How Vacuum Pumps Influence the Advancement of Tensegrity Structures

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tensegrity Evolution

The evolution of vacuum pump technology has played a crucial role in advancing tensegrity structures, marking significant milestones in the field of architectural and engineering innovation. This symbiotic relationship between vacuum pumps and tensegrity structures has its roots in the mid-20th century, coinciding with the initial conceptualization of tensegrity by Buckminster Fuller and Kenneth Snelson.

In the early stages, the integration of vacuum pumps with tensegrity structures was primarily experimental, focusing on small-scale models and prototypes. The 1960s and 1970s saw the first attempts to utilize vacuum technology to manipulate the tension and compression elements of tensegrity systems, albeit with limited success due to the rudimentary nature of available vacuum pumps.

The 1980s marked a turning point, as advancements in vacuum pump efficiency and reliability enabled more sophisticated applications in tensegrity research. This period witnessed the development of pneumatic tensegrity structures, where vacuum pumps were used to create negative pressure within enclosed tensegrity elements, enhancing structural stability and allowing for dynamic shape changes.

The 1990s and early 2000s brought about a revolution in vacuum pump miniaturization and energy efficiency. This technological leap forward facilitated the creation of more complex and responsive tensegrity systems. Researchers began exploring the potential of vacuum-actuated tensegrity structures for aerospace applications, deployable shelters, and adaptive architecture.

In recent years, the integration of smart materials and advanced control systems with vacuum pump technology has led to the emergence of self-adjusting tensegrity structures. These innovative designs can respond to environmental stimuli or user inputs by modifying their internal pressure distribution, thereby altering their shape, stiffness, or load-bearing capacity.

The latest developments in vacuum pump technology, including the advent of quantum vacuum pumps and nanoscale vacuum systems, are opening up new frontiers for tensegrity structures. These cutting-edge pumps offer unprecedented precision in pressure control, enabling the creation of highly responsive and adaptable tensegrity systems at both macro and micro scales.

Looking ahead, the continued evolution of vacuum pump technology promises to further revolutionize tensegrity structures. Anticipated advancements include the development of energy-harvesting vacuum systems that can power self-sustaining tensegrity structures, as well as the integration of artificial intelligence to optimize vacuum distribution for maximum structural efficiency and adaptability.

In the early stages, the integration of vacuum pumps with tensegrity structures was primarily experimental, focusing on small-scale models and prototypes. The 1960s and 1970s saw the first attempts to utilize vacuum technology to manipulate the tension and compression elements of tensegrity systems, albeit with limited success due to the rudimentary nature of available vacuum pumps.

The 1980s marked a turning point, as advancements in vacuum pump efficiency and reliability enabled more sophisticated applications in tensegrity research. This period witnessed the development of pneumatic tensegrity structures, where vacuum pumps were used to create negative pressure within enclosed tensegrity elements, enhancing structural stability and allowing for dynamic shape changes.

The 1990s and early 2000s brought about a revolution in vacuum pump miniaturization and energy efficiency. This technological leap forward facilitated the creation of more complex and responsive tensegrity systems. Researchers began exploring the potential of vacuum-actuated tensegrity structures for aerospace applications, deployable shelters, and adaptive architecture.

In recent years, the integration of smart materials and advanced control systems with vacuum pump technology has led to the emergence of self-adjusting tensegrity structures. These innovative designs can respond to environmental stimuli or user inputs by modifying their internal pressure distribution, thereby altering their shape, stiffness, or load-bearing capacity.

The latest developments in vacuum pump technology, including the advent of quantum vacuum pumps and nanoscale vacuum systems, are opening up new frontiers for tensegrity structures. These cutting-edge pumps offer unprecedented precision in pressure control, enabling the creation of highly responsive and adaptable tensegrity systems at both macro and micro scales.

Looking ahead, the continued evolution of vacuum pump technology promises to further revolutionize tensegrity structures. Anticipated advancements include the development of energy-harvesting vacuum systems that can power self-sustaining tensegrity structures, as well as the integration of artificial intelligence to optimize vacuum distribution for maximum structural efficiency and adaptability.

