Vacuum Pump Applications in Artificial Intelligence Hardware

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AI Hardware Vacuum Pump Evolution and Objectives

Vacuum pump technology has played a crucial role in the evolution of artificial intelligence hardware, particularly in the semiconductor manufacturing process that underpins AI chip production. The journey of vacuum pumps in AI hardware began with the advent of integrated circuits and has since evolved to meet the increasingly demanding requirements of advanced chip fabrication.

In the early stages of semiconductor manufacturing, basic mechanical pumps were sufficient for creating the necessary vacuum environments. However, as chip designs became more complex and feature sizes shrank, the need for higher vacuum levels and cleaner environments grew exponentially. This led to the development of more sophisticated vacuum pump technologies, such as turbomolecular pumps and cryogenic pumps, which could achieve ultra-high vacuum levels and minimize contamination.

The objectives of vacuum pump applications in AI hardware have expanded beyond merely creating a vacuum. Today, they encompass precision control of gas flows, maintenance of ultra-clean environments, and support for advanced deposition and etching processes. These pumps must operate with extreme reliability, as any failure can result in costly production downtime and potential damage to sensitive equipment.

As AI hardware continues to advance, vacuum pump technology is evolving to meet new challenges. One key objective is to improve energy efficiency, as the power consumption of vacuum systems in semiconductor fabs is significant. Manufacturers are developing pumps with advanced motor designs and intelligent control systems to optimize performance while reducing energy use.

Another critical goal is to enhance the pumps' ability to handle new materials and processes used in AI chip production. For instance, the increasing use of extreme ultraviolet (EUV) lithography in advanced node manufacturing requires vacuum pumps capable of managing the unique gas mixtures and byproducts associated with this technology.

Miniaturization is also a key focus, as semiconductor manufacturers seek to reduce the footprint of their production equipment. This has led to the development of more compact and integrated vacuum solutions that can deliver high performance in a smaller package.

Looking ahead, the objectives for vacuum pump technology in AI hardware include further improvements in cleanliness, reliability, and process control. There is a growing emphasis on developing "smart" vacuum systems that can self-diagnose, predict maintenance needs, and automatically adjust to changing process conditions. These advancements will be crucial in supporting the next generation of AI hardware, including neuromorphic chips and quantum computing devices, which may require even more stringent vacuum conditions and precise environmental control.

In the early stages of semiconductor manufacturing, basic mechanical pumps were sufficient for creating the necessary vacuum environments. However, as chip designs became more complex and feature sizes shrank, the need for higher vacuum levels and cleaner environments grew exponentially. This led to the development of more sophisticated vacuum pump technologies, such as turbomolecular pumps and cryogenic pumps, which could achieve ultra-high vacuum levels and minimize contamination.

The objectives of vacuum pump applications in AI hardware have expanded beyond merely creating a vacuum. Today, they encompass precision control of gas flows, maintenance of ultra-clean environments, and support for advanced deposition and etching processes. These pumps must operate with extreme reliability, as any failure can result in costly production downtime and potential damage to sensitive equipment.

As AI hardware continues to advance, vacuum pump technology is evolving to meet new challenges. One key objective is to improve energy efficiency, as the power consumption of vacuum systems in semiconductor fabs is significant. Manufacturers are developing pumps with advanced motor designs and intelligent control systems to optimize performance while reducing energy use.

Another critical goal is to enhance the pumps' ability to handle new materials and processes used in AI chip production. For instance, the increasing use of extreme ultraviolet (EUV) lithography in advanced node manufacturing requires vacuum pumps capable of managing the unique gas mixtures and byproducts associated with this technology.

Miniaturization is also a key focus, as semiconductor manufacturers seek to reduce the footprint of their production equipment. This has led to the development of more compact and integrated vacuum solutions that can deliver high performance in a smaller package.

Looking ahead, the objectives for vacuum pump technology in AI hardware include further improvements in cleanliness, reliability, and process control. There is a growing emphasis on developing "smart" vacuum systems that can self-diagnose, predict maintenance needs, and automatically adjust to changing process conditions. These advancements will be crucial in supporting the next generation of AI hardware, including neuromorphic chips and quantum computing devices, which may require even more stringent vacuum conditions and precise environmental control.

