Exploring Vacuum Pump Efficiency in Coastal Research Instruments

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution and Research Goals

Vacuum pump technology has undergone significant evolution since its inception in the 17th century. From early mechanical designs to modern high-efficiency systems, the progression has been driven by the need for improved performance in various scientific and industrial applications. In coastal research instruments, vacuum pumps play a crucial role in sample collection, analysis, and environmental monitoring.

The development of vacuum pumps can be traced through several key stages. Initially, piston-based designs dominated, followed by the introduction of rotary vane pumps in the early 20th century. The mid-20th century saw the emergence of turbomolecular pumps, which revolutionized high-vacuum applications. Recent decades have witnessed advancements in scroll pumps and dry pumps, addressing the need for oil-free operation in sensitive research environments.

In the context of coastal research instruments, the evolution of vacuum pump technology has been driven by specific requirements. These include the need for compact, portable designs suitable for field use, corrosion resistance to withstand marine environments, and energy efficiency to support long-term deployments. Additionally, the demand for higher vacuum levels and faster pumping speeds has pushed the boundaries of pump design and materials science.

The primary goal of current research in vacuum pump technology for coastal instruments is to enhance overall system efficiency. This encompasses several key objectives. Firstly, improving energy efficiency to extend battery life and reduce power consumption in remote locations. Secondly, increasing pumping speed and ultimate vacuum levels to enable more precise and rapid analysis of environmental samples. Thirdly, developing more robust and reliable designs capable of withstanding harsh coastal conditions, including exposure to salt spray and temperature fluctuations.

Another critical research goal is the miniaturization of vacuum pumps without compromising performance. This aim is particularly relevant for portable coastal research instruments, where size and weight constraints are significant factors. Researchers are exploring novel materials and pump geometries to achieve this balance between compactness and efficiency.

Furthermore, there is a growing focus on developing "smart" vacuum pumps with integrated sensors and control systems. These advanced pumps can adapt to changing environmental conditions, optimize their operation based on real-time data, and provide valuable diagnostic information to researchers. This intelligence not only enhances the reliability of coastal research instruments but also contributes to more accurate and consistent data collection.

The development of vacuum pumps can be traced through several key stages. Initially, piston-based designs dominated, followed by the introduction of rotary vane pumps in the early 20th century. The mid-20th century saw the emergence of turbomolecular pumps, which revolutionized high-vacuum applications. Recent decades have witnessed advancements in scroll pumps and dry pumps, addressing the need for oil-free operation in sensitive research environments.

In the context of coastal research instruments, the evolution of vacuum pump technology has been driven by specific requirements. These include the need for compact, portable designs suitable for field use, corrosion resistance to withstand marine environments, and energy efficiency to support long-term deployments. Additionally, the demand for higher vacuum levels and faster pumping speeds has pushed the boundaries of pump design and materials science.

The primary goal of current research in vacuum pump technology for coastal instruments is to enhance overall system efficiency. This encompasses several key objectives. Firstly, improving energy efficiency to extend battery life and reduce power consumption in remote locations. Secondly, increasing pumping speed and ultimate vacuum levels to enable more precise and rapid analysis of environmental samples. Thirdly, developing more robust and reliable designs capable of withstanding harsh coastal conditions, including exposure to salt spray and temperature fluctuations.

Another critical research goal is the miniaturization of vacuum pumps without compromising performance. This aim is particularly relevant for portable coastal research instruments, where size and weight constraints are significant factors. Researchers are exploring novel materials and pump geometries to achieve this balance between compactness and efficiency.

Furthermore, there is a growing focus on developing "smart" vacuum pumps with integrated sensors and control systems. These advanced pumps can adapt to changing environmental conditions, optimize their operation based on real-time data, and provide valuable diagnostic information to researchers. This intelligence not only enhances the reliability of coastal research instruments but also contributes to more accurate and consistent data collection.

