Vacuum Pumps in Next-Gen Molecular Communication Devices

JUL 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution

Vacuum pumps have undergone significant evolution since their inception, playing a crucial role in various scientific and industrial applications. In the context of next-generation molecular communication devices, the development of vacuum pumps has been particularly noteworthy. The journey of vacuum pump technology can be traced through several key stages, each marked by innovative breakthroughs and improved performance characteristics.

The earliest vacuum pumps, dating back to the 17th century, were mechanical devices that relied on pistons and valves to create a vacuum. These rudimentary pumps laid the foundation for future advancements but were limited in their ability to achieve high vacuum levels. The 19th century saw the introduction of mercury displacement pumps, which offered improved vacuum quality but posed environmental concerns due to mercury usage.

A significant leap forward came with the development of molecular pumps in the early 20th century. These pumps, based on the principle of molecular drag, could achieve much higher vacuum levels than their predecessors. The invention of the turbomolecular pump in the 1950s marked a revolutionary step, enabling the creation of ultra-high vacuum environments essential for many scientific experiments and industrial processes.

As the field of molecular communication began to emerge, the demands on vacuum pump technology intensified. The need for precise control over molecular environments necessitated pumps capable of maintaining stable, ultra-clean vacuums. This led to the development of specialized pumps designed to handle specific gases and molecules without contamination.

In recent decades, the focus has shifted towards miniaturization and energy efficiency. The advent of microelectromechanical systems (MEMS) technology has enabled the creation of microscale vacuum pumps, which are particularly relevant for next-generation molecular communication devices. These miniature pumps offer the advantage of integration into compact systems while maintaining high performance.

Concurrent with size reduction, significant strides have been made in improving pump reliability and reducing maintenance requirements. Modern vacuum pumps incorporate advanced materials and coatings that enhance durability and resistance to corrosion, crucial factors in molecular communication applications where purity is paramount.

The latest developments in vacuum pump technology for molecular communication devices include the integration of smart features. These pumps are equipped with sensors and control systems that allow real-time monitoring and adjustment of vacuum conditions. Such capabilities are essential for maintaining the precise molecular environments required in advanced communication systems.

Looking ahead, the evolution of vacuum pumps is likely to continue along the paths of further miniaturization, increased energy efficiency, and enhanced precision. Emerging technologies such as quantum-based vacuum pumps and novel materials like graphene may pave the way for even more sophisticated vacuum systems, capable of manipulating individual molecules with unprecedented control.

The earliest vacuum pumps, dating back to the 17th century, were mechanical devices that relied on pistons and valves to create a vacuum. These rudimentary pumps laid the foundation for future advancements but were limited in their ability to achieve high vacuum levels. The 19th century saw the introduction of mercury displacement pumps, which offered improved vacuum quality but posed environmental concerns due to mercury usage.

A significant leap forward came with the development of molecular pumps in the early 20th century. These pumps, based on the principle of molecular drag, could achieve much higher vacuum levels than their predecessors. The invention of the turbomolecular pump in the 1950s marked a revolutionary step, enabling the creation of ultra-high vacuum environments essential for many scientific experiments and industrial processes.

As the field of molecular communication began to emerge, the demands on vacuum pump technology intensified. The need for precise control over molecular environments necessitated pumps capable of maintaining stable, ultra-clean vacuums. This led to the development of specialized pumps designed to handle specific gases and molecules without contamination.

In recent decades, the focus has shifted towards miniaturization and energy efficiency. The advent of microelectromechanical systems (MEMS) technology has enabled the creation of microscale vacuum pumps, which are particularly relevant for next-generation molecular communication devices. These miniature pumps offer the advantage of integration into compact systems while maintaining high performance.

Concurrent with size reduction, significant strides have been made in improving pump reliability and reducing maintenance requirements. Modern vacuum pumps incorporate advanced materials and coatings that enhance durability and resistance to corrosion, crucial factors in molecular communication applications where purity is paramount.

The latest developments in vacuum pump technology for molecular communication devices include the integration of smart features. These pumps are equipped with sensors and control systems that allow real-time monitoring and adjustment of vacuum conditions. Such capabilities are essential for maintaining the precise molecular environments required in advanced communication systems.