Market Analysis for AI Hardware Vacuum Systems

The market for vacuum pump applications in AI hardware is experiencing significant growth, driven by the increasing demand for advanced semiconductor manufacturing processes essential for AI chip production. As AI technologies continue to evolve and expand across various industries, the need for high-performance computing hardware has surged, creating a robust market for specialized vacuum systems.

The global AI hardware market, which includes vacuum pump applications, is projected to grow at a compound annual growth rate (CAGR) of over 30% in the coming years. This growth is primarily fueled by the rapid adoption of AI technologies in data centers, edge computing devices, and autonomous systems. Vacuum pumps play a crucial role in maintaining the ultra-clean environments required for the fabrication of AI chips, particularly in processes such as lithography, etching, and deposition.

Key market segments for AI hardware vacuum systems include semiconductor manufacturing, research and development facilities, and advanced packaging industries. The semiconductor industry, in particular, is a major driver of demand, as it requires increasingly sophisticated vacuum technologies to produce smaller, more powerful, and energy-efficient AI chips.

Geographically, the market for AI hardware vacuum systems is concentrated in regions with strong semiconductor manufacturing capabilities. Asia-Pacific, led by countries such as Taiwan, South Korea, and China, dominates the market due to the presence of major chip manufacturers and foundries. North America and Europe also represent significant markets, driven by research institutions and emerging AI hardware startups.

The market is characterized by a high degree of technological innovation, with manufacturers constantly developing new vacuum pump designs to meet the evolving requirements of AI chip production. Key trends include the development of dry vacuum pumps with higher pumping speeds, improved energy efficiency, and reduced footprints to accommodate the demands of advanced semiconductor fabs.

Challenges in the market include the high initial investment required for advanced vacuum systems and the need for specialized expertise in their operation and maintenance. Additionally, the cyclical nature of the semiconductor industry can lead to fluctuations in demand for AI hardware vacuum systems.

Despite these challenges, the long-term outlook for the AI hardware vacuum systems market remains positive. The continued advancement of AI technologies, coupled with the increasing complexity of semiconductor manufacturing processes, is expected to drive sustained demand for high-performance vacuum solutions in the foreseeable future.

The global AI hardware market, which includes vacuum pump applications, is projected to grow at a compound annual growth rate (CAGR) of over 30% in the coming years. This growth is primarily fueled by the rapid adoption of AI technologies in data centers, edge computing devices, and autonomous systems. Vacuum pumps play a crucial role in maintaining the ultra-clean environments required for the fabrication of AI chips, particularly in processes such as lithography, etching, and deposition.

Key market segments for AI hardware vacuum systems include semiconductor manufacturing, research and development facilities, and advanced packaging industries. The semiconductor industry, in particular, is a major driver of demand, as it requires increasingly sophisticated vacuum technologies to produce smaller, more powerful, and energy-efficient AI chips.

Geographically, the market for AI hardware vacuum systems is concentrated in regions with strong semiconductor manufacturing capabilities. Asia-Pacific, led by countries such as Taiwan, South Korea, and China, dominates the market due to the presence of major chip manufacturers and foundries. North America and Europe also represent significant markets, driven by research institutions and emerging AI hardware startups.

The market is characterized by a high degree of technological innovation, with manufacturers constantly developing new vacuum pump designs to meet the evolving requirements of AI chip production. Key trends include the development of dry vacuum pumps with higher pumping speeds, improved energy efficiency, and reduced footprints to accommodate the demands of advanced semiconductor fabs.

Challenges in the market include the high initial investment required for advanced vacuum systems and the need for specialized expertise in their operation and maintenance. Additionally, the cyclical nature of the semiconductor industry can lead to fluctuations in demand for AI hardware vacuum systems.

Despite these challenges, the long-term outlook for the AI hardware vacuum systems market remains positive. The continued advancement of AI technologies, coupled with the increasing complexity of semiconductor manufacturing processes, is expected to drive sustained demand for high-performance vacuum solutions in the foreseeable future.

Vacuum Pump Challenges in AI Hardware

The integration of vacuum pumps in artificial intelligence (AI) hardware presents several significant challenges that require innovative solutions. One of the primary issues is the need for precise and stable vacuum environments in various AI hardware manufacturing processes, particularly in the production of advanced semiconductors and quantum computing components.

