How Vacuum Pumps Support Novel Thin-Layer Sensor Technologies

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution and Objectives

Vacuum pump technology has undergone significant evolution since its inception in the 17th century. The journey from early mechanical pumps to modern high-performance systems reflects the growing demands of various industries, particularly in the field of thin-layer sensor technologies. The primary objective of vacuum pumps in this context is to create and maintain the precise low-pressure environments essential for the fabrication and operation of advanced sensors.

The development of vacuum pumps has been driven by the need for increasingly lower pressures and higher pumping speeds. Early positive displacement pumps, such as the piston pump invented by Otto von Guericke, laid the foundation for vacuum technology. However, these pumps were limited in their ability to achieve high vacuums. The 20th century saw the introduction of more sophisticated designs, including rotary vane pumps, diffusion pumps, and turbomolecular pumps, each offering improvements in vacuum quality and pumping efficiency.

In recent decades, the focus has shifted towards developing pumps that can achieve ultra-high vacuums while maintaining cleanliness and reliability. This trend has been particularly crucial for thin-layer sensor technologies, where even minute contamination can significantly impact sensor performance. The emergence of dry pumps, such as scroll pumps and diaphragm pumps, has addressed the need for oil-free vacuum environments, which are essential for many sensor fabrication processes.

The objectives of modern vacuum pump technology in supporting thin-layer sensor development are multifaceted. Firstly, there is a continuous push for achieving lower ultimate pressures, with some applications requiring vacuums as low as 10^-12 mbar. This extreme level of vacuum is necessary for certain deposition techniques used in sensor fabrication, such as molecular beam epitaxy.

Secondly, pump manufacturers aim to increase pumping speeds while maintaining compact designs. This objective is driven by the need for faster processing times in sensor production and the space constraints in many research and manufacturing facilities. The development of compound pumping systems, which combine different pump types in series or parallel, has been a key strategy in meeting these demands.

Another critical objective is to enhance the cleanliness of vacuum environments. This involves developing pumps with lower particle emissions and better resistance to backstreaming, which is particularly important in the production of highly sensitive thin-layer sensors. Additionally, there is a growing emphasis on energy efficiency and environmental sustainability in vacuum pump design, aligning with broader industrial trends towards green technologies.

The evolution of vacuum pump technology continues to be closely tied to advancements in thin-layer sensor technologies. As sensors become more sophisticated and miniaturized, the demands on vacuum systems grow more stringent. This symbiotic relationship drives ongoing innovation in both fields, pushing the boundaries of what is possible in sensor design and performance.

The development of vacuum pumps has been driven by the need for increasingly lower pressures and higher pumping speeds. Early positive displacement pumps, such as the piston pump invented by Otto von Guericke, laid the foundation for vacuum technology. However, these pumps were limited in their ability to achieve high vacuums. The 20th century saw the introduction of more sophisticated designs, including rotary vane pumps, diffusion pumps, and turbomolecular pumps, each offering improvements in vacuum quality and pumping efficiency.

In recent decades, the focus has shifted towards developing pumps that can achieve ultra-high vacuums while maintaining cleanliness and reliability. This trend has been particularly crucial for thin-layer sensor technologies, where even minute contamination can significantly impact sensor performance. The emergence of dry pumps, such as scroll pumps and diaphragm pumps, has addressed the need for oil-free vacuum environments, which are essential for many sensor fabrication processes.

The objectives of modern vacuum pump technology in supporting thin-layer sensor development are multifaceted. Firstly, there is a continuous push for achieving lower ultimate pressures, with some applications requiring vacuums as low as 10^-12 mbar. This extreme level of vacuum is necessary for certain deposition techniques used in sensor fabrication, such as molecular beam epitaxy.

Secondly, pump manufacturers aim to increase pumping speeds while maintaining compact designs. This objective is driven by the need for faster processing times in sensor production and the space constraints in many research and manufacturing facilities. The development of compound pumping systems, which combine different pump types in series or parallel, has been a key strategy in meeting these demands.