Looking ahead, the evolution of vacuum pumps is likely to continue along the paths of further miniaturization, increased energy efficiency, and enhanced precision. Emerging technologies such as quantum-based vacuum pumps and novel materials like graphene may pave the way for even more sophisticated vacuum systems, capable of manipulating individual molecules with unprecedented control.

Market Demand Analysis

The market demand for vacuum pumps in next-generation molecular communication devices is experiencing significant growth, driven by advancements in nanotechnology and the increasing need for precise control in molecular-scale operations. As these devices become more sophisticated, the requirement for high-performance vacuum pumps has become critical to ensure optimal functionality and reliability.

In the field of molecular communication, vacuum pumps play a crucial role in creating and maintaining the controlled environments necessary for accurate signal transmission and reception. The ability to manipulate individual molecules or small clusters of molecules demands ultra-high vacuum conditions, which can only be achieved through advanced vacuum pump technologies. This has led to a surge in demand for specialized vacuum pumps that can operate at the nanoscale level.

The healthcare and biotechnology sectors are emerging as major drivers of this market demand. Applications such as drug delivery systems, diagnostic tools, and targeted therapies rely heavily on molecular communication devices, creating a substantial market for associated vacuum pump technologies. The pharmaceutical industry, in particular, is investing heavily in research and development of these devices, further fueling the demand for high-performance vacuum pumps.

Another significant factor contributing to market growth is the increasing adoption of molecular communication devices in environmental monitoring and industrial process control. These applications require precise measurement and manipulation of molecular-level phenomena, necessitating the use of advanced vacuum pump systems. As industries strive for greater efficiency and sustainability, the demand for these technologies is expected to rise steadily.

The telecommunications sector is also showing interest in molecular communication devices for potential future applications in data transmission and storage. This emerging market segment presents a promising opportunity for vacuum pump manufacturers to develop specialized solutions tailored to the unique requirements of molecular-scale communication networks.

As the field of molecular communication continues to evolve, there is a growing demand for vacuum pumps with enhanced capabilities. Key features sought after in the market include higher pumping speeds, lower ultimate pressures, improved energy efficiency, and miniaturization. Manufacturers are responding to these demands by investing in research and development to create next-generation vacuum pump technologies that can meet the exacting requirements of molecular communication devices.

The global market for vacuum pumps in molecular communication devices is projected to expand significantly over the coming years. This growth is attributed to increasing research activities, rising investments in nanotechnology, and the broadening application scope of molecular communication across various industries. As the technology matures and finds more practical applications, the demand for specialized vacuum pumps is expected to accelerate, creating new opportunities for innovation and market expansion in this niche but rapidly growing sector.

In the field of molecular communication, vacuum pumps play a crucial role in creating and maintaining the controlled environments necessary for accurate signal transmission and reception. The ability to manipulate individual molecules or small clusters of molecules demands ultra-high vacuum conditions, which can only be achieved through advanced vacuum pump technologies. This has led to a surge in demand for specialized vacuum pumps that can operate at the nanoscale level.

The healthcare and biotechnology sectors are emerging as major drivers of this market demand. Applications such as drug delivery systems, diagnostic tools, and targeted therapies rely heavily on molecular communication devices, creating a substantial market for associated vacuum pump technologies. The pharmaceutical industry, in particular, is investing heavily in research and development of these devices, further fueling the demand for high-performance vacuum pumps.

Another significant factor contributing to market growth is the increasing adoption of molecular communication devices in environmental monitoring and industrial process control. These applications require precise measurement and manipulation of molecular-level phenomena, necessitating the use of advanced vacuum pump systems. As industries strive for greater efficiency and sustainability, the demand for these technologies is expected to rise steadily.

The telecommunications sector is also showing interest in molecular communication devices for potential future applications in data transmission and storage. This emerging market segment presents a promising opportunity for vacuum pump manufacturers to develop specialized solutions tailored to the unique requirements of molecular-scale communication networks.

