How Vacuum Pumps Aid the Synthesis of Biodegradable Polymers

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech in Biopolymer Synthesis

Vacuum pump technology plays a crucial role in the synthesis of biodegradable polymers, offering significant advantages in process control and product quality. The evolution of this technology has been closely tied to the growing demand for sustainable materials in various industries. Over the past decades, vacuum pumps have transitioned from simple mechanical devices to sophisticated, digitally controlled systems capable of maintaining precise pressure conditions.

The primary objective of incorporating vacuum pumps in biopolymer synthesis is to enhance reaction efficiency, reduce processing time, and improve the overall quality of the final product. By creating low-pressure environments, vacuum pumps facilitate the removal of unwanted byproducts, moisture, and air bubbles, which can significantly impact the polymer's properties. This technology aims to achieve consistent molecular weight distribution, reduced degradation during processing, and improved mechanical properties of the resulting biodegradable polymers.

Recent advancements in vacuum pump technology have focused on energy efficiency, noise reduction, and integration with smart manufacturing systems. The development of oil-free vacuum pumps has been particularly noteworthy, as it addresses concerns about contamination in sensitive biopolymer applications. Additionally, the introduction of variable speed drives has allowed for more precise control over vacuum levels, adapting to the specific requirements of different stages in the polymerization process.

The trend towards miniaturization and modular design in vacuum pump systems has enabled greater flexibility in biopolymer production facilities. This has made it possible to scale processes more efficiently and adapt to changing production demands. Furthermore, the integration of IoT (Internet of Things) capabilities in modern vacuum pumps has enhanced real-time monitoring and predictive maintenance, contributing to improved process reliability and reduced downtime.

Looking forward, the technological goals for vacuum pumps in biodegradable polymer synthesis include further improvements in energy efficiency, the development of more compact and versatile systems, and enhanced integration with automated production lines. There is also a growing focus on developing vacuum pumps that can operate effectively with bio-based lubricants, aligning with the overall sustainability goals of biodegradable polymer production. As the demand for eco-friendly materials continues to rise, the role of advanced vacuum pump technology in biopolymer synthesis is expected to become increasingly critical, driving innovation in this field.

The primary objective of incorporating vacuum pumps in biopolymer synthesis is to enhance reaction efficiency, reduce processing time, and improve the overall quality of the final product. By creating low-pressure environments, vacuum pumps facilitate the removal of unwanted byproducts, moisture, and air bubbles, which can significantly impact the polymer's properties. This technology aims to achieve consistent molecular weight distribution, reduced degradation during processing, and improved mechanical properties of the resulting biodegradable polymers.

Recent advancements in vacuum pump technology have focused on energy efficiency, noise reduction, and integration with smart manufacturing systems. The development of oil-free vacuum pumps has been particularly noteworthy, as it addresses concerns about contamination in sensitive biopolymer applications. Additionally, the introduction of variable speed drives has allowed for more precise control over vacuum levels, adapting to the specific requirements of different stages in the polymerization process.

The trend towards miniaturization and modular design in vacuum pump systems has enabled greater flexibility in biopolymer production facilities. This has made it possible to scale processes more efficiently and adapt to changing production demands. Furthermore, the integration of IoT (Internet of Things) capabilities in modern vacuum pumps has enhanced real-time monitoring and predictive maintenance, contributing to improved process reliability and reduced downtime.

Looking forward, the technological goals for vacuum pumps in biodegradable polymer synthesis include further improvements in energy efficiency, the development of more compact and versatile systems, and enhanced integration with automated production lines. There is also a growing focus on developing vacuum pumps that can operate effectively with bio-based lubricants, aligning with the overall sustainability goals of biodegradable polymer production. As the demand for eco-friendly materials continues to rise, the role of advanced vacuum pump technology in biopolymer synthesis is expected to become increasingly critical, driving innovation in this field.

Market Demand for Biodegradable Polymers

The market demand for biodegradable polymers has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. As consumers become more environmentally conscious, there is a growing preference for sustainable and eco-friendly products across various industries.

The packaging industry represents the largest market segment for biodegradable polymers, with applications ranging from food packaging to consumer goods. This sector is expected to continue its rapid expansion due to stringent regulations on single-use plastics and the shift towards more sustainable packaging solutions. The food and beverage industry, in particular, has shown a strong inclination towards adopting biodegradable polymer packaging to reduce environmental impact and meet consumer expectations.