Another critical objective is to enhance the cleanliness of vacuum environments. This involves developing pumps with lower particle emissions and better resistance to backstreaming, which is particularly important in the production of highly sensitive thin-layer sensors. Additionally, there is a growing emphasis on energy efficiency and environmental sustainability in vacuum pump design, aligning with broader industrial trends towards green technologies.

The evolution of vacuum pump technology continues to be closely tied to advancements in thin-layer sensor technologies. As sensors become more sophisticated and miniaturized, the demands on vacuum systems grow more stringent. This symbiotic relationship drives ongoing innovation in both fields, pushing the boundaries of what is possible in sensor design and performance.

Thin-Layer Sensor Market Analysis

The thin-layer sensor market has experienced significant growth in recent years, driven by advancements in nanotechnology and increasing demand for miniaturized, high-performance sensing devices. These sensors, characterized by their ultra-thin profiles and exceptional sensitivity, find applications across various industries, including healthcare, environmental monitoring, and consumer electronics.

In the healthcare sector, thin-layer sensors are revolutionizing diagnostic and monitoring capabilities. The market for wearable medical devices incorporating these sensors is expanding rapidly, with a focus on continuous health monitoring and early disease detection. Applications range from glucose monitoring for diabetes management to real-time tracking of vital signs in hospital settings.

The environmental monitoring segment is another key driver of market growth. Thin-layer sensors enable more accurate and widespread detection of pollutants, greenhouse gases, and other environmental factors. This has led to increased adoption in smart city initiatives, industrial safety applications, and climate change research.

Consumer electronics represent a significant portion of the thin-layer sensor market. Smartphones, tablets, and other portable devices increasingly incorporate these sensors for improved user interfaces, augmented reality applications, and enhanced security features such as fingerprint recognition.

The automotive industry is also embracing thin-layer sensor technology. Advanced driver assistance systems (ADAS) and autonomous vehicles rely on these sensors for precise environmental perception and vehicle control. The market for automotive thin-layer sensors is expected to grow substantially as vehicle electrification and automation trends accelerate.

Geographically, North America and Asia-Pacific are the leading markets for thin-layer sensors. North America benefits from a strong presence of technology companies and research institutions, while Asia-Pacific's growth is fueled by rapid industrialization and increasing adoption of IoT technologies.

The market is characterized by intense competition and continuous innovation. Key players are investing heavily in research and development to improve sensor performance, reduce costs, and expand application areas. Collaborations between sensor manufacturers, technology companies, and end-users are becoming more common, driving further market expansion and technological advancements.

As the demand for more sophisticated and miniaturized sensing solutions continues to grow, the thin-layer sensor market is poised for sustained expansion. Emerging applications in fields such as robotics, smart agriculture, and personalized medicine are expected to create new opportunities for market growth in the coming years.

In the healthcare sector, thin-layer sensors are revolutionizing diagnostic and monitoring capabilities. The market for wearable medical devices incorporating these sensors is expanding rapidly, with a focus on continuous health monitoring and early disease detection. Applications range from glucose monitoring for diabetes management to real-time tracking of vital signs in hospital settings.

The environmental monitoring segment is another key driver of market growth. Thin-layer sensors enable more accurate and widespread detection of pollutants, greenhouse gases, and other environmental factors. This has led to increased adoption in smart city initiatives, industrial safety applications, and climate change research.

Consumer electronics represent a significant portion of the thin-layer sensor market. Smartphones, tablets, and other portable devices increasingly incorporate these sensors for improved user interfaces, augmented reality applications, and enhanced security features such as fingerprint recognition.

The automotive industry is also embracing thin-layer sensor technology. Advanced driver assistance systems (ADAS) and autonomous vehicles rely on these sensors for precise environmental perception and vehicle control. The market for automotive thin-layer sensors is expected to grow substantially as vehicle electrification and automation trends accelerate.

Geographically, North America and Asia-Pacific are the leading markets for thin-layer sensors. North America benefits from a strong presence of technology companies and research institutions, while Asia-Pacific's growth is fueled by rapid industrialization and increasing adoption of IoT technologies.

