How Vacuum Pumps Enhance Solar Cell Material R&D

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Cell Vacuum Tech Evolution

The evolution of vacuum technology in solar cell material research and development has been a crucial factor in advancing the efficiency and quality of photovoltaic devices. This progression can be traced through several key stages, each marked by significant technological breakthroughs and improvements in vacuum pump capabilities.

In the early days of solar cell development, basic mechanical pumps were used to create rudimentary vacuum environments. These pumps, while limited in their ability to achieve high vacuum levels, laid the groundwork for more sophisticated techniques. As researchers recognized the need for cleaner and more controlled environments, oil-sealed rotary vane pumps became prevalent, offering improved vacuum levels and reliability.

The introduction of turbomolecular pumps in the 1960s marked a significant leap forward. These pumps could achieve much higher vacuum levels, crucial for the deposition of thin films used in solar cell production. This advancement allowed for the creation of more complex multi-layer solar cell structures, improving overall cell efficiency.

The 1980s and 1990s saw the rise of ion pumps and cryopumps, which could maintain ultra-high vacuum conditions for extended periods. This development was particularly important for research into new solar cell materials, as it allowed for more precise control over the growth and deposition of semiconductor layers.

In recent years, the focus has shifted towards dry pumping technologies, such as scroll pumps and multi-stage root pumps. These pumps offer oil-free operation, critical for maintaining the purity of solar cell materials during the manufacturing process. The elimination of oil contamination has led to significant improvements in solar cell performance and longevity.

Concurrent with pump technology advancements, vacuum measurement and control systems have also evolved. The introduction of sophisticated pressure gauges and automated control systems has enabled researchers to maintain precise vacuum conditions throughout the solar cell production process, ensuring consistency and reproducibility in material research.

The latest frontier in vacuum technology for solar cell R&D involves the integration of in-situ characterization tools within vacuum chambers. This allows researchers to analyze material properties in real-time during deposition or growth processes, providing invaluable insights into the formation of solar cell structures at the atomic level.

As we look to the future, emerging technologies such as plasma-assisted vacuum pumps and smart vacuum systems with AI-driven control mechanisms promise to further enhance the capabilities of vacuum technology in solar cell material research. These advancements are expected to enable the development of next-generation solar cells with unprecedented efficiency and durability.

In the early days of solar cell development, basic mechanical pumps were used to create rudimentary vacuum environments. These pumps, while limited in their ability to achieve high vacuum levels, laid the groundwork for more sophisticated techniques. As researchers recognized the need for cleaner and more controlled environments, oil-sealed rotary vane pumps became prevalent, offering improved vacuum levels and reliability.

The introduction of turbomolecular pumps in the 1960s marked a significant leap forward. These pumps could achieve much higher vacuum levels, crucial for the deposition of thin films used in solar cell production. This advancement allowed for the creation of more complex multi-layer solar cell structures, improving overall cell efficiency.

The 1980s and 1990s saw the rise of ion pumps and cryopumps, which could maintain ultra-high vacuum conditions for extended periods. This development was particularly important for research into new solar cell materials, as it allowed for more precise control over the growth and deposition of semiconductor layers.

In recent years, the focus has shifted towards dry pumping technologies, such as scroll pumps and multi-stage root pumps. These pumps offer oil-free operation, critical for maintaining the purity of solar cell materials during the manufacturing process. The elimination of oil contamination has led to significant improvements in solar cell performance and longevity.

Concurrent with pump technology advancements, vacuum measurement and control systems have also evolved. The introduction of sophisticated pressure gauges and automated control systems has enabled researchers to maintain precise vacuum conditions throughout the solar cell production process, ensuring consistency and reproducibility in material research.

The latest frontier in vacuum technology for solar cell R&D involves the integration of in-situ characterization tools within vacuum chambers. This allows researchers to analyze material properties in real-time during deposition or growth processes, providing invaluable insights into the formation of solar cell structures at the atomic level.

