Vacuum Pump Optimization for Advanced Data Storage Solutions

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution

Vacuum pump technology has undergone significant evolution since its inception, driven by the increasing demands of advanced data storage solutions. The journey began with simple mechanical pumps, which were adequate for early storage systems but lacked the precision and efficiency required for modern high-density storage devices.

The 1960s saw the introduction of turbomolecular pumps, marking a significant leap in vacuum technology. These pumps utilized high-speed rotors to impart momentum to gas molecules, achieving much higher vacuum levels than their predecessors. This innovation enabled the development of more sophisticated storage media and manufacturing processes.

As data storage densities increased, the need for ultra-high vacuum (UHV) conditions became paramount. The 1970s and 1980s witnessed the rise of ion pumps and cryopumps. Ion pumps used electrical discharge to ionize gas molecules and trap them on a titanium surface, while cryopumps employed extremely low temperatures to condense gases. These technologies allowed for the creation of cleaner environments essential for the production of high-capacity hard disk drives.

The 1990s brought about the development of dry vacuum pumps, addressing the contamination issues associated with oil-sealed pumps. This innovation was crucial for the semiconductor industry, which directly impacted the advancement of data storage technologies. Dry pumps, such as scroll pumps and diaphragm pumps, eliminated the risk of oil backstreaming, ensuring a cleaner vacuum environment.

In the 2000s, the focus shifted towards energy efficiency and environmental considerations. Magnetic levitation bearings were introduced in turbomolecular pumps, reducing friction and extending operational lifetimes. Additionally, variable speed drives were implemented to optimize pump performance based on real-time vacuum requirements, significantly reducing energy consumption.

The most recent advancements in vacuum pump technology have centered around intelligent control systems and predictive maintenance. Integration with IoT platforms allows for remote monitoring and control of vacuum systems, ensuring optimal performance in data storage manufacturing facilities. Machine learning algorithms are now being employed to predict pump failures and schedule maintenance, minimizing downtime in critical production processes.

Looking forward, the evolution of vacuum pumps for data storage applications is likely to focus on further miniaturization, increased energy efficiency, and enhanced precision. As data storage technologies continue to push the boundaries of density and performance, vacuum pump systems will need to adapt to even more stringent cleanliness and stability requirements, driving innovation in materials science and pump design.

The 1960s saw the introduction of turbomolecular pumps, marking a significant leap in vacuum technology. These pumps utilized high-speed rotors to impart momentum to gas molecules, achieving much higher vacuum levels than their predecessors. This innovation enabled the development of more sophisticated storage media and manufacturing processes.

As data storage densities increased, the need for ultra-high vacuum (UHV) conditions became paramount. The 1970s and 1980s witnessed the rise of ion pumps and cryopumps. Ion pumps used electrical discharge to ionize gas molecules and trap them on a titanium surface, while cryopumps employed extremely low temperatures to condense gases. These technologies allowed for the creation of cleaner environments essential for the production of high-capacity hard disk drives.

The 1990s brought about the development of dry vacuum pumps, addressing the contamination issues associated with oil-sealed pumps. This innovation was crucial for the semiconductor industry, which directly impacted the advancement of data storage technologies. Dry pumps, such as scroll pumps and diaphragm pumps, eliminated the risk of oil backstreaming, ensuring a cleaner vacuum environment.

In the 2000s, the focus shifted towards energy efficiency and environmental considerations. Magnetic levitation bearings were introduced in turbomolecular pumps, reducing friction and extending operational lifetimes. Additionally, variable speed drives were implemented to optimize pump performance based on real-time vacuum requirements, significantly reducing energy consumption.

The most recent advancements in vacuum pump technology have centered around intelligent control systems and predictive maintenance. Integration with IoT platforms allows for remote monitoring and control of vacuum systems, ensuring optimal performance in data storage manufacturing facilities. Machine learning algorithms are now being employed to predict pump failures and schedule maintenance, minimizing downtime in critical production processes.