Market Demand Analysis

The market demand for tensegrity structures has been steadily growing across various industries, driven by their unique properties and potential applications. These lightweight yet robust structures, which rely on a balance of tension and compression forces, have garnered significant interest in architecture, engineering, and aerospace sectors. The integration of vacuum pumps with tensegrity structures has further expanded their potential applications and market opportunities.

In the construction industry, there is a growing demand for innovative building solutions that offer both structural integrity and energy efficiency. Tensegrity structures, enhanced by vacuum pump technology, provide an attractive option for creating large-span roofs, temporary shelters, and disaster-resistant buildings. The ability to adjust the internal pressure of these structures using vacuum pumps allows for dynamic load-bearing capabilities and improved adaptability to environmental conditions.

The aerospace sector has shown particular interest in tensegrity structures due to their high strength-to-weight ratio and deployability. With the incorporation of vacuum pump systems, these structures can be more precisely controlled and adjusted in space environments. This has led to increased demand for tensegrity-based deployable antennas, solar arrays, and even habitats for future space missions.

In the field of robotics and soft robotics, the combination of tensegrity principles and vacuum technology has opened up new possibilities for creating adaptable and resilient robotic systems. These structures can change shape, stiffness, and behavior in response to environmental stimuli, leading to growing interest from industries such as manufacturing, healthcare, and exploration.

The renewable energy sector has also recognized the potential of vacuum-enhanced tensegrity structures for wind turbine designs and solar panel support systems. These structures offer improved stability and efficiency in harsh weather conditions, driving demand for innovative energy harvesting solutions.

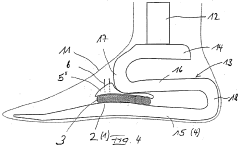

The medical field has begun exploring tensegrity structures for prosthetics and orthopedic devices. The integration of vacuum pump technology allows for better customization and adaptability to individual patient needs, potentially revolutionizing the market for assistive devices and rehabilitation equipment.

As sustainability becomes increasingly important across industries, the demand for lightweight, material-efficient structures continues to rise. Tensegrity structures, optimized through vacuum pump technology, offer a promising solution for reducing material usage while maintaining structural integrity.

While the market for vacuum pump-enhanced tensegrity structures is still emerging, industry analysts project significant growth potential in the coming years. The versatility and adaptability of these structures, combined with advancements in vacuum pump technology, position them as a disruptive force in multiple sectors. As research and development efforts continue to refine and expand the applications of these structures, the market demand is expected to accelerate, creating new opportunities for innovation and commercialization across diverse industries.

In the construction industry, there is a growing demand for innovative building solutions that offer both structural integrity and energy efficiency. Tensegrity structures, enhanced by vacuum pump technology, provide an attractive option for creating large-span roofs, temporary shelters, and disaster-resistant buildings. The ability to adjust the internal pressure of these structures using vacuum pumps allows for dynamic load-bearing capabilities and improved adaptability to environmental conditions.

The aerospace sector has shown particular interest in tensegrity structures due to their high strength-to-weight ratio and deployability. With the incorporation of vacuum pump systems, these structures can be more precisely controlled and adjusted in space environments. This has led to increased demand for tensegrity-based deployable antennas, solar arrays, and even habitats for future space missions.

In the field of robotics and soft robotics, the combination of tensegrity principles and vacuum technology has opened up new possibilities for creating adaptable and resilient robotic systems. These structures can change shape, stiffness, and behavior in response to environmental stimuli, leading to growing interest from industries such as manufacturing, healthcare, and exploration.

The renewable energy sector has also recognized the potential of vacuum-enhanced tensegrity structures for wind turbine designs and solar panel support systems. These structures offer improved stability and efficiency in harsh weather conditions, driving demand for innovative energy harvesting solutions.

The medical field has begun exploring tensegrity structures for prosthetics and orthopedic devices. The integration of vacuum pump technology allows for better customization and adaptability to individual patient needs, potentially revolutionizing the market for assistive devices and rehabilitation equipment.

As sustainability becomes increasingly important across industries, the demand for lightweight, material-efficient structures continues to rise. Tensegrity structures, optimized through vacuum pump technology, offer a promising solution for reducing material usage while maintaining structural integrity.

