Optimizing Vacuum Pumps for Ion Implantation in Semiconductors

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ion Implantation Vacuum Pump Evolution and Objectives

Ion implantation has been a critical process in semiconductor manufacturing since its introduction in the 1960s. The evolution of vacuum pumps for this application has been closely tied to the increasing demands of the semiconductor industry for higher precision, efficiency, and cleanliness in the implantation process.

Initially, oil-sealed rotary vane pumps were the primary choice for creating the necessary vacuum environment. However, as the semiconductor industry progressed, the need for oil-free solutions became apparent due to the risk of contamination. This led to the development of dry pumps in the 1980s, which marked a significant milestone in vacuum technology for ion implantation.

The 1990s saw the introduction of turbomolecular pumps, which offered higher pumping speeds and lower ultimate pressures. These pumps, combined with dry backing pumps, became the standard configuration for ion implantation systems. As the industry moved towards larger wafer sizes and higher implantation energies, the demands on vacuum systems increased correspondingly.

In the early 2000s, the focus shifted towards improving the energy efficiency and reliability of vacuum pumps. Manufacturers began developing pumps with advanced rotor designs and improved bearing systems to reduce power consumption and extend maintenance intervals. This period also saw the integration of smart control systems, allowing for better monitoring and optimization of pump performance.

The current technological landscape is characterized by the need for ultra-high vacuum (UHV) conditions, with pressures in the range of 10^-8 to 10^-10 mbar. This has led to the development of specialized pumps capable of achieving and maintaining these extreme vacuum levels while handling the high gas loads associated with ion implantation processes.

Looking forward, the objectives for vacuum pump optimization in ion implantation are multifaceted. There is a strong drive towards further reducing energy consumption, aligning with global sustainability goals. Pump manufacturers are exploring novel materials and designs to enhance thermal management and reduce friction, thereby improving overall efficiency.

Another key objective is to increase the pumping speed and capacity to accommodate the growing demands of next-generation semiconductor manufacturing processes. This includes the ability to handle higher gas loads and maintain stable vacuum levels during high-dose implantation.

Improving cleanliness and reducing particle generation remain critical goals. Advanced sealing technologies and contamination-resistant materials are being developed to minimize the risk of process contamination, which is crucial for producing high-performance semiconductor devices.

Initially, oil-sealed rotary vane pumps were the primary choice for creating the necessary vacuum environment. However, as the semiconductor industry progressed, the need for oil-free solutions became apparent due to the risk of contamination. This led to the development of dry pumps in the 1980s, which marked a significant milestone in vacuum technology for ion implantation.

The 1990s saw the introduction of turbomolecular pumps, which offered higher pumping speeds and lower ultimate pressures. These pumps, combined with dry backing pumps, became the standard configuration for ion implantation systems. As the industry moved towards larger wafer sizes and higher implantation energies, the demands on vacuum systems increased correspondingly.

In the early 2000s, the focus shifted towards improving the energy efficiency and reliability of vacuum pumps. Manufacturers began developing pumps with advanced rotor designs and improved bearing systems to reduce power consumption and extend maintenance intervals. This period also saw the integration of smart control systems, allowing for better monitoring and optimization of pump performance.

The current technological landscape is characterized by the need for ultra-high vacuum (UHV) conditions, with pressures in the range of 10^-8 to 10^-10 mbar. This has led to the development of specialized pumps capable of achieving and maintaining these extreme vacuum levels while handling the high gas loads associated with ion implantation processes.

Looking forward, the objectives for vacuum pump optimization in ion implantation are multifaceted. There is a strong drive towards further reducing energy consumption, aligning with global sustainability goals. Pump manufacturers are exploring novel materials and designs to enhance thermal management and reduce friction, thereby improving overall efficiency.

Another key objective is to increase the pumping speed and capacity to accommodate the growing demands of next-generation semiconductor manufacturing processes. This includes the ability to handle higher gas loads and maintain stable vacuum levels during high-dose implantation.

Improving cleanliness and reducing particle generation remain critical goals. Advanced sealing technologies and contamination-resistant materials are being developed to minimize the risk of process contamination, which is crucial for producing high-performance semiconductor devices.

Semiconductor Industry Demand for Advanced Vacuum Systems

The semiconductor industry's demand for advanced vacuum systems has been steadily increasing, driven by the continuous miniaturization of semiconductor devices and the need for more precise and efficient manufacturing processes. Ion implantation, a critical step in semiconductor fabrication, requires highly sophisticated vacuum technology to ensure the accurate placement of dopant atoms within the semiconductor material.

As chip manufacturers push the boundaries of Moore's Law, they require vacuum systems that can maintain ultra-high vacuum levels, typically in the range of 10^-6 to 10^-8 Torr, to prevent contamination and ensure the purity of the ion beam. This demand has led to significant advancements in vacuum pump technology, with a focus on improving pumping speed, ultimate pressure, and reliability.