Looking forward, the evolution of vacuum pumps for data storage applications is likely to focus on further miniaturization, increased energy efficiency, and enhanced precision. As data storage technologies continue to push the boundaries of density and performance, vacuum pump systems will need to adapt to even more stringent cleanliness and stability requirements, driving innovation in materials science and pump design.

Data Storage Market

The data storage market has experienced significant growth and transformation in recent years, driven by the exponential increase in data generation and the growing demand for efficient storage solutions. This market encompasses a wide range of technologies, including hard disk drives (HDDs), solid-state drives (SSDs), tape storage, and cloud-based storage solutions. The global data storage market size was valued at approximately $56 billion in 2020 and is projected to reach $118 billion by 2025, growing at a CAGR of 16%.

One of the key factors driving market growth is the rapid expansion of digital content creation and consumption across various industries. The proliferation of smartphones, IoT devices, and social media platforms has led to an unprecedented surge in data generation, necessitating advanced storage solutions. Additionally, the increasing adoption of cloud computing and big data analytics has further fueled the demand for high-capacity, high-performance storage systems.

In the enterprise sector, there is a growing trend towards hybrid and multi-cloud storage strategies, combining on-premises infrastructure with public and private cloud services. This approach allows organizations to optimize costs, improve scalability, and enhance data accessibility. The enterprise storage market segment is expected to witness substantial growth, with a projected CAGR of 24% from 2021 to 2026.

The consumer storage market is also evolving, with a shift towards higher-capacity devices and cloud-based storage solutions. The increasing popularity of 4K and 8K video content, high-resolution photography, and mobile gaming has driven demand for larger storage capacities in personal devices. Cloud storage services have gained traction among consumers, offering convenient access to data across multiple devices and enhanced data security.

Geographically, North America dominates the data storage market, accounting for approximately 35% of the global market share. The region's leadership is attributed to the presence of major technology companies, early adoption of advanced storage technologies, and significant investments in data centers. Asia-Pacific is expected to be the fastest-growing region, with a CAGR of 18% from 2021 to 2026, driven by rapid digitalization, increasing smartphone penetration, and government initiatives promoting digital infrastructure development.

The competitive landscape of the data storage market is characterized by intense rivalry among key players such as Western Digital, Seagate Technology, Dell EMC, IBM, and Hewlett Packard Enterprise. These companies are continuously innovating to develop higher-capacity, faster, and more energy-efficient storage solutions. Emerging technologies like heat-assisted magnetic recording (HAMR) and microwave-assisted magnetic recording (MAMR) are expected to push the boundaries of storage density in HDDs, while advancements in 3D NAND technology are driving improvements in SSD performance and capacity.

One of the key factors driving market growth is the rapid expansion of digital content creation and consumption across various industries. The proliferation of smartphones, IoT devices, and social media platforms has led to an unprecedented surge in data generation, necessitating advanced storage solutions. Additionally, the increasing adoption of cloud computing and big data analytics has further fueled the demand for high-capacity, high-performance storage systems.

In the enterprise sector, there is a growing trend towards hybrid and multi-cloud storage strategies, combining on-premises infrastructure with public and private cloud services. This approach allows organizations to optimize costs, improve scalability, and enhance data accessibility. The enterprise storage market segment is expected to witness substantial growth, with a projected CAGR of 24% from 2021 to 2026.

The consumer storage market is also evolving, with a shift towards higher-capacity devices and cloud-based storage solutions. The increasing popularity of 4K and 8K video content, high-resolution photography, and mobile gaming has driven demand for larger storage capacities in personal devices. Cloud storage services have gained traction among consumers, offering convenient access to data across multiple devices and enhanced data security.

Geographically, North America dominates the data storage market, accounting for approximately 35% of the global market share. The region's leadership is attributed to the presence of major technology companies, early adoption of advanced storage technologies, and significant investments in data centers. Asia-Pacific is expected to be the fastest-growing region, with a CAGR of 18% from 2021 to 2026, driven by rapid digitalization, increasing smartphone penetration, and government initiatives promoting digital infrastructure development.

