The Role of Vacuum Pumps in 3D Printing of Ceramics

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic 3D Printing and Vacuum Pump Integration

The integration of vacuum pumps in ceramic 3D printing represents a significant advancement in additive manufacturing technology. This combination addresses several key challenges inherent in the ceramic 3D printing process, particularly in the areas of material handling, print quality, and structural integrity of the final product.

Vacuum pumps play a crucial role in the material deposition phase of ceramic 3D printing. By creating a controlled low-pressure environment, these pumps facilitate the precise and uniform distribution of ceramic slurries or pastes. This controlled deposition is essential for achieving high-resolution prints and complex geometries that are often required in ceramic manufacturing.

One of the primary benefits of incorporating vacuum technology is the reduction of air bubbles and voids within the printed structure. During the printing process, air can become trapped within the ceramic material, leading to weaknesses and potential defects in the final product. Vacuum pumps effectively remove these air pockets, resulting in denser, stronger, and more uniform ceramic parts.

The use of vacuum systems also enhances the layer adhesion in ceramic 3D printing. By applying negative pressure during the printing process, each new layer is more firmly bonded to the previous one. This improved interlayer adhesion contributes to the overall structural integrity of the printed object, reducing the risk of delamination and improving the mechanical properties of the final product.

Furthermore, vacuum technology aids in the post-processing stages of ceramic 3D printing. Many ceramic parts require a drying phase before sintering. Vacuum drying techniques can accelerate this process while ensuring even moisture removal, which is critical for preventing warping or cracking during the subsequent firing stage.

In the context of material handling, vacuum pumps contribute to the efficient management of ceramic slurries. They assist in the mixing and degassing of these materials prior to printing, ensuring a homogeneous composition and reducing the likelihood of print defects caused by material inconsistencies.

The integration of vacuum pumps also opens up possibilities for new ceramic formulations and printing techniques. For instance, it enables the use of lower viscosity slurries that would be challenging to work with in conventional ceramic 3D printing setups. This expanded material compatibility broadens the range of achievable properties and applications for 3D printed ceramics.

As the field of ceramic 3D printing continues to evolve, the role of vacuum pumps is likely to become increasingly sophisticated. Future developments may include more precise pressure control systems, integration with real-time monitoring technologies, and adaptive vacuum applications that respond to the specific requirements of different ceramic materials and print geometries.

Vacuum pumps play a crucial role in the material deposition phase of ceramic 3D printing. By creating a controlled low-pressure environment, these pumps facilitate the precise and uniform distribution of ceramic slurries or pastes. This controlled deposition is essential for achieving high-resolution prints and complex geometries that are often required in ceramic manufacturing.

One of the primary benefits of incorporating vacuum technology is the reduction of air bubbles and voids within the printed structure. During the printing process, air can become trapped within the ceramic material, leading to weaknesses and potential defects in the final product. Vacuum pumps effectively remove these air pockets, resulting in denser, stronger, and more uniform ceramic parts.

The use of vacuum systems also enhances the layer adhesion in ceramic 3D printing. By applying negative pressure during the printing process, each new layer is more firmly bonded to the previous one. This improved interlayer adhesion contributes to the overall structural integrity of the printed object, reducing the risk of delamination and improving the mechanical properties of the final product.

Furthermore, vacuum technology aids in the post-processing stages of ceramic 3D printing. Many ceramic parts require a drying phase before sintering. Vacuum drying techniques can accelerate this process while ensuring even moisture removal, which is critical for preventing warping or cracking during the subsequent firing stage.

In the context of material handling, vacuum pumps contribute to the efficient management of ceramic slurries. They assist in the mixing and degassing of these materials prior to printing, ensuring a homogeneous composition and reducing the likelihood of print defects caused by material inconsistencies.

The integration of vacuum pumps also opens up possibilities for new ceramic formulations and printing techniques. For instance, it enables the use of lower viscosity slurries that would be challenging to work with in conventional ceramic 3D printing setups. This expanded material compatibility broadens the range of achievable properties and applications for 3D printed ceramics.