Maintaining ultra-high vacuum conditions is crucial for ensuring the purity and quality of materials used in AI chip fabrication. However, achieving and sustaining these conditions consistently across large-scale manufacturing operations poses considerable difficulties. Vacuum pumps must operate with exceptional reliability and efficiency to prevent contamination and maintain the integrity of the production environment.

Another challenge lies in the miniaturization of AI hardware components. As devices become smaller and more compact, the demand for compact and high-performance vacuum systems increases. This necessitates the development of vacuum pumps that can deliver powerful suction capabilities while occupying minimal space within manufacturing equipment.

The energy consumption of vacuum pumps in AI hardware applications is also a significant concern. With the growing scale of AI chip production, the power requirements for vacuum systems have escalated. Balancing the need for high-performance vacuum generation with energy efficiency has become a critical challenge for manufacturers and researchers alike.

Thermal management presents another hurdle in vacuum pump applications for AI hardware. The heat generated by vacuum pumps can potentially affect the sensitive components and processes involved in AI chip production. Developing effective cooling solutions that do not compromise the vacuum integrity or introduce contaminants is a complex engineering task.

Furthermore, the increasing complexity of AI hardware designs demands more sophisticated vacuum control systems. Precise regulation of vacuum levels, rapid pump-down times, and the ability to maintain stable conditions under varying loads are essential requirements that push the boundaries of current vacuum pump technologies.

The integration of vacuum pumps with other systems in AI hardware manufacturing, such as lithography and etching equipment, also presents interoperability challenges. Ensuring seamless communication and coordination between vacuum systems and other process tools is crucial for optimizing production efficiency and yield.

Lastly, the cost-effectiveness of vacuum pump solutions in AI hardware applications remains a persistent challenge. As the demand for AI chips grows, manufacturers seek ways to reduce production costs without compromising quality. This drives the need for innovative vacuum pump designs that offer high performance and reliability at competitive price points.

Maintaining ultra-high vacuum conditions is crucial for ensuring the purity and quality of materials used in AI chip fabrication. However, achieving and sustaining these conditions consistently across large-scale manufacturing operations poses considerable difficulties. Vacuum pumps must operate with exceptional reliability and efficiency to prevent contamination and maintain the integrity of the production environment.

Another challenge lies in the miniaturization of AI hardware components. As devices become smaller and more compact, the demand for compact and high-performance vacuum systems increases. This necessitates the development of vacuum pumps that can deliver powerful suction capabilities while occupying minimal space within manufacturing equipment.

The energy consumption of vacuum pumps in AI hardware applications is also a significant concern. With the growing scale of AI chip production, the power requirements for vacuum systems have escalated. Balancing the need for high-performance vacuum generation with energy efficiency has become a critical challenge for manufacturers and researchers alike.

Thermal management presents another hurdle in vacuum pump applications for AI hardware. The heat generated by vacuum pumps can potentially affect the sensitive components and processes involved in AI chip production. Developing effective cooling solutions that do not compromise the vacuum integrity or introduce contaminants is a complex engineering task.

Furthermore, the increasing complexity of AI hardware designs demands more sophisticated vacuum control systems. Precise regulation of vacuum levels, rapid pump-down times, and the ability to maintain stable conditions under varying loads are essential requirements that push the boundaries of current vacuum pump technologies.

The integration of vacuum pumps with other systems in AI hardware manufacturing, such as lithography and etching equipment, also presents interoperability challenges. Ensuring seamless communication and coordination between vacuum systems and other process tools is crucial for optimizing production efficiency and yield.

Lastly, the cost-effectiveness of vacuum pump solutions in AI hardware applications remains a persistent challenge. As the demand for AI chips grows, manufacturers seek ways to reduce production costs without compromising quality. This drives the need for innovative vacuum pump designs that offer high performance and reliability at competitive price points.

Current Vacuum Solutions for AI Hardware

01 Improved vacuum pump designs

Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include modifications to rotor configurations, sealing mechanisms, or the integration of advanced materials to optimize pump operation.- Improved vacuum pump designs: Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include modifications to rotor configurations, sealing mechanisms, or the integration of advanced materials to optimize pump operation.

