Investigating Vacuum Pump Efficiency in Ultra-Clean Gas Systems

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution and Objectives

Vacuum pump technology has undergone significant evolution since its inception in the 17th century. The journey from early mechanical pumps to modern ultra-high vacuum systems reflects the increasing demands of various industries, particularly in semiconductor manufacturing and scientific research. The primary objective in this field has been to achieve higher levels of vacuum while improving efficiency and reliability.

The development of vacuum pumps can be traced through several key stages. Early pumps relied on mechanical displacement, such as the piston pump invented by Otto von Guericke. These were followed by rotary vane pumps in the early 20th century, which offered improved performance and reliability. The mid-20th century saw the introduction of diffusion pumps, capable of achieving much higher vacuum levels, albeit with limitations in terms of contamination risks.

A major breakthrough came with the development of turbomolecular pumps in the 1950s. These pumps, utilizing high-speed rotors, could achieve ultra-high vacuum levels without the risk of oil contamination associated with diffusion pumps. Parallel to this, cryogenic pumps emerged, offering an alternative method for achieving ultra-high vacuums through gas condensation on super-cooled surfaces.

In recent decades, the focus has shifted towards developing more efficient and cleaner pumping technologies. Dry pumps, which operate without oil, have become increasingly popular in applications requiring ultra-clean environments. These pumps, including scroll pumps and multi-stage root pumps, offer significant advantages in terms of cleanliness and maintenance.

The current objectives in vacuum pump technology for ultra-clean gas systems are multifaceted. Firstly, there is a continuous drive to improve pumping efficiency, aiming to achieve higher vacuum levels with lower energy consumption. This is particularly crucial in large-scale industrial applications where energy costs are a significant factor.

Secondly, there is an emphasis on developing pumps with enhanced cleanliness and reduced particle generation. This is essential for industries like semiconductor manufacturing, where even minute contamination can have severe consequences. The goal is to create pumps that not only maintain a high vacuum but also contribute minimally to system contamination.

Another key objective is to improve the reliability and longevity of vacuum pumps. This involves developing more robust materials and designs that can withstand the harsh conditions often encountered in industrial applications. Additionally, there is a growing focus on creating smart pumping systems with integrated sensors and control mechanisms, allowing for real-time monitoring and optimization of pump performance.

As we look to the future, the objectives in vacuum pump technology are likely to include further miniaturization for portable and space-constrained applications, as well as the development of more environmentally friendly pumping solutions. The integration of vacuum pump technology with emerging fields such as nanotechnology and quantum computing also presents exciting new challenges and opportunities for innovation.

The development of vacuum pumps can be traced through several key stages. Early pumps relied on mechanical displacement, such as the piston pump invented by Otto von Guericke. These were followed by rotary vane pumps in the early 20th century, which offered improved performance and reliability. The mid-20th century saw the introduction of diffusion pumps, capable of achieving much higher vacuum levels, albeit with limitations in terms of contamination risks.

A major breakthrough came with the development of turbomolecular pumps in the 1950s. These pumps, utilizing high-speed rotors, could achieve ultra-high vacuum levels without the risk of oil contamination associated with diffusion pumps. Parallel to this, cryogenic pumps emerged, offering an alternative method for achieving ultra-high vacuums through gas condensation on super-cooled surfaces.

In recent decades, the focus has shifted towards developing more efficient and cleaner pumping technologies. Dry pumps, which operate without oil, have become increasingly popular in applications requiring ultra-clean environments. These pumps, including scroll pumps and multi-stage root pumps, offer significant advantages in terms of cleanliness and maintenance.

The current objectives in vacuum pump technology for ultra-clean gas systems are multifaceted. Firstly, there is a continuous drive to improve pumping efficiency, aiming to achieve higher vacuum levels with lower energy consumption. This is particularly crucial in large-scale industrial applications where energy costs are a significant factor.

Secondly, there is an emphasis on developing pumps with enhanced cleanliness and reduced particle generation. This is essential for industries like semiconductor manufacturing, where even minute contamination can have severe consequences. The goal is to create pumps that not only maintain a high vacuum but also contribute minimally to system contamination.

Another key objective is to improve the reliability and longevity of vacuum pumps. This involves developing more robust materials and designs that can withstand the harsh conditions often encountered in industrial applications. Additionally, there is a growing focus on creating smart pumping systems with integrated sensors and control mechanisms, allowing for real-time monitoring and optimization of pump performance.

As we look to the future, the objectives in vacuum pump technology are likely to include further miniaturization for portable and space-constrained applications, as well as the development of more environmentally friendly pumping solutions. The integration of vacuum pump technology with emerging fields such as nanotechnology and quantum computing also presents exciting new challenges and opportunities for innovation.

