Vacuum Pump Optimization for Aerodynamic Application in Wind Tunnels

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution and Objectives

Vacuum pumps have played a crucial role in aerodynamic applications, particularly in wind tunnels, since the early 20th century. The evolution of these pumps has been closely tied to advancements in aerospace technology and the increasing demands for more precise and efficient testing environments. Initially, basic mechanical pumps were used to create low-pressure environments, but their limitations in achieving high vacuum levels and maintaining stable conditions became apparent as wind tunnel testing requirements grew more sophisticated.

The mid-20th century saw significant improvements in vacuum pump technology, with the introduction of diffusion pumps and turbomolecular pumps. These innovations allowed for the creation of higher vacuum levels and more stable testing conditions, enabling researchers to conduct more accurate aerodynamic studies. As the aerospace industry progressed, the need for larger wind tunnels and more extreme testing conditions drove further developments in vacuum pump technology.

In recent decades, the focus has shifted towards optimizing vacuum pumps specifically for wind tunnel applications. This has involved addressing key challenges such as minimizing pump-induced vibrations, reducing power consumption, and improving pump reliability and longevity. The integration of advanced materials and precision engineering techniques has led to the development of pumps capable of maintaining ultra-high vacuum levels with minimal fluctuations, critical for accurate aerodynamic measurements.

The current objectives in vacuum pump optimization for wind tunnels are multifaceted. One primary goal is to enhance energy efficiency, as large-scale wind tunnels require significant power to operate. This involves developing pumps with higher throughput and lower energy consumption, potentially through the use of novel pump designs or advanced motor technologies. Another objective is to improve pump responsiveness and control, allowing for rapid adjustments to vacuum levels to simulate various atmospheric conditions accurately.

Reducing the environmental impact of vacuum pump operations is also a key focus. This includes developing pumps with lower emissions and exploring the use of environmentally friendly working fluids. Additionally, there is a push towards creating more compact and modular pump systems, allowing for easier installation, maintenance, and upgrades in existing wind tunnel facilities.

The integration of smart technologies and IoT capabilities into vacuum pump systems represents another important objective. This aims to enable real-time monitoring, predictive maintenance, and automated optimization of pump performance, enhancing overall system reliability and efficiency. Furthermore, researchers are exploring ways to extend the operational range of vacuum pumps, allowing for testing under more extreme conditions that simulate high-altitude or space environments.

As wind tunnel testing continues to play a vital role in aerospace research and development, the evolution of vacuum pump technology remains critical. The ongoing objectives in this field are driven by the need for more precise, efficient, and versatile testing capabilities, supporting advancements in aircraft design, space exploration, and other aerodynamic applications.

The mid-20th century saw significant improvements in vacuum pump technology, with the introduction of diffusion pumps and turbomolecular pumps. These innovations allowed for the creation of higher vacuum levels and more stable testing conditions, enabling researchers to conduct more accurate aerodynamic studies. As the aerospace industry progressed, the need for larger wind tunnels and more extreme testing conditions drove further developments in vacuum pump technology.

In recent decades, the focus has shifted towards optimizing vacuum pumps specifically for wind tunnel applications. This has involved addressing key challenges such as minimizing pump-induced vibrations, reducing power consumption, and improving pump reliability and longevity. The integration of advanced materials and precision engineering techniques has led to the development of pumps capable of maintaining ultra-high vacuum levels with minimal fluctuations, critical for accurate aerodynamic measurements.

The current objectives in vacuum pump optimization for wind tunnels are multifaceted. One primary goal is to enhance energy efficiency, as large-scale wind tunnels require significant power to operate. This involves developing pumps with higher throughput and lower energy consumption, potentially through the use of novel pump designs or advanced motor technologies. Another objective is to improve pump responsiveness and control, allowing for rapid adjustments to vacuum levels to simulate various atmospheric conditions accurately.

Reducing the environmental impact of vacuum pump operations is also a key focus. This includes developing pumps with lower emissions and exploring the use of environmentally friendly working fluids. Additionally, there is a push towards creating more compact and modular pump systems, allowing for easier installation, maintenance, and upgrades in existing wind tunnel facilities.