Coastal Research Instrument Market Analysis

The coastal research instrument market has been experiencing significant growth in recent years, driven by increasing concerns about climate change, rising sea levels, and the need for accurate environmental monitoring. This market segment encompasses a wide range of instruments used for oceanographic research, marine biology, coastal erosion studies, and water quality monitoring. The demand for these instruments is primarily fueled by government agencies, research institutions, and environmental organizations seeking to better understand and protect coastal ecosystems.

Vacuum pumps play a crucial role in many coastal research instruments, particularly in water sampling devices, sediment analysis equipment, and atmospheric monitoring systems. The efficiency of these pumps directly impacts the accuracy and reliability of data collection, making them a critical component in the overall performance of coastal research instruments.

Market analysis indicates that the global coastal research instrument market is expected to grow steadily over the next five years. This growth is attributed to several factors, including increased government funding for marine research, growing awareness of the importance of coastal ecosystems, and technological advancements in sensor technologies and data processing capabilities.

The market for vacuum pumps specifically designed for coastal research applications is relatively niche but shows promising growth potential. Manufacturers are focusing on developing more energy-efficient and corrosion-resistant pumps to meet the demanding requirements of coastal environments. The trend towards miniaturization and portability in research instruments is also driving innovation in vacuum pump design, with a focus on reducing size and weight without compromising performance.

Key players in the coastal research instrument market include established scientific equipment manufacturers as well as specialized marine technology companies. These companies are increasingly investing in research and development to improve the efficiency and reliability of their instruments, including vacuum pump systems.

The market is characterized by a high degree of customization, as different research applications often require specific instrument configurations. This has led to the emergence of modular instrument designs that allow for greater flexibility and adaptability in the field. Vacuum pump manufacturers are responding to this trend by developing more versatile pump systems that can be easily integrated into various instrument platforms.

Geographically, North America and Europe dominate the coastal research instrument market, owing to their extensive coastlines and well-established marine research programs. However, the Asia-Pacific region is emerging as a significant market, driven by increasing investments in coastal management and marine conservation efforts in countries like China, Japan, and Australia.

Vacuum pumps play a crucial role in many coastal research instruments, particularly in water sampling devices, sediment analysis equipment, and atmospheric monitoring systems. The efficiency of these pumps directly impacts the accuracy and reliability of data collection, making them a critical component in the overall performance of coastal research instruments.

Market analysis indicates that the global coastal research instrument market is expected to grow steadily over the next five years. This growth is attributed to several factors, including increased government funding for marine research, growing awareness of the importance of coastal ecosystems, and technological advancements in sensor technologies and data processing capabilities.

The market for vacuum pumps specifically designed for coastal research applications is relatively niche but shows promising growth potential. Manufacturers are focusing on developing more energy-efficient and corrosion-resistant pumps to meet the demanding requirements of coastal environments. The trend towards miniaturization and portability in research instruments is also driving innovation in vacuum pump design, with a focus on reducing size and weight without compromising performance.

Key players in the coastal research instrument market include established scientific equipment manufacturers as well as specialized marine technology companies. These companies are increasingly investing in research and development to improve the efficiency and reliability of their instruments, including vacuum pump systems.

The market is characterized by a high degree of customization, as different research applications often require specific instrument configurations. This has led to the emergence of modular instrument designs that allow for greater flexibility and adaptability in the field. Vacuum pump manufacturers are responding to this trend by developing more versatile pump systems that can be easily integrated into various instrument platforms.

Geographically, North America and Europe dominate the coastal research instrument market, owing to their extensive coastlines and well-established marine research programs. However, the Asia-Pacific region is emerging as a significant market, driven by increasing investments in coastal management and marine conservation efforts in countries like China, Japan, and Australia.

Vacuum Pump Challenges in Marine Environments

Vacuum pumps play a crucial role in coastal research instruments, providing essential suction for various scientific applications. However, operating these pumps in marine environments presents unique challenges that can significantly impact their efficiency and reliability. The corrosive nature of saltwater and high humidity levels in coastal areas pose substantial threats to vacuum pump performance and longevity.