Ultra-Clean Gas System Market Analysis

The ultra-clean gas system market has experienced significant growth in recent years, driven by the increasing demand for high-purity gases in various industries. This market segment is particularly crucial for semiconductor manufacturing, pharmaceuticals, and advanced research facilities where even minute impurities can have detrimental effects on processes and outcomes.

The global ultra-clean gas system market size was valued at approximately $5.2 billion in 2020 and is projected to reach $7.8 billion by 2025, growing at a CAGR of 8.4% during the forecast period. This growth is primarily attributed to the rapid expansion of the semiconductor industry, especially in Asia-Pacific regions such as Taiwan, South Korea, and China.

The semiconductor industry remains the largest end-user segment for ultra-clean gas systems, accounting for over 60% of the market share. The increasing complexity of semiconductor devices and the push towards smaller node sizes have heightened the need for ultra-pure gases and efficient gas delivery systems. Additionally, the growing adoption of IoT devices, 5G technology, and artificial intelligence has further fueled the demand for advanced semiconductors, indirectly boosting the ultra-clean gas system market.

Pharmaceuticals and biotechnology sectors are emerging as significant growth drivers for the ultra-clean gas system market. The stringent regulatory requirements for drug manufacturing and the increasing focus on biologics and personalized medicine have led to a greater emphasis on maintaining ultra-clean environments, thereby driving the demand for high-purity gas systems.

Geographically, Asia-Pacific dominates the ultra-clean gas system market, accounting for approximately 45% of the global market share. This dominance is primarily due to the presence of major semiconductor manufacturing hubs in countries like Taiwan, South Korea, and Japan. North America and Europe follow, with significant contributions from the pharmaceutical and research sectors.

The market is characterized by intense competition among key players such as Linde plc, Air Liquide, Air Products and Chemicals, Inc., and Praxair Technology, Inc. These companies are focusing on technological advancements, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolios.

A notable trend in the ultra-clean gas system market is the increasing focus on energy efficiency and sustainability. End-users are demanding gas delivery systems that not only ensure ultra-high purity but also optimize energy consumption. This trend aligns with the growing emphasis on reducing the carbon footprint in industrial processes, presenting opportunities for innovative solutions in vacuum pump technology and gas purification methods.

The global ultra-clean gas system market size was valued at approximately $5.2 billion in 2020 and is projected to reach $7.8 billion by 2025, growing at a CAGR of 8.4% during the forecast period. This growth is primarily attributed to the rapid expansion of the semiconductor industry, especially in Asia-Pacific regions such as Taiwan, South Korea, and China.

The semiconductor industry remains the largest end-user segment for ultra-clean gas systems, accounting for over 60% of the market share. The increasing complexity of semiconductor devices and the push towards smaller node sizes have heightened the need for ultra-pure gases and efficient gas delivery systems. Additionally, the growing adoption of IoT devices, 5G technology, and artificial intelligence has further fueled the demand for advanced semiconductors, indirectly boosting the ultra-clean gas system market.

Pharmaceuticals and biotechnology sectors are emerging as significant growth drivers for the ultra-clean gas system market. The stringent regulatory requirements for drug manufacturing and the increasing focus on biologics and personalized medicine have led to a greater emphasis on maintaining ultra-clean environments, thereby driving the demand for high-purity gas systems.

Geographically, Asia-Pacific dominates the ultra-clean gas system market, accounting for approximately 45% of the global market share. This dominance is primarily due to the presence of major semiconductor manufacturing hubs in countries like Taiwan, South Korea, and Japan. North America and Europe follow, with significant contributions from the pharmaceutical and research sectors.

The market is characterized by intense competition among key players such as Linde plc, Air Liquide, Air Products and Chemicals, Inc., and Praxair Technology, Inc. These companies are focusing on technological advancements, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolios.

A notable trend in the ultra-clean gas system market is the increasing focus on energy efficiency and sustainability. End-users are demanding gas delivery systems that not only ensure ultra-high purity but also optimize energy consumption. This trend aligns with the growing emphasis on reducing the carbon footprint in industrial processes, presenting opportunities for innovative solutions in vacuum pump technology and gas purification methods.

Vacuum Pump Efficiency Challenges

Vacuum pump efficiency in ultra-clean gas systems faces several significant challenges that impact overall system performance and operational costs. One of the primary issues is maintaining high efficiency under varying gas loads and pressure conditions. As process requirements fluctuate, pumps must adapt to changing demands while maintaining optimal performance, which can be particularly challenging in ultra-clean environments where even minor fluctuations can have significant impacts.

Another major challenge is preventing contamination and maintaining cleanliness within the pump itself. Ultra-clean gas systems require extremely high purity levels, and any contamination introduced by the pump can compromise the entire process. This necessitates the use of specialized materials and designs that can withstand aggressive cleaning procedures and minimize particle generation, often at the expense of pump efficiency.

Heat generation and management present additional hurdles in vacuum pump efficiency. As pumps operate, they generate heat which can affect both the pump's performance and the purity of the gas being processed. Efficient cooling systems are crucial but must be designed in a way that doesn't introduce potential contamination sources or reduce overall system efficiency.