The integration of smart technologies and IoT capabilities into vacuum pump systems represents another important objective. This aims to enable real-time monitoring, predictive maintenance, and automated optimization of pump performance, enhancing overall system reliability and efficiency. Furthermore, researchers are exploring ways to extend the operational range of vacuum pumps, allowing for testing under more extreme conditions that simulate high-altitude or space environments.

As wind tunnel testing continues to play a vital role in aerospace research and development, the evolution of vacuum pump technology remains critical. The ongoing objectives in this field are driven by the need for more precise, efficient, and versatile testing capabilities, supporting advancements in aircraft design, space exploration, and other aerodynamic applications.

Wind Tunnel Market Analysis

The wind tunnel market has experienced significant growth in recent years, driven by increasing demand for aerodynamic testing across various industries. The global wind tunnel market size was valued at approximately $2.5 billion in 2020 and is projected to reach $3.8 billion by 2027, growing at a CAGR of 6.2% during the forecast period. This growth is primarily attributed to the rising adoption of wind tunnels in automotive, aerospace, and defense sectors for performance optimization and design validation.

The automotive industry remains the largest end-user segment of wind tunnels, accounting for over 40% of the market share. Stringent fuel efficiency regulations and the growing focus on electric vehicles have led to increased investments in aerodynamic testing facilities. Major automotive manufacturers are continuously upgrading their wind tunnel capabilities to improve vehicle performance and reduce emissions.

In the aerospace sector, the demand for wind tunnels is driven by the development of next-generation aircraft, unmanned aerial vehicles (UAVs), and space exploration missions. The need for high-speed and hypersonic wind tunnels has grown significantly, particularly for military applications and supersonic commercial aircraft development.

Geographically, North America dominates the wind tunnel market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its strong presence in aerospace and defense industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by increasing investments in automotive R&D and the rapid expansion of aerospace industries in countries like China and India.

The wind tunnel market is characterized by the presence of both established players and new entrants. Key market players include Boeing, Lockheed Martin, Aiolos Engineering, and Mitsubishi Heavy Industries. These companies are focusing on technological advancements, such as the integration of computational fluid dynamics (CFD) with wind tunnel testing, to enhance their market position.

The COVID-19 pandemic has had a mixed impact on the wind tunnel market. While it initially caused disruptions in supply chains and project delays, the pandemic has also accelerated the adoption of digital technologies in wind tunnel testing, including remote operation capabilities and virtual testing environments.

Looking ahead, the wind tunnel market is poised for continued growth, driven by advancements in testing technologies, increasing focus on sustainable transportation, and the emergence of new applications in sectors such as renewable energy and urban planning. The optimization of vacuum pumps for aerodynamic applications in wind tunnels represents a critical area of development, as it directly impacts the efficiency and capabilities of these testing facilities.

The automotive industry remains the largest end-user segment of wind tunnels, accounting for over 40% of the market share. Stringent fuel efficiency regulations and the growing focus on electric vehicles have led to increased investments in aerodynamic testing facilities. Major automotive manufacturers are continuously upgrading their wind tunnel capabilities to improve vehicle performance and reduce emissions.

In the aerospace sector, the demand for wind tunnels is driven by the development of next-generation aircraft, unmanned aerial vehicles (UAVs), and space exploration missions. The need for high-speed and hypersonic wind tunnels has grown significantly, particularly for military applications and supersonic commercial aircraft development.

Geographically, North America dominates the wind tunnel market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its strong presence in aerospace and defense industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by increasing investments in automotive R&D and the rapid expansion of aerospace industries in countries like China and India.

The wind tunnel market is characterized by the presence of both established players and new entrants. Key market players include Boeing, Lockheed Martin, Aiolos Engineering, and Mitsubishi Heavy Industries. These companies are focusing on technological advancements, such as the integration of computational fluid dynamics (CFD) with wind tunnel testing, to enhance their market position.

The COVID-19 pandemic has had a mixed impact on the wind tunnel market. While it initially caused disruptions in supply chains and project delays, the pandemic has also accelerated the adoption of digital technologies in wind tunnel testing, including remote operation capabilities and virtual testing environments.