Another key market for biodegradable polymers is the agriculture sector. Biodegradable mulch films and controlled-release fertilizer coatings are gaining traction as farmers seek to reduce plastic waste in fields and improve soil health. The medical and pharmaceutical industries also present significant opportunities for biodegradable polymers, especially in the development of drug delivery systems and implantable medical devices.

The automotive and electronics industries are emerging as potential growth areas for biodegradable polymers. As these sectors strive to improve their environmental footprint, there is increasing interest in incorporating biodegradable materials into vehicle interiors and electronic components.

Geographically, Europe and North America currently lead the market for biodegradable polymers, primarily due to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable materials.

Despite the positive market outlook, challenges remain in the widespread adoption of biodegradable polymers. These include higher production costs compared to conventional plastics, limited processing capabilities, and the need for improved performance characteristics. However, ongoing research and development efforts, supported by vacuum pump technology in polymer synthesis, are addressing these challenges and expanding the potential applications of biodegradable polymers.

As the global focus on sustainability intensifies, the market demand for biodegradable polymers is projected to continue its upward trajectory. Industries across the board are recognizing the importance of transitioning to more environmentally friendly materials, creating a robust and diverse market for biodegradable polymer solutions.

The packaging industry represents the largest market segment for biodegradable polymers, with applications ranging from food packaging to consumer goods. This sector is expected to continue its rapid expansion due to stringent regulations on single-use plastics and the shift towards more sustainable packaging solutions. The food and beverage industry, in particular, has shown a strong inclination towards adopting biodegradable polymer packaging to reduce environmental impact and meet consumer expectations.

Another key market for biodegradable polymers is the agriculture sector. Biodegradable mulch films and controlled-release fertilizer coatings are gaining traction as farmers seek to reduce plastic waste in fields and improve soil health. The medical and pharmaceutical industries also present significant opportunities for biodegradable polymers, especially in the development of drug delivery systems and implantable medical devices.

The automotive and electronics industries are emerging as potential growth areas for biodegradable polymers. As these sectors strive to improve their environmental footprint, there is increasing interest in incorporating biodegradable materials into vehicle interiors and electronic components.

Geographically, Europe and North America currently lead the market for biodegradable polymers, primarily due to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable materials.

Despite the positive market outlook, challenges remain in the widespread adoption of biodegradable polymers. These include higher production costs compared to conventional plastics, limited processing capabilities, and the need for improved performance characteristics. However, ongoing research and development efforts, supported by vacuum pump technology in polymer synthesis, are addressing these challenges and expanding the potential applications of biodegradable polymers.

As the global focus on sustainability intensifies, the market demand for biodegradable polymers is projected to continue its upward trajectory. Industries across the board are recognizing the importance of transitioning to more environmentally friendly materials, creating a robust and diverse market for biodegradable polymer solutions.

Current Challenges in Biopolymer Production

The production of biodegradable polymers faces several significant challenges that hinder widespread adoption and commercialization. One of the primary obstacles is the high cost of production compared to conventional petroleum-based plastics. The complex synthesis processes and expensive raw materials contribute to this economic barrier, making biopolymers less competitive in the market.

Another major challenge is the inconsistent quality and performance of biodegradable polymers. The properties of these materials can vary significantly depending on the production conditions and raw material sources. This variability makes it difficult for manufacturers to maintain consistent product quality and meet specific industry standards, limiting their application in certain sectors.

The scalability of biopolymer production processes presents another hurdle. Many current synthesis methods are effective at laboratory scale but face difficulties when scaled up to industrial production levels. This scaling issue often results in reduced efficiency and increased production costs, further impacting the economic viability of biodegradable polymers.

Environmental concerns also pose challenges in biopolymer production. While these materials are designed to be biodegradable, the production processes themselves can have significant environmental impacts. Issues such as high energy consumption, water usage, and the generation of waste by-products need to be addressed to ensure the overall sustainability of biopolymer production.

The limited availability and competition for raw materials is another critical challenge. Many biodegradable polymers are derived from agricultural feedstocks, which can lead to competition with food production and raise ethical concerns about land use. Additionally, the supply chain for these raw materials can be less stable and more susceptible to environmental factors compared to petroleum-based alternatives.

Technological limitations in processing and manufacturing biodegradable polymers also present obstacles. Existing equipment and techniques optimized for conventional plastics may not be suitable for biopolymers, requiring significant investments in new machinery and process development. This technological gap slows down the integration of biodegradable polymers into existing manufacturing systems.