Energy consumption is a persistent concern in vacuum pump operations. High-efficiency pumps often come with increased complexity and cost, creating a balancing act between initial investment, operational expenses, and long-term energy savings. This is particularly relevant in industries where energy costs significantly impact the bottom line.

Maintenance and reliability also pose challenges to sustained pump efficiency. Ultra-clean environments often require frequent maintenance to ensure consistent performance, but each maintenance intervention introduces risks of contamination and downtime. Developing pumps that can maintain high efficiency over extended periods with minimal maintenance is a key area of focus.

The integration of advanced control systems and sensors to optimize pump performance in real-time is another challenge. While these technologies offer the potential for significant efficiency improvements, they also introduce additional complexity and potential failure points into the system.

Lastly, the development of new materials and coatings that can enhance pump efficiency while meeting the stringent requirements of ultra-clean environments remains an ongoing challenge. Innovations in this area must balance performance improvements with compatibility with ultra-pure gases and resistance to corrosion and degradation.

Another major challenge is preventing contamination and maintaining cleanliness within the pump itself. Ultra-clean gas systems require extremely high purity levels, and any contamination introduced by the pump can compromise the entire process. This necessitates the use of specialized materials and designs that can withstand aggressive cleaning procedures and minimize particle generation, often at the expense of pump efficiency.

Heat generation and management present additional hurdles in vacuum pump efficiency. As pumps operate, they generate heat which can affect both the pump's performance and the purity of the gas being processed. Efficient cooling systems are crucial but must be designed in a way that doesn't introduce potential contamination sources or reduce overall system efficiency.

Energy consumption is a persistent concern in vacuum pump operations. High-efficiency pumps often come with increased complexity and cost, creating a balancing act between initial investment, operational expenses, and long-term energy savings. This is particularly relevant in industries where energy costs significantly impact the bottom line.

Maintenance and reliability also pose challenges to sustained pump efficiency. Ultra-clean environments often require frequent maintenance to ensure consistent performance, but each maintenance intervention introduces risks of contamination and downtime. Developing pumps that can maintain high efficiency over extended periods with minimal maintenance is a key area of focus.

The integration of advanced control systems and sensors to optimize pump performance in real-time is another challenge. While these technologies offer the potential for significant efficiency improvements, they also introduce additional complexity and potential failure points into the system.

Lastly, the development of new materials and coatings that can enhance pump efficiency while meeting the stringent requirements of ultra-clean environments remains an ongoing challenge. Innovations in this area must balance performance improvements with compatibility with ultra-pure gases and resistance to corrosion and degradation.

Current Efficiency Enhancement Methods

01 Improved rotor design for vacuum pumps

Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping capacity. Advanced rotor designs can lead to better sealing, reduced wear, and improved overall performance of the vacuum pump.- Improved rotor design for vacuum pumps: Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping capacity. Advanced rotor designs can lead to better performance and higher vacuum levels.

- Innovative sealing mechanisms: Developing new sealing mechanisms or improving existing ones can greatly enhance vacuum pump efficiency. Effective seals prevent leakage, maintain vacuum integrity, and reduce power consumption. This may involve using advanced materials, precision engineering, or novel sealing designs to minimize friction and wear while maximizing sealing effectiveness.

- Integration of smart control systems: Incorporating smart control systems and sensors into vacuum pumps can optimize their operation in real-time. These systems can adjust pump parameters based on load conditions, monitor performance, and predict maintenance needs. This leads to improved energy efficiency, reduced downtime, and extended pump life.

- Advanced cooling and lubrication techniques: Implementing advanced cooling and lubrication systems can significantly enhance vacuum pump efficiency. This includes developing new cooling methods, using high-performance lubricants, and designing better heat dissipation mechanisms. Effective cooling and lubrication reduce friction, prevent overheating, and ensure optimal pump performance under various operating conditions.

- Multi-stage and hybrid pump designs: Developing multi-stage or hybrid vacuum pump designs can improve overall efficiency by combining the advantages of different pump types. These innovative configurations can achieve higher vacuum levels, increased pumping speeds, and better energy efficiency across a wider range of operating conditions. Such designs may integrate various pumping mechanisms to optimize performance for specific applications.

