Vacuum Pumps in Advanced Electromagnetic Interference Shielding

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Shielding Vacuum Pump Evolution and Objectives

Electromagnetic interference (EMI) shielding has become increasingly critical in modern electronic systems, particularly in high-precision equipment and sensitive environments. The evolution of vacuum pumps in advanced EMI shielding represents a significant technological advancement in this field. Initially, vacuum pumps were primarily used for creating low-pressure environments, with little consideration for their EMI characteristics. However, as electronic devices became more sophisticated and sensitive to electromagnetic disturbances, the need for EMI-shielded vacuum pumps emerged.

The development of EMI shielding for vacuum pumps can be traced back to the early 2000s when researchers began to recognize the potential interference caused by pump operations in sensitive scientific and industrial applications. Early attempts at shielding focused on basic enclosure techniques, using conductive materials to create Faraday cages around the pumps. These solutions, while effective to some degree, often compromised pump performance and heat dissipation.

As the demand for more effective shielding grew, particularly in sectors such as semiconductor manufacturing and advanced scientific research, the technology evolved rapidly. By the mid-2010s, manufacturers began integrating EMI shielding directly into pump designs, using advanced materials and innovative construction techniques. This shift marked a significant milestone in the field, as it allowed for the creation of pumps that maintained high performance while offering superior EMI protection.

The current state of the art in EMI-shielded vacuum pumps involves a multifaceted approach to interference mitigation. This includes the use of specialized conductive coatings, advanced composite materials, and sophisticated electronic filtering systems. These technologies work in concert to not only block external EMI but also to prevent the pump itself from generating interference that could affect nearby equipment.

Looking forward, the objectives for further advancement in this field are multifold. One primary goal is to develop vacuum pumps with even higher levels of EMI shielding effectiveness without compromising on pump efficiency or increasing energy consumption. This challenge requires innovative approaches to materials science and pump design.

Another key objective is the miniaturization of EMI-shielded vacuum pumps. As electronic devices continue to shrink, there is a growing need for compact, highly shielded pumps that can be integrated into smaller spaces without sacrificing performance or protection. This trend aligns with the broader movement towards more compact and portable high-tech equipment across various industries.

Additionally, researchers are exploring ways to make EMI-shielded vacuum pumps more versatile and adaptable to different electromagnetic environments. The aim is to develop pumps that can dynamically adjust their shielding properties based on the specific EMI challenges of their operating environment, potentially through the use of smart materials or adaptive electronic systems.

The development of EMI shielding for vacuum pumps can be traced back to the early 2000s when researchers began to recognize the potential interference caused by pump operations in sensitive scientific and industrial applications. Early attempts at shielding focused on basic enclosure techniques, using conductive materials to create Faraday cages around the pumps. These solutions, while effective to some degree, often compromised pump performance and heat dissipation.

As the demand for more effective shielding grew, particularly in sectors such as semiconductor manufacturing and advanced scientific research, the technology evolved rapidly. By the mid-2010s, manufacturers began integrating EMI shielding directly into pump designs, using advanced materials and innovative construction techniques. This shift marked a significant milestone in the field, as it allowed for the creation of pumps that maintained high performance while offering superior EMI protection.

The current state of the art in EMI-shielded vacuum pumps involves a multifaceted approach to interference mitigation. This includes the use of specialized conductive coatings, advanced composite materials, and sophisticated electronic filtering systems. These technologies work in concert to not only block external EMI but also to prevent the pump itself from generating interference that could affect nearby equipment.

Looking forward, the objectives for further advancement in this field are multifold. One primary goal is to develop vacuum pumps with even higher levels of EMI shielding effectiveness without compromising on pump efficiency or increasing energy consumption. This challenge requires innovative approaches to materials science and pump design.

Another key objective is the miniaturization of EMI-shielded vacuum pumps. As electronic devices continue to shrink, there is a growing need for compact, highly shielded pumps that can be integrated into smaller spaces without sacrificing performance or protection. This trend aligns with the broader movement towards more compact and portable high-tech equipment across various industries.