As the field of ceramic 3D printing continues to evolve, the role of vacuum pumps is likely to become increasingly sophisticated. Future developments may include more precise pressure control systems, integration with real-time monitoring technologies, and adaptive vacuum applications that respond to the specific requirements of different ceramic materials and print geometries.

Market Analysis for Ceramic 3D Printing

The ceramic 3D printing market has been experiencing significant growth in recent years, driven by advancements in materials science and manufacturing technologies. This sector is positioned at the intersection of traditional ceramics manufacturing and additive manufacturing, offering unique opportunities for complex geometries and customized production.

The global ceramic 3D printing market size was valued at approximately $98 million in 2020 and is projected to reach $384 million by 2025, growing at a CAGR of 31.4% during the forecast period. This rapid growth is attributed to the increasing demand for ceramic 3D printed products in various industries, including healthcare, aerospace, automotive, and consumer goods.

In the healthcare sector, ceramic 3D printing is gaining traction for the production of dental implants, prosthetics, and bone scaffolds. The ability to create patient-specific designs with biocompatible ceramics is driving adoption in this field. The aerospace industry is leveraging ceramic 3D printing for the manufacture of lightweight, heat-resistant components, contributing to fuel efficiency and performance improvements in aircraft and spacecraft.

The automotive sector is exploring ceramic 3D printing for the production of high-performance engine components and sensors. The technology's capacity to create complex internal structures and optimize thermal properties is particularly valuable in this application. In the consumer goods market, ceramic 3D printing is being utilized for customized tableware, decorative items, and artistic sculptures, offering unique design possibilities and on-demand production capabilities.

Geographically, North America and Europe currently dominate the ceramic 3D printing market, owing to their advanced manufacturing infrastructure and strong research and development initiatives. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing investments in additive manufacturing technologies, and growing demand from emerging economies like China and India.

Key market trends include the development of new ceramic materials optimized for 3D printing, improvements in printing resolution and surface finish, and the integration of ceramic 3D printing into hybrid manufacturing processes. The role of vacuum pumps in ceramic 3D printing is becoming increasingly important, as they contribute to enhanced print quality, material consistency, and overall process efficiency.

The global ceramic 3D printing market size was valued at approximately $98 million in 2020 and is projected to reach $384 million by 2025, growing at a CAGR of 31.4% during the forecast period. This rapid growth is attributed to the increasing demand for ceramic 3D printed products in various industries, including healthcare, aerospace, automotive, and consumer goods.

In the healthcare sector, ceramic 3D printing is gaining traction for the production of dental implants, prosthetics, and bone scaffolds. The ability to create patient-specific designs with biocompatible ceramics is driving adoption in this field. The aerospace industry is leveraging ceramic 3D printing for the manufacture of lightweight, heat-resistant components, contributing to fuel efficiency and performance improvements in aircraft and spacecraft.

The automotive sector is exploring ceramic 3D printing for the production of high-performance engine components and sensors. The technology's capacity to create complex internal structures and optimize thermal properties is particularly valuable in this application. In the consumer goods market, ceramic 3D printing is being utilized for customized tableware, decorative items, and artistic sculptures, offering unique design possibilities and on-demand production capabilities.

Geographically, North America and Europe currently dominate the ceramic 3D printing market, owing to their advanced manufacturing infrastructure and strong research and development initiatives. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing investments in additive manufacturing technologies, and growing demand from emerging economies like China and India.

Key market trends include the development of new ceramic materials optimized for 3D printing, improvements in printing resolution and surface finish, and the integration of ceramic 3D printing into hybrid manufacturing processes. The role of vacuum pumps in ceramic 3D printing is becoming increasingly important, as they contribute to enhanced print quality, material consistency, and overall process efficiency.