02 Enhanced sealing mechanisms

Developing more effective sealing mechanisms is crucial for improving vacuum pump efficiency. This involves implementing innovative sealing technologies, such as advanced gaskets, mechanical seals, or magnetic fluid seals. Improved sealing reduces leakage, maintains better vacuum levels, and minimizes power consumption, thereby enhancing overall pump efficiency.Expand Specific Solutions03 Optimized pump chamber geometry

Refining the geometry of the pump chamber can lead to significant efficiency gains. This includes designing the chamber shape to minimize dead space, improve gas flow dynamics, and reduce turbulence. Optimized chamber geometry can result in faster pump-down times, better ultimate vacuum, and reduced power consumption.Expand Specific Solutions04 Advanced motor and drive systems

Incorporating advanced motor and drive systems can greatly enhance vacuum pump efficiency. This includes using high-efficiency electric motors, variable speed drives, and intelligent control systems. These improvements allow for better power management, reduced energy consumption, and optimized pump performance across different operating conditions.Expand Specific Solutions05 Innovative cooling and lubrication techniques

Developing innovative cooling and lubrication techniques can significantly improve vacuum pump efficiency. This involves implementing advanced heat dissipation methods, using high-performance lubricants, and designing more effective cooling systems. Improved thermal management and lubrication reduce friction, extend pump life, and maintain consistent performance, leading to overall efficiency gains.Expand Specific Solutions

Key Vacuum Pump Manufacturers

The vacuum pump efficiency market for ultra-clean gas systems is in a mature growth phase, with a global market size estimated to be in the billions of dollars. The technology has reached a high level of maturity, with established players like Edwards Ltd., Pfeiffer Vacuum GmbH, and Leybold AG dominating the industry. These companies have developed advanced solutions that offer high efficiency and reliability in ultra-clean environments. Emerging players such as SAES Getters SpA and Inficon GmbH are also making significant contributions, focusing on innovative technologies to improve pump performance and energy efficiency. The competitive landscape is characterized by ongoing research and development efforts to enhance pump efficiency, reduce energy consumption, and meet the increasingly stringent requirements of ultra-clean gas systems in semiconductor manufacturing and other high-tech industries.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced turbomolecular pumps with magnetic bearings for ultra-clean gas systems. Their latest XDS dry scroll pumps utilize a patented tip-seal technology, reducing particulate generation and enhancing pump efficiency. The company's nEXT turbomolecular pumps incorporate a drag stage for improved compression of light gases, achieving pumping speeds up to 3000 l/s [1]. Edwards has also introduced adaptive control algorithms that optimize pump performance based on real-time process conditions, resulting in up to 20% energy savings in certain applications [3].

Strengths: High pumping speeds, advanced bearing technology, and adaptive control for energy efficiency. Weaknesses: Higher initial cost compared to traditional pumps, and potential complexity in maintenance for advanced features.

LEYBOLD AG

Technical Solution: LEYBOLD AG has focused on developing oil-free vacuum solutions for ultra-clean applications. Their SCREWLINE series of dry compressing screw pumps offers high robustness and reliability in harsh industrial environments. LEYBOLD's TURBOVAC i/iX turbomolecular pumps feature an integrated drive electronics design, reducing system complexity and footprint. The company has also introduced the NOVADRY pump series, which uses a unique twin-screw technology to achieve high efficiency in humid processes, with water vapor tolerance up to 100% relative humidity [2]. LEYBOLD's pumps incorporate advanced rotor designs that minimize internal leakage, resulting in improved pumping efficiency and reduced power consumption [4].

Strengths: Robust designs for industrial use, high water vapor tolerance, and integrated electronics for simplified systems. Weaknesses: May have limitations in extreme ultra-high vacuum applications compared to some competitors.