As we look to the future, emerging technologies such as plasma-assisted vacuum pumps and smart vacuum systems with AI-driven control mechanisms promise to further enhance the capabilities of vacuum technology in solar cell material research. These advancements are expected to enable the development of next-generation solar cells with unprecedented efficiency and durability.

Market Demand for High-Efficiency Solar Cells

The global demand for high-efficiency solar cells has been steadily increasing, driven by the growing need for sustainable energy solutions and the push towards reducing carbon emissions. This market trend is closely tied to advancements in solar cell material research and development, where vacuum pumps play a crucial role in enhancing the production processes.

In recent years, the solar energy sector has experienced significant growth, with the market for high-efficiency solar cells expanding at a rapid pace. This growth is fueled by several factors, including government incentives, declining costs of solar technology, and increasing awareness of environmental issues. As a result, there is a strong market pull for solar cells that can convert a higher percentage of sunlight into electricity, leading to improved overall system efficiency and reduced costs per watt of power generated.

The demand for high-efficiency solar cells is particularly pronounced in regions with limited space for solar installations, such as urban areas and countries with high population densities. In these markets, maximizing energy output per unit area is crucial, driving the need for solar cells with higher conversion efficiencies. Additionally, the growing adoption of building-integrated photovoltaics (BIPV) and the increasing popularity of electric vehicles with solar-powered features are creating new market segments that require advanced, high-efficiency solar cell technologies.

The industrial and commercial sectors are also significant drivers of demand for high-efficiency solar cells. Large-scale solar farms and commercial rooftop installations benefit greatly from increased efficiency, as it allows for higher energy production within the same footprint, leading to improved return on investment and shorter payback periods.

As the global focus on renewable energy intensifies, emerging markets in developing countries are showing increased interest in high-efficiency solar technologies. These markets present substantial growth opportunities, as they seek to leapfrog traditional energy infrastructure and move directly to advanced solar solutions.

The market demand for high-efficiency solar cells is closely linked to ongoing research and development efforts in solar cell materials and manufacturing processes. Vacuum pump technology plays a critical role in these R&D activities, enabling the creation of high-purity environments necessary for developing and producing advanced solar cell materials. The ability to precisely control the deposition of thin films, remove impurities, and maintain optimal conditions during the manufacturing process directly impacts the efficiency and quality of the resulting solar cells.

As the solar industry continues to evolve, the symbiotic relationship between market demand for high-efficiency solar cells and advancements in vacuum pump technology for material R&D becomes increasingly important. This interconnection drives innovation in both fields, pushing the boundaries of solar cell efficiency and opening new possibilities for sustainable energy production.

In recent years, the solar energy sector has experienced significant growth, with the market for high-efficiency solar cells expanding at a rapid pace. This growth is fueled by several factors, including government incentives, declining costs of solar technology, and increasing awareness of environmental issues. As a result, there is a strong market pull for solar cells that can convert a higher percentage of sunlight into electricity, leading to improved overall system efficiency and reduced costs per watt of power generated.

The demand for high-efficiency solar cells is particularly pronounced in regions with limited space for solar installations, such as urban areas and countries with high population densities. In these markets, maximizing energy output per unit area is crucial, driving the need for solar cells with higher conversion efficiencies. Additionally, the growing adoption of building-integrated photovoltaics (BIPV) and the increasing popularity of electric vehicles with solar-powered features are creating new market segments that require advanced, high-efficiency solar cell technologies.

The industrial and commercial sectors are also significant drivers of demand for high-efficiency solar cells. Large-scale solar farms and commercial rooftop installations benefit greatly from increased efficiency, as it allows for higher energy production within the same footprint, leading to improved return on investment and shorter payback periods.

As the global focus on renewable energy intensifies, emerging markets in developing countries are showing increased interest in high-efficiency solar technologies. These markets present substantial growth opportunities, as they seek to leapfrog traditional energy infrastructure and move directly to advanced solar solutions.