While the market for vacuum pump-enhanced tensegrity structures is still emerging, industry analysts project significant growth potential in the coming years. The versatility and adaptability of these structures, combined with advancements in vacuum pump technology, position them as a disruptive force in multiple sectors. As research and development efforts continue to refine and expand the applications of these structures, the market demand is expected to accelerate, creating new opportunities for innovation and commercialization across diverse industries.

Technical Challenges

The integration of vacuum pumps into tensegrity structures presents several significant technical challenges that researchers and engineers must overcome. One of the primary obstacles is the precise control and synchronization of vacuum pressure across multiple pneumatic elements within the structure. Achieving uniform pressure distribution is crucial for maintaining structural integrity and enabling controlled deformation, but it requires sophisticated control systems and sensors capable of real-time monitoring and adjustment.

Another major challenge lies in the design and fabrication of suitable materials for tensegrity components that can withstand repeated cycles of vacuum-induced stress without fatigue or failure. These materials must exhibit both flexibility to allow for structural deformation and strength to maintain overall stability under varying load conditions. Developing such materials with the right balance of properties remains an ongoing area of research and development.

The scalability of vacuum-driven tensegrity systems poses additional technical hurdles. While small-scale prototypes have demonstrated promising results, scaling up these structures for practical applications in architecture or large-scale engineering projects introduces complexities in vacuum distribution, structural stability, and overall system efficiency. Engineers must devise innovative solutions to maintain performance and reliability as the size and complexity of these structures increase.

Energy efficiency and sustainability represent another set of challenges in the advancement of vacuum-pump-influenced tensegrity structures. The continuous operation of vacuum pumps to maintain structural integrity can be energy-intensive, potentially limiting the practical applications of these systems. Developing more efficient pump technologies or exploring alternative energy sources to power these systems is crucial for their long-term viability and environmental sustainability.

Furthermore, the integration of sensing and actuation systems within tensegrity structures presents unique challenges. These systems are essential for adaptive and responsive behaviors but must be seamlessly incorporated without compromising the structural integrity or the vacuum-driven mechanisms. Miniaturization of sensors and actuators, along with the development of robust communication protocols for distributed control, are areas requiring significant technological advancements.

Lastly, the modeling and simulation of vacuum-influenced tensegrity structures present computational challenges. Accurately predicting the behavior of these complex systems under various loading conditions and vacuum pressures requires sophisticated multi-physics simulations that integrate structural mechanics, fluid dynamics, and control systems. Developing more accurate and computationally efficient modeling tools is essential for optimizing design and performance of these innovative structures.

Another major challenge lies in the design and fabrication of suitable materials for tensegrity components that can withstand repeated cycles of vacuum-induced stress without fatigue or failure. These materials must exhibit both flexibility to allow for structural deformation and strength to maintain overall stability under varying load conditions. Developing such materials with the right balance of properties remains an ongoing area of research and development.

The scalability of vacuum-driven tensegrity systems poses additional technical hurdles. While small-scale prototypes have demonstrated promising results, scaling up these structures for practical applications in architecture or large-scale engineering projects introduces complexities in vacuum distribution, structural stability, and overall system efficiency. Engineers must devise innovative solutions to maintain performance and reliability as the size and complexity of these structures increase.

Energy efficiency and sustainability represent another set of challenges in the advancement of vacuum-pump-influenced tensegrity structures. The continuous operation of vacuum pumps to maintain structural integrity can be energy-intensive, potentially limiting the practical applications of these systems. Developing more efficient pump technologies or exploring alternative energy sources to power these systems is crucial for their long-term viability and environmental sustainability.

Furthermore, the integration of sensing and actuation systems within tensegrity structures presents unique challenges. These systems are essential for adaptive and responsive behaviors but must be seamlessly incorporated without compromising the structural integrity or the vacuum-driven mechanisms. Miniaturization of sensors and actuators, along with the development of robust communication protocols for distributed control, are areas requiring significant technological advancements.

Lastly, the modeling and simulation of vacuum-influenced tensegrity structures present computational challenges. Accurately predicting the behavior of these complex systems under various loading conditions and vacuum pressures requires sophisticated multi-physics simulations that integrate structural mechanics, fluid dynamics, and control systems. Developing more accurate and computationally efficient modeling tools is essential for optimizing design and performance of these innovative structures.