Innovative Vacuum Pump Designs

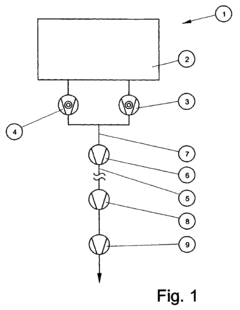

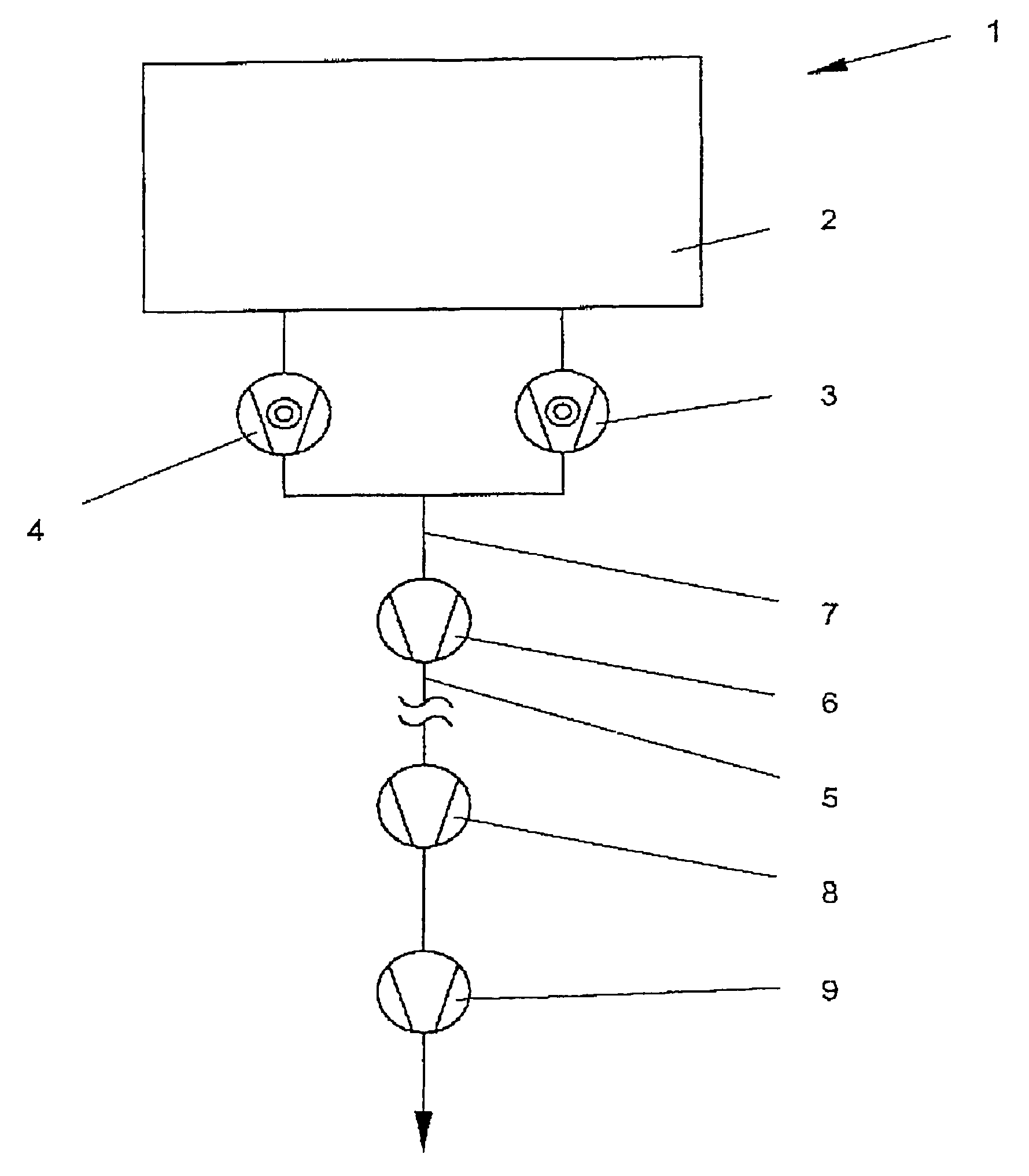

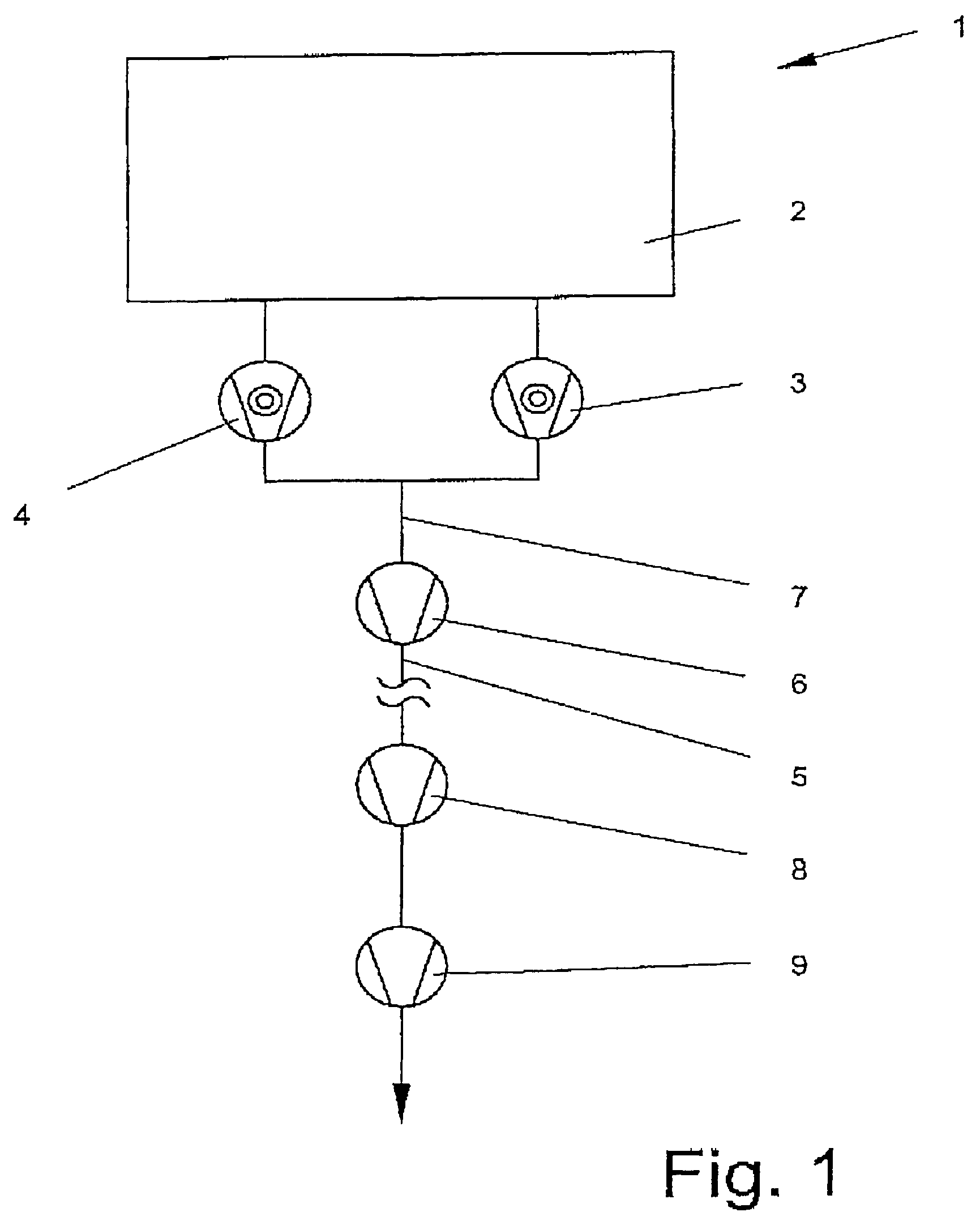

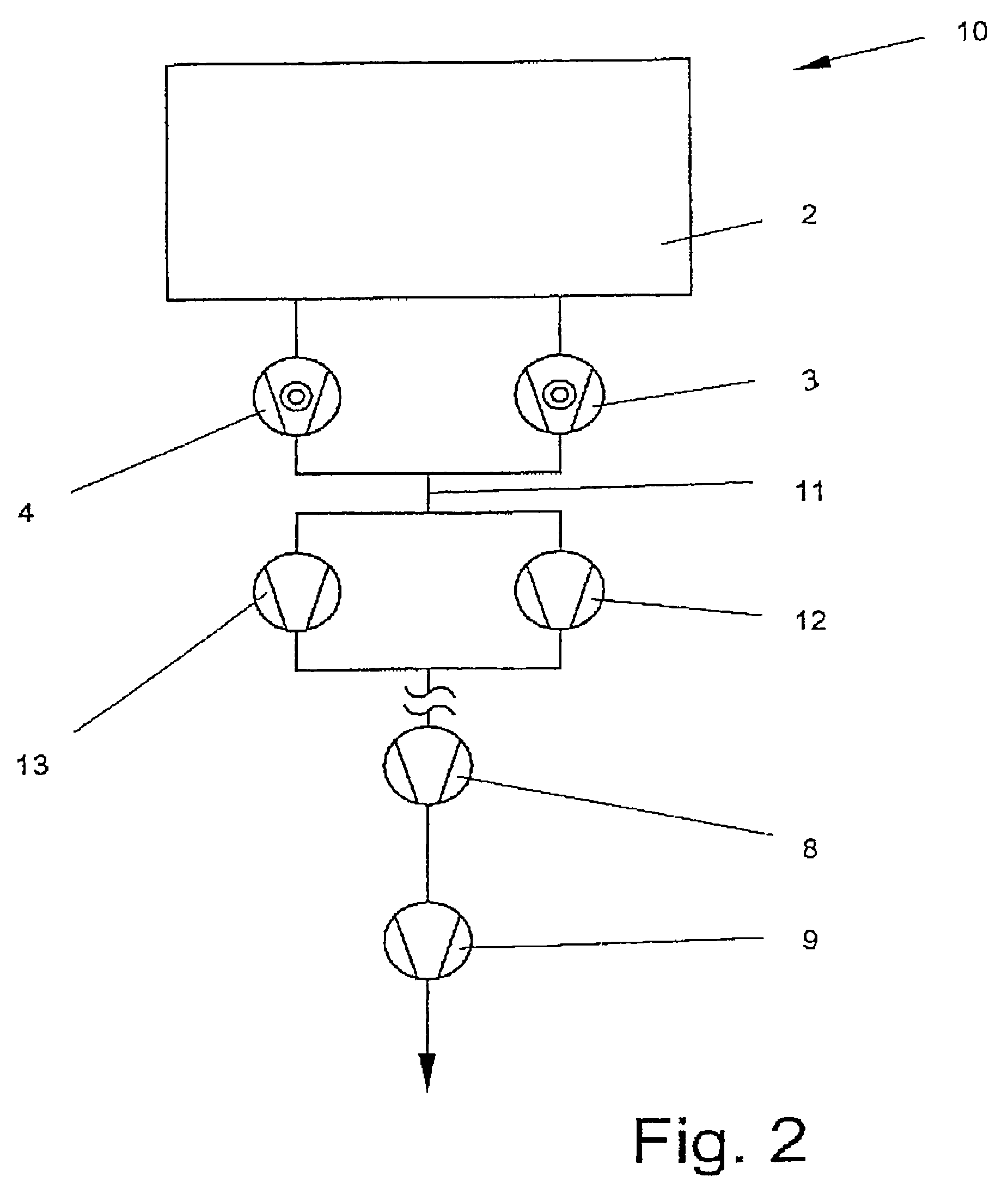

Vacuum pump system

PatentInactiveEP1441128A3

Innovation

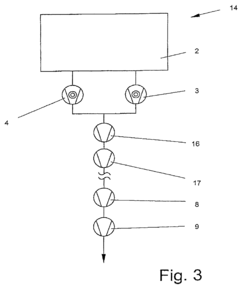

- Incorporating an intermediate pump between the high-vacuum pump discharge and the fore-vacuum system, which can be a molecular or turbomolecular pump, connected directly to minimize conductance losses and enhance compression, allowing for series or parallel configurations to increase pumping speed and throughput.

Vacuum pump system for light gases

PatentInactiveUS7033142B2

Innovation

- The introduction of an intermediate pump, preferably a molecular or turbomolecular pump, directly connected between the high-vacuum pump and the fore-vacuum pump to enhance compression and suction capacity, allowing for efficient handling of light gases without significant modifications or additional expenses.

Environmental Impact Assessment

The environmental impact of vacuum pump systems in ultra-clean gas applications is a critical consideration for industries striving to balance technological advancement with ecological responsibility. These systems, while essential for maintaining the purity of gases in various processes, can have significant environmental implications if not properly managed.

Energy consumption is a primary environmental concern associated with vacuum pump efficiency. High-performance pumps often require substantial electrical power, contributing to increased carbon emissions if the energy source is not renewable. Improving pump efficiency can lead to reduced energy consumption, thereby lowering the overall carbon footprint of the operation. This aligns with global efforts to mitigate climate change and meet stringent environmental regulations.