Additionally, researchers are exploring ways to make EMI-shielded vacuum pumps more versatile and adaptable to different electromagnetic environments. The aim is to develop pumps that can dynamically adjust their shielding properties based on the specific EMI challenges of their operating environment, potentially through the use of smart materials or adaptive electronic systems.

Market Analysis for EMI-Resistant Vacuum Systems

The market for EMI-resistant vacuum systems is experiencing significant growth, driven by the increasing demand for advanced electromagnetic interference shielding in various industries. This market segment is particularly crucial in sectors such as aerospace, defense, semiconductor manufacturing, and high-precision scientific research, where electromagnetic interference can severely impact the performance of sensitive equipment.

The global EMI shielding market, which includes EMI-resistant vacuum systems, is projected to reach a substantial value in the coming years. This growth is primarily attributed to the rapid advancement of wireless technologies, the proliferation of electronic devices, and the stringent regulations regarding electromagnetic compatibility in various industries.

In the aerospace and defense sectors, there is a growing need for EMI-resistant vacuum systems to protect critical electronic components in aircraft, satellites, and military equipment. The increasing complexity of these systems and the need for reliable operation in electromagnetically noisy environments are driving the demand for advanced shielding solutions.

The semiconductor industry is another key market for EMI-resistant vacuum systems. As chip manufacturers continue to push the boundaries of miniaturization and performance, the need for ultra-clean and electromagnetically shielded environments becomes paramount. EMI-resistant vacuum systems play a crucial role in maintaining the integrity of semiconductor manufacturing processes.

Research institutions and laboratories working on cutting-edge scientific projects, such as particle accelerators and quantum computing, also contribute significantly to the market demand. These facilities require highly specialized vacuum systems that can operate without interference from electromagnetic sources.

The market is characterized by a growing trend towards customized solutions, as different applications often require specific shielding characteristics. This has led to increased collaboration between vacuum pump manufacturers and EMI shielding specialists to develop integrated solutions that meet the unique requirements of various industries.

Geographically, North America and Europe currently dominate the market for EMI-resistant vacuum systems, owing to their strong presence in aerospace, defense, and advanced research sectors. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by the rapid expansion of the semiconductor industry and increasing investments in research and development.

As the Internet of Things (IoT) and 5G technologies continue to evolve, the demand for EMI-resistant vacuum systems is expected to further increase. These technologies will require more sophisticated shielding solutions to ensure the reliable operation of interconnected devices and communication infrastructure.

The global EMI shielding market, which includes EMI-resistant vacuum systems, is projected to reach a substantial value in the coming years. This growth is primarily attributed to the rapid advancement of wireless technologies, the proliferation of electronic devices, and the stringent regulations regarding electromagnetic compatibility in various industries.

In the aerospace and defense sectors, there is a growing need for EMI-resistant vacuum systems to protect critical electronic components in aircraft, satellites, and military equipment. The increasing complexity of these systems and the need for reliable operation in electromagnetically noisy environments are driving the demand for advanced shielding solutions.

The semiconductor industry is another key market for EMI-resistant vacuum systems. As chip manufacturers continue to push the boundaries of miniaturization and performance, the need for ultra-clean and electromagnetically shielded environments becomes paramount. EMI-resistant vacuum systems play a crucial role in maintaining the integrity of semiconductor manufacturing processes.

Research institutions and laboratories working on cutting-edge scientific projects, such as particle accelerators and quantum computing, also contribute significantly to the market demand. These facilities require highly specialized vacuum systems that can operate without interference from electromagnetic sources.

The market is characterized by a growing trend towards customized solutions, as different applications often require specific shielding characteristics. This has led to increased collaboration between vacuum pump manufacturers and EMI shielding specialists to develop integrated solutions that meet the unique requirements of various industries.

