Vacuum Pump Roles in Innovative Heat Exchange Systems

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution

Vacuum pumps have played a crucial role in the evolution of heat exchange systems, with their development closely intertwined with advancements in thermal management technologies. The journey of vacuum pumps in this context can be traced back to the early 20th century when the principles of vacuum-assisted heat transfer were first explored.

In the 1920s and 1930s, researchers began to recognize the potential of vacuum conditions in enhancing heat transfer efficiency. This led to the development of rudimentary vacuum-assisted heat exchangers, which relied on primitive vacuum pumps to create low-pressure environments. These early systems, while innovative, were limited in their effectiveness due to the constraints of vacuum pump technology at the time.

The 1950s and 1960s saw significant advancements in vacuum pump design, particularly with the introduction of rotary vane and diffusion pumps. These improvements allowed for the creation of more stable and deeper vacuums, enabling heat exchange systems to operate with greater efficiency. During this period, vacuum-assisted heat pipes emerged as a promising technology, leveraging the enhanced evaporation and condensation processes facilitated by low-pressure environments.

The 1970s and 1980s marked a turning point in vacuum pump technology for heat exchange applications. The development of turbomolecular pumps and cryopumps provided unprecedented levels of vacuum quality and stability. This breakthrough allowed for the design of more sophisticated heat exchange systems, particularly in industries requiring ultra-high vacuum conditions, such as semiconductor manufacturing and aerospace.

As environmental concerns gained prominence in the 1990s and 2000s, the focus shifted towards developing more energy-efficient and environmentally friendly vacuum pumps. This led to the introduction of dry pumps and scroll pumps, which offered oil-free operation and reduced power consumption. These advancements made vacuum-assisted heat exchange systems more viable for a broader range of applications, including in HVAC systems and industrial processes.

The past decade has seen a surge in research and development aimed at integrating smart technologies and IoT capabilities into vacuum pumps used in heat exchange systems. This has resulted in pumps with advanced monitoring and control features, allowing for real-time optimization of heat transfer processes. Additionally, there has been a growing interest in hybrid systems that combine vacuum pumps with other technologies, such as thermoelectric coolers, to achieve even greater energy efficiency and performance in heat exchange applications.

Looking ahead, the evolution of vacuum pumps in heat exchange systems is likely to continue along the path of increased efficiency, miniaturization, and integration with advanced control systems. Emerging technologies such as nanomaterials and quantum sensors may further revolutionize vacuum pump design, potentially leading to breakthroughs in heat transfer capabilities and energy conservation in the coming years.

In the 1920s and 1930s, researchers began to recognize the potential of vacuum conditions in enhancing heat transfer efficiency. This led to the development of rudimentary vacuum-assisted heat exchangers, which relied on primitive vacuum pumps to create low-pressure environments. These early systems, while innovative, were limited in their effectiveness due to the constraints of vacuum pump technology at the time.

The 1950s and 1960s saw significant advancements in vacuum pump design, particularly with the introduction of rotary vane and diffusion pumps. These improvements allowed for the creation of more stable and deeper vacuums, enabling heat exchange systems to operate with greater efficiency. During this period, vacuum-assisted heat pipes emerged as a promising technology, leveraging the enhanced evaporation and condensation processes facilitated by low-pressure environments.

The 1970s and 1980s marked a turning point in vacuum pump technology for heat exchange applications. The development of turbomolecular pumps and cryopumps provided unprecedented levels of vacuum quality and stability. This breakthrough allowed for the design of more sophisticated heat exchange systems, particularly in industries requiring ultra-high vacuum conditions, such as semiconductor manufacturing and aerospace.

As environmental concerns gained prominence in the 1990s and 2000s, the focus shifted towards developing more energy-efficient and environmentally friendly vacuum pumps. This led to the introduction of dry pumps and scroll pumps, which offered oil-free operation and reduced power consumption. These advancements made vacuum-assisted heat exchange systems more viable for a broader range of applications, including in HVAC systems and industrial processes.