Lastly, the end-of-life management of biodegradable polymers remains a challenge. While these materials are designed to break down more easily than conventional plastics, they often require specific conditions for proper biodegradation. The lack of appropriate infrastructure for collecting, sorting, and processing biodegradable polymers in many regions limits their environmental benefits and complicates waste management systems.

Another major challenge is the inconsistent quality and performance of biodegradable polymers. The properties of these materials can vary significantly depending on the production conditions and raw material sources. This variability makes it difficult for manufacturers to maintain consistent product quality and meet specific industry standards, limiting their application in certain sectors.

The scalability of biopolymer production processes presents another hurdle. Many current synthesis methods are effective at laboratory scale but face difficulties when scaled up to industrial production levels. This scaling issue often results in reduced efficiency and increased production costs, further impacting the economic viability of biodegradable polymers.

Environmental concerns also pose challenges in biopolymer production. While these materials are designed to be biodegradable, the production processes themselves can have significant environmental impacts. Issues such as high energy consumption, water usage, and the generation of waste by-products need to be addressed to ensure the overall sustainability of biopolymer production.

The limited availability and competition for raw materials is another critical challenge. Many biodegradable polymers are derived from agricultural feedstocks, which can lead to competition with food production and raise ethical concerns about land use. Additionally, the supply chain for these raw materials can be less stable and more susceptible to environmental factors compared to petroleum-based alternatives.

Technological limitations in processing and manufacturing biodegradable polymers also present obstacles. Existing equipment and techniques optimized for conventional plastics may not be suitable for biopolymers, requiring significant investments in new machinery and process development. This technological gap slows down the integration of biodegradable polymers into existing manufacturing systems.

Lastly, the end-of-life management of biodegradable polymers remains a challenge. While these materials are designed to break down more easily than conventional plastics, they often require specific conditions for proper biodegradation. The lack of appropriate infrastructure for collecting, sorting, and processing biodegradable polymers in many regions limits their environmental benefits and complicates waste management systems.

Existing Vacuum-Assisted Synthesis Methods

01 Improved vacuum pump designs

Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include novel rotor configurations, advanced sealing mechanisms, or optimized flow paths to achieve better vacuum levels and energy efficiency.- Improved vacuum pump designs: Various innovations in vacuum pump designs aim to enhance efficiency and performance. These improvements include novel rotor configurations, advanced sealing mechanisms, and optimized flow paths. Such designs can lead to increased pumping speed, better ultimate vacuum, and reduced power consumption.

- Synthesis of materials for vacuum pump components: Research focuses on developing and synthesizing new materials for vacuum pump components. These materials may offer improved wear resistance, thermal stability, or chemical compatibility. Advanced synthesis techniques are employed to create materials tailored for specific vacuum pump applications, potentially extending pump lifespan and performance.

- Integration of smart technologies in vacuum pumps: Incorporation of smart technologies and sensors in vacuum pumps enables real-time monitoring, predictive maintenance, and automated control. These advancements can optimize pump operation, reduce downtime, and improve overall system efficiency in various industrial and research applications.

- Specialized vacuum pumps for specific applications: Development of vacuum pumps tailored for specific industries or processes, such as semiconductor manufacturing, food packaging, or scientific research. These specialized pumps may incorporate unique features or operating principles to meet the demanding requirements of their intended applications.

- Energy-efficient vacuum pump systems: Focus on designing energy-efficient vacuum pump systems through innovative motor technologies, improved heat management, and optimized control strategies. These developments aim to reduce power consumption and operating costs while maintaining or enhancing pump performance across various industrial and scientific applications.

02 Synthesis of vacuum pump components

The development of new materials and manufacturing techniques for vacuum pump components can lead to improved durability, reduced friction, and enhanced performance. This may involve the synthesis of specialized alloys, coatings, or composite materials tailored for specific vacuum pump applications.Expand Specific Solutions03 Integration of smart technologies

Incorporating smart technologies into vacuum pumps can enable real-time monitoring, predictive maintenance, and automated control. This may include sensors, IoT connectivity, and advanced control systems to optimize pump operation and reduce downtime.Expand Specific Solutions04 Energy-efficient vacuum pump systems