The market for advanced vacuum systems in the semiconductor industry is projected to grow substantially in the coming years. This growth is fueled by the increasing adoption of advanced packaging technologies, such as 3D integration and fan-out wafer-level packaging, which require precise control of the vacuum environment during various manufacturing steps.

Vacuum pump manufacturers are responding to this demand by developing innovative solutions that offer higher pumping speeds and lower ultimate pressures. Dry pumps, which eliminate the need for oil and reduce the risk of contamination, have become increasingly popular in semiconductor manufacturing. These pumps are often combined with turbomolecular pumps to achieve the ultra-high vacuum levels required for ion implantation.

The semiconductor industry also demands vacuum systems with improved energy efficiency and reduced environmental impact. This has led to the development of pumps with advanced motor designs and intelligent control systems that optimize power consumption based on process requirements. Additionally, there is a growing interest in vacuum systems that can handle corrosive gases and byproducts generated during the ion implantation process, without compromising performance or reliability.

As the semiconductor industry continues to evolve, the demand for advanced vacuum systems is expected to extend beyond traditional silicon-based devices. Emerging technologies such as wide-bandgap semiconductors (e.g., silicon carbide and gallium nitride) and quantum computing are creating new challenges and opportunities for vacuum technology. These applications often require even more stringent vacuum conditions and specialized pumping solutions.

As chip manufacturers push the boundaries of Moore's Law, they require vacuum systems that can maintain ultra-high vacuum levels, typically in the range of 10^-6 to 10^-8 Torr, to prevent contamination and ensure the purity of the ion beam. This demand has led to significant advancements in vacuum pump technology, with a focus on improving pumping speed, ultimate pressure, and reliability.

The market for advanced vacuum systems in the semiconductor industry is projected to grow substantially in the coming years. This growth is fueled by the increasing adoption of advanced packaging technologies, such as 3D integration and fan-out wafer-level packaging, which require precise control of the vacuum environment during various manufacturing steps.

Vacuum pump manufacturers are responding to this demand by developing innovative solutions that offer higher pumping speeds and lower ultimate pressures. Dry pumps, which eliminate the need for oil and reduce the risk of contamination, have become increasingly popular in semiconductor manufacturing. These pumps are often combined with turbomolecular pumps to achieve the ultra-high vacuum levels required for ion implantation.

The semiconductor industry also demands vacuum systems with improved energy efficiency and reduced environmental impact. This has led to the development of pumps with advanced motor designs and intelligent control systems that optimize power consumption based on process requirements. Additionally, there is a growing interest in vacuum systems that can handle corrosive gases and byproducts generated during the ion implantation process, without compromising performance or reliability.

As the semiconductor industry continues to evolve, the demand for advanced vacuum systems is expected to extend beyond traditional silicon-based devices. Emerging technologies such as wide-bandgap semiconductors (e.g., silicon carbide and gallium nitride) and quantum computing are creating new challenges and opportunities for vacuum technology. These applications often require even more stringent vacuum conditions and specialized pumping solutions.

Current Challenges in Ion Implantation Vacuum Technology

Ion implantation is a critical process in semiconductor manufacturing, and maintaining a high-quality vacuum environment is essential for its success. However, the current vacuum technology used in ion implantation faces several significant challenges that hinder optimal performance and efficiency.

One of the primary challenges is the management of outgassing from various sources within the implantation chamber. As ions bombard the target material, they can cause the release of gases from both the substrate and chamber walls. This outgassing can contaminate the vacuum environment, leading to reduced ion beam quality and potential defects in the implanted material.

Another major issue is the handling of high gas loads during the implantation process. Some ion implantation techniques require the introduction of specific gases into the chamber, which can overwhelm conventional vacuum pumps. This challenge is particularly acute in high-dose implantation processes, where maintaining a stable vacuum becomes increasingly difficult.

The presence of particulate matter in the vacuum system poses yet another significant challenge. Particles generated during the implantation process can interfere with the ion beam, causing scattering and reducing the precision of the implantation. Moreover, these particles can accumulate on sensitive surfaces within the vacuum system, potentially leading to equipment malfunction or contamination of the semiconductor wafers.

Vacuum pump reliability and longevity are also ongoing concerns in ion implantation systems. The harsh environment created by the implantation process, including exposure to reactive species and high-energy particles, can cause accelerated wear and degradation of pump components. This not only increases maintenance requirements but also raises the risk of unexpected downtime, which can be extremely costly in semiconductor manufacturing.