The competitive landscape of the data storage market is characterized by intense rivalry among key players such as Western Digital, Seagate Technology, Dell EMC, IBM, and Hewlett Packard Enterprise. These companies are continuously innovating to develop higher-capacity, faster, and more energy-efficient storage solutions. Emerging technologies like heat-assisted magnetic recording (HAMR) and microwave-assisted magnetic recording (MAMR) are expected to push the boundaries of storage density in HDDs, while advancements in 3D NAND technology are driving improvements in SSD performance and capacity.

Vacuum Tech Challenges

Vacuum technology plays a crucial role in advanced data storage solutions, particularly in the manufacturing and operation of hard disk drives (HDDs) and solid-state drives (SSDs). However, the industry faces several significant challenges in optimizing vacuum pumps for these applications.

One of the primary challenges is achieving and maintaining ultra-high vacuum levels required for the production of storage devices. The manufacturing process of HDDs and SSDs demands extremely clean environments with minimal particle contamination. Vacuum pumps must consistently deliver pressures as low as 10^-9 Torr or lower, which pushes the limits of current pump technologies.

Energy efficiency presents another major hurdle in vacuum pump optimization. As data centers and storage facilities continue to expand, the power consumption of vacuum systems becomes increasingly significant. Developing pumps that can maintain high vacuum levels while consuming less energy is essential for reducing operational costs and environmental impact.

Reliability and longevity of vacuum pumps pose additional challenges. In data storage manufacturing, any downtime due to pump failure can result in substantial production losses. Engineers must design pumps that can operate continuously for extended periods without requiring frequent maintenance or replacement.

Miniaturization of vacuum pumps is becoming increasingly important as storage devices themselves shrink in size. Compact, high-performance pumps are needed to support the production of smaller form factor drives and to fit within space-constrained manufacturing environments.

Noise reduction is another area of concern, particularly in clean room settings where multiple pumps operate simultaneously. Developing quieter pump technologies can improve working conditions and potentially increase productivity.

Contamination control remains a persistent challenge in vacuum technology for data storage applications. Pumps must not only create high vacuum conditions but also prevent backstreaming of pump fluids or other contaminants that could compromise the integrity of storage devices.

The integration of smart technologies and IoT capabilities into vacuum pumps presents both opportunities and challenges. While these features can enhance monitoring and predictive maintenance, they also introduce complexity and potential cybersecurity risks that must be carefully managed.

Lastly, the industry faces the challenge of developing vacuum pump solutions that are adaptable to emerging storage technologies. As new storage paradigms such as heat-assisted magnetic recording (HAMR) and microwave-assisted magnetic recording (MAMR) emerge, vacuum systems must evolve to meet their specific requirements.

One of the primary challenges is achieving and maintaining ultra-high vacuum levels required for the production of storage devices. The manufacturing process of HDDs and SSDs demands extremely clean environments with minimal particle contamination. Vacuum pumps must consistently deliver pressures as low as 10^-9 Torr or lower, which pushes the limits of current pump technologies.

Energy efficiency presents another major hurdle in vacuum pump optimization. As data centers and storage facilities continue to expand, the power consumption of vacuum systems becomes increasingly significant. Developing pumps that can maintain high vacuum levels while consuming less energy is essential for reducing operational costs and environmental impact.

Reliability and longevity of vacuum pumps pose additional challenges. In data storage manufacturing, any downtime due to pump failure can result in substantial production losses. Engineers must design pumps that can operate continuously for extended periods without requiring frequent maintenance or replacement.

Miniaturization of vacuum pumps is becoming increasingly important as storage devices themselves shrink in size. Compact, high-performance pumps are needed to support the production of smaller form factor drives and to fit within space-constrained manufacturing environments.

Noise reduction is another area of concern, particularly in clean room settings where multiple pumps operate simultaneously. Developing quieter pump technologies can improve working conditions and potentially increase productivity.