Developing energy-efficient vacuum pump systems is crucial for reducing operational costs and environmental impact. This may involve innovative motor designs, regenerative technologies, or optimized control strategies to minimize power consumption while maintaining performance.Expand Specific Solutions05 Specialized vacuum pumps for specific applications

Designing vacuum pumps tailored for specific industries or applications can lead to improved performance and efficiency. This may include pumps optimized for semiconductor manufacturing, food processing, or medical applications, with features addressing unique requirements of each field.Expand Specific Solutions

Key Players in Vacuum and Biopolymer Industries

The synthesis of biodegradable polymers using vacuum pumps is an emerging field at the intersection of materials science and environmental sustainability. The market is in its early growth stage, with increasing demand driven by environmental concerns and regulatory pressures. Key players like Edwards Ltd., Newlight Technologies, and Danimer IPCo are advancing the technology, while established chemical companies such as FUJIFILM Corp. and China Petroleum & Chemical Corp. are also entering the space. The market size is expanding rapidly, though still relatively small compared to traditional plastics. Technological maturity varies, with some processes well-established and others still in development, indicating a dynamic and competitive landscape with significant potential for innovation and growth.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for the synthesis of biodegradable polymers. Their innovative approach involves the use of dry screw vacuum pumps that provide a clean, oil-free environment crucial for polymer synthesis[1]. These pumps maintain precise pressure control throughout the polymerization process, enabling the removal of volatile byproducts and moisture that could interfere with polymer formation. Edwards' vacuum systems are designed to handle aggressive chemicals and monomers commonly used in biodegradable polymer synthesis, with corrosion-resistant materials and specialized sealing technologies[3]. The company has also integrated intelligent control systems that optimize vacuum levels based on real-time process parameters, improving yield and consistency in polymer production[5].

Strengths: Specialized oil-free technology, precise pressure control, and corrosion resistance. Weaknesses: Potentially higher initial cost compared to traditional vacuum systems, may require specialized maintenance.

Newlight Technologies LLC

Technical Solution: Newlight Technologies LLC has developed an innovative approach to biodegradable polymer synthesis using vacuum technology in their AirCarbon™ production process. Their method involves capturing methane-based carbon emissions and converting them into biodegradable polymers using a biocatalyst[7]. Vacuum systems play a critical role in this process by maintaining precise control over gas concentrations and removing unwanted byproducts. Newlight's vacuum-assisted reactors enable efficient mass transfer between the gaseous feedstock and liquid medium, significantly enhancing the rate of polymer formation[8]. The company has also implemented advanced vacuum degassing techniques to remove dissolved gases from the polymer melt, improving the final product's quality and consistency[9].

Strengths: Unique carbon capture technology, high environmental sustainability. Weaknesses: Dependent on availability of methane-based feedstock, may require specialized infrastructure for implementation.

Innovations in Vacuum Pump Technology

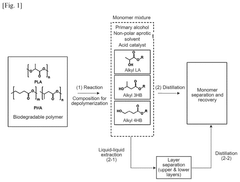

Method for regenerating biodegradable polymers

PatentPendingUS20250145790A1

Innovation

- A process involving the reaction of biodegradable polymers, such as polylactic acid (PLA) or polyhydroxyalkanoate (PHA), with a composition for depolymerization containing a primary alcohol, a non-polar aprotic solvent, and a Brønsted-Lowry acid catalyst at 90° C. or higher, achieving high monomerization conversion yields.

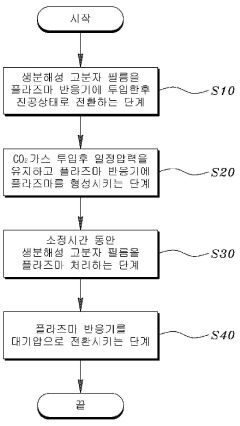

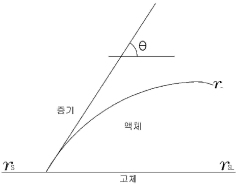

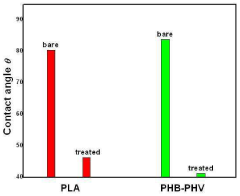

Surface modification for hydrophilic and biodegradable polymers to control their reaction rate using co2 reactive gas by inductively coupled plasma method

PatentInactiveKR1020090108874A

Innovation

- A method involving plasma surface treatment of biodegradable polymer films, specifically using an inductively coupled plasma reactor with CO2 gas, to control biodegradation rate and enhance hydrophilicity by forming hydrophilic functional groups on the polymer surface.