The market is characterized by intense competition and continuous innovation. Key players are investing heavily in research and development to improve sensor performance, reduce costs, and expand application areas. Collaborations between sensor manufacturers, technology companies, and end-users are becoming more common, driving further market expansion and technological advancements.

As the demand for more sophisticated and miniaturized sensing solutions continues to grow, the thin-layer sensor market is poised for sustained expansion. Emerging applications in fields such as robotics, smart agriculture, and personalized medicine are expected to create new opportunities for market growth in the coming years.

Vacuum Technology Challenges

Vacuum technology plays a crucial role in the development and production of novel thin-layer sensor technologies. However, this field faces several significant challenges that need to be addressed to advance the capabilities of these sensors. One of the primary challenges is achieving and maintaining ultra-high vacuum levels required for precise deposition of thin films. As sensor layers become increasingly thinner, even minute impurities or pressure fluctuations can significantly impact the quality and performance of the final product.

The miniaturization trend in sensor technologies demands vacuum systems capable of handling smaller substrates and more intricate geometries. This necessitates the development of specialized vacuum chambers and pumping configurations that can provide uniform vacuum conditions across complex surfaces. Additionally, the need for higher throughput in manufacturing processes puts pressure on vacuum systems to achieve faster pump-down times without compromising vacuum quality.

Another critical challenge lies in the control and stability of vacuum levels during the deposition process. Fluctuations in pressure can lead to inconsistencies in film thickness and composition, affecting the sensor's sensitivity and reliability. This requires advanced vacuum monitoring and control systems that can respond rapidly to changes in pressure and gas composition within the chamber.

The integration of in-situ measurement and characterization tools within vacuum systems presents another hurdle. These tools are essential for real-time monitoring of film growth and properties but can introduce additional complexity to the vacuum system design. Ensuring that these instruments do not compromise the vacuum integrity while providing accurate measurements is a delicate balance to maintain.

Energy efficiency and environmental considerations also pose challenges in vacuum technology for sensor production. As the demand for sensors grows, so does the need for more energy-efficient vacuum pumps and systems that can operate continuously with minimal environmental impact. This drives research into novel pumping technologies and more efficient cooling systems for vacuum equipment.

Contamination control remains a persistent challenge in vacuum-based sensor fabrication. Even trace amounts of contaminants can significantly affect the performance of thin-layer sensors. This necessitates the development of advanced cleaning and passivation techniques for vacuum chambers, as well as improved materials and coatings that minimize outgassing and particle generation within the vacuum environment.

Lastly, the increasing complexity of multi-layer sensor structures requires vacuum systems capable of handling multiple deposition steps without breaking vacuum. This challenge involves developing sophisticated load-lock systems and transfer mechanisms that can move substrates between different process chambers while maintaining vacuum integrity throughout the entire fabrication process.

The miniaturization trend in sensor technologies demands vacuum systems capable of handling smaller substrates and more intricate geometries. This necessitates the development of specialized vacuum chambers and pumping configurations that can provide uniform vacuum conditions across complex surfaces. Additionally, the need for higher throughput in manufacturing processes puts pressure on vacuum systems to achieve faster pump-down times without compromising vacuum quality.

Another critical challenge lies in the control and stability of vacuum levels during the deposition process. Fluctuations in pressure can lead to inconsistencies in film thickness and composition, affecting the sensor's sensitivity and reliability. This requires advanced vacuum monitoring and control systems that can respond rapidly to changes in pressure and gas composition within the chamber.

The integration of in-situ measurement and characterization tools within vacuum systems presents another hurdle. These tools are essential for real-time monitoring of film growth and properties but can introduce additional complexity to the vacuum system design. Ensuring that these instruments do not compromise the vacuum integrity while providing accurate measurements is a delicate balance to maintain.

Energy efficiency and environmental considerations also pose challenges in vacuum technology for sensor production. As the demand for sensors grows, so does the need for more energy-efficient vacuum pumps and systems that can operate continuously with minimal environmental impact. This drives research into novel pumping technologies and more efficient cooling systems for vacuum equipment.