The past decade has seen a surge in research and development aimed at integrating smart technologies and IoT capabilities into vacuum pumps used in heat exchange systems. This has resulted in pumps with advanced monitoring and control features, allowing for real-time optimization of heat transfer processes. Additionally, there has been a growing interest in hybrid systems that combine vacuum pumps with other technologies, such as thermoelectric coolers, to achieve even greater energy efficiency and performance in heat exchange applications.

Looking ahead, the evolution of vacuum pumps in heat exchange systems is likely to continue along the path of increased efficiency, miniaturization, and integration with advanced control systems. Emerging technologies such as nanomaterials and quantum sensors may further revolutionize vacuum pump design, potentially leading to breakthroughs in heat transfer capabilities and energy conservation in the coming years.

Heat Exchange Market

The heat exchange market has experienced significant growth in recent years, driven by increasing demand for energy-efficient solutions across various industries. This market encompasses a wide range of applications, including HVAC systems, industrial processes, power generation, and automotive cooling systems. The global heat exchanger market size was valued at USD 15.3 billion in 2020 and is projected to reach USD 20.8 billion by 2026, growing at a CAGR of 5.5% during the forecast period.

One of the key factors driving market growth is the rising focus on energy efficiency and sustainability. Governments worldwide are implementing stringent regulations to reduce carbon emissions, which has led to increased adoption of advanced heat exchange systems. Industries are increasingly investing in innovative heat exchange technologies to optimize their processes and reduce energy consumption, contributing to market expansion.

The industrial sector remains the largest end-user segment for heat exchangers, accounting for approximately 35% of the market share. This is primarily due to the extensive use of heat exchangers in chemical processing, oil and gas, food and beverage, and other manufacturing industries. The HVAC sector is also a significant contributor to market growth, driven by the increasing demand for energy-efficient heating and cooling solutions in commercial and residential buildings.

Geographically, Asia Pacific dominates the heat exchange market, with China and India being the major contributors. The region's rapid industrialization, urbanization, and growing emphasis on energy efficiency are the primary factors fueling market growth. North America and Europe follow closely, with a strong focus on technological advancements and stringent environmental regulations driving the adoption of advanced heat exchange systems.

The market is characterized by intense competition, with key players such as Alfa Laval, Kelvion Holdings GmbH, Danfoss, and Exchanger Industries Limited dominating the landscape. These companies are continuously investing in research and development to introduce innovative products and gain a competitive edge. The trend towards customization and the development of compact, high-efficiency heat exchangers is gaining traction, particularly in industries with space constraints.

Emerging technologies, such as 3D-printed heat exchangers and the integration of IoT and AI for predictive maintenance, are expected to reshape the market in the coming years. These advancements promise improved performance, reduced maintenance costs, and enhanced energy efficiency, further driving market growth and innovation in the heat exchange industry.

One of the key factors driving market growth is the rising focus on energy efficiency and sustainability. Governments worldwide are implementing stringent regulations to reduce carbon emissions, which has led to increased adoption of advanced heat exchange systems. Industries are increasingly investing in innovative heat exchange technologies to optimize their processes and reduce energy consumption, contributing to market expansion.

The industrial sector remains the largest end-user segment for heat exchangers, accounting for approximately 35% of the market share. This is primarily due to the extensive use of heat exchangers in chemical processing, oil and gas, food and beverage, and other manufacturing industries. The HVAC sector is also a significant contributor to market growth, driven by the increasing demand for energy-efficient heating and cooling solutions in commercial and residential buildings.

Geographically, Asia Pacific dominates the heat exchange market, with China and India being the major contributors. The region's rapid industrialization, urbanization, and growing emphasis on energy efficiency are the primary factors fueling market growth. North America and Europe follow closely, with a strong focus on technological advancements and stringent environmental regulations driving the adoption of advanced heat exchange systems.

The market is characterized by intense competition, with key players such as Alfa Laval, Kelvion Holdings GmbH, Danfoss, and Exchanger Industries Limited dominating the landscape. These companies are continuously investing in research and development to introduce innovative products and gain a competitive edge. The trend towards customization and the development of compact, high-efficiency heat exchangers is gaining traction, particularly in industries with space constraints.

Emerging technologies, such as 3D-printed heat exchangers and the integration of IoT and AI for predictive maintenance, are expected to reshape the market in the coming years. These advancements promise improved performance, reduced maintenance costs, and enhanced energy efficiency, further driving market growth and innovation in the heat exchange industry.