Environmental Impact Assessment

The synthesis of biodegradable polymers using vacuum pumps has significant environmental implications that warrant careful consideration. The use of vacuum technology in this process contributes to reduced energy consumption and minimized waste generation, aligning with sustainable manufacturing practices. By creating low-pressure environments, vacuum pumps enable more efficient polymerization reactions, often at lower temperatures, which translates to decreased energy requirements compared to traditional synthesis methods.

Furthermore, the precise control over reaction conditions facilitated by vacuum systems leads to higher product purity and fewer by-products. This reduction in unwanted side reactions and contaminants not only improves the quality of the biodegradable polymers but also diminishes the need for extensive purification steps, thereby reducing the use of solvents and other potentially harmful chemicals. Consequently, the environmental footprint associated with waste treatment and disposal is significantly lowered.

The enhanced efficiency of vacuum-assisted synthesis also contributes to resource conservation. By optimizing reaction yields and minimizing material losses, this approach helps conserve raw materials, many of which are derived from renewable sources. This conservation extends to water usage, as vacuum systems often require less cooling water compared to conventional polymer production methods.

From a lifecycle perspective, the environmental benefits of vacuum pump utilization in biodegradable polymer synthesis extend beyond the production phase. The improved quality and consistency of the polymers produced can lead to more durable and effective end products. This increased longevity can reduce the frequency of replacement and, by extension, the overall demand for new polymer production, further mitigating environmental impacts.

However, it is crucial to consider the energy consumption of vacuum pumps themselves. While they contribute to process efficiency, these pumps require electricity to operate. The environmental impact of this energy use depends largely on the source of electricity. In regions with a high proportion of renewable energy in the grid mix, the overall environmental footprint of vacuum-assisted synthesis would be more favorable compared to areas relying heavily on fossil fuels for power generation.

Additionally, the proper maintenance and operation of vacuum systems are essential to maximize their environmental benefits. Regular servicing and the use of energy-efficient pump models can further reduce the ecological impact of the synthesis process. Implementing heat recovery systems to capture and utilize waste heat from vacuum pumps can also enhance the overall energy efficiency of the production facility.

In conclusion, the integration of vacuum pumps in the synthesis of biodegradable polymers presents a net positive environmental impact when properly implemented and managed. The technology's contribution to energy efficiency, waste reduction, and resource conservation aligns well with principles of green chemistry and sustainable manufacturing, supporting the broader goal of developing environmentally friendly materials and processes.

Furthermore, the precise control over reaction conditions facilitated by vacuum systems leads to higher product purity and fewer by-products. This reduction in unwanted side reactions and contaminants not only improves the quality of the biodegradable polymers but also diminishes the need for extensive purification steps, thereby reducing the use of solvents and other potentially harmful chemicals. Consequently, the environmental footprint associated with waste treatment and disposal is significantly lowered.

The enhanced efficiency of vacuum-assisted synthesis also contributes to resource conservation. By optimizing reaction yields and minimizing material losses, this approach helps conserve raw materials, many of which are derived from renewable sources. This conservation extends to water usage, as vacuum systems often require less cooling water compared to conventional polymer production methods.

From a lifecycle perspective, the environmental benefits of vacuum pump utilization in biodegradable polymer synthesis extend beyond the production phase. The improved quality and consistency of the polymers produced can lead to more durable and effective end products. This increased longevity can reduce the frequency of replacement and, by extension, the overall demand for new polymer production, further mitigating environmental impacts.

However, it is crucial to consider the energy consumption of vacuum pumps themselves. While they contribute to process efficiency, these pumps require electricity to operate. The environmental impact of this energy use depends largely on the source of electricity. In regions with a high proportion of renewable energy in the grid mix, the overall environmental footprint of vacuum-assisted synthesis would be more favorable compared to areas relying heavily on fossil fuels for power generation.

Additionally, the proper maintenance and operation of vacuum systems are essential to maximize their environmental benefits. Regular servicing and the use of energy-efficient pump models can further reduce the ecological impact of the synthesis process. Implementing heat recovery systems to capture and utilize waste heat from vacuum pumps can also enhance the overall energy efficiency of the production facility.

In conclusion, the integration of vacuum pumps in the synthesis of biodegradable polymers presents a net positive environmental impact when properly implemented and managed. The technology's contribution to energy efficiency, waste reduction, and resource conservation aligns well with principles of green chemistry and sustainable manufacturing, supporting the broader goal of developing environmentally friendly materials and processes.