Energy efficiency is becoming an increasingly important consideration in vacuum technology for ion implantation. Current vacuum pumps often consume significant amounts of power, contributing to the overall energy footprint of semiconductor fabrication facilities. Improving the energy efficiency of these pumps without compromising their performance is a complex challenge that requires innovative approaches.

Lastly, the need for ultra-high vacuum (UHV) conditions in advanced ion implantation processes presents a formidable challenge. Achieving and maintaining UHV levels requires sophisticated pump designs and materials that can withstand the extreme conditions while providing consistent performance. The development of pumps capable of reaching and sustaining these ultra-low pressures efficiently remains an active area of research and development in the field.

One of the primary challenges is the management of outgassing from various sources within the implantation chamber. As ions bombard the target material, they can cause the release of gases from both the substrate and chamber walls. This outgassing can contaminate the vacuum environment, leading to reduced ion beam quality and potential defects in the implanted material.

Another major issue is the handling of high gas loads during the implantation process. Some ion implantation techniques require the introduction of specific gases into the chamber, which can overwhelm conventional vacuum pumps. This challenge is particularly acute in high-dose implantation processes, where maintaining a stable vacuum becomes increasingly difficult.

The presence of particulate matter in the vacuum system poses yet another significant challenge. Particles generated during the implantation process can interfere with the ion beam, causing scattering and reducing the precision of the implantation. Moreover, these particles can accumulate on sensitive surfaces within the vacuum system, potentially leading to equipment malfunction or contamination of the semiconductor wafers.

Vacuum pump reliability and longevity are also ongoing concerns in ion implantation systems. The harsh environment created by the implantation process, including exposure to reactive species and high-energy particles, can cause accelerated wear and degradation of pump components. This not only increases maintenance requirements but also raises the risk of unexpected downtime, which can be extremely costly in semiconductor manufacturing.

Energy efficiency is becoming an increasingly important consideration in vacuum technology for ion implantation. Current vacuum pumps often consume significant amounts of power, contributing to the overall energy footprint of semiconductor fabrication facilities. Improving the energy efficiency of these pumps without compromising their performance is a complex challenge that requires innovative approaches.

Lastly, the need for ultra-high vacuum (UHV) conditions in advanced ion implantation processes presents a formidable challenge. Achieving and maintaining UHV levels requires sophisticated pump designs and materials that can withstand the extreme conditions while providing consistent performance. The development of pumps capable of reaching and sustaining these ultra-low pressures efficiently remains an active area of research and development in the field.

Existing Vacuum Pump Solutions for Ion Implantation

01 Improved pump design and configuration

Optimization of vacuum pump designs focuses on enhancing efficiency and performance. This includes modifications to pump geometry, internal components, and overall configuration to improve suction capacity, reduce power consumption, and increase operational reliability.- Improved pump design and configuration: Optimization of vacuum pump design and configuration to enhance efficiency and performance. This includes modifications to pump geometry, internal components, and overall structure to improve suction capacity, reduce energy consumption, and increase operational reliability.

- Advanced control systems and automation: Implementation of sophisticated control systems and automation technologies to optimize vacuum pump operation. This involves the use of sensors, feedback mechanisms, and intelligent algorithms to regulate pump speed, pressure, and other parameters in real-time, ensuring optimal performance under varying conditions.

- Enhanced sealing and lubrication techniques: Development of improved sealing and lubrication methods to minimize leakage and reduce friction in vacuum pumps. This includes the use of advanced materials, innovative seal designs, and optimized lubrication systems to enhance pump efficiency and extend operational lifespan.

- Integration of energy recovery systems: Incorporation of energy recovery mechanisms in vacuum pump systems to improve overall efficiency. This involves capturing and reusing waste heat or pressure differentials generated during pump operation, thereby reducing energy consumption and operational costs.

- Optimization of multi-stage pump systems: Refinement of multi-stage vacuum pump configurations to achieve higher vacuum levels and improved efficiency. This includes optimizing the arrangement and interaction of different pump stages, as well as developing hybrid systems that combine various pump technologies to meet specific application requirements.

02 Advanced control systems and automation

Implementation of sophisticated control systems and automation techniques for vacuum pumps. This involves integrating sensors, feedback mechanisms, and intelligent algorithms to optimize pump operation, adjust parameters in real-time, and enhance overall system efficiency.Expand Specific Solutions03 Novel materials and coatings

Utilization of innovative materials and surface coatings in vacuum pump components. These advancements aim to reduce friction, improve wear resistance, enhance thermal management, and increase the overall lifespan and performance of the pump.Expand Specific Solutions04 Energy efficiency and heat management

Strategies to improve energy efficiency and heat management in vacuum pumps. This includes optimizing motor designs, implementing energy recovery systems, and enhancing cooling mechanisms to reduce power consumption and improve overall pump performance.Expand Specific Solutions05 Multi-stage and hybrid pump systems