Vacuum Pump Technology in Ceramic Additive Manufacturing

Vacuum pump technology plays a crucial role in the additive manufacturing of ceramics, particularly in the 3D printing process. The integration of vacuum systems in ceramic 3D printing has significantly enhanced the quality and precision of printed objects, addressing several challenges inherent to ceramic materials.

The primary function of vacuum pumps in ceramic 3D printing is to remove air and other gases from the printing environment. This process is essential for achieving optimal material properties and structural integrity in the final product. By creating a low-pressure environment, vacuum pumps help eliminate air bubbles and voids that can form during the printing process, which would otherwise compromise the strength and density of the printed ceramic components.

In the context of ceramic slurry-based 3D printing, vacuum technology is particularly valuable. It assists in the de-aeration of ceramic slurries before and during the printing process. This step is critical as it ensures the homogeneity of the material and prevents the formation of defects in the printed structure. The removal of entrapped air bubbles also contributes to improved surface finish and reduced porosity in the final product.

Vacuum systems are also employed in post-processing stages of ceramic 3D printing. After the initial printing, vacuum-assisted drying techniques can be used to remove residual moisture from the green body in a controlled manner. This process helps prevent cracking and warping during the subsequent sintering stage, thereby improving the overall dimensional accuracy of the printed parts.

The application of vacuum technology extends to the sintering process as well. Vacuum sintering furnaces are used to densify ceramic parts at high temperatures while maintaining a controlled atmosphere. This approach not only enhances the material properties but also allows for the production of ceramics with specific characteristics, such as high purity or controlled porosity.

Recent advancements in vacuum pump technology have led to the development of more efficient and precise systems tailored for ceramic 3D printing applications. These include the integration of smart control systems that can dynamically adjust vacuum levels based on the specific requirements of different ceramic materials and printing stages. Such innovations have expanded the range of printable ceramic materials and improved the overall quality of 3D printed ceramic components.

As the field of ceramic additive manufacturing continues to evolve, vacuum pump technology is expected to play an increasingly important role. Future developments may focus on further optimizing vacuum systems for specific ceramic compositions, enhancing energy efficiency, and integrating vacuum technology more seamlessly into automated 3D printing processes for large-scale production of complex ceramic parts.

The primary function of vacuum pumps in ceramic 3D printing is to remove air and other gases from the printing environment. This process is essential for achieving optimal material properties and structural integrity in the final product. By creating a low-pressure environment, vacuum pumps help eliminate air bubbles and voids that can form during the printing process, which would otherwise compromise the strength and density of the printed ceramic components.

In the context of ceramic slurry-based 3D printing, vacuum technology is particularly valuable. It assists in the de-aeration of ceramic slurries before and during the printing process. This step is critical as it ensures the homogeneity of the material and prevents the formation of defects in the printed structure. The removal of entrapped air bubbles also contributes to improved surface finish and reduced porosity in the final product.

Vacuum systems are also employed in post-processing stages of ceramic 3D printing. After the initial printing, vacuum-assisted drying techniques can be used to remove residual moisture from the green body in a controlled manner. This process helps prevent cracking and warping during the subsequent sintering stage, thereby improving the overall dimensional accuracy of the printed parts.

The application of vacuum technology extends to the sintering process as well. Vacuum sintering furnaces are used to densify ceramic parts at high temperatures while maintaining a controlled atmosphere. This approach not only enhances the material properties but also allows for the production of ceramics with specific characteristics, such as high purity or controlled porosity.

Recent advancements in vacuum pump technology have led to the development of more efficient and precise systems tailored for ceramic 3D printing applications. These include the integration of smart control systems that can dynamically adjust vacuum levels based on the specific requirements of different ceramic materials and printing stages. Such innovations have expanded the range of printable ceramic materials and improved the overall quality of 3D printed ceramic components.

As the field of ceramic additive manufacturing continues to evolve, vacuum pump technology is expected to play an increasingly important role. Future developments may focus on further optimizing vacuum systems for specific ceramic compositions, enhancing energy efficiency, and integrating vacuum technology more seamlessly into automated 3D printing processes for large-scale production of complex ceramic parts.