The market demand for high-efficiency solar cells is closely linked to ongoing research and development efforts in solar cell materials and manufacturing processes. Vacuum pump technology plays a critical role in these R&D activities, enabling the creation of high-purity environments necessary for developing and producing advanced solar cell materials. The ability to precisely control the deposition of thin films, remove impurities, and maintain optimal conditions during the manufacturing process directly impacts the efficiency and quality of the resulting solar cells.

As the solar industry continues to evolve, the symbiotic relationship between market demand for high-efficiency solar cells and advancements in vacuum pump technology for material R&D becomes increasingly important. This interconnection drives innovation in both fields, pushing the boundaries of solar cell efficiency and opening new possibilities for sustainable energy production.

Vacuum Pump Challenges in Solar R&D

Vacuum pumps play a crucial role in solar cell material research and development, yet they face several significant challenges in this specialized application. One of the primary issues is maintaining ultra-high vacuum levels consistently over extended periods. Solar cell material research often requires vacuum environments in the range of 10^-6 to 10^-9 Torr, which pushes the limits of many conventional vacuum systems.

The need for contamination-free environments presents another major challenge. Even minute impurities can significantly affect the properties and performance of solar cell materials. This necessitates the use of oil-free vacuum pumps to eliminate the risk of hydrocarbon contamination, which is particularly critical in thin-film deposition processes commonly used in solar cell fabrication.

Temperature control poses a significant hurdle in vacuum pump operation for solar R&D. Many solar cell material processes involve high temperatures, which can lead to outgassing and increased gas loads on the vacuum system. This requires pumps capable of handling elevated temperatures while maintaining their performance and reliability.

The demand for precise and stable pressure control adds another layer of complexity. Certain solar cell fabrication steps, such as molecular beam epitaxy or atomic layer deposition, require extremely precise pressure regulation. Achieving and maintaining such precise control over a wide range of pressures is technically challenging and often requires sophisticated pump control systems.

Scalability and cost-effectiveness present ongoing challenges as researchers strive to transition laboratory-scale processes to industrial production. Vacuum pumps must be able to scale up in capacity while maintaining the same level of performance and cleanliness, often at a lower cost per unit of pumping speed.

Reliability and maintenance issues are particularly pertinent in solar R&D applications. Downtime due to pump failures or maintenance can be extremely costly in terms of lost research time and potentially compromised experiments. This drives the need for robust, low-maintenance vacuum solutions that can operate continuously for extended periods.

Energy efficiency is becoming an increasingly important consideration, especially as solar cell research facilities aim to reduce their overall environmental impact. Developing vacuum pumps that consume less power while delivering the required performance is an ongoing challenge for manufacturers.

Lastly, the integration of vacuum pumps with other research equipment and control systems presents significant technical hurdles. Ensuring seamless operation and data exchange between vacuum systems and other research tools, such as in-situ characterization equipment, requires advanced control interfaces and software solutions.

The need for contamination-free environments presents another major challenge. Even minute impurities can significantly affect the properties and performance of solar cell materials. This necessitates the use of oil-free vacuum pumps to eliminate the risk of hydrocarbon contamination, which is particularly critical in thin-film deposition processes commonly used in solar cell fabrication.

Temperature control poses a significant hurdle in vacuum pump operation for solar R&D. Many solar cell material processes involve high temperatures, which can lead to outgassing and increased gas loads on the vacuum system. This requires pumps capable of handling elevated temperatures while maintaining their performance and reliability.

The demand for precise and stable pressure control adds another layer of complexity. Certain solar cell fabrication steps, such as molecular beam epitaxy or atomic layer deposition, require extremely precise pressure regulation. Achieving and maintaining such precise control over a wide range of pressures is technically challenging and often requires sophisticated pump control systems.

Scalability and cost-effectiveness present ongoing challenges as researchers strive to transition laboratory-scale processes to industrial production. Vacuum pumps must be able to scale up in capacity while maintaining the same level of performance and cleanliness, often at a lower cost per unit of pumping speed.