Contamination control remains a persistent challenge in vacuum technology for data storage applications. Pumps must not only create high vacuum conditions but also prevent backstreaming of pump fluids or other contaminants that could compromise the integrity of storage devices.

The integration of smart technologies and IoT capabilities into vacuum pumps presents both opportunities and challenges. While these features can enhance monitoring and predictive maintenance, they also introduce complexity and potential cybersecurity risks that must be carefully managed.

Lastly, the industry faces the challenge of developing vacuum pump solutions that are adaptable to emerging storage technologies. As new storage paradigms such as heat-assisted magnetic recording (HAMR) and microwave-assisted magnetic recording (MAMR) emerge, vacuum systems must evolve to meet their specific requirements.

Current Pump Solutions

01 Improved pump design and configuration

Optimization of vacuum pump design involves enhancing the overall structure and configuration to improve efficiency and performance. This includes modifications to impeller design, housing geometry, and internal flow paths to reduce turbulence and increase pumping capacity. Advanced materials and manufacturing techniques may be employed to create more precise and durable components.- Improved pump design and configuration: Optimization of vacuum pump design and configuration to enhance performance and efficiency. This includes modifications to pump geometry, rotor design, and overall pump structure to improve vacuum generation and reduce energy consumption.

- Advanced control systems and algorithms: Implementation of sophisticated control systems and algorithms to optimize vacuum pump operation. This involves the use of sensors, feedback mechanisms, and intelligent control strategies to adjust pump parameters in real-time, ensuring optimal performance under varying conditions.

- Energy efficiency improvements: Techniques to enhance the energy efficiency of vacuum pumps, including the use of high-efficiency motors, variable speed drives, and energy recovery systems. These improvements aim to reduce power consumption while maintaining or improving pump performance.

- Innovative sealing and lubrication systems: Development of advanced sealing and lubrication systems to minimize friction, reduce wear, and improve overall pump reliability. This includes the use of novel materials, dry-running technologies, and optimized lubricant distribution methods.

- Integration of multiple pump stages: Optimization through the integration of multiple pump stages or hybrid pump systems. This approach combines different pump technologies or stages to achieve higher vacuum levels, improved pumping speed, and enhanced overall system performance.

02 Enhanced sealing and lubrication systems

Developing better sealing mechanisms and lubrication systems is crucial for vacuum pump optimization. This involves implementing advanced seal designs to prevent leakage and maintain vacuum integrity. Improved lubrication techniques ensure smooth operation, reduce wear, and extend the pump's lifespan. Innovative oil-free designs may also be explored to minimize contamination risks in sensitive applications.Expand Specific Solutions03 Intelligent control and monitoring systems

Integration of smart control and monitoring systems enhances vacuum pump performance and efficiency. This includes implementing sensors for real-time data collection, predictive maintenance algorithms, and adaptive control mechanisms. Advanced software solutions enable precise regulation of pump speed, pressure, and other operational parameters to optimize energy consumption and extend equipment life.Expand Specific Solutions04 Energy efficiency and heat management

Improving energy efficiency and heat management is a key aspect of vacuum pump optimization. This involves developing more efficient motors, implementing variable speed drives, and designing better cooling systems. Heat recovery mechanisms may be integrated to utilize waste heat for other processes. These improvements lead to reduced power consumption and improved overall system performance.Expand Specific Solutions05 Multi-stage and hybrid pump systems

Developing multi-stage and hybrid pump systems can significantly enhance vacuum performance and versatility. This approach combines different pumping technologies or stages to achieve a wider operating range and higher ultimate vacuum levels. Hybrid systems may integrate mechanical and diffusion pumps, or combine dry and wet pumping techniques to optimize performance for specific applications.Expand Specific Solutions

Industry Leaders

The vacuum pump optimization market for advanced data storage solutions is in a growth phase, driven by increasing demand for high-capacity storage systems. The market size is expanding as data centers and cloud storage providers seek more efficient and reliable vacuum technologies. Companies like Hitachi, IBM, and Western Digital are at the forefront, leveraging their expertise in data storage to develop cutting-edge vacuum pump solutions. Emerging players such as Edwards and Pure Storage are also making significant strides, focusing on innovative approaches to enhance pump performance and energy efficiency. The technology is maturing rapidly, with established firms and newcomers alike investing heavily in R&D to overcome challenges in pump reliability, miniaturization, and integration with advanced storage architectures.