Development of multi-stage and hybrid vacuum pump systems that combine different pumping technologies. These configurations aim to achieve higher vacuum levels, improved pumping speeds, and enhanced overall system efficiency across a wide range of operating conditions.Expand Specific Solutions

Key Players in Semiconductor Vacuum Pump Manufacturing

The optimization of vacuum pumps for ion implantation in semiconductors is a critical area in the mature semiconductor industry. The market for this technology is substantial, driven by the growing demand for advanced semiconductor devices. Key players like Applied Materials, Axcelis Technologies, and Varian Semiconductor Equipment Associates dominate the field, leveraging their extensive experience and R&D capabilities. The technology is well-established but continues to evolve, with companies like ULVAC and Edwards Ltd. contributing innovations in vacuum technology. Asian manufacturers, including Samsung Electronics and SK hynix, are also significant contributors, reflecting the global nature of this competitive landscape.

Varian Semiconductor Equipment Associates, Inc.

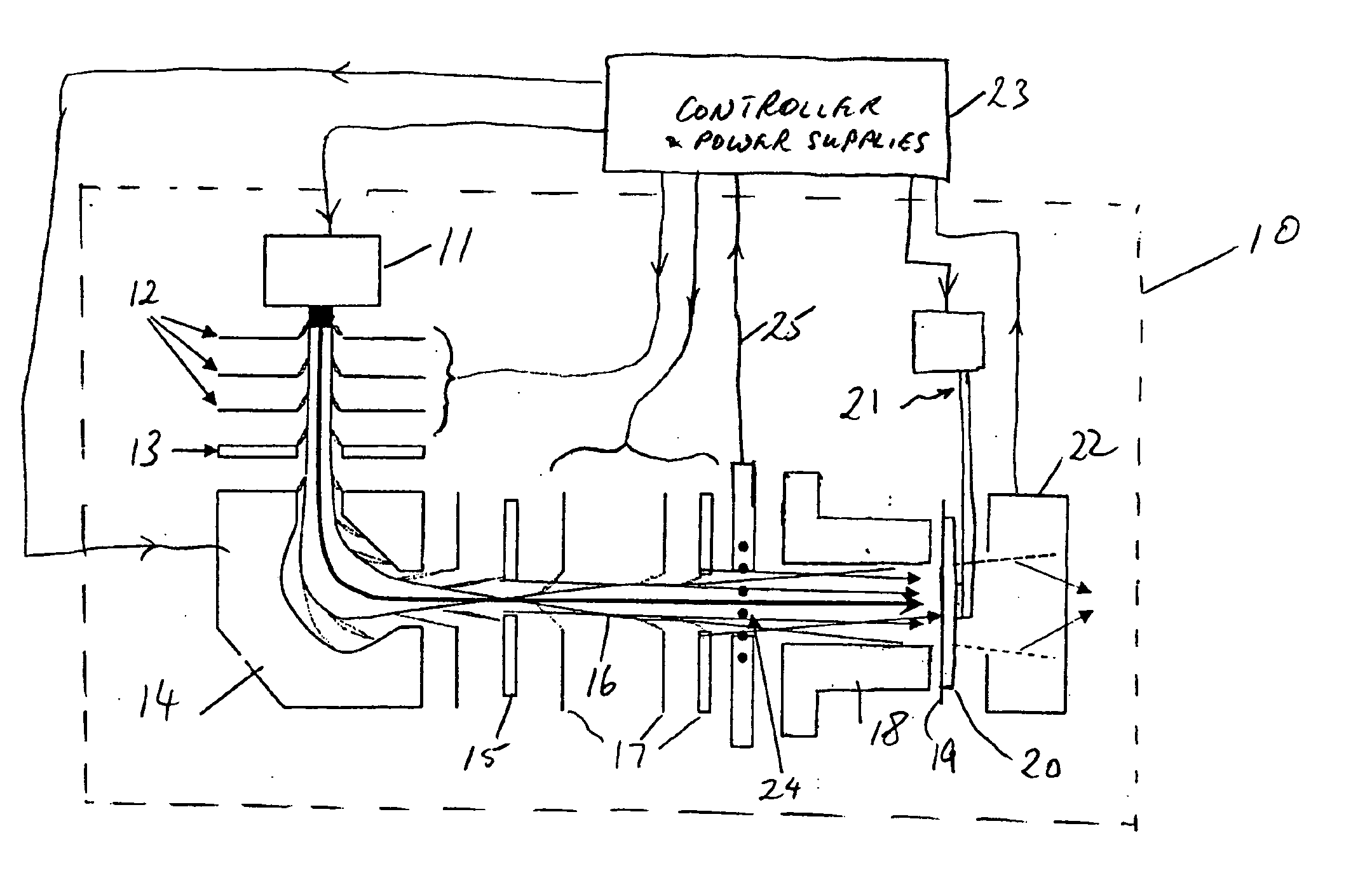

Technical Solution: Varian has developed advanced vacuum pump systems specifically optimized for ion implantation in semiconductors. Their technology utilizes a combination of turbomolecular and cryogenic pumps to achieve ultra-high vacuum levels necessary for precise ion implantation[1]. The system incorporates advanced control algorithms that dynamically adjust pumping speeds based on real-time pressure measurements, ensuring optimal vacuum conditions throughout the implantation process[2]. Additionally, Varian has implemented innovative pump designs that minimize particle generation and backstreaming, critical for maintaining clean implantation environments[3].