Current Vacuum-Tensegrity Solutions

01 Improved pump efficiency and performance

Advancements in vacuum pump technology focus on enhancing efficiency and overall performance. This includes optimizing pump designs, improving sealing mechanisms, and incorporating advanced materials to reduce friction and wear. These improvements result in higher pumping speeds, better ultimate vacuum levels, and increased reliability.- Improved pump efficiency and performance: Advancements in vacuum pump technology focus on enhancing overall efficiency and performance. This includes optimizing pump designs, improving sealing mechanisms, and incorporating advanced materials to reduce friction and wear. These improvements result in higher pumping speeds, better ultimate vacuum levels, and increased reliability in various applications.

- Integration of smart technologies: Modern vacuum pumps are incorporating smart technologies such as sensors, IoT connectivity, and advanced control systems. These features enable real-time monitoring, predictive maintenance, and remote operation capabilities. Smart vacuum pumps can optimize their performance based on operating conditions and provide valuable data for process improvement and energy efficiency.

- Energy-efficient vacuum pump designs: Vacuum pump manufacturers are focusing on developing energy-efficient designs to reduce power consumption and operating costs. This includes the use of variable speed drives, optimized motor designs, and innovative compression technologies. Energy-efficient vacuum pumps contribute to sustainability efforts and help reduce the carbon footprint of industrial processes.

- Specialized vacuum pumps for specific applications: Advancements in vacuum pump technology have led to the development of specialized pumps tailored for specific industries and applications. These pumps are designed to meet unique requirements such as high purity, chemical resistance, or extreme operating conditions. Specialized vacuum pumps offer improved performance and reliability in fields like semiconductor manufacturing, pharmaceutical production, and aerospace.

- Compact and modular vacuum pump systems: Recent advancements focus on developing compact and modular vacuum pump systems that offer flexibility and space-saving benefits. These systems integrate multiple pump stages or combine different pump technologies in a single unit. Modular designs allow for easy maintenance, upgrades, and customization to meet specific process requirements while minimizing footprint and installation complexity.

02 Integration of smart technologies

Modern vacuum pumps are incorporating smart technologies such as sensors, IoT connectivity, and advanced control systems. These features enable real-time monitoring, predictive maintenance, and remote operation. Smart vacuum pumps can optimize their performance based on operating conditions and provide valuable data for process improvement.Expand Specific Solutions03 Energy-efficient and environmentally friendly designs

Vacuum pump manufacturers are focusing on developing energy-efficient and environmentally friendly designs. This includes the use of variable speed drives, heat recovery systems, and eco-friendly lubricants. These advancements reduce power consumption, minimize environmental impact, and lower operating costs for end-users.Expand Specific Solutions04 Specialized pumps for specific applications

Advancements in vacuum pump technology have led to the development of specialized pumps tailored for specific industries and applications. These pumps are designed to meet unique requirements such as high purity, chemical resistance, or extreme operating conditions. Examples include pumps for semiconductor manufacturing, food processing, and medical applications.Expand Specific Solutions05 Compact and modular designs

Recent advancements in vacuum pump technology focus on creating compact and modular designs. These pumps offer space-saving benefits, easier installation, and improved serviceability. Modular designs allow for quick component replacement and customization to meet specific application needs, reducing downtime and maintenance costs.Expand Specific Solutions

Key Industry Players

The vacuum pump industry's influence on tensegrity structures is in a nascent stage, with significant potential for growth. The market size is relatively small but expanding as researchers explore innovative applications. Technologically, the field is still developing, with companies like Pfeiffer Vacuum GmbH, Edwards Ltd., and SKY Technology Development Co., Ltd. CAS leading the way in pump technology advancements. These firms are adapting their expertise in vacuum systems to meet the unique requirements of tensegrity structures, potentially revolutionizing fields such as aerospace, architecture, and robotics. As the technology matures, we can expect increased collaboration between vacuum pump manufacturers and research institutions to drive further innovation in this promising area.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed advanced vacuum pump technologies specifically tailored for tensegrity structures. Their HiPace turbomolecular pumps provide high pumping speeds and compression ratios, crucial for maintaining precise vacuum levels in tensegrity applications[1]. The company's ACP multi-stage roots pumps offer oil-free operation, ensuring contamination-free environments essential for sensitive tensegrity experiments[2]. Pfeiffer's vacuum solutions incorporate smart sensors and digital interfaces, allowing real-time monitoring and adjustment of vacuum conditions, which is vital for dynamic tensegrity structures that require adaptive pressure control[3].