Reliability and maintenance issues are particularly pertinent in solar R&D applications. Downtime due to pump failures or maintenance can be extremely costly in terms of lost research time and potentially compromised experiments. This drives the need for robust, low-maintenance vacuum solutions that can operate continuously for extended periods.

Energy efficiency is becoming an increasingly important consideration, especially as solar cell research facilities aim to reduce their overall environmental impact. Developing vacuum pumps that consume less power while delivering the required performance is an ongoing challenge for manufacturers.

Lastly, the integration of vacuum pumps with other research equipment and control systems presents significant technical hurdles. Ensuring seamless operation and data exchange between vacuum systems and other research tools, such as in-situ characterization equipment, requires advanced control interfaces and software solutions.

Current Vacuum Solutions for Solar Cell Fabrication

01 Improved pump design and efficiency

Enhancements in vacuum pump design focus on improving overall efficiency and performance. This includes optimizing internal components, reducing friction, and enhancing sealing mechanisms. Advanced materials and manufacturing techniques are employed to create more durable and efficient pump parts, resulting in increased vacuum levels and reduced energy consumption.- Improved pump design and efficiency: Enhancements in vacuum pump design focus on improving overall efficiency and performance. This includes optimizing internal components, reducing friction, and enhancing sealing mechanisms. Advanced materials and manufacturing techniques are employed to create more durable and efficient pump parts, resulting in increased vacuum capacity and reduced energy consumption.

- Multi-stage vacuum systems: Multi-stage vacuum pump systems are developed to achieve higher vacuum levels and improved pumping speeds. These systems combine different types of pumps in series or parallel configurations to optimize performance across various pressure ranges. This approach allows for more efficient evacuation of gases and better overall system performance in diverse applications.

- Smart control and monitoring systems: Integration of advanced control and monitoring systems enhances vacuum pump operation. These smart systems utilize sensors, data analytics, and automation to optimize pump performance, predict maintenance needs, and adjust operating parameters in real-time. This results in improved efficiency, reduced downtime, and extended equipment lifespan.

- Noise and vibration reduction: Innovations in vacuum pump technology focus on reducing noise and vibration levels. This is achieved through improved pump designs, advanced isolation techniques, and the use of sound-absorbing materials. These enhancements result in quieter operation, reduced environmental impact, and improved working conditions in industrial settings.

- Application-specific vacuum solutions: Development of specialized vacuum pumps tailored for specific applications and industries. These pumps are designed to meet unique requirements in fields such as semiconductor manufacturing, medical devices, and aerospace. Custom features and materials are incorporated to optimize performance, reliability, and compatibility with specific process gases or environmental conditions.

02 Noise reduction and vibration control

Vacuum pump enhancements include strategies to minimize noise and vibration during operation. This involves redesigning pump housings, implementing sound-absorbing materials, and developing advanced mounting systems. These improvements result in quieter pump operation, reduced structural vibrations, and increased overall system stability.Expand Specific Solutions03 Integration of smart technologies

Modern vacuum pumps incorporate smart technologies for improved control and monitoring. This includes the integration of sensors, IoT connectivity, and advanced control systems. These enhancements allow for real-time performance monitoring, predictive maintenance, and remote operation, leading to increased reliability and reduced downtime.Expand Specific Solutions04 Multi-stage and hybrid pump systems

Vacuum pump enhancements involve the development of multi-stage and hybrid pump systems. These configurations combine different pump technologies or stages to achieve higher vacuum levels and improved performance across a wider range of operating conditions. This approach allows for greater flexibility and efficiency in various applications.Expand Specific Solutions05 Environmental and energy-efficient solutions

Vacuum pump enhancements focus on developing environmentally friendly and energy-efficient solutions. This includes the use of eco-friendly materials, oil-free designs, and energy recovery systems. These improvements result in reduced environmental impact, lower operating costs, and compliance with stringent environmental regulations.Expand Specific Solutions