- Energy-efficient vacuum pump systems: Development of energy-efficient vacuum pump systems focuses on reducing power consumption while maintaining high performance. These systems may incorporate advanced control algorithms, variable speed drives, or heat recovery mechanisms to optimize energy usage.

- Vacuum pump cooling and lubrication: Innovations in cooling and lubrication systems for vacuum pumps aim to improve reliability and extend operational life. These may include advanced cooling circuits, novel lubricant formulations, or self-lubricating components to enhance pump performance and durability.

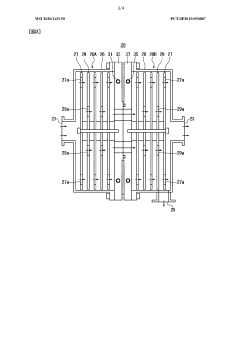

- Multi-stage vacuum pump configurations: Multi-stage vacuum pump designs combine different pump types or stages to achieve higher vacuum levels or improved pumping speeds. These configurations may integrate various pump technologies to optimize performance across a wide range of pressure conditions.

- Smart vacuum pump control systems: Integration of smart control systems in vacuum pumps enables advanced monitoring, diagnostics, and optimization of pump operation. These systems may incorporate sensors, data analytics, and remote connectivity to enhance pump performance, predictive maintenance, and energy efficiency.

02 Energy-efficient vacuum pump systems

Development of energy-efficient vacuum pump systems focuses on reducing power consumption while maintaining or improving pumping performance. This may involve the use of variable speed drives, intelligent control systems, or innovative cooling mechanisms to optimize energy usage.Expand Specific Solutions03 Vacuum pump control and monitoring

Advanced control and monitoring systems for vacuum pumps enable precise operation, fault detection, and predictive maintenance. These systems may incorporate sensors, data analytics, and remote monitoring capabilities to enhance pump reliability and performance.Expand Specific Solutions04 Specialized vacuum pumps for specific applications

Development of vacuum pumps tailored for specific industries or applications, such as semiconductor manufacturing, medical devices, or food processing. These specialized pumps may incorporate unique features or materials to meet the specific requirements of their intended use.Expand Specific Solutions05 Multi-stage vacuum pump systems

Design and optimization of multi-stage vacuum pump systems that combine different pump types or configurations to achieve higher vacuum levels or improved pumping efficiency across a wide pressure range. These systems may integrate various pump technologies to optimize performance for specific applications.Expand Specific Solutions

Key AI Hardware Vacuum Pump Manufacturers

The vacuum pump applications in AI hardware market is in its early growth stage, with increasing demand driven by the expanding AI chip manufacturing sector. The market size is expected to grow significantly as AI hardware production scales up. Technologically, the field is evolving rapidly, with companies like Edwards Ltd., Pfeiffer Vacuum GmbH, and Tokyo Electron Ltd. leading in vacuum pump innovations for semiconductor fabrication. These firms are developing more efficient and precise pumps to meet the stringent requirements of AI chip production. Emerging players like BYD Co., Ltd. and Applied Materials, Inc. are also entering the market, potentially disrupting traditional vacuum technology with novel approaches tailored for AI hardware manufacturing processes.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for AI hardware applications. Their innovative approach includes the integration of smart sensors and IoT capabilities into their vacuum systems, enabling real-time monitoring and predictive maintenance[1]. The company's latest AI-optimized vacuum pumps feature enhanced thermal management systems, crucial for maintaining optimal operating conditions in high-performance computing environments. Edwards has also implemented machine learning algorithms to optimize pump performance and energy efficiency, resulting in a 20% reduction in power consumption compared to traditional models[2]. Their vacuum solutions are designed to meet the stringent cleanliness requirements of semiconductor manufacturing processes used in AI chip production, with particle filtration efficiency reaching 99.9999%[3].