Strengths: Highly specialized for ion implantation, excellent vacuum performance, and clean operation. Weaknesses: Potentially higher cost and complexity compared to more general-purpose vacuum systems.

Axcelis Technologies, Inc.

Technical Solution: Axcelis has developed a proprietary vacuum system for their ion implanters, focusing on high-throughput and energy-efficient operation. Their approach utilizes a multi-stage pumping system, combining dry pumps and turbomolecular pumps with advanced flow management[4]. The system incorporates intelligent load-lock designs that minimize pump-down times and reduce overall cycle times[5]. Axcelis has also implemented advanced vacuum sealing technologies and materials to enhance reliability and reduce maintenance requirements[6].

Strengths: High throughput, energy efficiency, and reduced maintenance needs. Weaknesses: May be less flexible for non-standard implantation processes.

Innovative Vacuum Pump Designs for Ion Implantation

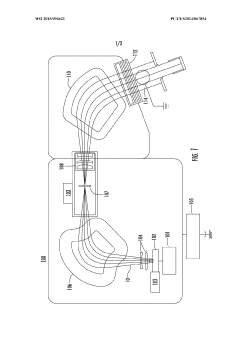

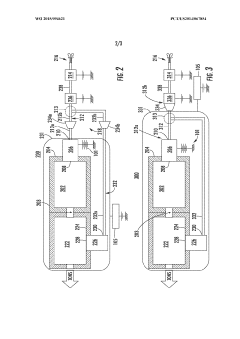

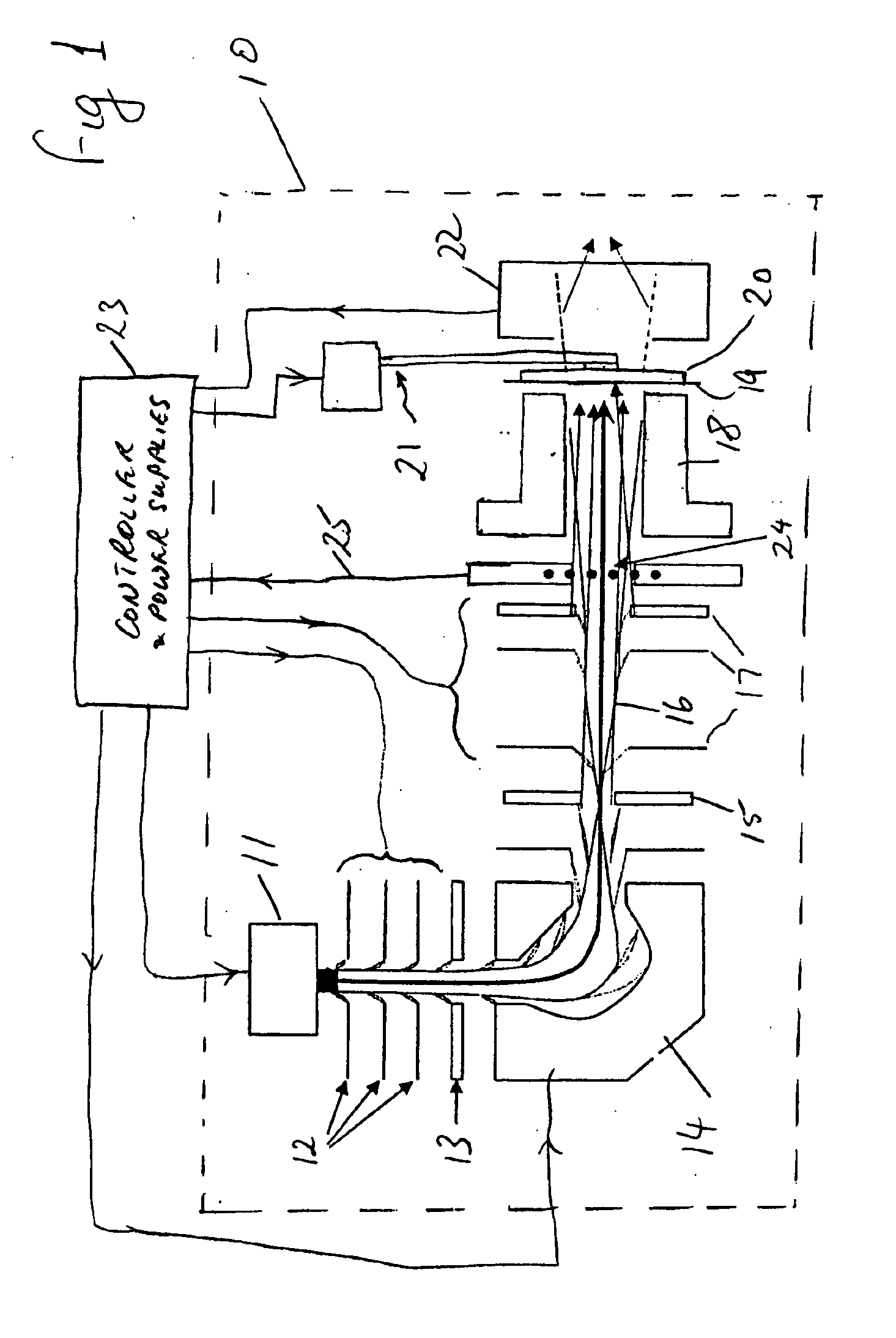

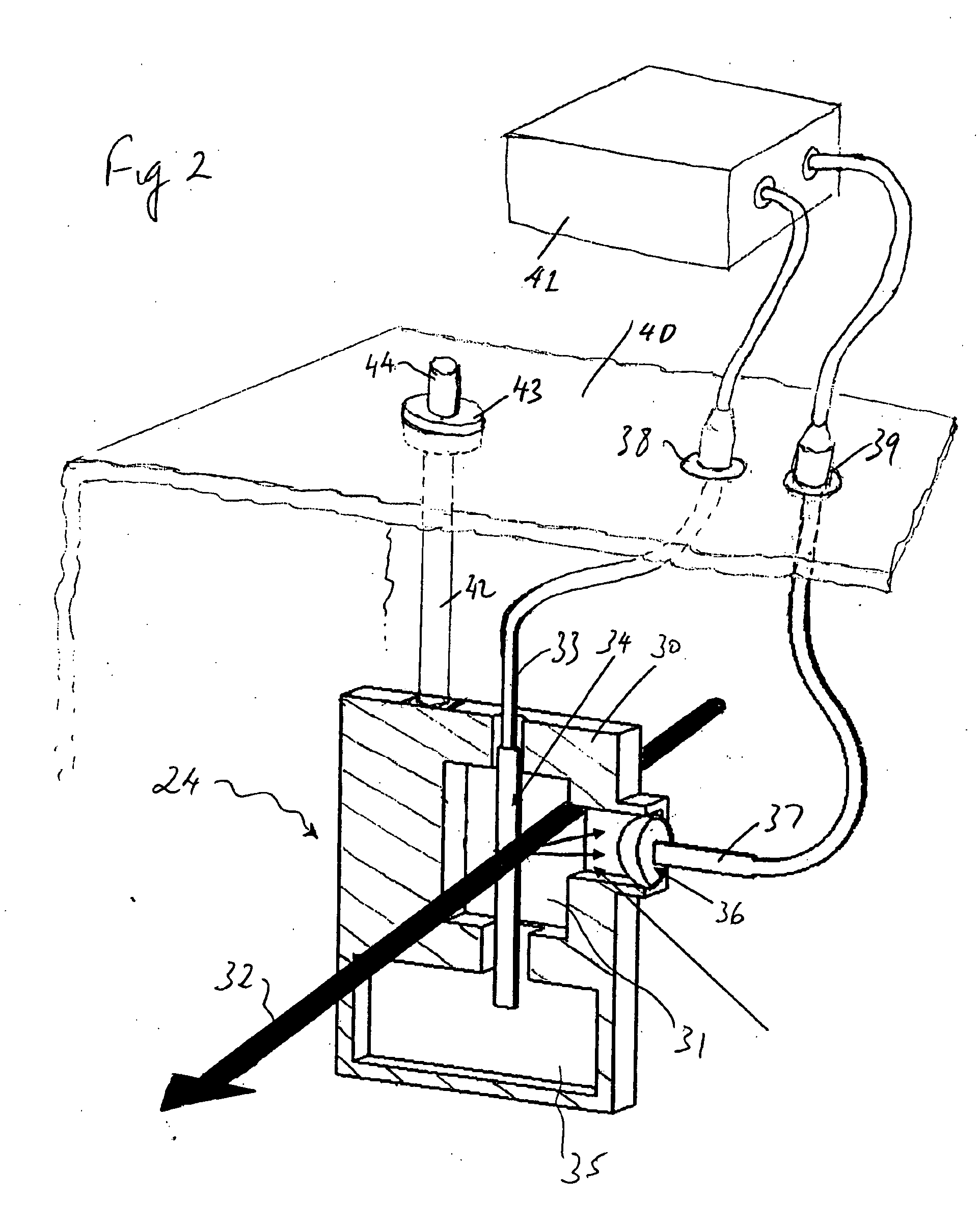

Vacuum assembly for an ion implanter system

PatentWO2015094621A1

Innovation

- A vacuum assembly with a voltage isolator allows the backing pump to operate at ground potential, electrically isolating it from turbomolecular pumps, thereby eliminating the need for three-phase AC power in the high voltage region and preventing Paschen discharges by maintaining high vacuum levels in the backing lines.

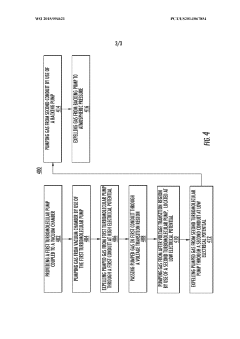

Semiconductor device manufacturing apparatus and a method of controlling a semiconductor device manufacturing process

PatentInactiveUS20060035396A1

Innovation

- A method and apparatus that measure the flux of contaminant particles within the vacuum chamber during semiconductor device manufacturing, allowing for real-time adjustment of process parameters, such as ion beam alignment and focussing voltages, to reduce particle production while maintaining continuous process conditions.

Environmental Impact of Vacuum Pump Operations