Key Players in Solar Vacuum Equipment

The vacuum pump technology for solar cell material R&D is in a growth phase, with increasing market size driven by the expanding solar energy sector. The global market for vacuum pumps in solar applications is estimated to reach several hundred million dollars annually. Technologically, vacuum pumps for solar R&D are moderately mature, with ongoing innovations to improve efficiency and performance. Key players like Applied Materials, Meyer Burger, and ULVAC are at the forefront, developing specialized vacuum systems for solar cell manufacturing processes. Emerging companies such as LOT VACUUM and NanoX Medical are also contributing novel solutions, indicating a competitive and dynamic landscape in this niche but growing market segment.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced vacuum-based deposition systems for solar cell manufacturing. Their AKT-PiVot 55K PVD system utilizes high-vacuum chambers to deposit thin films of materials like aluminum, silver, and transparent conductive oxides onto solar cell substrates[1]. This system can achieve deposition rates up to 2.5 nm/s for aluminum and 4 nm/s for silver[2]. The company also offers the AKT-PiVot PECVD system, which uses plasma-enhanced chemical vapor deposition in a vacuum environment to create high-quality passivation and anti-reflective coating layers for solar cells[3]. These vacuum-based processes allow for precise control of film thickness and composition, crucial for optimizing solar cell efficiency.

Strengths: Industry-leading deposition technology, high throughput, precise control. Weaknesses: High initial equipment cost, complexity of vacuum systems maintenance.

Meyer Burger (Germany) AG

Technical Solution: Meyer Burger has developed innovative vacuum-based technologies for solar cell manufacturing. Their heterojunction (HJT) cell technology relies on plasma-enhanced chemical vapor deposition (PECVD) processes conducted in high-vacuum environments to deposit thin amorphous silicon layers on crystalline silicon wafers[10]. This process allows for the creation of high-efficiency solar cells with conversion efficiencies exceeding 24%[11]. The company's SmartWire Connection Technology (SWCT) also utilizes vacuum lamination to embed wires into a polymer foil, reducing silver consumption by up to 80% compared to traditional busbar technology[12]. Meyer Burger's CAiA platform for PERC solar cells incorporates vacuum-based processes for rear-side passivation and metallization, contributing to cell efficiencies of over 22%[13].

Strengths: Cutting-edge HJT and SWCT technologies, high-efficiency cell production. Weaknesses: Transition from equipment supplier to cell manufacturer may pose challenges.

Innovative Vacuum Techniques for PV Materials

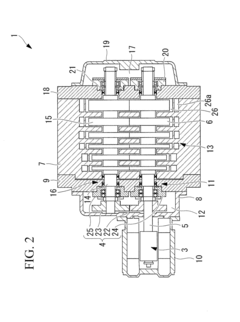

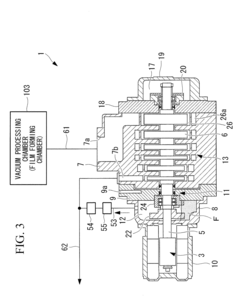

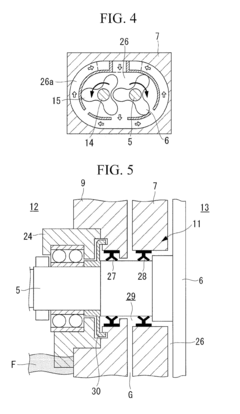

Dry vacuum pump

PatentInactiveEP2434156A1

Innovation

- The implementation of a dry vacuum pump design featuring a seal mechanism with ring-like lip parts that can be brought into elastic contact with the shaft, along with a purge mechanism introducing inert gas into the electromagnetic motor chamber to reduce hydrogen partial pressure, effectively preventing hydrogen corrosion and ensuring reliable sealing.