As the field of molecular communication continues to evolve, there is a growing demand for vacuum pumps with enhanced capabilities. Key features sought after in the market include higher pumping speeds, lower ultimate pressures, improved energy efficiency, and miniaturization. Manufacturers are responding to these demands by investing in research and development to create next-generation vacuum pump technologies that can meet the exacting requirements of molecular communication devices.

The global market for vacuum pumps in molecular communication devices is projected to expand significantly over the coming years. This growth is attributed to increasing research activities, rising investments in nanotechnology, and the broadening application scope of molecular communication across various industries. As the technology matures and finds more practical applications, the demand for specialized vacuum pumps is expected to accelerate, creating new opportunities for innovation and market expansion in this niche but rapidly growing sector.

Technical Challenges

The development of next-generation molecular communication devices faces several significant technical challenges, particularly in the realm of vacuum pump technology. One of the primary obstacles is the miniaturization of vacuum pumps while maintaining their efficiency and performance. As these devices become increasingly compact, traditional vacuum pump designs struggle to meet the stringent size requirements without compromising their functionality.

Another critical challenge lies in the power consumption of vacuum pumps in molecular communication devices. The need for energy-efficient operation is paramount, especially in portable or implantable applications where battery life is a crucial factor. Researchers are grappling with the task of developing vacuum pumps that can operate at low power levels while still achieving the necessary vacuum levels for effective molecular communication.

The precision and stability of vacuum control present another hurdle. Molecular communication relies on the accurate manipulation of particles at the nanoscale, requiring exceptionally stable and precise vacuum conditions. Achieving and maintaining such precise vacuum levels in miniaturized devices is a complex engineering challenge that demands innovative solutions.

Material compatibility is also a significant concern in the development of vacuum pumps for these advanced devices. The materials used must be biocompatible for certain applications, resistant to corrosion from the molecular substances being transported, and capable of withstanding the mechanical stresses involved in vacuum generation.

Thermal management poses yet another challenge. The operation of vacuum pumps generates heat, which can be detrimental to the sensitive components of molecular communication devices. Effective heat dissipation in compact designs is crucial to prevent performance degradation and ensure the longevity of the devices.

The integration of vacuum pumps with other components of molecular communication systems presents its own set of challenges. Seamless interfacing between the pump, molecular channels, and detection systems is essential for optimal device performance. This integration must be achieved while maintaining the overall compact form factor of the device.

Lastly, the reliability and durability of vacuum pumps in these applications are of utmost importance. Given the potentially critical nature of molecular communication devices, especially in medical applications, the vacuum pumps must operate consistently over extended periods without failure or significant performance degradation. Addressing these multifaceted challenges requires interdisciplinary collaboration and innovative approaches in materials science, nanotechnology, and precision engineering.

Another critical challenge lies in the power consumption of vacuum pumps in molecular communication devices. The need for energy-efficient operation is paramount, especially in portable or implantable applications where battery life is a crucial factor. Researchers are grappling with the task of developing vacuum pumps that can operate at low power levels while still achieving the necessary vacuum levels for effective molecular communication.

The precision and stability of vacuum control present another hurdle. Molecular communication relies on the accurate manipulation of particles at the nanoscale, requiring exceptionally stable and precise vacuum conditions. Achieving and maintaining such precise vacuum levels in miniaturized devices is a complex engineering challenge that demands innovative solutions.

Material compatibility is also a significant concern in the development of vacuum pumps for these advanced devices. The materials used must be biocompatible for certain applications, resistant to corrosion from the molecular substances being transported, and capable of withstanding the mechanical stresses involved in vacuum generation.

Thermal management poses yet another challenge. The operation of vacuum pumps generates heat, which can be detrimental to the sensitive components of molecular communication devices. Effective heat dissipation in compact designs is crucial to prevent performance degradation and ensure the longevity of the devices.

The integration of vacuum pumps with other components of molecular communication systems presents its own set of challenges. Seamless interfacing between the pump, molecular channels, and detection systems is essential for optimal device performance. This integration must be achieved while maintaining the overall compact form factor of the device.

Lastly, the reliability and durability of vacuum pumps in these applications are of utmost importance. Given the potentially critical nature of molecular communication devices, especially in medical applications, the vacuum pumps must operate consistently over extended periods without failure or significant performance degradation. Addressing these multifaceted challenges requires interdisciplinary collaboration and innovative approaches in materials science, nanotechnology, and precision engineering.