Contamination control remains a persistent challenge in vacuum-based sensor fabrication. Even trace amounts of contaminants can significantly affect the performance of thin-layer sensors. This necessitates the development of advanced cleaning and passivation techniques for vacuum chambers, as well as improved materials and coatings that minimize outgassing and particle generation within the vacuum environment.

Lastly, the increasing complexity of multi-layer sensor structures requires vacuum systems capable of handling multiple deposition steps without breaking vacuum. This challenge involves developing sophisticated load-lock systems and transfer mechanisms that can move substrates between different process chambers while maintaining vacuum integrity throughout the entire fabrication process.

Current Vacuum Solutions for Sensors

01 Thin-film deposition using vacuum pumps

Vacuum pumps are essential in thin-film deposition processes, creating the low-pressure environment necessary for precise material deposition. These pumps maintain the required vacuum levels, enabling the formation of uniform and high-quality thin layers in various applications such as semiconductor manufacturing and optical coatings.- Thin-film deposition using vacuum pumps: Vacuum pumps are utilized in thin-film deposition processes to create and maintain low-pressure environments. This enables precise control over the deposition of thin layers of materials onto substrates, which is crucial for various applications in semiconductor manufacturing and nanotechnology.

- Vacuum pump design for thin-layer applications: Specialized vacuum pump designs are developed to meet the specific requirements of thin-layer processing. These pumps often feature improved pumping speeds, cleanliness, and stability to ensure consistent and high-quality thin-film deposition.

- Integration of vacuum pumps in thin-film equipment: Vacuum pumps are integrated into various thin-film processing equipment, such as chemical vapor deposition (CVD) and physical vapor deposition (PVD) systems. This integration ensures optimal performance and efficiency in creating thin layers of materials for advanced applications.

- Vacuum control systems for thin-layer processes: Advanced vacuum control systems are employed to regulate and maintain precise pressure levels during thin-layer deposition. These systems often incorporate multiple vacuum pumps, pressure sensors, and sophisticated control algorithms to achieve the desired thin-film characteristics.

- Vacuum pump maintenance for thin-film applications: Proper maintenance of vacuum pumps is crucial for ensuring consistent performance in thin-layer processing. This includes regular cleaning, lubrication, and replacement of components to prevent contamination and maintain the required vacuum levels for high-quality thin-film deposition.

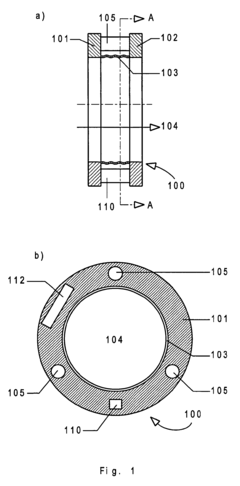

02 Vacuum pump design for thin-layer applications

Specialized vacuum pump designs cater to thin-layer processing requirements. These pumps often feature optimized flow paths, reduced contamination risks, and enhanced pumping speeds to meet the demands of thin-film deposition systems. Innovations in pump technology focus on maintaining stable vacuum levels and minimizing particle generation.Expand Specific Solutions03 Integration of vacuum pumps in thin-layer processing systems

Vacuum pumps are integrated into complex thin-layer processing systems, working in conjunction with other components such as gas delivery systems, substrate holders, and monitoring equipment. This integration ensures optimal performance and control over the thin-film deposition process, allowing for precise layer thickness and composition.Expand Specific Solutions04 Vacuum pump maintenance for thin-layer applications

Proper maintenance of vacuum pumps is crucial in thin-layer processing to ensure consistent performance and longevity. This includes regular cleaning, lubrication, and replacement of wear parts. Specialized maintenance procedures are often required to prevent contamination and maintain the high vacuum levels necessary for thin-film deposition.Expand Specific Solutions05 Advanced control systems for vacuum pumps in thin-layer processes

Sophisticated control systems are employed to manage vacuum pumps in thin-layer applications. These systems monitor and adjust pump performance in real-time, ensuring optimal vacuum levels throughout the deposition process. Advanced features may include predictive maintenance, energy efficiency optimization, and integration with overall process control systems.Expand Specific Solutions