Strengths: High-performance pumps, contamination-free operation, and smart control systems. Weaknesses: Potentially higher cost compared to simpler vacuum solutions, may require specialized maintenance.

Edwards Ltd.

Technical Solution: Edwards Ltd. has pioneered vacuum technologies that significantly contribute to tensegrity structure advancements. Their nEXT turbomolecular pumps feature a unique splitflow stage, enhancing pumping efficiency across a wide pressure range, which is crucial for maintaining stability in tensegrity systems[4]. Edwards' GXS dry screw vacuum pumps provide consistent performance in challenging environments, supporting the diverse conditions encountered in tensegrity research and applications[5]. The company's Vacuum Management System (VMS) offers integrated control and monitoring capabilities, enabling precise vacuum regulation essential for optimizing tensegrity structure behavior[6].

Strengths: Versatile pump designs, robust performance in varied conditions, and advanced control systems. Weaknesses: May have a steeper learning curve for operators, potentially higher initial investment.

Core Innovations Analysis

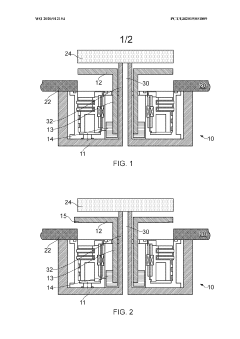

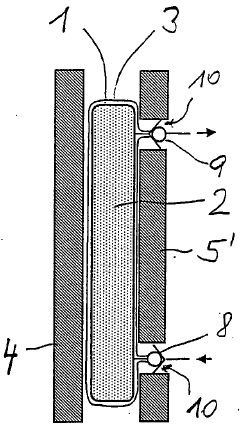

Vacuum pump with through channel and vacuum chamber

PatentWO2020012154A1

Innovation

- A vacuum pump design featuring a rotor, stator, and a controllable valve plate with an axial passage for central substrate mounting and power connections, allowing for uniform gas flow and fast pressure control, along with the option of magnetic levitation for rotor positioning and actuator-controlled axial movement of the valve plate to optimize inlet conductance.

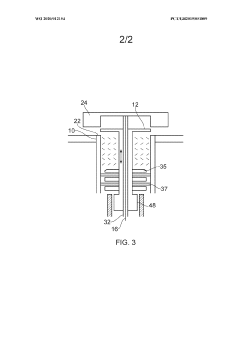

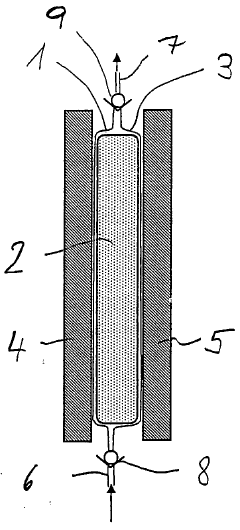

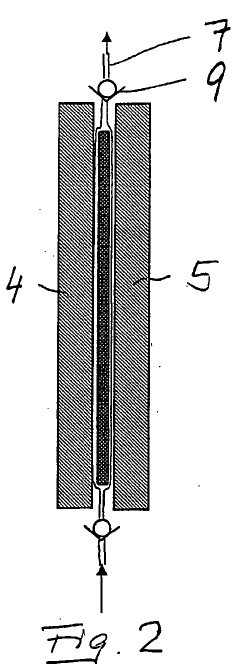

Pump comprising a moving wall and use of a pump of this type

PatentWO2006012820A1

Innovation

- A vacuum pump design utilizing an elastically deformable material to reduce and restore fluid volume, generating low to medium negative pressure through external forces, with options for rigid and flexible wall configurations and integrated valves, allowing for a compact and efficient fluid handling system.