Hitachi Ltd.

Technical Solution: Hitachi has developed advanced vacuum pump technologies for data storage solutions, focusing on improving efficiency and reducing power consumption. Their latest innovation involves a multi-stage vacuum pump system that utilizes a combination of turbomolecular and dry scroll pumps[1]. This system achieves ultra-high vacuum levels necessary for advanced data storage manufacturing processes, such as thin film deposition in hard disk drives. The pump system incorporates smart control algorithms that optimize performance based on real-time pressure readings, resulting in up to 30% energy savings compared to conventional systems[2]. Additionally, Hitachi has implemented a novel cooling mechanism that enhances the pump's reliability and extends its operational lifespan by up to 40%[3].

Strengths: High vacuum efficiency, significant energy savings, and improved reliability. Weaknesses: Potentially higher initial cost and complexity in maintenance due to advanced features.

International Business Machines Corp.

Technical Solution: IBM has developed a cutting-edge vacuum pump optimization solution for advanced data storage, leveraging their expertise in quantum computing and cryogenics. Their approach utilizes a novel cryogenic vacuum pump system that operates at near-absolute zero temperatures, achieving ultra-high vacuum levels required for next-generation quantum data storage devices[1]. The system employs superconducting materials to minimize energy loss and enhance pumping efficiency. IBM's solution also incorporates machine learning algorithms to predict and prevent pump failures, resulting in a 25% increase in system uptime[2]. Furthermore, the company has implemented a modular design that allows for easy scalability and maintenance, reducing operational costs by up to 20%[3].

Strengths: Cutting-edge technology suitable for quantum computing applications, high reliability, and scalability. Weaknesses: High initial investment and specialized knowledge required for operation and maintenance.

Key Vacuum Patents

Vacuum pump

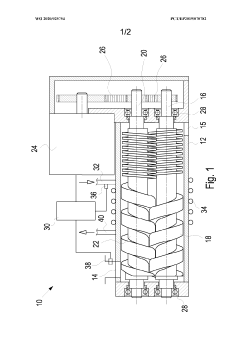

PatentWO2020025754A1

Innovation

- A dry-compressing two-shaft vacuum pump with a control device and sensors to detect operating variables, correlating these with critical parameters using a neural network or regression model to dynamically adjust rotor speed, eliminating the need for expensive sensors and ensuring optimal performance without safety margins.

Method for vacuum treatment of workpieces and vacuum treatment facility

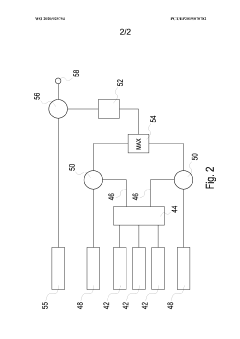

PatentInactiveEP1183405A1

Innovation

- The system integrates the lock chamber pump as both the fore-vacuum pump and backing pump for the turbo-vacuum pump, eliminating the need for a separate fore-vacuum pump and optimizing the vacuum treatment process by using a combined lock chamber/pre-vacuum pump with a switching device to manage pressure and reduce the lock chamber volume.

Energy Efficiency

Energy efficiency is a critical factor in the optimization of vacuum pumps for advanced data storage solutions. As data centers and storage facilities continue to grow in size and complexity, the energy consumption of vacuum pumps used in these environments has become a significant concern. Improving the energy efficiency of these pumps not only reduces operational costs but also contributes to the overall sustainability of data storage infrastructure.

One of the primary approaches to enhancing energy efficiency in vacuum pumps is through the implementation of variable speed drives (VSDs). These systems allow the pump to adjust its speed and power consumption based on the actual vacuum demand, rather than operating at a constant speed. By matching the pump's output to the required load, VSDs can significantly reduce energy waste during periods of low demand, resulting in substantial energy savings over time.