Hybrid solar-powered vacuum-based water pumping system for agricultural irrigation and drinking water in terrains

PatentPendingIN202411050693A

Innovation

- A hybrid solar-powered vacuum-based water pumping system that uses a pair of tanks, barrels, and a pump to create a pressure differential for continuous water flow, combined with a solar unit for energy conversion and a filtration unit for clean water, allowing year-round operation with minimal environmental impact and costs.

Environmental Impact of Vacuum Processes

The use of vacuum pumps in solar cell material research and development has significant environmental implications that warrant careful consideration. While these processes contribute to advancing renewable energy technologies, they also have potential environmental impacts that need to be addressed.

Vacuum-based manufacturing processes for solar cells typically consume substantial amounts of energy. High-performance vacuum pumps require continuous operation to maintain the necessary low-pressure environments, leading to increased electricity consumption. This energy demand can contribute to indirect greenhouse gas emissions if the power source is not renewable. However, the long-term environmental benefits of improved solar cell efficiency may outweigh these short-term energy costs.

The production of vacuum equipment and components also has environmental considerations. The manufacturing of specialized materials and precision parts for vacuum systems can involve resource-intensive processes and potentially harmful chemicals. Proper disposal and recycling of vacuum pump components, particularly those containing lubricants or other potentially hazardous materials, is crucial to minimize environmental impact.

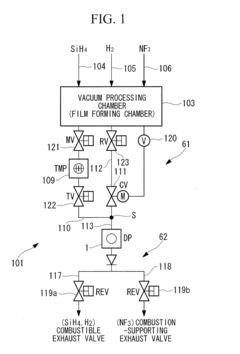

Vacuum processes in solar cell R&D often involve the use of various gases and chemicals. While many of these substances are inert, some may have global warming potential or ozone depletion effects if released into the atmosphere. Implementing robust gas handling and abatement systems is essential to prevent accidental releases and mitigate environmental risks.

On the positive side, vacuum-based thin-film deposition techniques used in solar cell development can be more material-efficient compared to traditional manufacturing methods. This can lead to reduced waste generation and more efficient use of rare or expensive materials, contributing to resource conservation.

The clean, controlled environments provided by vacuum systems can also reduce the need for certain chemical cleaning processes, potentially decreasing the use of environmentally harmful solvents and cleaning agents in solar cell production.

As the solar industry continues to grow, the environmental impact of vacuum processes in R&D and manufacturing will likely become more significant. Developing more energy-efficient vacuum pumps, implementing closed-loop gas recycling systems, and exploring alternative low-pressure technologies could help mitigate these impacts. Additionally, life cycle assessments of vacuum-based solar cell production processes can provide valuable insights for optimizing environmental performance across the entire value chain.

Vacuum-based manufacturing processes for solar cells typically consume substantial amounts of energy. High-performance vacuum pumps require continuous operation to maintain the necessary low-pressure environments, leading to increased electricity consumption. This energy demand can contribute to indirect greenhouse gas emissions if the power source is not renewable. However, the long-term environmental benefits of improved solar cell efficiency may outweigh these short-term energy costs.

The production of vacuum equipment and components also has environmental considerations. The manufacturing of specialized materials and precision parts for vacuum systems can involve resource-intensive processes and potentially harmful chemicals. Proper disposal and recycling of vacuum pump components, particularly those containing lubricants or other potentially hazardous materials, is crucial to minimize environmental impact.

Vacuum processes in solar cell R&D often involve the use of various gases and chemicals. While many of these substances are inert, some may have global warming potential or ozone depletion effects if released into the atmosphere. Implementing robust gas handling and abatement systems is essential to prevent accidental releases and mitigate environmental risks.

On the positive side, vacuum-based thin-film deposition techniques used in solar cell development can be more material-efficient compared to traditional manufacturing methods. This can lead to reduced waste generation and more efficient use of rare or expensive materials, contributing to resource conservation.

The clean, controlled environments provided by vacuum systems can also reduce the need for certain chemical cleaning processes, potentially decreasing the use of environmentally harmful solvents and cleaning agents in solar cell production.