Material Science Advancements

The advancement of tensegrity structures has been significantly influenced by material science innovations, particularly in the context of vacuum pump technology. The development of high-performance materials has enabled the creation of more efficient and durable vacuum pumps, which in turn have expanded the possibilities for tensegrity structures.

Composite materials have played a crucial role in enhancing the performance of vacuum pumps used in tensegrity applications. Carbon fiber reinforced polymers (CFRPs) have been increasingly utilized in pump components due to their exceptional strength-to-weight ratio and resistance to corrosion. These materials allow for the construction of lighter, more compact pumps that can achieve higher vacuum levels while consuming less energy.

Advancements in ceramic materials have also contributed to the improvement of vacuum pump technology. Ceramic coatings, such as titanium nitride and silicon carbide, have been applied to pump components to increase wear resistance and extend operational lifetimes. This has resulted in more reliable vacuum systems for tensegrity structures, reducing maintenance requirements and improving overall performance.

Nanotechnology has opened up new avenues for material innovation in vacuum pump design. Nanostructured materials, such as carbon nanotubes and graphene, have been explored for their potential to enhance pump efficiency and reduce friction. These materials exhibit unique properties at the nanoscale, including increased surface area and improved thermal conductivity, which can lead to more effective vacuum generation and heat dissipation in pump systems.

The development of smart materials has introduced new possibilities for adaptive tensegrity structures. Shape memory alloys and piezoelectric materials have been integrated into vacuum pump systems, allowing for dynamic control of pump performance and real-time adjustment of tensegrity configurations. This synergy between advanced materials and vacuum technology has enabled the creation of more responsive and adaptable tensegrity structures.

Biodegradable and environmentally friendly materials have also gained attention in the context of vacuum pump technology for tensegrity structures. Researchers are exploring bio-based polymers and sustainable composites that can reduce the environmental impact of pump manufacturing and disposal while maintaining the required performance characteristics.

As material science continues to evolve, it is expected that further advancements in vacuum pump technology will drive innovation in tensegrity structures. The ongoing development of novel materials with enhanced properties will likely lead to more efficient, compact, and versatile vacuum systems, expanding the potential applications and capabilities of tensegrity-based designs across various industries.

Composite materials have played a crucial role in enhancing the performance of vacuum pumps used in tensegrity applications. Carbon fiber reinforced polymers (CFRPs) have been increasingly utilized in pump components due to their exceptional strength-to-weight ratio and resistance to corrosion. These materials allow for the construction of lighter, more compact pumps that can achieve higher vacuum levels while consuming less energy.

Advancements in ceramic materials have also contributed to the improvement of vacuum pump technology. Ceramic coatings, such as titanium nitride and silicon carbide, have been applied to pump components to increase wear resistance and extend operational lifetimes. This has resulted in more reliable vacuum systems for tensegrity structures, reducing maintenance requirements and improving overall performance.

Nanotechnology has opened up new avenues for material innovation in vacuum pump design. Nanostructured materials, such as carbon nanotubes and graphene, have been explored for their potential to enhance pump efficiency and reduce friction. These materials exhibit unique properties at the nanoscale, including increased surface area and improved thermal conductivity, which can lead to more effective vacuum generation and heat dissipation in pump systems.

The development of smart materials has introduced new possibilities for adaptive tensegrity structures. Shape memory alloys and piezoelectric materials have been integrated into vacuum pump systems, allowing for dynamic control of pump performance and real-time adjustment of tensegrity configurations. This synergy between advanced materials and vacuum technology has enabled the creation of more responsive and adaptable tensegrity structures.

Biodegradable and environmentally friendly materials have also gained attention in the context of vacuum pump technology for tensegrity structures. Researchers are exploring bio-based polymers and sustainable composites that can reduce the environmental impact of pump manufacturing and disposal while maintaining the required performance characteristics.

As material science continues to evolve, it is expected that further advancements in vacuum pump technology will drive innovation in tensegrity structures. The ongoing development of novel materials with enhanced properties will likely lead to more efficient, compact, and versatile vacuum systems, expanding the potential applications and capabilities of tensegrity-based designs across various industries.