Current Vacuum Solutions

01 Improvements in vacuum pump design

Various advancements have been made in vacuum pump design to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high cleanliness levels, and provide stable vacuum conditions. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.

- Energy-efficient vacuum pump systems: Innovations in vacuum pump technology have focused on improving energy efficiency. These developments include the use of variable speed drives, optimized motor designs, and intelligent control systems. Such advancements result in reduced power consumption, lower operating costs, and improved environmental sustainability of vacuum pump operations.

- Multi-stage vacuum pump configurations: Multi-stage vacuum pump designs have been created to achieve higher vacuum levels and improved pumping efficiency. These configurations typically combine different pump types or multiple pumping stages in series. This approach allows for better gas handling capabilities, wider operating pressure ranges, and enhanced overall system performance.

- Vacuum pump monitoring and control systems: Advanced monitoring and control systems have been developed for vacuum pumps to optimize performance and maintenance. These systems may include sensors for real-time monitoring of pump parameters, predictive maintenance algorithms, and remote monitoring capabilities. Such features enable improved pump reliability, reduced downtime, and more efficient operation of vacuum systems.

02 Vacuum pump applications in semiconductor manufacturing

Vacuum pumps play a crucial role in semiconductor manufacturing processes. They are used in various stages, including wafer processing, thin film deposition, and etching. Specialized vacuum pumps have been developed to meet the stringent requirements of the semiconductor industry, such as high cleanliness, low particle generation, and compatibility with corrosive gases.Expand Specific Solutions03 Historical developments in vacuum pump technology

The evolution of vacuum pump technology spans several decades, with significant advancements made over time. Early designs focused on mechanical pumps, while later developments introduced new technologies such as diffusion pumps, turbomolecular pumps, and cryogenic pumps. These historical innovations have laid the foundation for modern vacuum pump systems.Expand Specific Solutions04 Energy-efficient vacuum pump solutions

Recent developments in vacuum pump technology have focused on improving energy efficiency. This includes the use of variable speed drives, optimized motor designs, and intelligent control systems. Energy-efficient vacuum pumps help reduce operational costs and environmental impact while maintaining high performance levels.Expand Specific Solutions05 Specialized vacuum pumps for specific industries

Various industries require specialized vacuum pump solutions tailored to their unique needs. For example, the food packaging industry uses vacuum pumps designed for hygienic operations, while the automotive industry employs pumps suitable for brake system evacuation. These specialized pumps are engineered to meet specific performance, reliability, and regulatory requirements of different sectors.Expand Specific Solutions

Key Industry Players

The research on vacuum pumps in next-generation molecular communication devices is in its early stages, with the market still developing. The technology's maturity varies among key players, with established companies like Edwards Ltd., Pfeiffer Vacuum GmbH, and Agilent Technologies leading in vacuum pump innovation. Emerging players such as KYKY Technology and SiEn (Qingdao) Integrated Circuits are also contributing to advancements. The market size is expected to grow as molecular communication devices gain traction in various industries. Companies like Applied Materials and MKS, Inc. are leveraging their expertise in semiconductor manufacturing to explore potential applications, while research institutions like the Korea Research Institute of Standards & Science are driving fundamental breakthroughs in this field.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pumps for next-generation molecular communication devices, focusing on ultra-high vacuum (UHV) technology. Their latest innovation is the nEXT turbomolecular pump series, which achieves ultimate pressures below 5 × 10^-10 mbar [1]. This pump incorporates a unique blade design that optimizes molecular flow, enhancing communication efficiency in nanoscale environments. Edwards has also integrated adaptive control algorithms that dynamically adjust pump speed based on molecular density, ensuring consistent performance across various communication scenarios [3]. Additionally, their pumps feature advanced bearing technology, reducing friction and enabling operation at higher speeds, which is crucial for maintaining stable molecular signals in communication devices [5].