Noise pollution is another environmental factor to consider. Vacuum pumps, especially those operating at high speeds or under heavy loads, can generate considerable noise. This not only affects the immediate working environment but can also impact surrounding ecosystems if the facility is located near sensitive habitats. Implementing noise reduction technologies and proper insulation can help mitigate this issue.

The disposal of pump oils and lubricants presents a potential environmental hazard. Many vacuum pumps require regular oil changes, and improper disposal of these substances can lead to soil and water contamination. Adopting oil-free pump technologies or implementing rigorous recycling and disposal protocols can significantly reduce this environmental risk.

In ultra-clean gas systems, the release of process gases or contaminants into the atmosphere is a critical concern. Inefficient pumps may lead to leaks or incomplete gas capture, potentially releasing harmful substances into the environment. Enhancing pump sealing mechanisms and implementing advanced gas recovery systems can minimize these emissions, protecting both air quality and the ozone layer.

Water consumption is another environmental aspect to consider, particularly in pumps that use water for cooling or as a sealant. Efficient water management systems, including closed-loop cooling and water recycling, can substantially reduce the environmental impact of these operations.

The lifecycle assessment of vacuum pumps is crucial for understanding their long-term environmental impact. This includes considering the environmental costs of manufacturing, transportation, operation, and eventual disposal or recycling of the equipment. Choosing pumps with longer operational lifespans and those made from recyclable materials can contribute to a more sustainable approach.