One of the primary challenges is the accelerated corrosion of pump components due to exposure to salt-laden air and moisture. This corrosion can lead to premature wear of internal parts, compromising the pump's ability to maintain consistent vacuum levels. Additionally, the accumulation of salt deposits on surfaces can interfere with moving parts, reducing overall efficiency and increasing energy consumption.

Humidity poses another significant obstacle for vacuum pumps in coastal settings. The presence of excess moisture in the air can lead to condensation within the pump system, potentially causing water contamination in the pump oil or other lubricants. This contamination not only reduces the pump's efficiency but also increases the risk of mechanical failures and shortens the pump's operational lifespan.

Temperature fluctuations common in coastal areas can also affect vacuum pump performance. Extreme heat can cause overheating issues, while cold temperatures may lead to condensation problems and increased viscosity of lubricants. These temperature-related challenges necessitate careful consideration of pump design and materials to ensure optimal functioning across a wide range of environmental conditions.

The ingress of particulate matter, such as sand and salt crystals, presents yet another challenge for vacuum pumps in coastal research applications. These particles can cause abrasive wear on internal components and clog filters, leading to reduced pumping capacity and increased maintenance requirements. Designing effective filtration systems that can withstand the harsh coastal environment while maintaining pump efficiency is a significant engineering challenge.

Electrical components of vacuum pumps are particularly vulnerable in marine environments. Saltwater spray and high humidity can lead to short circuits, corrosion of electrical contacts, and degradation of insulation materials. This necessitates the use of specialized, marine-grade electrical components and robust sealing techniques to protect sensitive electronics from environmental damage.

Addressing these challenges requires innovative approaches in pump design, material selection, and protective measures. The development of corrosion-resistant alloys, advanced sealing technologies, and intelligent control systems that can adapt to changing environmental conditions are key areas of focus for improving vacuum pump efficiency in coastal research instruments.

One of the primary challenges is the accelerated corrosion of pump components due to exposure to salt-laden air and moisture. This corrosion can lead to premature wear of internal parts, compromising the pump's ability to maintain consistent vacuum levels. Additionally, the accumulation of salt deposits on surfaces can interfere with moving parts, reducing overall efficiency and increasing energy consumption.

Humidity poses another significant obstacle for vacuum pumps in coastal settings. The presence of excess moisture in the air can lead to condensation within the pump system, potentially causing water contamination in the pump oil or other lubricants. This contamination not only reduces the pump's efficiency but also increases the risk of mechanical failures and shortens the pump's operational lifespan.

Temperature fluctuations common in coastal areas can also affect vacuum pump performance. Extreme heat can cause overheating issues, while cold temperatures may lead to condensation problems and increased viscosity of lubricants. These temperature-related challenges necessitate careful consideration of pump design and materials to ensure optimal functioning across a wide range of environmental conditions.

The ingress of particulate matter, such as sand and salt crystals, presents yet another challenge for vacuum pumps in coastal research applications. These particles can cause abrasive wear on internal components and clog filters, leading to reduced pumping capacity and increased maintenance requirements. Designing effective filtration systems that can withstand the harsh coastal environment while maintaining pump efficiency is a significant engineering challenge.

Electrical components of vacuum pumps are particularly vulnerable in marine environments. Saltwater spray and high humidity can lead to short circuits, corrosion of electrical contacts, and degradation of insulation materials. This necessitates the use of specialized, marine-grade electrical components and robust sealing techniques to protect sensitive electronics from environmental damage.

Addressing these challenges requires innovative approaches in pump design, material selection, and protective measures. The development of corrosion-resistant alloys, advanced sealing technologies, and intelligent control systems that can adapt to changing environmental conditions are key areas of focus for improving vacuum pump efficiency in coastal research instruments.

Current Vacuum Pump Efficiency Solutions

01 Improved rotor design for vacuum pumps

Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping capacity. Advanced rotor designs can also contribute to better sealing and reduced leakage, further improving overall pump efficiency.- Improved rotor design for vacuum pumps: Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping capacity. Advanced rotor designs can also help in reducing wear and extending the pump's lifespan.