Technical Challenges

The integration of vacuum pumps in innovative heat exchange systems presents several technical challenges that researchers and engineers must address. One of the primary obstacles is maintaining optimal vacuum levels within the system. Fluctuations in pressure can significantly impact the efficiency of heat transfer, requiring precise control mechanisms and robust sealing technologies to prevent leaks and maintain consistent performance.

Another challenge lies in the design of vacuum pump systems that can operate effectively across a wide range of temperatures and pressures. As heat exchange systems often involve extreme thermal conditions, the vacuum pumps must be engineered to withstand these environments without compromising their functionality or longevity. This necessitates the development of advanced materials and cooling strategies to ensure reliable operation under diverse operating conditions.

Energy efficiency remains a critical concern in the implementation of vacuum pumps within heat exchange systems. The power consumption of vacuum pumps can be substantial, potentially offsetting the energy savings achieved through improved heat transfer. Researchers are tasked with developing more energy-efficient pump designs and optimizing their integration within the overall system to maximize net energy benefits.

The scalability of vacuum-assisted heat exchange technologies presents another significant challenge. While these systems may demonstrate promising results in laboratory settings or small-scale applications, scaling them up for industrial use introduces complexities in terms of system design, control, and maintenance. Engineers must address issues related to uniform vacuum distribution, heat transfer consistency, and system reliability when increasing the size and capacity of these innovative heat exchange solutions.

Compatibility between vacuum pumps and working fluids used in heat exchange systems is another area of technical difficulty. Some working fluids may have properties that are incompatible with certain vacuum pump technologies, leading to degradation of pump components or contamination of the heat exchange medium. Developing pumps that can handle a variety of working fluids without compromising performance or requiring frequent maintenance is crucial for the widespread adoption of these systems.

Noise and vibration reduction in vacuum pump operation is an often-overlooked challenge that becomes increasingly important as these systems are integrated into various applications, including residential and commercial settings. Engineers must develop innovative solutions to minimize acoustic and mechanical disturbances without sacrificing pump efficiency or increasing system complexity.

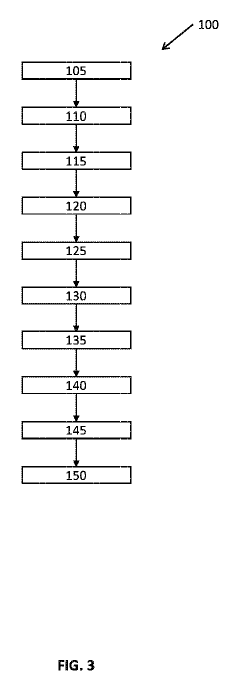

Lastly, the integration of smart control systems and predictive maintenance capabilities into vacuum-assisted heat exchange systems poses both opportunities and challenges. While these technologies can significantly enhance system performance and reliability, their implementation requires overcoming hurdles related to sensor integration, data analysis, and the development of robust algorithms capable of optimizing system operation in real-time across diverse operating conditions.

Another challenge lies in the design of vacuum pump systems that can operate effectively across a wide range of temperatures and pressures. As heat exchange systems often involve extreme thermal conditions, the vacuum pumps must be engineered to withstand these environments without compromising their functionality or longevity. This necessitates the development of advanced materials and cooling strategies to ensure reliable operation under diverse operating conditions.

Energy efficiency remains a critical concern in the implementation of vacuum pumps within heat exchange systems. The power consumption of vacuum pumps can be substantial, potentially offsetting the energy savings achieved through improved heat transfer. Researchers are tasked with developing more energy-efficient pump designs and optimizing their integration within the overall system to maximize net energy benefits.

The scalability of vacuum-assisted heat exchange technologies presents another significant challenge. While these systems may demonstrate promising results in laboratory settings or small-scale applications, scaling them up for industrial use introduces complexities in terms of system design, control, and maintenance. Engineers must address issues related to uniform vacuum distribution, heat transfer consistency, and system reliability when increasing the size and capacity of these innovative heat exchange solutions.