Key Vacuum Pump Manufacturers

The vacuum pump industry supporting novel thin-layer sensor technologies is in a growth phase, driven by increasing demand for advanced sensing applications. The market size is expanding as these sensors find applications in various industries. Technologically, vacuum pumps for thin-layer sensors are evolving rapidly, with companies like Applied Materials, Leybold, Pfeiffer Vacuum, and Edwards leading innovation. These firms are developing more precise, efficient pumps to meet the stringent requirements of thin-film deposition processes. Research institutions like Korea Research Institute of Standards & Science and universities such as MIT are also contributing to advancements in this field, pushing the boundaries of sensor technology and vacuum pump capabilities.

Applied Materials, Inc.

Technical Solution: Applied Materials, Inc. has developed comprehensive vacuum-based solutions for thin-layer sensor fabrication. Their Endura® platform integrates advanced PVD (Physical Vapor Deposition) technology with high-performance vacuum systems to enable the deposition of ultra-thin, uniform sensor layers[10]. The company's iSYS™ vacuum control system provides real-time monitoring and adjustment of chamber pressures, crucial for maintaining consistent deposition rates and film qualities across large substrate areas. Applied Materials has also introduced the Producer® SE system, which combines PECVD (Plasma-Enhanced Chemical Vapor Deposition) with specialized vacuum pumping configurations to achieve precise control over film thickness and composition for next-generation sensor devices[11]. Their vacuum solutions incorporate multi-stage pumping systems that efficiently handle a wide range of process gases and byproducts encountered in sensor fabrication.

Strengths: Integrated solutions combining deposition technology with vacuum systems; Advanced process control for high-precision thin films; Scalable systems for large-area sensor production. Weaknesses: High capital investment required; Complex systems may have longer learning curves for operators.

LEYBOLD AG

Technical Solution: LEYBOLD AG has developed advanced vacuum pump technologies specifically tailored for thin-layer sensor production. Their SCREWLINE dry screw vacuum pumps offer oil-free operation, crucial for maintaining the purity of thin-film deposition processes[1]. These pumps achieve ultimate pressures down to 0.01 mbar, enabling precise control over the deposition environment[2]. LEYBOLD's DRYVAC systems integrate intelligent control features, allowing for real-time adjustments to maintain optimal vacuum conditions throughout the sensor fabrication process. The company has also introduced the NOVADRY series, which combines high pumping speeds with low power consumption, making it ideal for continuous operation in sensor production lines[3].

Strengths: Oil-free operation ensures high purity; Intelligent control systems for precise vacuum management; Energy-efficient designs for long-term operation. Weaknesses: Higher initial cost compared to traditional pumps; May require specialized maintenance.

Innovative Vacuum Pump Designs

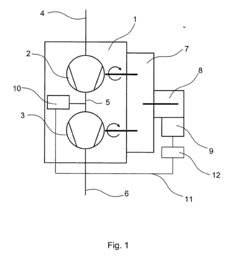

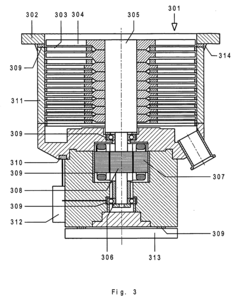

Vacuum pump

PatentInactiveEP1918585A2

Innovation

- A compact vacuum pump design with a gas-pressure-sensitive signal transmitter integrated between pump stages, allowing for continuous speed adjustment based on gas pressure without additional components, and incorporating a common evaluation unit and motor control for efficient power management, reducing wear and noise.

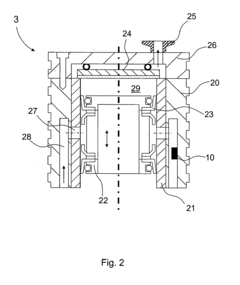

Vibration reducing apparatus and vacuum pump system incorporating the same

PatentActiveEP1715190A1

Innovation

- The implementation of active vibration-reducing components with vibration-recording sensors that convert vibrations into electronic signals, allowing the system to generate actuating signals for oscillation in phase opposition, enabling dynamic adjustment of damping characteristics and reducing vibrations effectively.