Geographically, North America and Europe currently dominate the market for EMI-resistant vacuum systems, owing to their strong presence in aerospace, defense, and advanced research sectors. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by the rapid expansion of the semiconductor industry and increasing investments in research and development.

As the Internet of Things (IoT) and 5G technologies continue to evolve, the demand for EMI-resistant vacuum systems is expected to further increase. These technologies will require more sophisticated shielding solutions to ensure the reliable operation of interconnected devices and communication infrastructure.

Current Challenges in Vacuum Pump EMI Shielding

The current challenges in vacuum pump EMI shielding are multifaceted and require innovative solutions to address the increasing demands of advanced electromagnetic interference protection. One of the primary obstacles is the need for more effective shielding materials that can withstand the harsh operating conditions of vacuum pumps while maintaining their EMI suppression properties.

Traditional metallic shielding materials, while effective, often face limitations in terms of weight, corrosion resistance, and flexibility. This has led to a growing interest in developing composite materials that combine the conductivity of metals with the lightweight and corrosion-resistant properties of polymers. However, achieving the right balance between shielding effectiveness and material properties remains a significant challenge.

Another critical issue is the integration of EMI shielding solutions without compromising the performance and efficiency of vacuum pumps. The compact design of modern vacuum systems leaves little room for additional shielding components, necessitating the development of thin, yet highly effective shielding layers. This constraint has pushed researchers to explore nanotechnology-based solutions, such as graphene and carbon nanotubes, which offer promising shielding capabilities at minimal thicknesses.

The dynamic nature of electromagnetic interference in vacuum pump environments poses another challenge. Fluctuating electromagnetic fields generated by the pump's operation, coupled with external sources of EMI, create a complex shielding scenario. Developing adaptive shielding systems that can respond to varying EMI intensities and frequencies is an area of ongoing research and development.

Furthermore, the increasing use of high-frequency electronic components in vacuum pump control systems has exacerbated the EMI problem. These components are more susceptible to interference and can also be sources of EMI themselves. Addressing this issue requires a holistic approach that combines shielding techniques with advanced circuit design and signal processing methods.

The cost-effectiveness of EMI shielding solutions for vacuum pumps is another significant challenge. While high-performance shielding materials and techniques exist, their implementation in commercial vacuum pump systems must be economically viable. This economic constraint drives the need for innovative manufacturing processes and material designs that can deliver effective shielding at a reasonable cost.

Lastly, the lack of standardized testing and certification procedures specifically tailored for vacuum pump EMI shielding presents a challenge in evaluating and comparing different shielding solutions. Developing comprehensive testing protocols that accurately simulate the unique electromagnetic environment of vacuum pumps is crucial for advancing the field and ensuring the reliability of shielding technologies.

Traditional metallic shielding materials, while effective, often face limitations in terms of weight, corrosion resistance, and flexibility. This has led to a growing interest in developing composite materials that combine the conductivity of metals with the lightweight and corrosion-resistant properties of polymers. However, achieving the right balance between shielding effectiveness and material properties remains a significant challenge.

Another critical issue is the integration of EMI shielding solutions without compromising the performance and efficiency of vacuum pumps. The compact design of modern vacuum systems leaves little room for additional shielding components, necessitating the development of thin, yet highly effective shielding layers. This constraint has pushed researchers to explore nanotechnology-based solutions, such as graphene and carbon nanotubes, which offer promising shielding capabilities at minimal thicknesses.

The dynamic nature of electromagnetic interference in vacuum pump environments poses another challenge. Fluctuating electromagnetic fields generated by the pump's operation, coupled with external sources of EMI, create a complex shielding scenario. Developing adaptive shielding systems that can respond to varying EMI intensities and frequencies is an area of ongoing research and development.

Furthermore, the increasing use of high-frequency electronic components in vacuum pump control systems has exacerbated the EMI problem. These components are more susceptible to interference and can also be sources of EMI themselves. Addressing this issue requires a holistic approach that combines shielding techniques with advanced circuit design and signal processing methods.