The environmental impact of vacuum pump operations in ion implantation processes for semiconductor manufacturing is a critical consideration in the industry's pursuit of sustainability. These pumps, essential for maintaining the ultra-high vacuum conditions required for ion implantation, consume significant amounts of energy and contribute to the overall carbon footprint of semiconductor fabrication facilities.

Energy consumption is a primary environmental concern associated with vacuum pump operations. The continuous operation of these pumps, often running 24/7, requires substantial electrical power. This high energy demand not only increases operational costs but also indirectly contributes to greenhouse gas emissions, depending on the energy sources used by the facility. Efforts to optimize pump efficiency and implement energy-saving technologies are crucial for reducing this environmental impact.

Another significant environmental aspect is the use and disposal of pump oils and lubricants. Many vacuum pumps, particularly rotary vane and diffusion pumps, require oil for proper functioning. These oils can become contaminated over time and require regular replacement. The disposal of used pump oils presents potential environmental hazards if not managed properly, as they may contain harmful substances that can contaminate soil and water resources.

Noise pollution is an often-overlooked environmental impact of vacuum pump operations. The continuous operation of multiple pumps can create significant noise levels within semiconductor fabrication facilities. This not only affects the working environment for employees but can also contribute to noise pollution in surrounding areas if not properly contained.

The production and disposal of vacuum pumps themselves also have environmental implications. The manufacturing process of these sophisticated devices involves the use of various materials, including metals and plastics, which have their own environmental footprints. Additionally, the disposal of obsolete or damaged pumps at the end of their lifecycle requires careful consideration to minimize waste and maximize recycling opportunities.