Looking ahead, the wind tunnel market is poised for continued growth, driven by advancements in testing technologies, increasing focus on sustainable transportation, and the emergence of new applications in sectors such as renewable energy and urban planning. The optimization of vacuum pumps for aerodynamic applications in wind tunnels represents a critical area of development, as it directly impacts the efficiency and capabilities of these testing facilities.

Vacuum Pump Challenges in Wind Tunnels

Vacuum pumps play a crucial role in wind tunnel operations, providing the necessary low-pressure environment for aerodynamic testing. However, their application in this context presents several significant challenges that researchers and engineers must address to ensure optimal performance and reliable results.

One of the primary challenges is maintaining consistent vacuum levels throughout the wind tunnel test section. As air flows through the tunnel at high speeds, it can create pressure fluctuations that affect the stability of the vacuum. These fluctuations can lead to inconsistent test conditions, potentially compromising the accuracy of aerodynamic measurements. Engineers must develop sophisticated control systems and pump configurations to mitigate these effects and maintain a stable vacuum environment.

The scale of wind tunnels also poses a significant challenge for vacuum pump systems. Large-scale wind tunnels require substantial pumping capacity to evacuate the air quickly and efficiently. This necessitates the use of multiple high-capacity pumps working in tandem, which introduces complexities in system design, synchronization, and maintenance. Balancing the pumping speed with the required vacuum level becomes a delicate optimization problem, especially when considering energy efficiency and operational costs.

Heat generation is another critical issue in vacuum pump operation for wind tunnels. The compression of air during the pumping process generates considerable heat, which can affect both the pump's performance and the overall temperature control within the wind tunnel. Effective cooling systems must be integrated to dissipate this heat and prevent thermal interference with aerodynamic tests. Additionally, the heat generated can lead to increased wear on pump components, potentially reducing their lifespan and reliability.

Contamination control presents yet another challenge. Wind tunnel experiments often involve the use of smoke, particles, or other tracer materials for flow visualization. These substances can potentially enter the vacuum system, leading to pump degradation or failure. Implementing robust filtration systems and regular maintenance protocols is essential to protect the pumps and ensure their longevity.

The dynamic nature of wind tunnel testing also demands rapid vacuum cycling capabilities. Experiments may require quick changes in pressure conditions, necessitating vacuum pumps that can respond swiftly to varying demands. This requirement often conflicts with the need for stable, consistent vacuum levels, creating a complex engineering trade-off that must be carefully managed.

Noise and vibration generated by vacuum pumps can interfere with sensitive measurements in wind tunnel experiments. Isolating these disturbances through advanced mounting techniques and sound-dampening enclosures is crucial for maintaining the integrity of aerodynamic data. However, these solutions must be implemented without compromising the accessibility and serviceability of the pump systems.

One of the primary challenges is maintaining consistent vacuum levels throughout the wind tunnel test section. As air flows through the tunnel at high speeds, it can create pressure fluctuations that affect the stability of the vacuum. These fluctuations can lead to inconsistent test conditions, potentially compromising the accuracy of aerodynamic measurements. Engineers must develop sophisticated control systems and pump configurations to mitigate these effects and maintain a stable vacuum environment.

The scale of wind tunnels also poses a significant challenge for vacuum pump systems. Large-scale wind tunnels require substantial pumping capacity to evacuate the air quickly and efficiently. This necessitates the use of multiple high-capacity pumps working in tandem, which introduces complexities in system design, synchronization, and maintenance. Balancing the pumping speed with the required vacuum level becomes a delicate optimization problem, especially when considering energy efficiency and operational costs.

Heat generation is another critical issue in vacuum pump operation for wind tunnels. The compression of air during the pumping process generates considerable heat, which can affect both the pump's performance and the overall temperature control within the wind tunnel. Effective cooling systems must be integrated to dissipate this heat and prevent thermal interference with aerodynamic tests. Additionally, the heat generated can lead to increased wear on pump components, potentially reducing their lifespan and reliability.

Contamination control presents yet another challenge. Wind tunnel experiments often involve the use of smoke, particles, or other tracer materials for flow visualization. These substances can potentially enter the vacuum system, leading to pump degradation or failure. Implementing robust filtration systems and regular maintenance protocols is essential to protect the pumps and ensure their longevity.