Strengths: Industry-leading UHV performance, adaptive control for varying molecular densities, and low-friction bearing technology. Weaknesses: Higher cost compared to conventional pumps, and potential complexity in integration with existing molecular communication systems.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed the TwisTorr FS-X series, a range of turbomolecular pumps specifically designed for molecular communication applications. These pumps utilize a novel split-flow technology that enhances pumping efficiency for light gases, crucial in maintaining precise molecular concentrations for signal transmission [2]. The pumps incorporate a hybrid bearing system combining ceramic ball bearings and magnetic levitation, which significantly reduces mechanical wear and extends operational life in continuous communication scenarios [4]. Agilent has also implemented advanced rotor designs that minimize backstreaming, ensuring the purity of molecular signals in communication devices. Their pumps feature integrated intelligence with self-diagnostic capabilities, allowing for predictive maintenance and minimizing downtime in critical communication applications [6].

Strengths: Excellent light gas pumping efficiency, long operational life, and intelligent self-diagnostic features. Weaknesses: May require specialized maintenance, and initial cost could be higher than traditional vacuum systems.

Core Pump Innovations

Molecular drag vacuum pumps

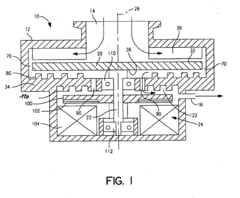

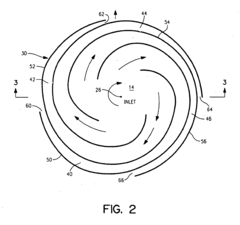

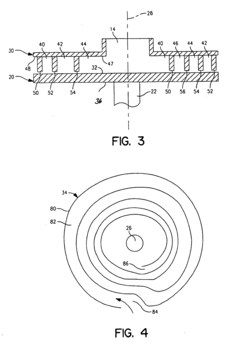

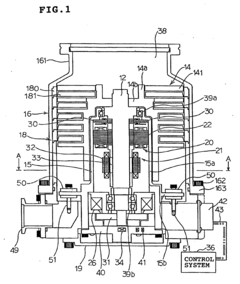

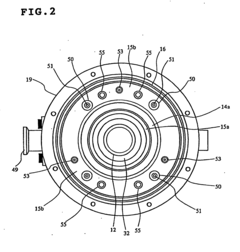

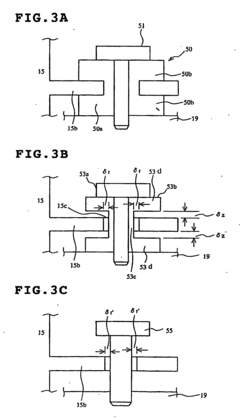

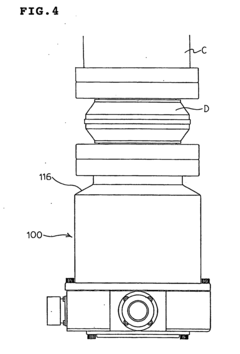

PatentInactiveEP1170508B1

Innovation

- A vacuum pumping apparatus featuring a rotor and stator with spiral channels that decrease in cross-sectional area from the inner to the outer portion, with multiple stages connected in series or parallel, utilizing a pancake-type motor for efficient gas pumping, and optionally including regenerative or molecular drag vacuum pumping stages.

Vacuum pump

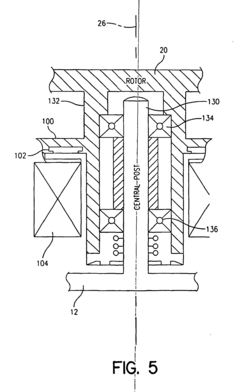

PatentInactiveEP1118774B1

Innovation

- A vacuum pump design that incorporates a vibration absorbing member with a specific natural frequency formula, silicon gel materials, and magnetic shielding to suppress vibrations and magnetic flux leakage without the need for external dampers, while maintaining a compact size and reducing electric noise transmission.

Molecular Comm Standards

In the rapidly evolving field of molecular communication, the establishment of standardized protocols and guidelines is crucial for ensuring interoperability, reliability, and widespread adoption of this emerging technology. As vacuum pumps play a pivotal role in next-generation molecular communication devices, it is essential to develop comprehensive standards that address their integration and performance within these systems.