Water usage is another environmental factor to consider, particularly in pump cooling systems. Some high-capacity vacuum pumps require water cooling to maintain optimal performance. The water used in these cooling systems may need treatment before disposal, and the overall water consumption contributes to the facility's environmental impact, especially in water-scarce regions.

To address these environmental concerns, the semiconductor industry is increasingly focusing on developing and implementing more sustainable vacuum pump technologies. This includes the adoption of dry pumps that eliminate the need for oil, improving pump efficiency to reduce energy consumption, and implementing advanced control systems to optimize pump operation based on real-time demand. Additionally, some facilities are exploring the use of renewable energy sources to power their vacuum systems, further reducing their carbon footprint.

Energy consumption is a primary environmental concern associated with vacuum pump operations. The continuous operation of these pumps, often running 24/7, requires substantial electrical power. This high energy demand not only increases operational costs but also indirectly contributes to greenhouse gas emissions, depending on the energy sources used by the facility. Efforts to optimize pump efficiency and implement energy-saving technologies are crucial for reducing this environmental impact.

Another significant environmental aspect is the use and disposal of pump oils and lubricants. Many vacuum pumps, particularly rotary vane and diffusion pumps, require oil for proper functioning. These oils can become contaminated over time and require regular replacement. The disposal of used pump oils presents potential environmental hazards if not managed properly, as they may contain harmful substances that can contaminate soil and water resources.

Noise pollution is an often-overlooked environmental impact of vacuum pump operations. The continuous operation of multiple pumps can create significant noise levels within semiconductor fabrication facilities. This not only affects the working environment for employees but can also contribute to noise pollution in surrounding areas if not properly contained.