The dynamic nature of wind tunnel testing also demands rapid vacuum cycling capabilities. Experiments may require quick changes in pressure conditions, necessitating vacuum pumps that can respond swiftly to varying demands. This requirement often conflicts with the need for stable, consistent vacuum levels, creating a complex engineering trade-off that must be carefully managed.

Noise and vibration generated by vacuum pumps can interfere with sensitive measurements in wind tunnel experiments. Isolating these disturbances through advanced mounting techniques and sound-dampening enclosures is crucial for maintaining the integrity of aerodynamic data. However, these solutions must be implemented without compromising the accessibility and serviceability of the pump systems.

Current Vacuum Solutions for Wind Tunnels

01 Improved pump design and configuration

Optimization of vacuum pump design involves enhancing the overall configuration and structure of the pump. This includes improvements in rotor design, housing geometry, and the arrangement of internal components to increase efficiency and performance. Advanced materials and manufacturing techniques may be employed to reduce weight and improve durability.- Improved pump design and configuration: Optimization of vacuum pump design involves enhancing the overall configuration and structure of the pump. This includes improvements in rotor design, housing geometry, and internal component layout to increase efficiency and performance. Advanced materials and manufacturing techniques may be employed to reduce weight and improve durability.

- Enhanced sealing and lubrication systems: Developing better sealing mechanisms and lubrication systems is crucial for vacuum pump optimization. This involves implementing advanced sealing technologies to minimize leakage and improve vacuum quality. Optimized lubrication systems ensure smooth operation, reduce wear, and extend the pump's lifespan.

- Intelligent control and monitoring systems: Incorporating smart control systems and sensors for real-time monitoring and adjustment of pump parameters enhances overall performance. These systems can optimize pump operation based on varying load conditions, detect potential issues early, and facilitate predictive maintenance strategies.

- Energy efficiency improvements: Focusing on energy efficiency involves optimizing motor designs, implementing variable speed drives, and utilizing energy recovery systems. These improvements reduce power consumption, lower operating costs, and minimize environmental impact while maintaining or improving pump performance.

- Multi-stage and hybrid pump systems: Developing multi-stage vacuum pump configurations and hybrid systems that combine different pump technologies can optimize performance across a wider range of operating conditions. These systems can provide better vacuum levels, increased pumping speed, and improved overall efficiency for specific applications.

02 Enhanced sealing and lubrication systems

Developing better sealing mechanisms and lubrication systems is crucial for vacuum pump optimization. This involves designing more effective seals to prevent leakage and maintain vacuum integrity, as well as implementing advanced lubrication techniques to reduce friction and wear on moving parts, thereby increasing pump efficiency and lifespan.Expand Specific Solutions03 Integration of smart control systems

Incorporating intelligent control systems and sensors into vacuum pumps allows for real-time monitoring and adjustment of pump parameters. This can include adaptive control algorithms, predictive maintenance capabilities, and remote monitoring features, leading to optimized performance, energy efficiency, and reduced downtime.Expand Specific Solutions04 Energy efficiency improvements

Focusing on enhancing the energy efficiency of vacuum pumps through various means such as optimizing motor designs, implementing variable speed drives, and improving heat management systems. This can lead to reduced power consumption, lower operating costs, and improved overall pump performance.Expand Specific Solutions05 Multi-stage and hybrid pump systems

Developing multi-stage vacuum pump configurations or hybrid systems that combine different pump technologies to achieve higher vacuum levels and improved efficiency across a wider range of operating conditions. This approach can offer better performance and flexibility in various industrial applications.Expand Specific Solutions