Environmental Impact of Vacuum Pumps

Vacuum pumps, while essential for thin-layer sensor technologies, have significant environmental implications that warrant careful consideration. The production and operation of vacuum pumps contribute to various environmental concerns, primarily related to energy consumption and greenhouse gas emissions. Modern vacuum pumps, especially those used in high-precision applications, require substantial electrical power to maintain the desired vacuum levels. This energy demand often translates to increased carbon footprints, particularly when the electricity source is not from renewable energy.

The manufacturing process of vacuum pumps also raises environmental issues. The production of specialized materials and components used in these pumps, such as high-grade metals and lubricants, involves resource extraction and processing that can lead to habitat disruption and pollution. Additionally, the disposal of worn-out vacuum pumps and their components presents challenges in terms of waste management and potential environmental contamination.

However, it's important to note that the environmental impact of vacuum pumps in thin-layer sensor technologies should be considered in the context of their overall benefits. These pumps enable the development of more efficient and sensitive sensors, which can lead to improved environmental monitoring and control systems. For instance, thin-layer sensors supported by vacuum technology can detect minute levels of pollutants or greenhouse gases, contributing to more effective environmental protection measures.

The vacuum industry has been making strides in developing more environmentally friendly pump designs. Energy-efficient models that consume less power while maintaining high performance are becoming increasingly available. Some manufacturers are also focusing on using more sustainable materials and implementing recycling programs for end-of-life pumps, aiming to reduce the overall environmental footprint of their products.

In the context of thin-layer sensor production, the environmental impact of vacuum pumps can be mitigated through careful process optimization. By fine-tuning vacuum levels and pump operation times, manufacturers can reduce energy consumption without compromising sensor quality. Furthermore, the integration of smart control systems and predictive maintenance can extend the lifespan of vacuum pumps, reducing the frequency of replacements and associated waste.

As environmental concerns continue to grow, the vacuum pump industry is likely to face increased pressure to innovate towards more sustainable solutions. This may drive research into alternative vacuum technologies or novel materials that could reduce the environmental impact while maintaining or improving performance for thin-layer sensor applications. Balancing the technological benefits with environmental responsibility will be crucial for the continued development and adoption of vacuum-dependent sensor technologies.

The manufacturing process of vacuum pumps also raises environmental issues. The production of specialized materials and components used in these pumps, such as high-grade metals and lubricants, involves resource extraction and processing that can lead to habitat disruption and pollution. Additionally, the disposal of worn-out vacuum pumps and their components presents challenges in terms of waste management and potential environmental contamination.

However, it's important to note that the environmental impact of vacuum pumps in thin-layer sensor technologies should be considered in the context of their overall benefits. These pumps enable the development of more efficient and sensitive sensors, which can lead to improved environmental monitoring and control systems. For instance, thin-layer sensors supported by vacuum technology can detect minute levels of pollutants or greenhouse gases, contributing to more effective environmental protection measures.

The vacuum industry has been making strides in developing more environmentally friendly pump designs. Energy-efficient models that consume less power while maintaining high performance are becoming increasingly available. Some manufacturers are also focusing on using more sustainable materials and implementing recycling programs for end-of-life pumps, aiming to reduce the overall environmental footprint of their products.

In the context of thin-layer sensor production, the environmental impact of vacuum pumps can be mitigated through careful process optimization. By fine-tuning vacuum levels and pump operation times, manufacturers can reduce energy consumption without compromising sensor quality. Furthermore, the integration of smart control systems and predictive maintenance can extend the lifespan of vacuum pumps, reducing the frequency of replacements and associated waste.

As environmental concerns continue to grow, the vacuum pump industry is likely to face increased pressure to innovate towards more sustainable solutions. This may drive research into alternative vacuum technologies or novel materials that could reduce the environmental impact while maintaining or improving performance for thin-layer sensor applications. Balancing the technological benefits with environmental responsibility will be crucial for the continued development and adoption of vacuum-dependent sensor technologies.