Compatibility between vacuum pumps and working fluids used in heat exchange systems is another area of technical difficulty. Some working fluids may have properties that are incompatible with certain vacuum pump technologies, leading to degradation of pump components or contamination of the heat exchange medium. Developing pumps that can handle a variety of working fluids without compromising performance or requiring frequent maintenance is crucial for the widespread adoption of these systems.

Noise and vibration reduction in vacuum pump operation is an often-overlooked challenge that becomes increasingly important as these systems are integrated into various applications, including residential and commercial settings. Engineers must develop innovative solutions to minimize acoustic and mechanical disturbances without sacrificing pump efficiency or increasing system complexity.

Lastly, the integration of smart control systems and predictive maintenance capabilities into vacuum-assisted heat exchange systems poses both opportunities and challenges. While these technologies can significantly enhance system performance and reliability, their implementation requires overcoming hurdles related to sensor integration, data analysis, and the development of robust algorithms capable of optimizing system operation in real-time across diverse operating conditions.

Current Solutions

01 Heat exchange systems for vacuum pumps

Vacuum pumps often incorporate heat exchange systems to manage temperature during operation. These systems can include cooling jackets, heat exchangers, or other mechanisms to dissipate heat generated by the pump. Effective heat exchange helps maintain optimal performance and extends the lifespan of the pump.- Heat exchange systems for vacuum pumps: Vacuum pumps often incorporate heat exchange systems to manage temperature during operation. These systems can include cooling jackets, heat sinks, or specialized heat exchangers designed to efficiently transfer heat away from the pump components. This helps maintain optimal performance and extends the lifespan of the pump.

- Cooling mechanisms for vacuum pump motors: Specific cooling mechanisms are designed for vacuum pump motors to prevent overheating. These can include forced air cooling, liquid cooling systems, or thermally conductive materials integrated into the motor housing. Effective motor cooling ensures consistent pump performance and reduces the risk of motor failure due to heat stress.

- Energy recovery from vacuum pump exhaust: Some vacuum pump systems incorporate energy recovery mechanisms that capture and utilize the heat from the pump exhaust. This recovered energy can be used for various purposes, such as preheating process fluids or generating electricity, thereby improving overall system efficiency and reducing energy consumption.

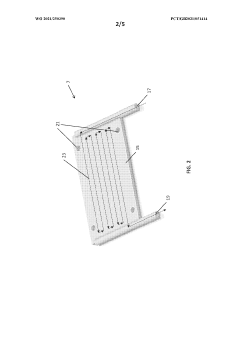

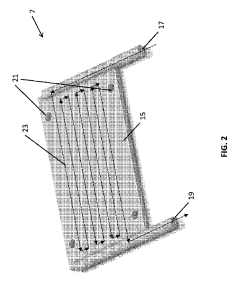

- Compact heat exchanger designs for vacuum systems: Innovative compact heat exchanger designs are being developed specifically for vacuum pump applications. These designs aim to maximize heat transfer efficiency while minimizing space requirements. They often feature advanced materials and geometries that enhance heat dissipation in confined spaces typical of vacuum pump installations.

- Temperature control in multi-stage vacuum pumps: Multi-stage vacuum pumps require careful temperature management between stages to maintain optimal performance. Heat exchange systems are integrated to cool the gas between compression stages, improving overall efficiency and preventing overheating. These inter-stage cooling mechanisms often involve specialized heat exchangers or cooling circuits designed for the specific requirements of multi-stage vacuum systems.

02 Cooling mechanisms in vacuum pump designs

Various cooling mechanisms are employed in vacuum pump designs to prevent overheating. These can include air-cooled systems, liquid cooling circuits, or thermoelectric cooling devices. The choice of cooling mechanism depends on the specific pump type, size, and application requirements.Expand Specific Solutions03 Energy efficiency improvements in vacuum pump heat exchange

Innovations in vacuum pump heat exchange focus on improving energy efficiency. This includes optimizing heat transfer surfaces, using advanced materials with better thermal properties, and implementing smart control systems to regulate cooling based on pump load and ambient conditions.Expand Specific Solutions04 Integration of heat recovery systems in vacuum pumps

Some vacuum pump designs incorporate heat recovery systems to utilize the waste heat generated during operation. This recovered heat can be used for other processes or converted back into usable energy, improving overall system efficiency and reducing operational costs.Expand Specific Solutions05 Advanced materials and coatings for heat exchange in vacuum pumps