The cost-effectiveness of EMI shielding solutions for vacuum pumps is another significant challenge. While high-performance shielding materials and techniques exist, their implementation in commercial vacuum pump systems must be economically viable. This economic constraint drives the need for innovative manufacturing processes and material designs that can deliver effective shielding at a reasonable cost.

Lastly, the lack of standardized testing and certification procedures specifically tailored for vacuum pump EMI shielding presents a challenge in evaluating and comparing different shielding solutions. Developing comprehensive testing protocols that accurately simulate the unique electromagnetic environment of vacuum pumps is crucial for advancing the field and ensuring the reliability of shielding technologies.

State-of-the-Art EMI Shielding Solutions for Vacuum Pumps

01 Improvements in vacuum pump design

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, reduced power consumption, and improved vacuum levels.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps tailored for semiconductor manufacturing processes have been developed. These pumps are designed to handle specific gases and maintain ultra-high vacuum levels required in semiconductor fabrication. Features may include corrosion-resistant materials, contamination control mechanisms, and integration with process control systems.

- Historical developments in vacuum pump technology: The evolution of vacuum pump technology spans several decades, with numerous innovations contributing to improved performance and reliability. Historical patents showcase early designs and fundamental principles that have shaped modern vacuum pump technology, including advancements in rotary, reciprocating, and diffusion pumps.

- Integration of vacuum pumps in larger systems: Vacuum pumps have been integrated into various systems and applications, such as automotive engines, industrial processing equipment, and scientific instruments. These integrations often require specialized pump designs to meet specific operational requirements, including size constraints, noise reduction, and compatibility with other system components.

- Novel vacuum pump mechanisms and principles: Innovative vacuum pump mechanisms and operating principles have been developed to address specific challenges or improve upon existing designs. These may include new types of displacement mechanisms, alternative compression methods, or novel approaches to gas extraction and exhaust. Such innovations aim to enhance pump efficiency, reliability, or suitability for particular applications.

02 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high cleanliness levels, and provide stable vacuum conditions. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.Expand Specific Solutions03 Historical developments in vacuum pump technology

The evolution of vacuum pump technology spans several decades, with numerous innovations contributing to the field. Early designs focused on mechanical improvements, while later advancements incorporated new materials and manufacturing techniques. These historical developments have laid the foundation for modern vacuum pump systems used in various industries.Expand Specific Solutions04 Integration of vacuum pumps in automotive applications

Vacuum pumps have found applications in automotive systems, particularly in brake boosters and engine management. Specialized designs have been developed to meet the specific requirements of vehicles, including compact size, durability under varying conditions, and integration with other automotive components. These pumps contribute to improved vehicle performance and safety.Expand Specific Solutions05 Energy-efficient vacuum pump solutions

Recent innovations in vacuum pump technology have focused on improving energy efficiency. These developments include the use of advanced motor designs, intelligent control systems, and optimized pump geometries. Energy-efficient vacuum pumps help reduce operational costs and environmental impact across various industrial applications.Expand Specific Solutions

Key Players in EMI-Shielded Vacuum Pump Industry

The research on vacuum pumps in advanced electromagnetic interference shielding is in a growth phase, with increasing market size driven by demand in electronics, telecommunications, and aerospace industries. The technology is maturing rapidly, with key players like Pfeiffer Vacuum GmbH, Edwards Vacuum LLC, and SKY Technology Development Co., Ltd. CAS leading innovation. These companies are developing more efficient and specialized vacuum pumps for EMI shielding applications. The competitive landscape is characterized by a mix of established manufacturers and emerging tech firms, with a focus on developing high-performance, compact solutions to meet evolving industry needs.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed advanced vacuum pumps with integrated electromagnetic interference (EMI) shielding for use in sensitive research environments. Their HiPace turbomolecular pumps utilize a hybrid rotor design with ceramic ball bearings and a five-axis magnetic bearing system, achieving ultimate pressures below 10^-10 mbar [1]. The pumps incorporate multi-layer EMI shielding materials in the housing and electrical components, reducing electromagnetic emissions by up to 60 dB across a wide frequency range [3]. Additionally, Pfeiffer has implemented active EMI cancellation technology, using sensors to detect and counteract electromagnetic noise in real-time, further improving shielding effectiveness in critical applications [5].