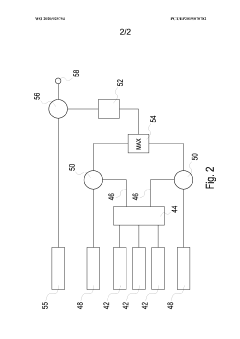

- Multi-stage vacuum pump systems: Implementing multi-stage vacuum pump systems can enhance overall efficiency. By combining different types of pumps or multiple pumping stages, these systems can achieve higher vacuum levels and improved pumping speeds. This approach allows for optimized performance across various pressure ranges and applications.

- Advanced sealing and lubrication techniques: Developing advanced sealing and lubrication techniques can significantly boost vacuum pump efficiency. This includes using innovative sealing materials, optimizing seal designs, and implementing improved lubrication systems. These enhancements reduce friction, minimize leakage, and ensure smooth operation of the pump components.

- Energy recovery and heat management systems: Incorporating energy recovery and heat management systems can improve the overall efficiency of vacuum pumps. These systems can capture and reuse waste heat, reduce power consumption, and optimize the pump's thermal performance. Advanced cooling techniques and energy-efficient motors also contribute to improved efficiency.

- Smart control and monitoring systems: Implementing smart control and monitoring systems can enhance vacuum pump efficiency through real-time optimization. These systems use sensors, data analytics, and adaptive algorithms to adjust pump operation based on changing conditions. This approach enables predictive maintenance, energy optimization, and improved overall performance.

02 Advanced sealing technologies

Implementing advanced sealing technologies in vacuum pumps can greatly enhance their efficiency. This involves using innovative materials and designs for seals to minimize leakage and maintain optimal vacuum levels. Improved sealing can reduce power consumption, extend pump lifespan, and ensure consistent performance across various operating conditions.Expand Specific Solutions03 Intelligent control systems for vacuum pumps

Incorporating intelligent control systems can optimize vacuum pump operation and efficiency. These systems can adjust pump speed, monitor performance parameters, and implement predictive maintenance strategies. By dynamically adapting to changing conditions and requirements, smart control systems can significantly reduce energy consumption and improve overall pump efficiency.Expand Specific Solutions04 Multi-stage vacuum pump configurations

Utilizing multi-stage vacuum pump configurations can enhance overall system efficiency. By combining different pump types or stages optimized for specific pressure ranges, these configurations can achieve higher ultimate vacuum levels and improved pumping speeds. This approach allows for more efficient operation across a wider range of pressure conditions.Expand Specific Solutions05 Energy recovery and heat management systems

Implementing energy recovery and heat management systems can significantly boost vacuum pump efficiency. These systems can capture and repurpose waste heat generated during pump operation, reducing overall energy consumption. Additionally, effective heat management can prevent overheating, extend component lifespan, and maintain optimal performance under various operating conditions.Expand Specific Solutions

Key Vacuum Pump Manufacturers and Researchers

The vacuum pump efficiency market for coastal research instruments is in a growth phase, driven by increasing demand for advanced oceanographic and environmental monitoring. The market size is expanding as coastal research intensifies globally. Technologically, the field is moderately mature, with ongoing innovations focused on improving efficiency and reliability. Key players like Agilent Technologies, Edwards Ltd., and ANEST IWATA Corp. are leading development efforts, while research institutions such as Korea Research Institute of Standards & Science and National Institute of Environmental Research contribute to advancements. The competitive landscape is characterized by a mix of established manufacturers and specialized research entities, fostering both collaboration and competition in pushing the boundaries of vacuum pump technology for coastal applications.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed advanced vacuum pump systems specifically designed for coastal research instruments. Their technology focuses on improving efficiency through innovative turbomolecular pumps with magnetic bearings, reducing friction and power consumption. These pumps achieve high vacuum levels (10^-8 mbar) rapidly, crucial for sensitive oceanographic measurements[1]. Agilent's pumps incorporate smart control systems that adjust pumping speed based on environmental conditions, optimizing performance in varying coastal environments[3]. The company has also introduced corrosion-resistant materials and coatings to protect pumps from salt spray and humid conditions typical in coastal research settings[5].

