a convergence of established players and emerging startups, fostering a competitive landscape that drives innovation in pump efficiency, miniaturization, and integration with microfluidic systems.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for microfluidic device fabrication. Their innovative approach involves the use of dry pumping systems that provide contamination-free, high-performance vacuum environments. These systems utilize multi-stage roots technology, which allows for efficient gas handling and precise pressure control[1]. The company's GXS dry screw pump series, for instance, offers pumping speeds up to 3400 m³/h and ultimate pressures down to 5x10⁻⁴ mbar, making it ideal for critical microfluidic applications[2]. Edwards' vacuum pumps also incorporate intelligent control systems that optimize performance and energy efficiency, ensuring consistent results in microfluidic device production[3].

Strengths: High pumping speeds, contamination-free operation, and precise pressure control. Weaknesses: Potentially higher initial cost compared to traditional pumping systems, and may require specialized maintenance.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered several vacuum-assisted techniques for microfluidic device fabrication. One notable innovation is their vacuum-assisted microfluidic cell loading method, which enhances the efficiency and uniformity of cell seeding in microfluidic channels[4]. This technique utilizes controlled vacuum pressure to draw cells into microfluidic structures, significantly improving the reproducibility of cell-based experiments. Additionally, MIT researchers have developed vacuum-enabled soft lithography processes for creating complex 3D microfluidic structures[5]. By applying vacuum during the molding process, they can achieve intricate designs with high aspect ratios and minimal defects, which are crucial for advanced microfluidic applications such as organ-on-a-chip devices[6].

Strengths: Cutting-edge research in vacuum-assisted microfluidic fabrication techniques, enabling complex 3D structures and improved cell loading. Weaknesses: Some techniques may be at the research stage and not yet fully commercialized or standardized for industrial applications.

Innovations in Vacuum Pump Technology for Microfluidics

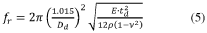

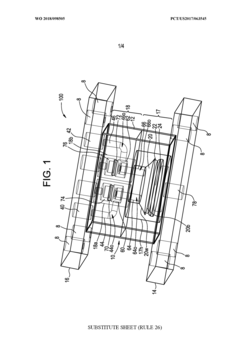

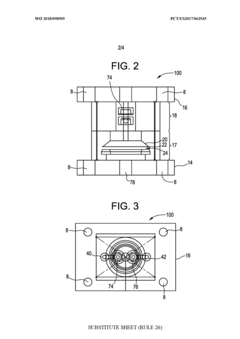

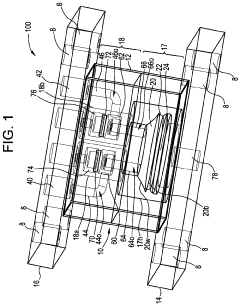

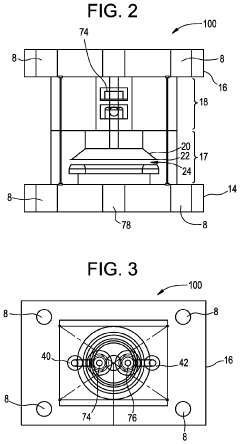

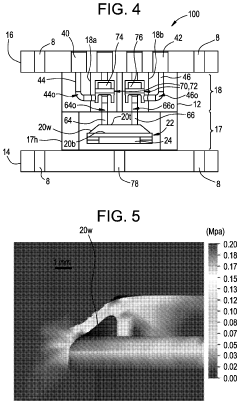

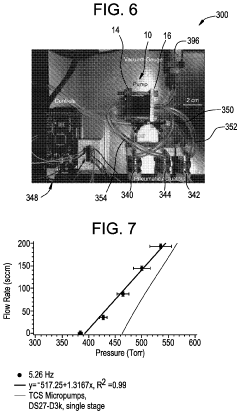

Vacuum pumps and methods of manufacturing the same

PatentWO2018098505A1

Innovation

- The development of multi-material, additively manufactured miniaturized diaphragm pumps with a compression chamber and valves made from flexible materials of varying stiffness, utilizing techniques like polyjet printing, fused filament fabrication, and stereolithography to create complex geometries and reduce dead volume, allowing for improved performance and longevity.