The use of advanced materials and coatings in vacuum pump components enhances heat exchange efficiency. These materials may include high thermal conductivity alloys, ceramic coatings, or nanostructured surfaces that improve heat transfer and resist corrosion or fouling in challenging environments.Expand Specific Solutions

Key Industry Players

The vacuum pump market for innovative heat exchange systems is in a growth phase, driven by increasing demand for energy-efficient solutions across industries. The market size is expanding, with significant potential in sectors like automotive, electronics, and industrial manufacturing. Technologically, the field is advancing rapidly, with companies like Edwards Ltd., Pfeiffer Vacuum GmbH, and Leybold Ltd. leading in vacuum pump innovations. Major players such as Hyundai Motor Co., Kia Corp., and Samsung Electronics are integrating these technologies into their products, indicating a maturing market. The involvement of diverse companies, from specialized vacuum pump manufacturers to large conglomerates, suggests a competitive and dynamic landscape with opportunities for both niche players and industry giants.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed innovative vacuum pump solutions for heat exchange systems, focusing on energy efficiency and performance optimization. Their latest technology incorporates advanced dry pumping mechanisms that minimize heat generation and maximize thermal management [1]. The company's vacuum pumps utilize a unique screw rotor design that enhances gas flow and reduces internal friction, resulting in improved heat dissipation [2]. Edwards has also integrated smart control systems that dynamically adjust pump speed based on process requirements, optimizing energy consumption and heat exchange efficiency [3]. Their pumps feature specialized coatings and materials that resist corrosion and fouling, ensuring long-term reliability in challenging heat exchange environments [4].

Strengths: High energy efficiency, advanced thermal management, smart control systems, and corrosion-resistant materials. Weaknesses: Potentially higher initial costs and complexity in maintenance due to advanced technologies.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed cutting-edge vacuum pump technology for heat exchange systems, focusing on high performance and reliability. Their innovative pumps utilize multi-stage designs that optimize gas flow and heat transfer [1]. Pfeiffer's pumps incorporate advanced rotor geometries that minimize internal leakage and improve compression efficiency, resulting in reduced heat generation and enhanced overall system performance [2]. The company has also implemented sophisticated cooling systems, including liquid cooling options, to manage heat more effectively in demanding applications [3]. Pfeiffer's vacuum pumps feature intelligent control interfaces that allow for precise regulation of pump speed and pressure, enabling adaptive performance in variable heat exchange conditions [4].

Strengths: High-performance multi-stage designs, advanced cooling systems, and intelligent control interfaces. Weaknesses: Potentially higher complexity and cost compared to simpler pump designs.

Core Technologies

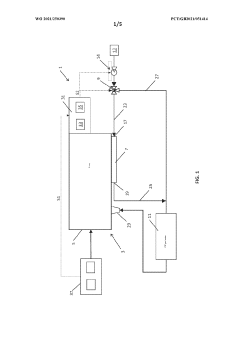

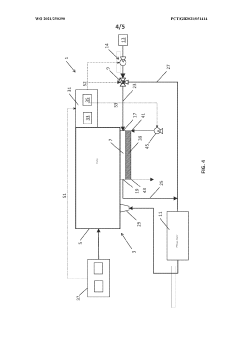

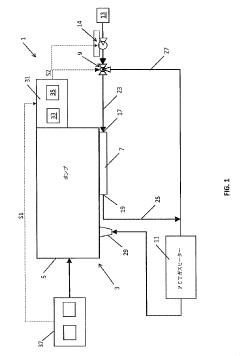

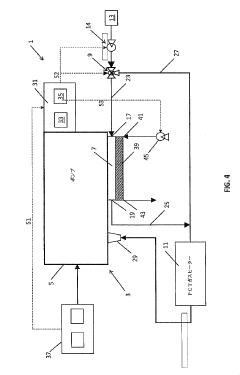

Vacuum system apparatus and method

PatentWO2021250390A1

Innovation

- A vacuum system incorporating a heat exchanger thermally coupled to the vacuum pump, using a heat transfer fluid that can be controlled based on operating parameters, with a controller to manage heat transfer fluid supply, allowing for efficient heat rejection and reduced power consumption.