Key Vacuum Pump Manufacturers

The vacuum pump optimization for aerodynamic applications in wind tunnels is in a mature stage of industry development, with a substantial market size driven by aerospace, automotive, and research sectors. The technology's maturity is evident from the involvement of established players like Pfeiffer Vacuum GmbH, Edwards Ltd., and SKY Technology Development Co., Ltd. CAS, who offer advanced solutions. However, the field continues to evolve with ongoing research and development efforts by academic institutions such as Northeastern University and Chang'an University, as well as aerospace entities like China Academy of Aerospace Aerodynamics. This collaborative ecosystem of industry leaders and research institutions suggests a competitive landscape focused on incremental improvements in efficiency, precision, and specialized applications for wind tunnel testing.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum has developed advanced turbomolecular pumps specifically optimized for wind tunnel applications. Their HiPace series utilizes a hybrid bearing system combining ceramic ball bearings and permanent magnetic bearings, allowing for high pumping speeds up to 3000 l/s and ultimate pressures below 10^-10 mbar [1]. The company has also introduced intelligent pump control systems that can automatically adjust pumping parameters based on real-time pressure and flow measurements in the wind tunnel, ensuring optimal performance across different test conditions [2]. Additionally, Pfeiffer's latest vacuum pumps incorporate advanced rotor designs with optimized blade geometries, resulting in up to 30% higher compression ratios compared to previous generations [3].

Strengths: High pumping speeds, ultra-low ultimate pressures, intelligent control systems. Weaknesses: Higher initial cost, may require specialized maintenance.

Edwards Ltd.

Technical Solution: Edwards has developed a range of dry pumps specifically designed for wind tunnel applications. Their GXS series of screw pumps offers high pumping speeds up to 3600 m³/h and can handle large gas loads typical in aerodynamic testing [4]. The company has also introduced advanced control systems that allow for precise pressure control and flow modulation, essential for maintaining consistent test conditions in wind tunnels [5]. Edwards' latest innovation includes the implementation of variable frequency drives in their pumps, enabling energy savings of up to 50% compared to conventional fixed-speed pumps [6]. Furthermore, their pumps feature a unique tapered screw design that reduces internal backflow, resulting in improved pumping efficiency and lower ultimate pressures.

Strengths: High pumping capacity, energy efficiency, precise pressure control. Weaknesses: May have limitations in achieving ultra-high vacuums compared to turbomolecular pumps.

Innovative Vacuum Pump Designs

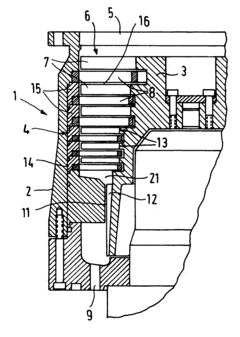

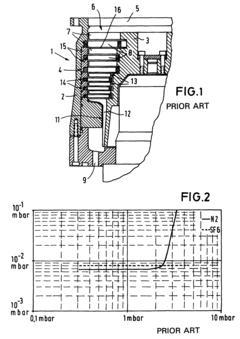

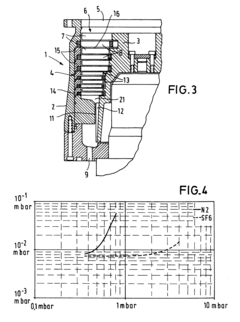

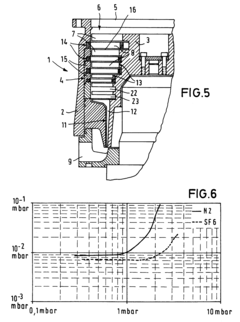

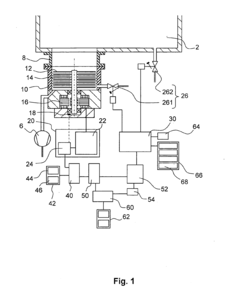

Friction vacuum pump for use in a system for regulating pressure and pressure regulating system comprising a friction vacuum pump of this type

PatentInactiveUS6702544B1

Innovation

- Modifying the Holweck pump stage by creating a partial space without active pumping elements between the last row of stator vanes and the thread, and reducing the number of stator vanes in the turbomolecular pump section, allows for a consistent pressure dependence between high vacuum and fore-vacuum pressures, enabling effective pressure regulation across different gas types.