The development of molecular communication standards for vacuum pumps requires a collaborative effort from various stakeholders, including academic institutions, industry leaders, and regulatory bodies. These standards should encompass a wide range of aspects, from technical specifications and performance metrics to safety guidelines and environmental considerations.

One of the primary focuses of these standards should be the establishment of uniform performance metrics for vacuum pumps in molecular communication applications. This includes defining parameters such as pumping speed, ultimate pressure, and power consumption, as well as specifying testing methodologies to ensure consistent evaluation across different manufacturers and models.

Interoperability is another critical aspect that must be addressed in these standards. As molecular communication devices become more complex and diverse, it is essential to establish standardized interfaces and communication protocols for vacuum pumps. This will facilitate seamless integration with other components of the molecular communication system and enable modular design approaches.

Safety considerations should also be a key component of these standards, particularly given the potential use of molecular communication devices in sensitive environments such as healthcare or industrial settings. Guidelines for proper installation, operation, and maintenance of vacuum pumps should be clearly outlined to minimize risks and ensure long-term reliability.

Environmental impact is an increasingly important factor in technology development, and molecular communication standards should reflect this concern. Specifications for energy efficiency, noise levels, and the use of environmentally friendly materials in vacuum pump construction should be incorporated into the standards to promote sustainable practices in the industry.

As the field of molecular communication continues to advance, these standards must remain flexible and adaptable to accommodate new technologies and applications. Regular review and updating of the standards will be necessary to keep pace with technological progress and evolving industry needs.

The implementation of these standards will require a concerted effort from all stakeholders in the molecular communication ecosystem. Industry associations and regulatory bodies should work together to promote awareness and adoption of these standards, while manufacturers should align their product development processes with the established guidelines.

By establishing comprehensive and widely accepted standards for vacuum pumps in molecular communication devices, the industry can foster innovation, improve product quality, and accelerate the commercialization of this groundbreaking technology. These standards will serve as a foundation for the continued growth and development of molecular communication systems, paving the way for new applications and advancements in fields ranging from healthcare to environmental monitoring.

The development of molecular communication standards for vacuum pumps requires a collaborative effort from various stakeholders, including academic institutions, industry leaders, and regulatory bodies. These standards should encompass a wide range of aspects, from technical specifications and performance metrics to safety guidelines and environmental considerations.

One of the primary focuses of these standards should be the establishment of uniform performance metrics for vacuum pumps in molecular communication applications. This includes defining parameters such as pumping speed, ultimate pressure, and power consumption, as well as specifying testing methodologies to ensure consistent evaluation across different manufacturers and models.

Interoperability is another critical aspect that must be addressed in these standards. As molecular communication devices become more complex and diverse, it is essential to establish standardized interfaces and communication protocols for vacuum pumps. This will facilitate seamless integration with other components of the molecular communication system and enable modular design approaches.

Safety considerations should also be a key component of these standards, particularly given the potential use of molecular communication devices in sensitive environments such as healthcare or industrial settings. Guidelines for proper installation, operation, and maintenance of vacuum pumps should be clearly outlined to minimize risks and ensure long-term reliability.

Environmental impact is an increasingly important factor in technology development, and molecular communication standards should reflect this concern. Specifications for energy efficiency, noise levels, and the use of environmentally friendly materials in vacuum pump construction should be incorporated into the standards to promote sustainable practices in the industry.

As the field of molecular communication continues to advance, these standards must remain flexible and adaptable to accommodate new technologies and applications. Regular review and updating of the standards will be necessary to keep pace with technological progress and evolving industry needs.

The implementation of these standards will require a concerted effort from all stakeholders in the molecular communication ecosystem. Industry associations and regulatory bodies should work together to promote awareness and adoption of these standards, while manufacturers should align their product development processes with the established guidelines.

By establishing comprehensive and widely accepted standards for vacuum pumps in molecular communication devices, the industry can foster innovation, improve product quality, and accelerate the commercialization of this groundbreaking technology. These standards will serve as a foundation for the continued growth and development of molecular communication systems, paving the way for new applications and advancements in fields ranging from healthcare to environmental monitoring.