Vacuum system device and method

PatentPendingJP2023529662A

Innovation

- A vacuum system with a thermally coupled heat exchanger and control mechanism that adjusts heat transfer fluid supply based on pump load, bypassing the heat exchanger during low loads to reduce thermal energy absorption and using a gas heater to preheat the fluid during high loads.

Energy Efficiency

Vacuum pumps play a crucial role in enhancing energy efficiency within innovative heat exchange systems. These systems leverage the unique properties of vacuum to significantly reduce heat transfer and improve overall system performance. By creating low-pressure environments, vacuum pumps minimize convective heat losses, allowing for more efficient heat transfer processes.

In the context of heat exchangers, vacuum insulation panels (VIPs) have emerged as a groundbreaking application. These panels utilize vacuum pump technology to create an ultra-low pressure environment within a sealed enclosure, dramatically reducing thermal conductivity. The resulting insulation performance is up to ten times more effective than traditional materials, leading to substantial energy savings in various applications, including refrigeration, building insulation, and thermal management systems.

Another innovative application is the vacuum-assisted heat pipe, which combines vacuum pump technology with the principles of phase change heat transfer. By maintaining a low-pressure environment within the heat pipe, the working fluid can evaporate at lower temperatures, enhancing heat transfer efficiency. This technology has found applications in electronics cooling, solar thermal systems, and waste heat recovery processes, contributing to overall energy efficiency improvements.

Vacuum pumps also enable the development of advanced adsorption cooling systems. These systems utilize the vacuum environment to enhance the adsorption and desorption processes of working fluids on specialized adsorbent materials. The improved efficiency of these cycles leads to higher coefficient of performance (COP) values, making them viable alternatives to conventional vapor compression systems in certain applications, particularly where waste heat or low-grade thermal energy is available.

In industrial processes, vacuum distillation and evaporation systems benefit from vacuum pump technology to lower the boiling point of liquids. This reduction in operating temperatures translates to significant energy savings, as less heat input is required to achieve the desired separation or concentration processes. Industries such as food processing, pharmaceutical manufacturing, and chemical production have adopted these vacuum-assisted technologies to improve energy efficiency and product quality.

The integration of vacuum pumps in heat exchange systems also extends to advanced heat recovery applications. By creating low-pressure environments, it becomes possible to extract useful energy from low-temperature waste heat sources that would otherwise be discarded. This approach has been particularly effective in improving the efficiency of power generation cycles, industrial processes, and HVAC systems, contributing to overall energy conservation efforts.

In the context of heat exchangers, vacuum insulation panels (VIPs) have emerged as a groundbreaking application. These panels utilize vacuum pump technology to create an ultra-low pressure environment within a sealed enclosure, dramatically reducing thermal conductivity. The resulting insulation performance is up to ten times more effective than traditional materials, leading to substantial energy savings in various applications, including refrigeration, building insulation, and thermal management systems.

Another innovative application is the vacuum-assisted heat pipe, which combines vacuum pump technology with the principles of phase change heat transfer. By maintaining a low-pressure environment within the heat pipe, the working fluid can evaporate at lower temperatures, enhancing heat transfer efficiency. This technology has found applications in electronics cooling, solar thermal systems, and waste heat recovery processes, contributing to overall energy efficiency improvements.

Vacuum pumps also enable the development of advanced adsorption cooling systems. These systems utilize the vacuum environment to enhance the adsorption and desorption processes of working fluids on specialized adsorbent materials. The improved efficiency of these cycles leads to higher coefficient of performance (COP) values, making them viable alternatives to conventional vapor compression systems in certain applications, particularly where waste heat or low-grade thermal energy is available.

In industrial processes, vacuum distillation and evaporation systems benefit from vacuum pump technology to lower the boiling point of liquids. This reduction in operating temperatures translates to significant energy savings, as less heat input is required to achieve the desired separation or concentration processes. Industries such as food processing, pharmaceutical manufacturing, and chemical production have adopted these vacuum-assisted technologies to improve energy efficiency and product quality.