Current Vacuum Pump Solutions for Ceramic 3D Printing

01 Rotary vacuum pump designs

Various designs of rotary vacuum pumps have been developed to improve efficiency and performance. These designs may include modifications to rotor configurations, sealing mechanisms, and fluid flow paths to enhance vacuum generation and reduce power consumption.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.

- Specialized vacuum pumps for specific applications: Vacuum pumps have been developed for specific industrial and scientific applications. These specialized pumps are designed to meet unique requirements such as high vacuum levels, corrosive gas handling, or clean room compatibility. The tailored designs ensure optimal performance in diverse fields including semiconductor manufacturing, aerospace, and scientific research.

- Integration of vacuum pumps with other systems: Vacuum pumps are increasingly integrated with other systems to create more comprehensive solutions. This integration can involve combining pumps with control systems, monitoring devices, or other process equipment. Such integrated systems offer improved automation, better process control, and enhanced overall system efficiency in various industrial and scientific applications.

- Historical developments in vacuum pump technology: The evolution of vacuum pump technology spans several decades, with significant advancements in pump designs and operating principles. Historical patents showcase the progression from early mechanical pumps to more sophisticated designs, including improvements in sealing mechanisms, pump capacities, and overall efficiency. These developments have laid the foundation for modern vacuum pump technologies.

- Energy-efficient and environmentally friendly vacuum pumps: Recent innovations in vacuum pump technology focus on improving energy efficiency and reducing environmental impact. These advancements include the development of oil-free pumps, the use of more sustainable materials, and the implementation of energy-saving control systems. Such improvements contribute to reduced power consumption, lower maintenance requirements, and decreased environmental footprint in various industrial applications.

02 Improvements in reciprocating vacuum pumps

Advancements in reciprocating vacuum pump technology focus on enhancing piston designs, valve systems, and cylinder arrangements. These improvements aim to increase pumping capacity, reduce wear, and improve overall reliability in various industrial applications.Expand Specific Solutions03 Vacuum pump control systems

Modern vacuum pumps incorporate sophisticated control systems to optimize performance and energy efficiency. These systems may include sensors, variable speed drives, and intelligent algorithms to adjust pump operation based on demand and operating conditions.Expand Specific Solutions04 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps designed specifically for semiconductor manufacturing processes have been developed to meet the stringent requirements of clean room environments. These pumps often feature advanced materials, contamination control measures, and precise pressure control capabilities.Expand Specific Solutions05 Vacuum pump sealing and lubrication systems

Innovations in vacuum pump sealing and lubrication systems aim to improve pump performance, extend operational life, and reduce maintenance requirements. These advancements may include novel seal designs, lubricant formulations, and oil-free technologies for specific applications.Expand Specific Solutions

Key Players in Ceramic 3D Printing Industry

The vacuum pump market in 3D printing of ceramics is in a growth phase, driven by increasing adoption of additive manufacturing in various industries. The market size is expanding as more companies recognize the potential of ceramic 3D printing for producing complex, high-performance parts. Technologically, vacuum pumps for this application are becoming more sophisticated, with companies like Edwards Ltd., Pfeiffer Vacuum GmbH, and Edwards Vacuum LLC leading innovation. These firms are developing specialized pumps that can handle the unique requirements of ceramic 3D printing, such as precise pressure control and resistance to abrasive particles. The technology is maturing rapidly, with ongoing research at institutions like Xi'an Jiaotong University and Huazhong University of Science & Technology contributing to advancements in process optimization and material development.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump solutions specifically tailored for ceramic 3D printing applications. Their technology focuses on precise pressure control and contamination management, which are crucial for the successful printing of ceramic materials. Edwards' vacuum pumps utilize a combination of dry pumping technology and intelligent control systems to maintain optimal vacuum levels throughout the printing process. This approach ensures consistent material deposition and minimizes defects in the final ceramic parts. The company has also introduced adaptive pumping algorithms that can adjust vacuum levels in real-time based on the specific requirements of different ceramic materials and printing parameters[1][3].