Vacuum pumps and methods of manufacturing the same

PatentActiveUS20190345926A1

Innovation

- The development of multi-material, additively manufactured miniaturized diaphragm pumps with a compression chamber and valves made from flexible materials of varying stiffness, utilizing techniques like polyjet printing, fused filament fabrication, and stereolithography to create complex geometries and reduce dead volume, allowing for improved performance and longevity.

Environmental Impact of Vacuum-Based Microfabrication Processes

The environmental impact of vacuum-based microfabrication processes in microfluidic device fabrication is a critical consideration as this technology continues to advance. These processes, while essential for creating precise and intricate microfluidic structures, can have both positive and negative effects on the environment.

One of the primary environmental benefits of vacuum-based microfabrication is its potential for reducing material waste. The precise control offered by vacuum pumps allows for more efficient use of raw materials, minimizing excess and reducing the overall environmental footprint of the manufacturing process. This efficiency can lead to a decrease in resource consumption and associated energy costs.

However, the energy consumption of vacuum pumps themselves is a significant environmental concern. These pumps often require substantial power to maintain the necessary vacuum levels for microfabrication processes. The increased energy demand can contribute to higher carbon emissions if the energy source is not renewable, potentially offsetting some of the environmental gains achieved through material efficiency.

The use of certain chemicals and gases in vacuum-based microfabrication processes also poses environmental risks. Some of these substances may be hazardous or have high global warming potential. Proper handling, storage, and disposal of these materials are crucial to prevent environmental contamination and minimize their impact on air and water quality.

Vacuum-based processes can also contribute to noise pollution in manufacturing environments. The continuous operation of vacuum pumps can generate significant noise levels, potentially affecting both workers and surrounding communities. Implementing noise reduction strategies and proper insulation is essential to mitigate this impact.

On a positive note, the miniaturization enabled by vacuum-based microfabrication can lead to more compact and energy-efficient devices. Microfluidic devices produced through these processes often require smaller sample volumes and consume less power during operation, potentially reducing the overall environmental impact throughout the product lifecycle.

The longevity and durability of microfluidic devices fabricated using vacuum-based processes can also have positive environmental implications. Higher-quality devices with longer lifespans reduce the need for frequent replacements, thereby decreasing waste generation and resource consumption in the long term.

As the field of microfluidic device fabrication evolves, there is a growing focus on developing more environmentally friendly vacuum-based processes. This includes research into alternative materials, more efficient pump designs, and improved recycling methods for process byproducts. These advancements aim to further reduce the environmental footprint of microfabrication while maintaining or enhancing the quality of the final products.

One of the primary environmental benefits of vacuum-based microfabrication is its potential for reducing material waste. The precise control offered by vacuum pumps allows for more efficient use of raw materials, minimizing excess and reducing the overall environmental footprint of the manufacturing process. This efficiency can lead to a decrease in resource consumption and associated energy costs.

However, the energy consumption of vacuum pumps themselves is a significant environmental concern. These pumps often require substantial power to maintain the necessary vacuum levels for microfabrication processes. The increased energy demand can contribute to higher carbon emissions if the energy source is not renewable, potentially offsetting some of the environmental gains achieved through material efficiency.

The use of certain chemicals and gases in vacuum-based microfabrication processes also poses environmental risks. Some of these substances may be hazardous or have high global warming potential. Proper handling, storage, and disposal of these materials are crucial to prevent environmental contamination and minimize their impact on air and water quality.

Vacuum-based processes can also contribute to noise pollution in manufacturing environments. The continuous operation of vacuum pumps can generate significant noise levels, potentially affecting both workers and surrounding communities. Implementing noise reduction strategies and proper insulation is essential to mitigate this impact.

On a positive note, the miniaturization enabled by vacuum-based microfabrication can lead to more compact and energy-efficient devices. Microfluidic devices produced through these processes often require smaller sample volumes and consume less power during operation, potentially reducing the overall environmental impact throughout the product lifecycle.

The longevity and durability of microfluidic devices fabricated using vacuum-based processes can also have positive environmental implications. Higher-quality devices with longer lifespans reduce the need for frequent replacements, thereby decreasing waste generation and resource consumption in the long term.

As the field of microfluidic device fabrication evolves, there is a growing focus on developing more environmentally friendly vacuum-based processes. This includes research into alternative materials, more efficient pump designs, and improved recycling methods for process byproducts. These advancements aim to further reduce the environmental footprint of microfabrication while maintaining or enhancing the quality of the final products.