Strengths: High vacuum efficiency, corrosion resistance, and smart control systems. Weaknesses: Potentially higher initial cost and complexity compared to simpler pump designs.

Edwards Ltd.

Technical Solution: Edwards Ltd. has pioneered dry vacuum pump technology for coastal research applications. Their GXS dry screw pump series offers oil-free operation, crucial for preventing sample contamination in sensitive marine research[2]. These pumps utilize advanced screw mechanisms that provide high pumping speeds (up to 3400 m³/h) while maintaining low power consumption. Edwards has implemented a unique temperature management system that allows the pumps to operate efficiently in humid coastal environments without the risk of condensation[4]. Additionally, their pumps feature remote monitoring capabilities, enabling researchers to track performance and conduct preventive maintenance, ensuring reliability during extended offshore operations[6].

Strengths: Oil-free operation, high pumping speeds, and remote monitoring capabilities. Weaknesses: May require more frequent maintenance due to the absence of lubricating oil.

Innovative Vacuum Pump Design Patents

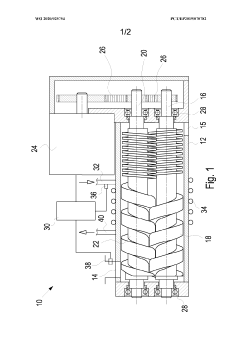

Vacuum pump

PatentWO2020025754A1

Innovation

- A dry-compressing two-shaft vacuum pump with a control device and sensors to detect operating variables, correlating these with critical parameters using a neural network or regression model to dynamically adjust rotor speed, eliminating the need for expensive sensors and ensuring optimal performance without safety margins.

Vacuum pump

PatentInactiveEP1668255A1

Innovation

- Incorporating a regenerative pumping mechanism downstream of a molecular drag pumping mechanism, where the rotor element of the molecular drag mechanism surrounds the rotor elements of the regenerative mechanism, to reduce power consumption and improve performance while maintaining pump size.

Environmental Impact of Vacuum Pump Operations

The environmental impact of vacuum pump operations in coastal research instruments is a critical consideration that extends beyond mere efficiency concerns. These pumps, while essential for various scientific applications, can have significant ecological implications if not properly managed.

Vacuum pumps used in coastal research often release exhaust gases and particulate matter into the atmosphere. The composition of these emissions varies depending on the pump type and the specific research application. Oil-sealed rotary vane pumps, for instance, may release oil vapor, which can contribute to air pollution and potentially harm local flora and fauna. Dry pumps, while generally cleaner, still produce heat and noise that can affect the surrounding ecosystem.

Water consumption is another environmental factor to consider. Some vacuum pump systems require water for cooling or as a sealant, which can strain local water resources, especially in water-scarce coastal areas. The disposal of this water, potentially contaminated with oils or other chemicals, poses additional environmental risks if not properly treated.

Energy consumption is a significant environmental concern associated with vacuum pump operations. These devices often require substantial power to operate, contributing to increased electricity demand and, by extension, greenhouse gas emissions if the energy source is not renewable. The carbon footprint of vacuum pump usage in coastal research can be considerable, particularly for long-term or large-scale projects.

Noise pollution from vacuum pumps is an often-overlooked environmental impact. In sensitive coastal ecosystems, excessive noise can disrupt wildlife behavior, affecting feeding, mating, and migration patterns of various species. This is particularly problematic for marine mammals and birds that rely on acoustic communication.

The disposal of vacuum pump components and consumables also presents environmental challenges. Oil, filters, and worn-out parts may contain hazardous materials that require special handling and disposal procedures to prevent soil and water contamination in coastal areas.

To mitigate these environmental impacts, researchers and instrument designers are increasingly focusing on developing more eco-friendly vacuum pump technologies. This includes the use of variable speed drives to optimize energy consumption, the implementation of noise reduction technologies, and the adoption of dry pump technologies that eliminate the need for oil and reduce the risk of contamination.