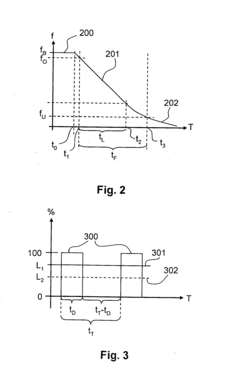

Method for ventilating a vacuum pump and assembly with a vacuum pump

PatentActiveEP2466145A2

Innovation

- A method that evaluates time measurements of speed reduction to adjust the flow rate of flood valves, allowing for adaptive and self-learning gas admission processes, reducing the time required for venting while ensuring safety and cost-effectiveness, using time-based measurements and valve control to optimize gas flow.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the optimization of vacuum pumps for aerodynamic applications in wind tunnels. The power consumption of these pumps can significantly impact the overall operational costs and environmental footprint of wind tunnel facilities. To address this, researchers and engineers are focusing on several key areas to enhance energy efficiency.

One primary approach involves improving the design of vacuum pump components. Advanced computational fluid dynamics (CFD) simulations are being utilized to optimize impeller geometries, diffuser designs, and flow paths within the pump. These refinements aim to minimize energy losses due to friction, turbulence, and recirculation, thereby increasing the overall efficiency of the pump.

Another area of focus is the implementation of variable speed drives (VSDs) in vacuum pump systems. VSDs allow for precise control of pump speed, enabling the system to adjust its output based on the specific requirements of different wind tunnel tests. This dynamic operation prevents unnecessary energy consumption during periods of reduced demand, leading to substantial energy savings over time.

Heat recovery systems are also being integrated into vacuum pump setups to harness waste heat generated during operation. This recovered thermal energy can be repurposed for various applications within the wind tunnel facility, such as heating office spaces or preheating process air. By utilizing this otherwise wasted energy, the overall energy efficiency of the system is significantly improved.

Advanced materials and coatings are being explored to reduce friction and wear within pump components. Low-friction coatings and high-performance lubricants can minimize energy losses due to mechanical friction, extending the lifespan of pump components while simultaneously improving energy efficiency.

Intelligent control systems and predictive maintenance strategies are being developed to optimize pump operation and prevent energy waste due to inefficiencies or failures. These systems utilize real-time monitoring and machine learning algorithms to adjust pump parameters for optimal performance and schedule maintenance activities proactively, ensuring consistent energy-efficient operation.

Furthermore, researchers are investigating the potential of hybrid vacuum systems that combine different pump technologies to achieve optimal energy efficiency across various operating conditions. By leveraging the strengths of different pump types, these hybrid systems can maintain high efficiency over a broader range of pressure and flow requirements typical in wind tunnel applications.

As energy costs continue to rise and environmental regulations become more stringent, the focus on energy efficiency in vacuum pump optimization for wind tunnels is expected to intensify. Future developments may include the integration of renewable energy sources to power pump systems and the exploration of novel pump designs that fundamentally reimagine the vacuum generation process for improved efficiency.

One primary approach involves improving the design of vacuum pump components. Advanced computational fluid dynamics (CFD) simulations are being utilized to optimize impeller geometries, diffuser designs, and flow paths within the pump. These refinements aim to minimize energy losses due to friction, turbulence, and recirculation, thereby increasing the overall efficiency of the pump.

Another area of focus is the implementation of variable speed drives (VSDs) in vacuum pump systems. VSDs allow for precise control of pump speed, enabling the system to adjust its output based on the specific requirements of different wind tunnel tests. This dynamic operation prevents unnecessary energy consumption during periods of reduced demand, leading to substantial energy savings over time.

Heat recovery systems are also being integrated into vacuum pump setups to harness waste heat generated during operation. This recovered thermal energy can be repurposed for various applications within the wind tunnel facility, such as heating office spaces or preheating process air. By utilizing this otherwise wasted energy, the overall energy efficiency of the system is significantly improved.

Advanced materials and coatings are being explored to reduce friction and wear within pump components. Low-friction coatings and high-performance lubricants can minimize energy losses due to mechanical friction, extending the lifespan of pump components while simultaneously improving energy efficiency.

Intelligent control systems and predictive maintenance strategies are being developed to optimize pump operation and prevent energy waste due to inefficiencies or failures. These systems utilize real-time monitoring and machine learning algorithms to adjust pump parameters for optimal performance and schedule maintenance activities proactively, ensuring consistent energy-efficient operation.

Furthermore, researchers are investigating the potential of hybrid vacuum systems that combine different pump technologies to achieve optimal energy efficiency across various operating conditions. By leveraging the strengths of different pump types, these hybrid systems can maintain high efficiency over a broader range of pressure and flow requirements typical in wind tunnel applications.