Strengths: Cutting-edge hybrid bearing system for ultra-high vacuum, advanced multi-layer EMI shielding, and active noise cancellation. Weaknesses: Higher cost compared to conventional pumps, increased complexity may require specialized maintenance.

3M Innovative Properties Co.

Technical Solution: 3M has developed a range of advanced electromagnetic interference (EMI) shielding materials specifically designed for vacuum environments. Their Flex & Seal Vacuum Bag Film incorporates a proprietary conductive polymer matrix that provides both flexibility and high EMI attenuation. This film can be used to create custom-shaped EMI shields for vacuum chambers and pump systems, offering up to 80 dB of shielding effectiveness across a broad frequency spectrum (1 MHz to 10 GHz) [2]. 3M has also introduced a series of vacuum-compatible conductive adhesives and gaskets that maintain their EMI shielding properties under high vacuum conditions, with outgassing rates below 1 x 10^-6 Torr·L/s·cm² [4]. These materials enable the creation of seamless EMI barriers in complex vacuum pump assemblies.

Strengths: Highly flexible and customizable EMI shielding solutions, excellent shielding effectiveness, and low outgassing properties. Weaknesses: May require specialized application techniques, and potential for higher material costs compared to traditional shielding methods.

Breakthrough EMI Shielding Technologies for Vacuum Systems

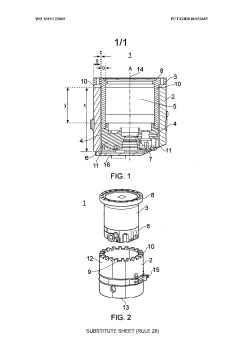

Magnetic shield for a vacuum pump

PatentWO2019122869A1

Innovation

- A magnetically shielded vacuum pump design featuring a pump envelope with an outer magnetic shield and a longitudinally extending circumferential channel, using magnetically soft materials like mild steel and electroless nickel plating, to guide magnetic flux around the rotor cavity and prevent overheating through cooling fluid circulation.

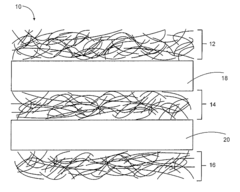

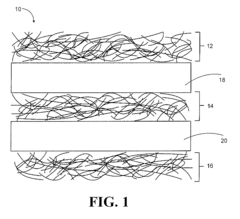

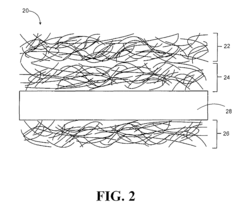

Electromagnetic interference shielding structure including carbon nanotube or nanofiber films

PatentInactiveUS9119294B2

Innovation

- A composite material comprising multiple layers of electrically conductive nanoscale fiber films spaced apart by insulating gaps, which utilize multiple internal reflections to enhance EMI shielding effectiveness, allowing for high nanotube loading without compromising mechanical properties, and can be fabricated into thin, flexible structures.

EMI Standards and Regulations for Vacuum Equipment

Electromagnetic Interference (EMI) standards and regulations for vacuum equipment play a crucial role in ensuring the proper functioning and safety of these devices in various industrial and scientific applications. These standards are designed to limit the emission of electromagnetic energy from vacuum pumps and other related equipment, as well as to ensure their immunity to external electromagnetic disturbances.