The integration of vacuum pumps in heat exchange systems also extends to advanced heat recovery applications. By creating low-pressure environments, it becomes possible to extract useful energy from low-temperature waste heat sources that would otherwise be discarded. This approach has been particularly effective in improving the efficiency of power generation cycles, industrial processes, and HVAC systems, contributing to overall energy conservation efforts.

Environmental Impact

The integration of vacuum pumps in innovative heat exchange systems has significant environmental implications that warrant careful consideration. These systems, designed to enhance energy efficiency and thermal management, can contribute to reduced energy consumption and greenhouse gas emissions when compared to conventional heat exchange methods. By creating low-pressure environments, vacuum pumps enable more effective heat transfer processes, potentially leading to decreased power requirements for cooling and heating applications across various industries.

However, the environmental impact of vacuum pump-based heat exchange systems extends beyond energy efficiency. The production and disposal of vacuum pumps involve resource extraction and waste generation, which must be factored into the overall environmental assessment. Additionally, the use of certain working fluids or refrigerants in these systems may have varying degrees of global warming potential, necessitating a lifecycle analysis to determine the net environmental benefit.

Noise pollution is another environmental concern associated with vacuum pump operation. While innovative designs aim to minimize acoustic emissions, the cumulative effect of multiple units in industrial settings could still pose challenges to local ecosystems and human populations. This aspect underscores the importance of noise reduction technologies and proper installation practices to mitigate potential negative impacts on surrounding environments.

The longevity and maintenance requirements of vacuum pumps in heat exchange systems also influence their environmental footprint. Systems with extended operational lifespans and reduced maintenance needs can significantly decrease the frequency of component replacement and associated waste generation. Furthermore, the development of more durable materials and advanced lubricants can enhance the overall sustainability of these systems by reducing the consumption of resources over time.

As the adoption of vacuum pump-based heat exchange systems increases, considerations for end-of-life management become crucial. Implementing effective recycling and refurbishment programs for these components can minimize waste and conserve valuable materials. Moreover, the potential for recovering and repurposing waste heat from vacuum pump operations presents an opportunity to further improve the environmental performance of these systems, contributing to circular economy principles.

In conclusion, while vacuum pumps in innovative heat exchange systems offer promising environmental benefits through enhanced energy efficiency, a holistic approach to assessing their environmental impact is essential. This includes considering manufacturing processes, operational characteristics, maintenance requirements, and end-of-life management to ensure that the integration of these technologies aligns with broader sustainability goals and environmental protection efforts.

However, the environmental impact of vacuum pump-based heat exchange systems extends beyond energy efficiency. The production and disposal of vacuum pumps involve resource extraction and waste generation, which must be factored into the overall environmental assessment. Additionally, the use of certain working fluids or refrigerants in these systems may have varying degrees of global warming potential, necessitating a lifecycle analysis to determine the net environmental benefit.

Noise pollution is another environmental concern associated with vacuum pump operation. While innovative designs aim to minimize acoustic emissions, the cumulative effect of multiple units in industrial settings could still pose challenges to local ecosystems and human populations. This aspect underscores the importance of noise reduction technologies and proper installation practices to mitigate potential negative impacts on surrounding environments.

The longevity and maintenance requirements of vacuum pumps in heat exchange systems also influence their environmental footprint. Systems with extended operational lifespans and reduced maintenance needs can significantly decrease the frequency of component replacement and associated waste generation. Furthermore, the development of more durable materials and advanced lubricants can enhance the overall sustainability of these systems by reducing the consumption of resources over time.

As the adoption of vacuum pump-based heat exchange systems increases, considerations for end-of-life management become crucial. Implementing effective recycling and refurbishment programs for these components can minimize waste and conserve valuable materials. Moreover, the potential for recovering and repurposing waste heat from vacuum pump operations presents an opportunity to further improve the environmental performance of these systems, contributing to circular economy principles.

In conclusion, while vacuum pumps in innovative heat exchange systems offer promising environmental benefits through enhanced energy efficiency, a holistic approach to assessing their environmental impact is essential. This includes considering manufacturing processes, operational characteristics, maintenance requirements, and end-of-life management to ensure that the integration of these technologies aligns with broader sustainability goals and environmental protection efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!