Scalability and Industrial Application

The scalability and industrial application of vacuum pumps in the synthesis of biodegradable polymers represent a critical aspect of their practical implementation. As the demand for sustainable materials continues to grow, the ability to scale up production processes becomes increasingly important.

Vacuum pumps play a crucial role in enhancing the efficiency and quality of biodegradable polymer synthesis at industrial scales. By creating controlled low-pressure environments, these pumps facilitate the removal of unwanted byproducts and moisture, leading to improved polymer properties and increased reaction rates. This capability is particularly valuable in large-scale production settings, where maintaining consistent quality across batches is essential.

In industrial applications, vacuum pumps are integrated into various stages of the polymer synthesis process. During polymerization, they help control the reaction environment, preventing unwanted side reactions and ensuring uniform molecular weight distribution. In post-processing steps, such as drying and purification, vacuum pumps aid in the removal of residual solvents and monomers, contributing to the production of high-purity biodegradable polymers.

The scalability of vacuum pump technology in polymer synthesis is evident in its adaptability to different production volumes. From pilot-scale reactors to large industrial units, vacuum systems can be designed and optimized to meet specific process requirements. This flexibility allows manufacturers to gradually scale up production while maintaining product quality and process efficiency.

Furthermore, the integration of advanced control systems and automation with vacuum pump technology enhances the scalability of biodegradable polymer production. These systems enable precise control over pressure levels, temperature, and other critical parameters, ensuring consistency across different production scales and reducing the need for manual intervention.

The industrial application of vacuum pumps in biodegradable polymer synthesis also contributes to improved energy efficiency and reduced environmental impact. By optimizing reaction conditions and minimizing waste generation, these systems align with the broader goals of sustainable manufacturing practices. This aspect is particularly relevant in the context of biodegradable polymers, where environmental considerations are a key driver of innovation and adoption.

As the field of biodegradable polymers continues to evolve, the role of vacuum pump technology in industrial applications is likely to expand. Ongoing research and development efforts focus on enhancing pump efficiency, reducing energy consumption, and developing specialized vacuum systems tailored to specific polymer synthesis processes. These advancements will further improve the scalability and industrial viability of biodegradable polymer production, supporting the transition towards more sustainable material solutions across various sectors.

Vacuum pumps play a crucial role in enhancing the efficiency and quality of biodegradable polymer synthesis at industrial scales. By creating controlled low-pressure environments, these pumps facilitate the removal of unwanted byproducts and moisture, leading to improved polymer properties and increased reaction rates. This capability is particularly valuable in large-scale production settings, where maintaining consistent quality across batches is essential.

In industrial applications, vacuum pumps are integrated into various stages of the polymer synthesis process. During polymerization, they help control the reaction environment, preventing unwanted side reactions and ensuring uniform molecular weight distribution. In post-processing steps, such as drying and purification, vacuum pumps aid in the removal of residual solvents and monomers, contributing to the production of high-purity biodegradable polymers.

The scalability of vacuum pump technology in polymer synthesis is evident in its adaptability to different production volumes. From pilot-scale reactors to large industrial units, vacuum systems can be designed and optimized to meet specific process requirements. This flexibility allows manufacturers to gradually scale up production while maintaining product quality and process efficiency.

Furthermore, the integration of advanced control systems and automation with vacuum pump technology enhances the scalability of biodegradable polymer production. These systems enable precise control over pressure levels, temperature, and other critical parameters, ensuring consistency across different production scales and reducing the need for manual intervention.

The industrial application of vacuum pumps in biodegradable polymer synthesis also contributes to improved energy efficiency and reduced environmental impact. By optimizing reaction conditions and minimizing waste generation, these systems align with the broader goals of sustainable manufacturing practices. This aspect is particularly relevant in the context of biodegradable polymers, where environmental considerations are a key driver of innovation and adoption.

As the field of biodegradable polymers continues to evolve, the role of vacuum pump technology in industrial applications is likely to expand. Ongoing research and development efforts focus on enhancing pump efficiency, reducing energy consumption, and developing specialized vacuum systems tailored to specific polymer synthesis processes. These advancements will further improve the scalability and industrial viability of biodegradable polymer production, supporting the transition towards more sustainable material solutions across various sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!