Strengths: Highly specialized for ceramic 3D printing, precise pressure control, and adaptive algorithms. Weaknesses: Potentially higher cost due to specialized features, may require more maintenance for complex systems.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has developed a range of vacuum solutions for ceramic 3D printing, focusing on high-performance turbomolecular pumps and backing pump systems. Their technology emphasizes clean, oil-free vacuum environments, which are essential for maintaining the purity of ceramic materials during the printing process. Pfeiffer's pumps incorporate advanced rotor designs and magnetic bearings to achieve high pumping speeds and low vibration, crucial for precise material deposition in ceramic 3D printing. The company has also introduced smart vacuum control systems that integrate with 3D printers to optimize vacuum levels for different stages of the printing process, enhancing overall print quality and consistency[2][4].

Strengths: High-performance, oil-free vacuum systems, smart integration with 3D printers. Weaknesses: May be over-engineered for simpler ceramic printing applications, potentially higher initial investment.

Innovations in Vacuum Technology for Ceramics

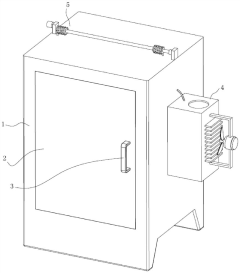

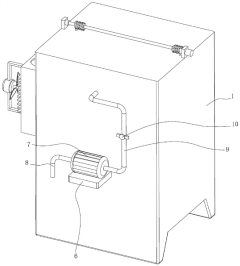

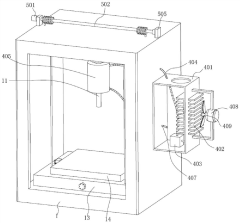

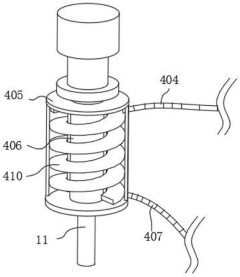

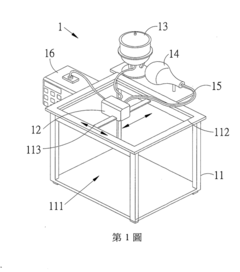

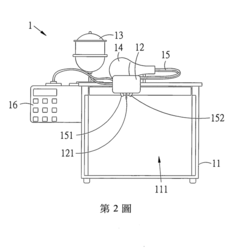

3D printing device capable of adjusting air pressure

PatentActiveCN113119461A

Innovation

- A 3D printing device with adjustable air pressure is designed. It uses a vacuum pump and vacuum valve to control the ambient air pressure, and achieves cooling and heat dissipation through a water tank and heat dissipation fins. A water pump and fan are used to circulate water for heat dissipation to avoid the impact of air flow on the product. At the same time, through The lifting component adjusts the height of the print head and the limit component facilitates installation and cleaning.

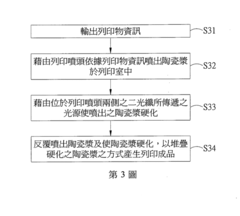

Ceramic 3D printing device and method thereof

PatentInactiveTW201545846A

Innovation

- Integration of optical fibers with the printing jet for improved precision and control during ceramic 3D printing.

- Strategic placement of the lighting unit and optical fibers to optimize the curing process of ceramic slurry.

- Compact and efficient design with the controller, storage tank, and lighting unit positioned around the printing room opening.

Material Considerations for Vacuum-Assisted Ceramic Printing

The selection of appropriate materials is crucial for successful vacuum-assisted ceramic 3D printing. The choice of ceramic materials significantly impacts the printing process, final product quality, and the effectiveness of vacuum assistance. Ceramic slurries used in this process must possess specific rheological properties to ensure proper flow through the nozzle and maintain shape after deposition.