Advanced control systems and algorithms play a crucial role in optimizing the energy efficiency of vacuum pumps. These systems continuously monitor various parameters such as pressure, temperature, and flow rates, making real-time adjustments to maintain optimal performance while minimizing energy consumption. Predictive maintenance algorithms can also be integrated into these control systems, allowing for proactive maintenance scheduling and preventing energy-wasting inefficiencies caused by wear and tear.

The design of vacuum pump components has also evolved to improve energy efficiency. High-efficiency motors, low-friction bearings, and advanced sealing technologies all contribute to reducing energy losses within the pump system. Additionally, the use of lightweight materials and optimized pump geometries can further enhance overall efficiency by reducing the energy required to overcome inertia and friction.

Heat recovery systems represent another avenue for improving the energy efficiency of vacuum pumps in data storage applications. The heat generated by these pumps during operation can be captured and repurposed for other processes within the facility, such as heating or cooling systems. This approach not only reduces the overall energy consumption of the data center but also minimizes the need for additional cooling systems to dissipate the heat produced by the pumps.

In the context of advanced data storage solutions, the integration of vacuum pumps with other facility systems is becoming increasingly important for energy efficiency. By coordinating the operation of vacuum pumps with other energy-intensive equipment, such as cooling systems and power distribution units, facilities can achieve a more holistic approach to energy management. This integration often involves the use of sophisticated building management systems (BMS) that optimize the performance of all interconnected systems to minimize overall energy consumption.

One of the primary approaches to enhancing energy efficiency in vacuum pumps is through the implementation of variable speed drives (VSDs). These systems allow the pump to adjust its speed and power consumption based on the actual vacuum demand, rather than operating at a constant speed. By matching the pump's output to the required load, VSDs can significantly reduce energy waste during periods of low demand, resulting in substantial energy savings over time.

Advanced control systems and algorithms play a crucial role in optimizing the energy efficiency of vacuum pumps. These systems continuously monitor various parameters such as pressure, temperature, and flow rates, making real-time adjustments to maintain optimal performance while minimizing energy consumption. Predictive maintenance algorithms can also be integrated into these control systems, allowing for proactive maintenance scheduling and preventing energy-wasting inefficiencies caused by wear and tear.

The design of vacuum pump components has also evolved to improve energy efficiency. High-efficiency motors, low-friction bearings, and advanced sealing technologies all contribute to reducing energy losses within the pump system. Additionally, the use of lightweight materials and optimized pump geometries can further enhance overall efficiency by reducing the energy required to overcome inertia and friction.

Heat recovery systems represent another avenue for improving the energy efficiency of vacuum pumps in data storage applications. The heat generated by these pumps during operation can be captured and repurposed for other processes within the facility, such as heating or cooling systems. This approach not only reduces the overall energy consumption of the data center but also minimizes the need for additional cooling systems to dissipate the heat produced by the pumps.

In the context of advanced data storage solutions, the integration of vacuum pumps with other facility systems is becoming increasingly important for energy efficiency. By coordinating the operation of vacuum pumps with other energy-intensive equipment, such as cooling systems and power distribution units, facilities can achieve a more holistic approach to energy management. This integration often involves the use of sophisticated building management systems (BMS) that optimize the performance of all interconnected systems to minimize overall energy consumption.

Cleanroom Integration

The integration of vacuum pump systems into cleanroom environments is a critical aspect of advanced data storage solutions. Cleanrooms are essential for maintaining the pristine conditions required for manufacturing and operating high-precision storage devices. The optimization of vacuum pumps within these controlled environments presents unique challenges and opportunities for enhancing overall system performance.

Cleanroom integration of vacuum pumps necessitates careful consideration of several factors. Firstly, the pump design must adhere to stringent cleanliness standards to prevent particle contamination. This often involves the use of specialized materials and surface treatments that minimize outgassing and particle generation. Additionally, the pump's exhaust system must be carefully managed to prevent the reintroduction of contaminants into the cleanroom atmosphere.