Scalability and Cost-Effectiveness of Vacuum Pump Integration

The integration of vacuum pumps in microfluidic device fabrication presents significant potential for scalability and cost-effectiveness. As the demand for microfluidic devices continues to grow across various industries, including healthcare, biotechnology, and environmental monitoring, the ability to scale up production while maintaining cost efficiency becomes crucial.

Vacuum pumps play a pivotal role in enhancing the scalability of microfluidic device fabrication. By providing precise control over pressure and fluid flow, these pumps enable the production of more complex and intricate microfluidic designs. This increased complexity allows for the development of multi-functional devices capable of performing multiple analyses on a single chip, thereby expanding the range of applications and market potential.

Furthermore, vacuum pump integration facilitates the automation of key fabrication processes, such as bonding, sealing, and fluid manipulation. Automation not only increases production throughput but also improves consistency and reduces human error, leading to higher quality outputs and lower rejection rates. This enhanced efficiency translates directly into improved scalability, as manufacturers can produce larger quantities of devices with greater reliability.

From a cost-effectiveness perspective, the initial investment in vacuum pump technology may seem substantial. However, the long-term benefits often outweigh the upfront costs. The precision and control offered by vacuum pumps result in reduced material waste and improved yield rates. This optimization of resources contributes significantly to overall cost reduction, especially in large-scale production scenarios.

Additionally, the versatility of vacuum pumps allows for their use across different stages of the fabrication process and various device designs. This multi-purpose functionality eliminates the need for multiple specialized tools, further enhancing cost-effectiveness through equipment consolidation. As production scales up, the cost per unit decreases, making vacuum pump integration an increasingly attractive option for manufacturers looking to optimize their operations.

The scalability and cost-effectiveness of vacuum pump integration also extend to the realm of customization. With the ability to rapidly prototype and iterate designs, manufacturers can respond more quickly to market demands and customer specifications. This agility in production not only opens up new market opportunities but also allows for more efficient use of resources, as production runs can be tailored to specific needs rather than relying on large-scale, one-size-fits-all approaches.

In conclusion, the integration of vacuum pumps in microfluidic device fabrication offers a compelling combination of scalability and cost-effectiveness. As the technology continues to evolve and mature, it is likely to play an increasingly important role in driving innovation and efficiency in the microfluidics industry.

Vacuum pumps play a pivotal role in enhancing the scalability of microfluidic device fabrication. By providing precise control over pressure and fluid flow, these pumps enable the production of more complex and intricate microfluidic designs. This increased complexity allows for the development of multi-functional devices capable of performing multiple analyses on a single chip, thereby expanding the range of applications and market potential.

Furthermore, vacuum pump integration facilitates the automation of key fabrication processes, such as bonding, sealing, and fluid manipulation. Automation not only increases production throughput but also improves consistency and reduces human error, leading to higher quality outputs and lower rejection rates. This enhanced efficiency translates directly into improved scalability, as manufacturers can produce larger quantities of devices with greater reliability.

From a cost-effectiveness perspective, the initial investment in vacuum pump technology may seem substantial. However, the long-term benefits often outweigh the upfront costs. The precision and control offered by vacuum pumps result in reduced material waste and improved yield rates. This optimization of resources contributes significantly to overall cost reduction, especially in large-scale production scenarios.

Additionally, the versatility of vacuum pumps allows for their use across different stages of the fabrication process and various device designs. This multi-purpose functionality eliminates the need for multiple specialized tools, further enhancing cost-effectiveness through equipment consolidation. As production scales up, the cost per unit decreases, making vacuum pump integration an increasingly attractive option for manufacturers looking to optimize their operations.

The scalability and cost-effectiveness of vacuum pump integration also extend to the realm of customization. With the ability to rapidly prototype and iterate designs, manufacturers can respond more quickly to market demands and customer specifications. This agility in production not only opens up new market opportunities but also allows for more efficient use of resources, as production runs can be tailored to specific needs rather than relying on large-scale, one-size-fits-all approaches.

In conclusion, the integration of vacuum pumps in microfluidic device fabrication offers a compelling combination of scalability and cost-effectiveness. As the technology continues to evolve and mature, it is likely to play an increasingly important role in driving innovation and efficiency in the microfluidics industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!