By addressing these environmental concerns through improved vacuum pump efficiency and responsible management practices, industries can significantly reduce their ecological footprint while maintaining the high standards required for ultra-clean gas systems.

Energy consumption is a primary environmental concern associated with vacuum pump efficiency. High-performance pumps often require substantial electrical power, contributing to increased carbon emissions if the energy source is not renewable. Improving pump efficiency can lead to reduced energy consumption, thereby lowering the overall carbon footprint of the operation. This aligns with global efforts to mitigate climate change and meet stringent environmental regulations.

Noise pollution is another environmental factor to consider. Vacuum pumps, especially those operating at high speeds or under heavy loads, can generate considerable noise. This not only affects the immediate working environment but can also impact surrounding ecosystems if the facility is located near sensitive habitats. Implementing noise reduction technologies and proper insulation can help mitigate this issue.

The disposal of pump oils and lubricants presents a potential environmental hazard. Many vacuum pumps require regular oil changes, and improper disposal of these substances can lead to soil and water contamination. Adopting oil-free pump technologies or implementing rigorous recycling and disposal protocols can significantly reduce this environmental risk.

In ultra-clean gas systems, the release of process gases or contaminants into the atmosphere is a critical concern. Inefficient pumps may lead to leaks or incomplete gas capture, potentially releasing harmful substances into the environment. Enhancing pump sealing mechanisms and implementing advanced gas recovery systems can minimize these emissions, protecting both air quality and the ozone layer.