Alumina (Al2O3) and zirconia (ZrO2) are commonly used materials in vacuum-assisted ceramic 3D printing due to their excellent mechanical properties and thermal stability. These materials are typically prepared as fine powders and mixed with binders and dispersants to create printable slurries. The particle size distribution of the ceramic powder plays a vital role in determining the slurry's viscosity and its behavior under vacuum conditions.

The binder system used in the ceramic slurry formulation must be compatible with vacuum-assisted printing. Water-based binders are often preferred due to their environmental friendliness and ease of removal. However, the use of vacuum during printing can lead to rapid evaporation of water, potentially causing clogging or inconsistent material flow. To mitigate this, additives such as glycerol or polyethylene glycol may be incorporated to control the drying rate.

Viscosity modifiers and dispersants are essential components in ceramic slurries for vacuum-assisted printing. These additives help maintain a stable suspension of ceramic particles and control the slurry's flow properties. The ideal viscosity should allow for smooth extrusion under normal conditions while being responsive to vacuum-induced changes in pressure.

The solid loading of the ceramic slurry is another critical factor. Higher solid content generally leads to better mechanical properties in the final product but can also increase viscosity, making printing more challenging. Balancing solid loading with printability is essential, especially when considering the effects of vacuum on material flow.

Porosity control is an important consideration in vacuum-assisted ceramic printing. The application of vacuum can help remove air bubbles from the printed structure, potentially leading to denser final products. However, some applications may require controlled porosity, necessitating careful material selection and process parameter optimization.

In conclusion, the material considerations for vacuum-assisted ceramic printing encompass a wide range of factors, from the choice of ceramic powders to the formulation of printable slurries. The interplay between material properties and vacuum effects must be carefully balanced to achieve optimal printing results and desired product characteristics.

Alumina (Al2O3) and zirconia (ZrO2) are commonly used materials in vacuum-assisted ceramic 3D printing due to their excellent mechanical properties and thermal stability. These materials are typically prepared as fine powders and mixed with binders and dispersants to create printable slurries. The particle size distribution of the ceramic powder plays a vital role in determining the slurry's viscosity and its behavior under vacuum conditions.

The binder system used in the ceramic slurry formulation must be compatible with vacuum-assisted printing. Water-based binders are often preferred due to their environmental friendliness and ease of removal. However, the use of vacuum during printing can lead to rapid evaporation of water, potentially causing clogging or inconsistent material flow. To mitigate this, additives such as glycerol or polyethylene glycol may be incorporated to control the drying rate.

Viscosity modifiers and dispersants are essential components in ceramic slurries for vacuum-assisted printing. These additives help maintain a stable suspension of ceramic particles and control the slurry's flow properties. The ideal viscosity should allow for smooth extrusion under normal conditions while being responsive to vacuum-induced changes in pressure.

The solid loading of the ceramic slurry is another critical factor. Higher solid content generally leads to better mechanical properties in the final product but can also increase viscosity, making printing more challenging. Balancing solid loading with printability is essential, especially when considering the effects of vacuum on material flow.

Porosity control is an important consideration in vacuum-assisted ceramic printing. The application of vacuum can help remove air bubbles from the printed structure, potentially leading to denser final products. However, some applications may require controlled porosity, necessitating careful material selection and process parameter optimization.

In conclusion, the material considerations for vacuum-assisted ceramic printing encompass a wide range of factors, from the choice of ceramic powders to the formulation of printable slurries. The interplay between material properties and vacuum effects must be carefully balanced to achieve optimal printing results and desired product characteristics.

Environmental Impact of Ceramic 3D Printing Processes

The environmental impact of ceramic 3D printing processes is a critical consideration as this technology continues to evolve and gain widespread adoption. The use of vacuum pumps in ceramic 3D printing plays a significant role in shaping the environmental footprint of these processes.