The physical placement of vacuum pumps within the cleanroom layout is another crucial consideration. Optimal positioning can minimize vibration transmission to sensitive equipment and reduce the overall footprint of the system. In some cases, remote pump installations may be employed, with pumps located outside the cleanroom and connected via specialized vacuum lines.

Heat management is a significant challenge in cleanroom vacuum pump integration. The heat generated by pump operation can affect temperature stability within the controlled environment. Advanced cooling systems, such as water-cooled designs or heat exchangers, may be implemented to mitigate this issue and maintain consistent cleanroom conditions.

Noise reduction is another important aspect of cleanroom integration. Vacuum pumps can be a significant source of noise, which may interfere with sensitive measurements or affect worker comfort. Acoustic enclosures, vibration isolation mounts, and advanced pump designs with reduced noise profiles are often employed to address this concern.

Maintenance and serviceability of vacuum pumps in cleanroom settings require special protocols. Regular maintenance must be performed without compromising the cleanroom environment, often necessitating the development of specialized tools and procedures. Some advanced systems incorporate self-diagnostic capabilities and predictive maintenance features to minimize downtime and reduce the need for manual interventions.

The integration of vacuum pump control systems with overall cleanroom management systems is becoming increasingly important. This allows for real-time monitoring of pump performance, energy consumption, and environmental impact. Advanced control algorithms can optimize pump operation based on cleanroom conditions and process requirements, leading to improved efficiency and reliability.

In conclusion, the successful integration of vacuum pumps into cleanroom environments for advanced data storage solutions requires a multifaceted approach. By addressing challenges related to cleanliness, placement, heat management, noise reduction, maintenance, and control integration, manufacturers can achieve optimal performance while maintaining the integrity of the cleanroom environment.

Cleanroom integration of vacuum pumps necessitates careful consideration of several factors. Firstly, the pump design must adhere to stringent cleanliness standards to prevent particle contamination. This often involves the use of specialized materials and surface treatments that minimize outgassing and particle generation. Additionally, the pump's exhaust system must be carefully managed to prevent the reintroduction of contaminants into the cleanroom atmosphere.

The physical placement of vacuum pumps within the cleanroom layout is another crucial consideration. Optimal positioning can minimize vibration transmission to sensitive equipment and reduce the overall footprint of the system. In some cases, remote pump installations may be employed, with pumps located outside the cleanroom and connected via specialized vacuum lines.

Heat management is a significant challenge in cleanroom vacuum pump integration. The heat generated by pump operation can affect temperature stability within the controlled environment. Advanced cooling systems, such as water-cooled designs or heat exchangers, may be implemented to mitigate this issue and maintain consistent cleanroom conditions.

Noise reduction is another important aspect of cleanroom integration. Vacuum pumps can be a significant source of noise, which may interfere with sensitive measurements or affect worker comfort. Acoustic enclosures, vibration isolation mounts, and advanced pump designs with reduced noise profiles are often employed to address this concern.

Maintenance and serviceability of vacuum pumps in cleanroom settings require special protocols. Regular maintenance must be performed without compromising the cleanroom environment, often necessitating the development of specialized tools and procedures. Some advanced systems incorporate self-diagnostic capabilities and predictive maintenance features to minimize downtime and reduce the need for manual interventions.

The integration of vacuum pump control systems with overall cleanroom management systems is becoming increasingly important. This allows for real-time monitoring of pump performance, energy consumption, and environmental impact. Advanced control algorithms can optimize pump operation based on cleanroom conditions and process requirements, leading to improved efficiency and reliability.

In conclusion, the successful integration of vacuum pumps into cleanroom environments for advanced data storage solutions requires a multifaceted approach. By addressing challenges related to cleanliness, placement, heat management, noise reduction, maintenance, and control integration, manufacturers can achieve optimal performance while maintaining the integrity of the cleanroom environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!