Water consumption is another environmental aspect to consider, particularly in pumps that use water for cooling or as a sealant. Efficient water management systems, including closed-loop cooling and water recycling, can substantially reduce the environmental impact of these operations.

The lifecycle assessment of vacuum pumps is crucial for understanding their long-term environmental impact. This includes considering the environmental costs of manufacturing, transportation, operation, and eventual disposal or recycling of the equipment. Choosing pumps with longer operational lifespans and those made from recyclable materials can contribute to a more sustainable approach.

By addressing these environmental concerns through improved vacuum pump efficiency and responsible management practices, industries can significantly reduce their ecological footprint while maintaining the high standards required for ultra-clean gas systems.

Vacuum Pump Standardization

Vacuum pump standardization plays a crucial role in enhancing the efficiency and reliability of ultra-clean gas systems. This process involves establishing uniform specifications, performance criteria, and operational guidelines for vacuum pumps across various applications. By implementing standardized practices, industries can achieve consistent performance, improved interoperability, and reduced maintenance costs.

One of the primary benefits of vacuum pump standardization is the simplification of system design and integration. When pumps adhere to standardized specifications, engineers can more easily incorporate them into existing or new ultra-clean gas systems without extensive modifications. This streamlines the design process and reduces the likelihood of compatibility issues, ultimately leading to faster project completion and lower overall costs.

Standardization also facilitates more accurate performance comparisons between different vacuum pump models and manufacturers. By establishing uniform testing protocols and performance metrics, end-users can make informed decisions when selecting pumps for specific applications. This transparency in performance data encourages healthy competition among manufacturers, driving innovation and continuous improvement in pump technology.

Maintenance and spare parts management become significantly more straightforward with standardized vacuum pumps. Technicians can develop standardized maintenance procedures that apply across multiple pump models, reducing the need for specialized training and minimizing the risk of errors during servicing. Additionally, standardization often leads to a reduction in the variety of spare parts required, simplifying inventory management and reducing storage costs for replacement components.

In the context of ultra-clean gas systems, vacuum pump standardization contributes to improved process control and repeatability. When pumps operate within well-defined parameters, it becomes easier to maintain consistent vacuum levels and gas flow rates, which are critical for many high-purity applications. This consistency translates to better product quality and reduced variability in manufacturing processes.

Standardization efforts often extend beyond individual pumps to encompass entire vacuum systems. This holistic approach includes standardizing connection interfaces, control protocols, and monitoring systems. By creating a unified ecosystem of vacuum components, industries can achieve greater system-wide efficiency and reliability, while also simplifying troubleshooting and optimization processes.

As the demand for ultra-clean gas systems continues to grow across various industries, including semiconductor manufacturing, pharmaceutical production, and advanced materials research, the importance of vacuum pump standardization becomes increasingly apparent. It serves as a foundation for technological advancement, enabling more sophisticated and efficient processes while ensuring compatibility and ease of integration across diverse applications.

One of the primary benefits of vacuum pump standardization is the simplification of system design and integration. When pumps adhere to standardized specifications, engineers can more easily incorporate them into existing or new ultra-clean gas systems without extensive modifications. This streamlines the design process and reduces the likelihood of compatibility issues, ultimately leading to faster project completion and lower overall costs.

Standardization also facilitates more accurate performance comparisons between different vacuum pump models and manufacturers. By establishing uniform testing protocols and performance metrics, end-users can make informed decisions when selecting pumps for specific applications. This transparency in performance data encourages healthy competition among manufacturers, driving innovation and continuous improvement in pump technology.

Maintenance and spare parts management become significantly more straightforward with standardized vacuum pumps. Technicians can develop standardized maintenance procedures that apply across multiple pump models, reducing the need for specialized training and minimizing the risk of errors during servicing. Additionally, standardization often leads to a reduction in the variety of spare parts required, simplifying inventory management and reducing storage costs for replacement components.

In the context of ultra-clean gas systems, vacuum pump standardization contributes to improved process control and repeatability. When pumps operate within well-defined parameters, it becomes easier to maintain consistent vacuum levels and gas flow rates, which are critical for many high-purity applications. This consistency translates to better product quality and reduced variability in manufacturing processes.

Standardization efforts often extend beyond individual pumps to encompass entire vacuum systems. This holistic approach includes standardizing connection interfaces, control protocols, and monitoring systems. By creating a unified ecosystem of vacuum components, industries can achieve greater system-wide efficiency and reliability, while also simplifying troubleshooting and optimization processes.

As the demand for ultra-clean gas systems continues to grow across various industries, including semiconductor manufacturing, pharmaceutical production, and advanced materials research, the importance of vacuum pump standardization becomes increasingly apparent. It serves as a foundation for technological advancement, enabling more sophisticated and efficient processes while ensuring compatibility and ease of integration across diverse applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!