As the solar industry continues to grow, the environmental impact of vacuum processes in R&D and manufacturing will likely become more significant. Developing more energy-efficient vacuum pumps, implementing closed-loop gas recycling systems, and exploring alternative low-pressure technologies could help mitigate these impacts. Additionally, life cycle assessments of vacuum-based solar cell production processes can provide valuable insights for optimizing environmental performance across the entire value chain.

Cost-Benefit Analysis of Vacuum Tech in Solar R&D

The implementation of vacuum technology in solar cell material research and development presents a complex cost-benefit scenario. On the cost side, vacuum pumps and associated equipment require significant initial capital investment. High-quality vacuum systems can range from tens of thousands to hundreds of thousands of dollars, depending on the scale and precision required. Additionally, ongoing operational costs include energy consumption, maintenance, and occasional replacement of components.

However, the benefits of utilizing vacuum technology in solar R&D often outweigh these costs. Vacuum environments enable precise control over material deposition processes, crucial for developing high-efficiency solar cells. This precision leads to improved material quality, reduced defects, and enhanced overall cell performance. The ability to create ultra-thin layers and complex multi-junction structures is greatly facilitated by vacuum deposition techniques, potentially increasing solar cell efficiency by several percentage points.

From a long-term perspective, the use of vacuum technology can significantly accelerate the R&D process. It allows for rapid prototyping and testing of new material combinations and structures, potentially reducing the time-to-market for innovative solar technologies. This acceleration can lead to substantial cost savings in the overall R&D lifecycle and provide a competitive edge in the fast-evolving solar industry.

Moreover, vacuum-based processes often result in more consistent and reproducible results compared to atmospheric processing. This consistency is crucial for scaling up production and maintaining quality control, which can lead to reduced manufacturing costs and improved yield rates in large-scale production scenarios.

The environmental benefits should also be considered. Vacuum-based processes typically produce less waste and require fewer chemical treatments compared to traditional manufacturing methods. This can result in reduced environmental impact and lower costs associated with waste management and regulatory compliance.

In terms of return on investment, while the initial costs are high, the long-term benefits in terms of improved product quality, reduced time-to-market, and potential for breakthrough innovations can provide significant financial returns. Companies that invest in advanced vacuum technology for solar R&D often position themselves at the forefront of technological advancements, potentially securing valuable patents and market share.

However, the benefits of utilizing vacuum technology in solar R&D often outweigh these costs. Vacuum environments enable precise control over material deposition processes, crucial for developing high-efficiency solar cells. This precision leads to improved material quality, reduced defects, and enhanced overall cell performance. The ability to create ultra-thin layers and complex multi-junction structures is greatly facilitated by vacuum deposition techniques, potentially increasing solar cell efficiency by several percentage points.

From a long-term perspective, the use of vacuum technology can significantly accelerate the R&D process. It allows for rapid prototyping and testing of new material combinations and structures, potentially reducing the time-to-market for innovative solar technologies. This acceleration can lead to substantial cost savings in the overall R&D lifecycle and provide a competitive edge in the fast-evolving solar industry.

Moreover, vacuum-based processes often result in more consistent and reproducible results compared to atmospheric processing. This consistency is crucial for scaling up production and maintaining quality control, which can lead to reduced manufacturing costs and improved yield rates in large-scale production scenarios.

The environmental benefits should also be considered. Vacuum-based processes typically produce less waste and require fewer chemical treatments compared to traditional manufacturing methods. This can result in reduced environmental impact and lower costs associated with waste management and regulatory compliance.

In terms of return on investment, while the initial costs are high, the long-term benefits in terms of improved product quality, reduced time-to-market, and potential for breakthrough innovations can provide significant financial returns. Companies that invest in advanced vacuum technology for solar R&D often position themselves at the forefront of technological advancements, potentially securing valuable patents and market share.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!