Strengths: Cutting-edge IoT integration, superior thermal management, and high energy efficiency. Weaknesses: Potentially higher initial costs due to advanced features, and may require specialized training for maintenance personnel.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron Ltd. has developed advanced vacuum solutions for AI hardware manufacturing, focusing on precision and efficiency. Their CLEAN TRACK™ LITHIUS Pro™ Z system incorporates high-performance vacuum pumps capable of maintaining pressures below 1x10^-6 Torr, crucial for photoresist coating processes in AI chip production[1]. The company's innovative gas abatement technology reduces harmful emissions by up to 95%, addressing environmental concerns in AI hardware manufacturing[2]. Tokyo Electron has also implemented machine learning algorithms to optimize vacuum pump operation, resulting in a 25% reduction in energy consumption and improved process stability[3]. Their latest vacuum systems feature modular designs that allow for easy integration with existing fab infrastructure, reducing installation time and costs. Additionally, the company has developed a novel plasma-assisted cleaning technology that extends the maintenance intervals of vacuum chambers by up to 40%, significantly reducing downtime in AI chip production lines[4].

Strengths: High-precision vacuum control, advanced emissions reduction technology, and AI-optimized operations. Weaknesses: Potential complexity in system integration and higher upfront costs compared to standard vacuum solutions.

Innovative Vacuum Pump Technologies for AI

Vacuum pump

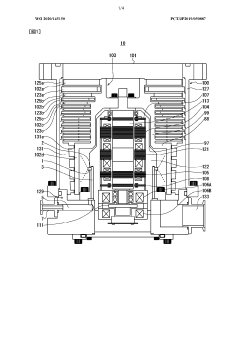

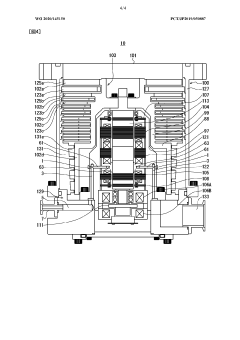

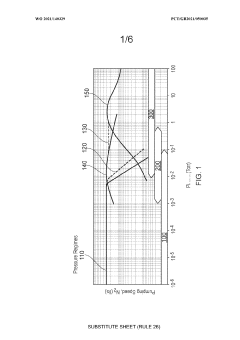

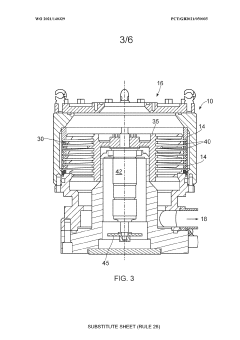

PatentWO2020145150A1

Innovation

- A vacuum pump design featuring a magnetic bearing system with liquid cooling, where liquid is injected to cool the rotor blades and shaft, and a vaporization-based cooling mechanism that efficiently manages heat dissipation, allowing continuous high-volume gas exhaust while preventing overheating.

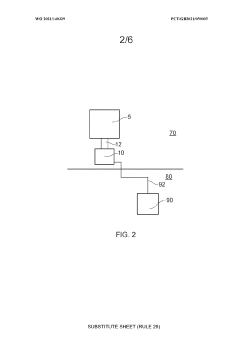

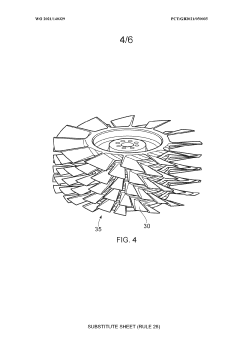

Vacuum pump, vacuum pump set for evacuating a semiconductor processing chamber and method of evacuating a semiconductor processing chamber

PatentWO2021140329A1

Innovation

- A vacuum pump with a rotor and stator design featuring angled blades on a helical path, magnetically levitated bearings, and high transparency perforated elements, allowing effective pumping between 1 mbar and 5 × 10^2 mbar, backed by a roots blower for enhanced performance across the transitional flow regime.

Energy Efficiency in AI Vacuum Pump Systems

Energy efficiency in AI vacuum pump systems has become a critical focus as the demand for artificial intelligence hardware continues to grow. The integration of vacuum pumps in AI systems, particularly in semiconductor manufacturing and advanced cooling solutions, necessitates a careful balance between performance and energy consumption. Recent advancements in pump design and control mechanisms have led to significant improvements in energy efficiency, with some systems achieving up to 30% reduction in power consumption compared to traditional models.