The International Electrotechnical Commission (IEC) has established several standards that directly apply to vacuum equipment. IEC 61000-6-2 and IEC 61000-6-4 are particularly relevant, as they specify the generic immunity and emission standards for industrial environments, respectively. These standards outline the acceptable levels of electromagnetic emissions and the required immunity to electromagnetic disturbances for vacuum pumps and associated equipment.

In the United States, the Federal Communications Commission (FCC) regulates EMI through its Part 15 rules. These regulations set limits on the amount of electromagnetic energy that electronic devices, including vacuum equipment, can emit. Vacuum pumps used in industrial settings typically fall under the Class A category, which has more lenient emission limits compared to consumer-grade equipment.

The European Union enforces EMI regulations through the Electromagnetic Compatibility (EMC) Directive 2014/30/EU. This directive requires all electronic equipment, including vacuum pumps, to meet specific EMI standards before they can be sold or used within the EU. Manufacturers must ensure their products comply with these standards and obtain CE marking to demonstrate compliance.

For vacuum equipment used in specialized environments, such as medical or aerospace applications, additional standards may apply. For instance, the ISO 14971 standard for medical devices includes considerations for electromagnetic compatibility in risk management processes. In aerospace applications, the RTCA DO-160 standard provides guidelines for environmental conditions and test procedures for airborne equipment, including EMI requirements.

Compliance with these standards and regulations often requires manufacturers to implement various shielding techniques and design considerations in their vacuum pump systems. This may include the use of conductive enclosures, proper grounding, filtered power supplies, and shielded cables. Regular testing and certification processes are necessary to ensure ongoing compliance with evolving EMI standards.

As technology advances and the use of vacuum equipment in sensitive applications increases, EMI standards and regulations continue to evolve. Regulatory bodies are constantly reviewing and updating their requirements to address new challenges and ensure the safe and reliable operation of vacuum pumps in electromagnetically complex environments.

The International Electrotechnical Commission (IEC) has established several standards that directly apply to vacuum equipment. IEC 61000-6-2 and IEC 61000-6-4 are particularly relevant, as they specify the generic immunity and emission standards for industrial environments, respectively. These standards outline the acceptable levels of electromagnetic emissions and the required immunity to electromagnetic disturbances for vacuum pumps and associated equipment.

In the United States, the Federal Communications Commission (FCC) regulates EMI through its Part 15 rules. These regulations set limits on the amount of electromagnetic energy that electronic devices, including vacuum equipment, can emit. Vacuum pumps used in industrial settings typically fall under the Class A category, which has more lenient emission limits compared to consumer-grade equipment.

The European Union enforces EMI regulations through the Electromagnetic Compatibility (EMC) Directive 2014/30/EU. This directive requires all electronic equipment, including vacuum pumps, to meet specific EMI standards before they can be sold or used within the EU. Manufacturers must ensure their products comply with these standards and obtain CE marking to demonstrate compliance.

For vacuum equipment used in specialized environments, such as medical or aerospace applications, additional standards may apply. For instance, the ISO 14971 standard for medical devices includes considerations for electromagnetic compatibility in risk management processes. In aerospace applications, the RTCA DO-160 standard provides guidelines for environmental conditions and test procedures for airborne equipment, including EMI requirements.

Compliance with these standards and regulations often requires manufacturers to implement various shielding techniques and design considerations in their vacuum pump systems. This may include the use of conductive enclosures, proper grounding, filtered power supplies, and shielded cables. Regular testing and certification processes are necessary to ensure ongoing compliance with evolving EMI standards.

As technology advances and the use of vacuum equipment in sensitive applications increases, EMI standards and regulations continue to evolve. Regulatory bodies are constantly reviewing and updating their requirements to address new challenges and ensure the safe and reliable operation of vacuum pumps in electromagnetically complex environments.

Environmental Impact of Advanced EMI Shielding Materials

The environmental impact of advanced electromagnetic interference (EMI) shielding materials is a critical consideration in the development and implementation of vacuum pump technologies for EMI shielding applications. As these materials become more sophisticated and widely used, their potential effects on the environment throughout their lifecycle must be carefully evaluated.