One of the primary environmental concerns associated with ceramic 3D printing is the generation of fine particulate matter during the printing process. Vacuum pumps are instrumental in mitigating this issue by creating a controlled environment that captures and contains these particles. This not only improves air quality in the immediate vicinity of the printer but also reduces the potential for harmful emissions to be released into the broader environment.

Energy consumption is another key factor in assessing the environmental impact of ceramic 3D printing. Vacuum pumps contribute to the overall energy usage of the printing system, but their role in improving process efficiency can lead to net energy savings. By maintaining optimal pressure conditions, vacuum pumps enable more precise control over material deposition, potentially reducing waste and the need for post-processing.

Water usage in ceramic 3D printing is often overlooked but can be substantial, particularly in processes that require slurry-based materials. Vacuum pumps assist in the efficient handling and recycling of these materials, potentially reducing water consumption and minimizing the discharge of contaminated wastewater.

The lifecycle of materials used in ceramic 3D printing is also influenced by vacuum pump technology. By enabling the use of finer powders and more complex material compositions, vacuum pumps can contribute to the development of more durable and longer-lasting ceramic products. This extended product lifespan can offset the environmental costs associated with production.

However, the environmental impact of vacuum pumps themselves must be considered. The production, maintenance, and eventual disposal of these components contribute to the overall environmental footprint of ceramic 3D printing systems. Manufacturers are increasingly focusing on developing more energy-efficient and durable vacuum pump technologies to address these concerns.

In the context of waste reduction, vacuum pumps play a crucial role in minimizing material loss during the printing process. By maintaining consistent pressure and material flow, they help ensure that ceramic materials are used more efficiently, reducing the amount of waste generated and the associated environmental impact of disposal.

As the ceramic 3D printing industry continues to grow, the role of vacuum pumps in shaping its environmental impact will likely become even more significant. Future developments in vacuum pump technology, such as the integration of smart controls and more sustainable materials, have the potential to further reduce the environmental footprint of ceramic 3D printing processes.

One of the primary environmental concerns associated with ceramic 3D printing is the generation of fine particulate matter during the printing process. Vacuum pumps are instrumental in mitigating this issue by creating a controlled environment that captures and contains these particles. This not only improves air quality in the immediate vicinity of the printer but also reduces the potential for harmful emissions to be released into the broader environment.

Energy consumption is another key factor in assessing the environmental impact of ceramic 3D printing. Vacuum pumps contribute to the overall energy usage of the printing system, but their role in improving process efficiency can lead to net energy savings. By maintaining optimal pressure conditions, vacuum pumps enable more precise control over material deposition, potentially reducing waste and the need for post-processing.

Water usage in ceramic 3D printing is often overlooked but can be substantial, particularly in processes that require slurry-based materials. Vacuum pumps assist in the efficient handling and recycling of these materials, potentially reducing water consumption and minimizing the discharge of contaminated wastewater.

The lifecycle of materials used in ceramic 3D printing is also influenced by vacuum pump technology. By enabling the use of finer powders and more complex material compositions, vacuum pumps can contribute to the development of more durable and longer-lasting ceramic products. This extended product lifespan can offset the environmental costs associated with production.

However, the environmental impact of vacuum pumps themselves must be considered. The production, maintenance, and eventual disposal of these components contribute to the overall environmental footprint of ceramic 3D printing systems. Manufacturers are increasingly focusing on developing more energy-efficient and durable vacuum pump technologies to address these concerns.

In the context of waste reduction, vacuum pumps play a crucial role in minimizing material loss during the printing process. By maintaining consistent pressure and material flow, they help ensure that ceramic materials are used more efficiently, reducing the amount of waste generated and the associated environmental impact of disposal.

As the ceramic 3D printing industry continues to grow, the role of vacuum pumps in shaping its environmental impact will likely become even more significant. Future developments in vacuum pump technology, such as the integration of smart controls and more sustainable materials, have the potential to further reduce the environmental footprint of ceramic 3D printing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!