One of the key strategies for enhancing energy efficiency is the implementation of variable speed drives (VSDs) in vacuum pump systems. These drives allow for precise control of pump speed, adjusting it based on the real-time demands of the AI hardware. This dynamic operation ensures that the pump consumes only the energy required for the current workload, eliminating unnecessary power usage during periods of lower demand. Additionally, the use of advanced materials and coatings in pump construction has reduced friction and heat generation, further contributing to overall energy savings.

Intelligent pump management systems have also played a crucial role in optimizing energy consumption. These systems utilize machine learning algorithms to predict and adapt to changing operational requirements, ensuring that pumps operate at their most efficient points. By analyzing historical data and current conditions, these management systems can make real-time adjustments to pump parameters, maximizing efficiency without compromising performance.

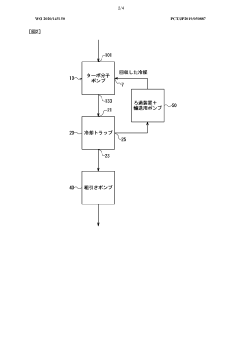

The development of hybrid vacuum systems, combining different pump technologies, has shown promising results in energy efficiency. For instance, the integration of turbomolecular pumps with backing pumps allows for a more efficient distribution of workload across different pressure ranges. This approach not only improves overall system efficiency but also extends the lifespan of individual components, reducing long-term energy and maintenance costs.

Heat recovery systems have emerged as an innovative solution for further improving energy efficiency in AI vacuum pump applications. These systems capture and repurpose the heat generated by vacuum pumps, utilizing it for other processes within the facility or for environmental control. This approach not only reduces the overall energy footprint of the AI hardware infrastructure but also contributes to broader sustainability goals.

As the field of AI hardware continues to evolve, the focus on energy-efficient vacuum pump systems is likely to intensify. Future developments may include the integration of renewable energy sources, such as solar or wind power, to offset the energy consumption of these critical components. Additionally, ongoing research into novel pump designs and materials promises to push the boundaries of efficiency even further, potentially revolutionizing the role of vacuum technology in AI hardware applications.

One of the key strategies for enhancing energy efficiency is the implementation of variable speed drives (VSDs) in vacuum pump systems. These drives allow for precise control of pump speed, adjusting it based on the real-time demands of the AI hardware. This dynamic operation ensures that the pump consumes only the energy required for the current workload, eliminating unnecessary power usage during periods of lower demand. Additionally, the use of advanced materials and coatings in pump construction has reduced friction and heat generation, further contributing to overall energy savings.

Intelligent pump management systems have also played a crucial role in optimizing energy consumption. These systems utilize machine learning algorithms to predict and adapt to changing operational requirements, ensuring that pumps operate at their most efficient points. By analyzing historical data and current conditions, these management systems can make real-time adjustments to pump parameters, maximizing efficiency without compromising performance.

The development of hybrid vacuum systems, combining different pump technologies, has shown promising results in energy efficiency. For instance, the integration of turbomolecular pumps with backing pumps allows for a more efficient distribution of workload across different pressure ranges. This approach not only improves overall system efficiency but also extends the lifespan of individual components, reducing long-term energy and maintenance costs.

Heat recovery systems have emerged as an innovative solution for further improving energy efficiency in AI vacuum pump applications. These systems capture and repurpose the heat generated by vacuum pumps, utilizing it for other processes within the facility or for environmental control. This approach not only reduces the overall energy footprint of the AI hardware infrastructure but also contributes to broader sustainability goals.

As the field of AI hardware continues to evolve, the focus on energy-efficient vacuum pump systems is likely to intensify. Future developments may include the integration of renewable energy sources, such as solar or wind power, to offset the energy consumption of these critical components. Additionally, ongoing research into novel pump designs and materials promises to push the boundaries of efficiency even further, potentially revolutionizing the role of vacuum technology in AI hardware applications.

Thermal Management in AI Hardware Vacuum Applications

Thermal management is a critical aspect of AI hardware vacuum applications, particularly in the context of vacuum pump systems. As AI hardware continues to advance in complexity and processing power, the need for efficient heat dissipation becomes increasingly paramount. Vacuum environments present unique challenges for thermal management due to the absence of convective heat transfer mechanisms typically relied upon in atmospheric conditions.