Advanced EMI shielding materials often incorporate metals, conductive polymers, and composite structures. The production of these materials can involve energy-intensive processes and the use of potentially hazardous substances. For instance, the manufacturing of metal-based shielding materials may require extensive mining and refining operations, contributing to resource depletion and greenhouse gas emissions. Similarly, the synthesis of conductive polymers may involve the use of toxic solvents or catalysts, posing risks to both human health and the environment if not properly managed.

During the operational phase, advanced EMI shielding materials in vacuum pump systems generally have a minimal direct environmental impact. However, the increased efficiency and performance of these materials can lead to indirect environmental benefits. By enhancing the effectiveness of EMI shielding, these materials can reduce electromagnetic pollution, potentially mitigating adverse effects on wildlife and ecosystems sensitive to electromagnetic fields.

The disposal and end-of-life management of advanced EMI shielding materials present significant environmental challenges. Many of these materials are not easily recyclable due to their complex compositions and the difficulty in separating individual components. This can lead to increased waste generation and potential environmental contamination if not properly handled. Furthermore, some materials may contain heavy metals or other toxic substances that could leach into soil and water systems if disposed of in landfills.

To address these environmental concerns, researchers and manufacturers are exploring more sustainable approaches to EMI shielding materials. This includes the development of bio-based and biodegradable shielding materials, as well as the implementation of closed-loop recycling systems for metal-based shields. Additionally, efforts are being made to optimize material usage and reduce waste during the manufacturing process, thereby minimizing the overall environmental footprint of these technologies.

As the demand for advanced EMI shielding in vacuum pump applications continues to grow, it is crucial to balance technological advancements with environmental stewardship. This requires a holistic approach that considers the entire lifecycle of these materials, from raw material extraction to end-of-life disposal. By prioritizing sustainability in material design and production, the industry can work towards minimizing negative environmental impacts while maximizing the benefits of advanced EMI shielding technologies.

Advanced EMI shielding materials often incorporate metals, conductive polymers, and composite structures. The production of these materials can involve energy-intensive processes and the use of potentially hazardous substances. For instance, the manufacturing of metal-based shielding materials may require extensive mining and refining operations, contributing to resource depletion and greenhouse gas emissions. Similarly, the synthesis of conductive polymers may involve the use of toxic solvents or catalysts, posing risks to both human health and the environment if not properly managed.

During the operational phase, advanced EMI shielding materials in vacuum pump systems generally have a minimal direct environmental impact. However, the increased efficiency and performance of these materials can lead to indirect environmental benefits. By enhancing the effectiveness of EMI shielding, these materials can reduce electromagnetic pollution, potentially mitigating adverse effects on wildlife and ecosystems sensitive to electromagnetic fields.

The disposal and end-of-life management of advanced EMI shielding materials present significant environmental challenges. Many of these materials are not easily recyclable due to their complex compositions and the difficulty in separating individual components. This can lead to increased waste generation and potential environmental contamination if not properly handled. Furthermore, some materials may contain heavy metals or other toxic substances that could leach into soil and water systems if disposed of in landfills.

To address these environmental concerns, researchers and manufacturers are exploring more sustainable approaches to EMI shielding materials. This includes the development of bio-based and biodegradable shielding materials, as well as the implementation of closed-loop recycling systems for metal-based shields. Additionally, efforts are being made to optimize material usage and reduce waste during the manufacturing process, thereby minimizing the overall environmental footprint of these technologies.

As the demand for advanced EMI shielding in vacuum pump applications continues to grow, it is crucial to balance technological advancements with environmental stewardship. This requires a holistic approach that considers the entire lifecycle of these materials, from raw material extraction to end-of-life disposal. By prioritizing sustainability in material design and production, the industry can work towards minimizing negative environmental impacts while maximizing the benefits of advanced EMI shielding technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!