Energy Efficiency Trends

The energy efficiency of vacuum pumps in next-generation molecular communication devices has become a critical focus in recent years. As these devices continue to miniaturize and integrate more complex functionalities, the demand for energy-efficient vacuum pumps has intensified. The trend towards improved energy efficiency is driven by several factors, including the need for longer battery life in portable devices, reduced operational costs, and environmental considerations.

One significant trend in energy efficiency is the development of advanced materials and coatings for vacuum pump components. These innovations aim to reduce friction and heat generation, thereby improving overall pump efficiency. For instance, the use of diamond-like carbon coatings on pump surfaces has shown promising results in reducing energy consumption while maintaining high vacuum performance.

Another notable trend is the integration of smart control systems and sensors into vacuum pumps. These systems enable real-time monitoring and adjustment of pump operation, optimizing energy usage based on the specific requirements of the molecular communication device. Adaptive control algorithms have demonstrated the ability to reduce energy consumption by up to 30% in some applications, without compromising vacuum quality.

The miniaturization of vacuum pump components is also contributing to enhanced energy efficiency. Researchers are exploring novel designs that utilize microelectromechanical systems (MEMS) technology to create ultra-compact pumps with reduced power requirements. These miniaturized pumps not only consume less energy but also allow for more efficient integration within the limited space of molecular communication devices.

Furthermore, there is a growing interest in hybrid vacuum pump systems that combine different pumping mechanisms to achieve optimal energy efficiency across various pressure ranges. For example, a combination of turbomolecular and ion pumps can provide high vacuum performance while minimizing energy consumption during different operational phases of the molecular communication device.

The trend towards energy-efficient vacuum pumps is also driving innovations in power management and energy recovery systems. Some advanced designs incorporate regenerative braking mechanisms, similar to those used in electric vehicles, to recover and reuse energy during pump deceleration. Additionally, the integration of high-efficiency power electronics and motor designs is further contributing to overall system efficiency.

As the field progresses, researchers are exploring the potential of quantum-based vacuum pumps, which could revolutionize energy efficiency in molecular communication devices. While still in the early stages of development, these concepts promise to leverage quantum effects to achieve ultra-high vacuum levels with minimal energy input, potentially surpassing the limitations of conventional pumping technologies.

One significant trend in energy efficiency is the development of advanced materials and coatings for vacuum pump components. These innovations aim to reduce friction and heat generation, thereby improving overall pump efficiency. For instance, the use of diamond-like carbon coatings on pump surfaces has shown promising results in reducing energy consumption while maintaining high vacuum performance.

Another notable trend is the integration of smart control systems and sensors into vacuum pumps. These systems enable real-time monitoring and adjustment of pump operation, optimizing energy usage based on the specific requirements of the molecular communication device. Adaptive control algorithms have demonstrated the ability to reduce energy consumption by up to 30% in some applications, without compromising vacuum quality.

The miniaturization of vacuum pump components is also contributing to enhanced energy efficiency. Researchers are exploring novel designs that utilize microelectromechanical systems (MEMS) technology to create ultra-compact pumps with reduced power requirements. These miniaturized pumps not only consume less energy but also allow for more efficient integration within the limited space of molecular communication devices.

Furthermore, there is a growing interest in hybrid vacuum pump systems that combine different pumping mechanisms to achieve optimal energy efficiency across various pressure ranges. For example, a combination of turbomolecular and ion pumps can provide high vacuum performance while minimizing energy consumption during different operational phases of the molecular communication device.

The trend towards energy-efficient vacuum pumps is also driving innovations in power management and energy recovery systems. Some advanced designs incorporate regenerative braking mechanisms, similar to those used in electric vehicles, to recover and reuse energy during pump deceleration. Additionally, the integration of high-efficiency power electronics and motor designs is further contributing to overall system efficiency.

As the field progresses, researchers are exploring the potential of quantum-based vacuum pumps, which could revolutionize energy efficiency in molecular communication devices. While still in the early stages of development, these concepts promise to leverage quantum effects to achieve ultra-high vacuum levels with minimal energy input, potentially surpassing the limitations of conventional pumping technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!