As energy costs continue to rise and environmental regulations become more stringent, the focus on energy efficiency in vacuum pump optimization for wind tunnels is expected to intensify. Future developments may include the integration of renewable energy sources to power pump systems and the exploration of novel pump designs that fundamentally reimagine the vacuum generation process for improved efficiency.

Noise Reduction Strategies

Noise reduction strategies play a crucial role in optimizing vacuum pumps for aerodynamic applications in wind tunnels. The primary objective is to minimize acoustic disturbances that could interfere with precise measurements and affect the overall performance of wind tunnel experiments.

One of the most effective approaches to noise reduction is the implementation of advanced acoustic insulation materials. These materials, such as high-density foams and composite panels, are strategically placed around the vacuum pump to absorb and dampen sound waves. The selection of insulation materials is based on their sound absorption coefficients and frequency-specific performance characteristics.

Vibration isolation techniques are another key component of noise reduction strategies. By employing vibration-dampening mounts and flexible couplings, the transmission of mechanical vibrations from the pump to the surrounding structure can be significantly reduced. This not only decreases noise levels but also enhances the longevity of the pump and associated equipment.

Active noise control systems represent a more sophisticated approach to noise reduction. These systems utilize advanced algorithms and real-time signal processing to generate anti-noise waves that cancel out unwanted sound. While more complex and costly to implement, active noise control can be particularly effective in addressing low-frequency noise that is challenging to mitigate through passive methods alone.

The design of the pump housing and exhaust system also plays a critical role in noise reduction. Aerodynamically optimized housings can minimize turbulence and associated noise, while specially designed mufflers and silencers in the exhaust system can significantly attenuate noise emissions. The integration of resonators and expansion chambers within the exhaust path can further reduce noise by targeting specific frequency ranges.

Operational strategies also contribute to noise reduction efforts. Variable speed drives allow for the adjustment of pump speed to match the required flow rate, potentially reducing noise levels during periods of lower demand. Additionally, implementing proper maintenance schedules and lubrication practices can prevent the development of excessive noise due to wear and tear.

In the context of wind tunnel applications, it is essential to consider the entire system when developing noise reduction strategies. This holistic approach involves analyzing the interaction between the vacuum pump, wind tunnel structure, and surrounding environment to identify and address potential noise transmission paths and resonance issues.

One of the most effective approaches to noise reduction is the implementation of advanced acoustic insulation materials. These materials, such as high-density foams and composite panels, are strategically placed around the vacuum pump to absorb and dampen sound waves. The selection of insulation materials is based on their sound absorption coefficients and frequency-specific performance characteristics.

Vibration isolation techniques are another key component of noise reduction strategies. By employing vibration-dampening mounts and flexible couplings, the transmission of mechanical vibrations from the pump to the surrounding structure can be significantly reduced. This not only decreases noise levels but also enhances the longevity of the pump and associated equipment.

Active noise control systems represent a more sophisticated approach to noise reduction. These systems utilize advanced algorithms and real-time signal processing to generate anti-noise waves that cancel out unwanted sound. While more complex and costly to implement, active noise control can be particularly effective in addressing low-frequency noise that is challenging to mitigate through passive methods alone.

The design of the pump housing and exhaust system also plays a critical role in noise reduction. Aerodynamically optimized housings can minimize turbulence and associated noise, while specially designed mufflers and silencers in the exhaust system can significantly attenuate noise emissions. The integration of resonators and expansion chambers within the exhaust path can further reduce noise by targeting specific frequency ranges.

Operational strategies also contribute to noise reduction efforts. Variable speed drives allow for the adjustment of pump speed to match the required flow rate, potentially reducing noise levels during periods of lower demand. Additionally, implementing proper maintenance schedules and lubrication practices can prevent the development of excessive noise due to wear and tear.

In the context of wind tunnel applications, it is essential to consider the entire system when developing noise reduction strategies. This holistic approach involves analyzing the interaction between the vacuum pump, wind tunnel structure, and surrounding environment to identify and address potential noise transmission paths and resonance issues.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!