In AI hardware vacuum applications, the primary sources of heat generation include processors, memory modules, and power delivery components. These elements produce significant thermal energy during operation, which must be effectively managed to maintain optimal performance and prevent system failures. The vacuum environment limits the available cooling options, necessitating innovative approaches to heat dissipation.

One key strategy for thermal management in AI hardware vacuum applications is the implementation of conduction-based cooling systems. These systems utilize high thermal conductivity materials, such as copper or aluminum, to efficiently transfer heat from heat-generating components to designated heat sinks or cooling interfaces. Advanced thermal interface materials (TIMs) are employed to enhance thermal contact between components and heat spreaders, minimizing thermal resistance and improving overall heat transfer efficiency.

Another approach involves the integration of phase-change materials (PCMs) into the thermal management system. PCMs absorb and release thermal energy during phase transitions, effectively acting as thermal buffers to mitigate temperature fluctuations in AI hardware components. This technique is particularly valuable in vacuum environments where traditional air or liquid cooling methods are not feasible.

Radiation-based cooling techniques also play a crucial role in AI hardware vacuum applications. By optimizing the emissivity of component surfaces and incorporating radiative heat spreaders, excess thermal energy can be efficiently radiated away from critical components. This approach leverages the principles of thermal radiation to dissipate heat in the absence of convective cooling mechanisms.

Advanced thermal simulation and modeling tools are essential for optimizing thermal management strategies in AI hardware vacuum applications. These tools enable engineers to predict heat distribution, identify potential hotspots, and evaluate the effectiveness of various cooling solutions before physical implementation. By leveraging computational fluid dynamics (CFD) and finite element analysis (FEA), designers can iteratively refine thermal management systems to achieve optimal performance in vacuum environments.

As AI hardware continues to evolve, the development of novel materials and cooling technologies specifically tailored for vacuum applications remains an active area of research. Emerging solutions, such as two-phase cooling systems and micro-channel heat sinks, show promise in addressing the unique thermal challenges posed by AI hardware in vacuum environments. These advancements will be crucial in supporting the continued growth and performance improvements of AI systems operating in vacuum conditions.

In AI hardware vacuum applications, the primary sources of heat generation include processors, memory modules, and power delivery components. These elements produce significant thermal energy during operation, which must be effectively managed to maintain optimal performance and prevent system failures. The vacuum environment limits the available cooling options, necessitating innovative approaches to heat dissipation.

One key strategy for thermal management in AI hardware vacuum applications is the implementation of conduction-based cooling systems. These systems utilize high thermal conductivity materials, such as copper or aluminum, to efficiently transfer heat from heat-generating components to designated heat sinks or cooling interfaces. Advanced thermal interface materials (TIMs) are employed to enhance thermal contact between components and heat spreaders, minimizing thermal resistance and improving overall heat transfer efficiency.

Another approach involves the integration of phase-change materials (PCMs) into the thermal management system. PCMs absorb and release thermal energy during phase transitions, effectively acting as thermal buffers to mitigate temperature fluctuations in AI hardware components. This technique is particularly valuable in vacuum environments where traditional air or liquid cooling methods are not feasible.

Radiation-based cooling techniques also play a crucial role in AI hardware vacuum applications. By optimizing the emissivity of component surfaces and incorporating radiative heat spreaders, excess thermal energy can be efficiently radiated away from critical components. This approach leverages the principles of thermal radiation to dissipate heat in the absence of convective cooling mechanisms.

Advanced thermal simulation and modeling tools are essential for optimizing thermal management strategies in AI hardware vacuum applications. These tools enable engineers to predict heat distribution, identify potential hotspots, and evaluate the effectiveness of various cooling solutions before physical implementation. By leveraging computational fluid dynamics (CFD) and finite element analysis (FEA), designers can iteratively refine thermal management systems to achieve optimal performance in vacuum environments.

As AI hardware continues to evolve, the development of novel materials and cooling technologies specifically tailored for vacuum applications remains an active area of research. Emerging solutions, such as two-phase cooling systems and micro-channel heat sinks, show promise in addressing the unique thermal challenges posed by AI hardware in vacuum environments. These advancements will be crucial in supporting the continued growth and performance improvements of AI systems operating in vacuum conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!