The production and disposal of vacuum pumps themselves also have environmental implications. The manufacturing process of these sophisticated devices involves the use of various materials, including metals and plastics, which have their own environmental footprints. Additionally, the disposal of obsolete or damaged pumps at the end of their lifecycle requires careful consideration to minimize waste and maximize recycling opportunities.

Water usage is another environmental factor to consider, particularly in pump cooling systems. Some high-capacity vacuum pumps require water cooling to maintain optimal performance. The water used in these cooling systems may need treatment before disposal, and the overall water consumption contributes to the facility's environmental impact, especially in water-scarce regions.

To address these environmental concerns, the semiconductor industry is increasingly focusing on developing and implementing more sustainable vacuum pump technologies. This includes the adoption of dry pumps that eliminate the need for oil, improving pump efficiency to reduce energy consumption, and implementing advanced control systems to optimize pump operation based on real-time demand. Additionally, some facilities are exploring the use of renewable energy sources to power their vacuum systems, further reducing their carbon footprint.

Cost-Benefit Analysis of Advanced Vacuum Pump Systems

The cost-benefit analysis of advanced vacuum pump systems for ion implantation in semiconductors reveals significant potential for long-term savings and improved process efficiency. Initial investment in high-performance vacuum pumps, such as dry screw pumps or turbomolecular pumps, typically ranges from $50,000 to $200,000 per unit, depending on capacity and specifications. While this represents a substantial upfront cost, the benefits often outweigh the initial expenditure over time.

Energy efficiency is a primary advantage of advanced vacuum pump systems. Modern pumps can reduce energy consumption by 30-50% compared to older models, translating to annual savings of $10,000 to $30,000 per pump in electricity costs for a typical semiconductor fabrication facility. This energy reduction also aligns with sustainability goals, potentially qualifying for energy efficiency incentives or carbon credits in some regions.

Maintenance costs and downtime are significantly reduced with advanced pump systems. Traditional oil-sealed pumps require frequent oil changes and overhauls, incurring costs of $5,000 to $15,000 annually per pump. In contrast, dry pumps can operate for 3-5 years without major maintenance, reducing these costs by up to 80%. The increased reliability also minimizes production interruptions, with potential savings of $50,000 to $100,000 per day in avoided downtime for a high-volume manufacturing line.

Process improvements enabled by advanced vacuum systems can lead to substantial yield increases. Better vacuum quality and stability can reduce defects in ion implantation by 5-10%, potentially increasing overall chip yield by 1-2%. For a facility producing 50,000 wafers per month, this could translate to additional revenue of $1-2 million monthly.

The lifespan of advanced vacuum pumps typically exceeds 10 years, compared to 5-7 years for conventional systems. This extended operational life further enhances the return on investment, reducing the frequency of capital expenditures for pump replacements.

When considering total cost of ownership over a 10-year period, advanced vacuum pump systems often demonstrate a positive return on investment within 2-3 years. The cumulative savings in energy, maintenance, and improved yield can exceed the initial investment by 300-500% over the pump's lifetime, making them a financially sound choice for semiconductor manufacturers focused on long-term operational efficiency and competitiveness.

Energy efficiency is a primary advantage of advanced vacuum pump systems. Modern pumps can reduce energy consumption by 30-50% compared to older models, translating to annual savings of $10,000 to $30,000 per pump in electricity costs for a typical semiconductor fabrication facility. This energy reduction also aligns with sustainability goals, potentially qualifying for energy efficiency incentives or carbon credits in some regions.

Maintenance costs and downtime are significantly reduced with advanced pump systems. Traditional oil-sealed pumps require frequent oil changes and overhauls, incurring costs of $5,000 to $15,000 annually per pump. In contrast, dry pumps can operate for 3-5 years without major maintenance, reducing these costs by up to 80%. The increased reliability also minimizes production interruptions, with potential savings of $50,000 to $100,000 per day in avoided downtime for a high-volume manufacturing line.

Process improvements enabled by advanced vacuum systems can lead to substantial yield increases. Better vacuum quality and stability can reduce defects in ion implantation by 5-10%, potentially increasing overall chip yield by 1-2%. For a facility producing 50,000 wafers per month, this could translate to additional revenue of $1-2 million monthly.

The lifespan of advanced vacuum pumps typically exceeds 10 years, compared to 5-7 years for conventional systems. This extended operational life further enhances the return on investment, reducing the frequency of capital expenditures for pump replacements.

When considering total cost of ownership over a 10-year period, advanced vacuum pump systems often demonstrate a positive return on investment within 2-3 years. The cumulative savings in energy, maintenance, and improved yield can exceed the initial investment by 300-500% over the pump's lifetime, making them a financially sound choice for semiconductor manufacturers focused on long-term operational efficiency and competitiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!