Sustainability Implications

The integration of vacuum pumps in tensegrity structures presents significant sustainability implications that extend beyond the immediate technological advancements. These implications touch upon environmental, economic, and social aspects of sustainability, offering both opportunities and challenges for future development.

From an environmental perspective, the use of vacuum pumps in tensegrity structures can lead to improved energy efficiency. By creating a vacuum within the structural elements, these systems can potentially reduce the overall weight and material requirements of buildings and infrastructure. This reduction in material usage translates to lower carbon emissions associated with manufacturing and transportation processes. Additionally, the enhanced structural efficiency may result in buildings that require less energy for heating and cooling, further reducing their environmental footprint over their lifecycle.

Economically, the adoption of vacuum pump-enhanced tensegrity structures could drive innovation in the construction industry. This technology has the potential to create new markets for specialized materials and components, stimulating economic growth and job creation in related sectors. The increased durability and adaptability of these structures may also lead to reduced maintenance costs and extended lifespans, providing long-term economic benefits for building owners and operators.

However, the sustainability of this technology also faces challenges. The production and operation of vacuum pumps require energy and resources, which must be balanced against the benefits they provide. There is a need for comprehensive life cycle assessments to accurately determine the net environmental impact of these systems compared to traditional construction methods.

From a social sustainability perspective, the implementation of vacuum pump-enhanced tensegrity structures could contribute to the development of more resilient and adaptable urban environments. These structures have the potential to withstand extreme weather events and natural disasters more effectively, enhancing public safety and reducing the social and economic costs associated with rebuilding after such events.

Moreover, the flexibility and lightweight nature of these structures could enable the creation of temporary or rapidly deployable buildings for disaster relief or humanitarian purposes. This application aligns with sustainable development goals related to providing shelter and improving the quality of life in vulnerable communities.

In conclusion, the sustainability implications of integrating vacuum pumps into tensegrity structures are multifaceted and far-reaching. While offering promising benefits in terms of resource efficiency, economic innovation, and social resilience, careful consideration must be given to the full lifecycle impacts of this technology. As research and development in this field progress, it will be crucial to prioritize sustainable practices and holistic assessments to ensure that the advancement of tensegrity structures contributes positively to global sustainability objectives.

From an environmental perspective, the use of vacuum pumps in tensegrity structures can lead to improved energy efficiency. By creating a vacuum within the structural elements, these systems can potentially reduce the overall weight and material requirements of buildings and infrastructure. This reduction in material usage translates to lower carbon emissions associated with manufacturing and transportation processes. Additionally, the enhanced structural efficiency may result in buildings that require less energy for heating and cooling, further reducing their environmental footprint over their lifecycle.

Economically, the adoption of vacuum pump-enhanced tensegrity structures could drive innovation in the construction industry. This technology has the potential to create new markets for specialized materials and components, stimulating economic growth and job creation in related sectors. The increased durability and adaptability of these structures may also lead to reduced maintenance costs and extended lifespans, providing long-term economic benefits for building owners and operators.

However, the sustainability of this technology also faces challenges. The production and operation of vacuum pumps require energy and resources, which must be balanced against the benefits they provide. There is a need for comprehensive life cycle assessments to accurately determine the net environmental impact of these systems compared to traditional construction methods.

From a social sustainability perspective, the implementation of vacuum pump-enhanced tensegrity structures could contribute to the development of more resilient and adaptable urban environments. These structures have the potential to withstand extreme weather events and natural disasters more effectively, enhancing public safety and reducing the social and economic costs associated with rebuilding after such events.

Moreover, the flexibility and lightweight nature of these structures could enable the creation of temporary or rapidly deployable buildings for disaster relief or humanitarian purposes. This application aligns with sustainable development goals related to providing shelter and improving the quality of life in vulnerable communities.

In conclusion, the sustainability implications of integrating vacuum pumps into tensegrity structures are multifaceted and far-reaching. While offering promising benefits in terms of resource efficiency, economic innovation, and social resilience, careful consideration must be given to the full lifecycle impacts of this technology. As research and development in this field progress, it will be crucial to prioritize sustainable practices and holistic assessments to ensure that the advancement of tensegrity structures contributes positively to global sustainability objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!