Vacuum Pump Miniaturization Trends

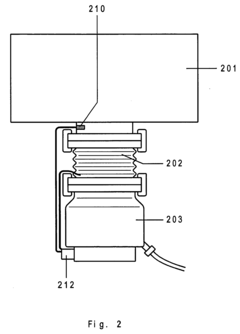

The miniaturization of vacuum pumps has been a significant trend in recent years, driven by the increasing demand for compact and efficient pumping solutions in various industries, particularly in the field of thin-layer sensor technologies. This trend is characterized by the development of smaller, lighter, and more energy-efficient vacuum pumps that can be integrated into portable devices and miniaturized systems.

One of the key drivers of this trend is the advancement in materials science and manufacturing techniques. The use of advanced materials, such as high-strength alloys and composites, has enabled the production of smaller pump components without compromising their performance or durability. Additionally, precision manufacturing techniques, including 3D printing and micro-machining, have allowed for the fabrication of intricate pump designs that were previously impossible to produce at such small scales.

The miniaturization of vacuum pumps has also been facilitated by improvements in motor technology. The development of high-efficiency, compact motors has made it possible to reduce the overall size of vacuum pumps while maintaining or even improving their pumping capacity. These motors often incorporate advanced control systems that optimize performance and energy consumption, further contributing to the miniaturization trend.

Another important aspect of vacuum pump miniaturization is the integration of smart technologies. Modern miniaturized vacuum pumps often feature embedded sensors and microcontrollers that enable real-time monitoring and control of pump performance. This integration allows for more precise vacuum control, predictive maintenance, and remote operation, which are particularly valuable in thin-layer sensor applications where precise environmental control is crucial.

The trend towards miniaturization has also led to the development of novel pump designs. For instance, micro-electromechanical systems (MEMS) based vacuum pumps have emerged as a promising solution for ultra-compact applications. These pumps utilize microscale structures and principles to achieve vacuum generation in extremely small form factors, opening up new possibilities for integration into miniaturized sensor systems.

As the demand for smaller and more efficient vacuum pumps continues to grow, researchers and manufacturers are exploring innovative approaches to further push the boundaries of miniaturization. This includes investigating new materials with enhanced properties, developing advanced manufacturing techniques for even smaller components, and exploring alternative vacuum generation principles that could potentially lead to even more compact pump designs.

One of the key drivers of this trend is the advancement in materials science and manufacturing techniques. The use of advanced materials, such as high-strength alloys and composites, has enabled the production of smaller pump components without compromising their performance or durability. Additionally, precision manufacturing techniques, including 3D printing and micro-machining, have allowed for the fabrication of intricate pump designs that were previously impossible to produce at such small scales.

The miniaturization of vacuum pumps has also been facilitated by improvements in motor technology. The development of high-efficiency, compact motors has made it possible to reduce the overall size of vacuum pumps while maintaining or even improving their pumping capacity. These motors often incorporate advanced control systems that optimize performance and energy consumption, further contributing to the miniaturization trend.

Another important aspect of vacuum pump miniaturization is the integration of smart technologies. Modern miniaturized vacuum pumps often feature embedded sensors and microcontrollers that enable real-time monitoring and control of pump performance. This integration allows for more precise vacuum control, predictive maintenance, and remote operation, which are particularly valuable in thin-layer sensor applications where precise environmental control is crucial.

The trend towards miniaturization has also led to the development of novel pump designs. For instance, micro-electromechanical systems (MEMS) based vacuum pumps have emerged as a promising solution for ultra-compact applications. These pumps utilize microscale structures and principles to achieve vacuum generation in extremely small form factors, opening up new possibilities for integration into miniaturized sensor systems.

As the demand for smaller and more efficient vacuum pumps continues to grow, researchers and manufacturers are exploring innovative approaches to further push the boundaries of miniaturization. This includes investigating new materials with enhanced properties, developing advanced manufacturing techniques for even smaller components, and exploring alternative vacuum generation principles that could potentially lead to even more compact pump designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!