Furthermore, the integration of recycling and waste management protocols specific to vacuum pump operations is becoming standard practice in coastal research facilities. This includes proper disposal of oils and filters, as well as the recycling of metal components from decommissioned pumps.

In conclusion, while vacuum pumps are indispensable tools in coastal research, their environmental impact must be carefully managed. Balancing the need for scientific advancement with environmental stewardship requires ongoing innovation in pump technology and operational practices.

Vacuum pumps used in coastal research often release exhaust gases and particulate matter into the atmosphere. The composition of these emissions varies depending on the pump type and the specific research application. Oil-sealed rotary vane pumps, for instance, may release oil vapor, which can contribute to air pollution and potentially harm local flora and fauna. Dry pumps, while generally cleaner, still produce heat and noise that can affect the surrounding ecosystem.

Water consumption is another environmental factor to consider. Some vacuum pump systems require water for cooling or as a sealant, which can strain local water resources, especially in water-scarce coastal areas. The disposal of this water, potentially contaminated with oils or other chemicals, poses additional environmental risks if not properly treated.

Energy consumption is a significant environmental concern associated with vacuum pump operations. These devices often require substantial power to operate, contributing to increased electricity demand and, by extension, greenhouse gas emissions if the energy source is not renewable. The carbon footprint of vacuum pump usage in coastal research can be considerable, particularly for long-term or large-scale projects.

Noise pollution from vacuum pumps is an often-overlooked environmental impact. In sensitive coastal ecosystems, excessive noise can disrupt wildlife behavior, affecting feeding, mating, and migration patterns of various species. This is particularly problematic for marine mammals and birds that rely on acoustic communication.

The disposal of vacuum pump components and consumables also presents environmental challenges. Oil, filters, and worn-out parts may contain hazardous materials that require special handling and disposal procedures to prevent soil and water contamination in coastal areas.

To mitigate these environmental impacts, researchers and instrument designers are increasingly focusing on developing more eco-friendly vacuum pump technologies. This includes the use of variable speed drives to optimize energy consumption, the implementation of noise reduction technologies, and the adoption of dry pump technologies that eliminate the need for oil and reduce the risk of contamination.

Furthermore, the integration of recycling and waste management protocols specific to vacuum pump operations is becoming standard practice in coastal research facilities. This includes proper disposal of oils and filters, as well as the recycling of metal components from decommissioned pumps.

In conclusion, while vacuum pumps are indispensable tools in coastal research, their environmental impact must be carefully managed. Balancing the need for scientific advancement with environmental stewardship requires ongoing innovation in pump technology and operational practices.

Corrosion Resistance in Coastal Vacuum Systems

Corrosion resistance is a critical factor in the design and operation of coastal vacuum systems, particularly for research instruments deployed in marine environments. The harsh conditions of coastal areas, characterized by high humidity, salt spray, and fluctuating temperatures, pose significant challenges to the longevity and performance of vacuum pumps and associated equipment.

To address these challenges, manufacturers and researchers have developed various strategies to enhance corrosion resistance in coastal vacuum systems. One primary approach involves the use of corrosion-resistant materials in the construction of pump components. Stainless steel alloys, such as 316L and duplex grades, have proven effective due to their high resistance to chloride-induced corrosion. Additionally, titanium and its alloys are increasingly utilized for their exceptional corrosion resistance in marine environments.

Surface treatments and coatings play a crucial role in protecting vacuum system components from corrosive elements. Advanced coating technologies, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), are employed to apply thin, protective layers of materials like titanium nitride or diamond-like carbon. These coatings not only enhance corrosion resistance but also improve wear resistance and reduce friction, contributing to overall system efficiency.

Innovative design features have been incorporated to minimize exposure to corrosive agents. For instance, sealed bearing systems and labyrinth seals help prevent the ingress of salt-laden air into critical components. Some manufacturers have developed specialized "coastal packages" for their vacuum pumps, which include additional protective measures such as corrosion-resistant paint finishes and enhanced sealing systems.

Maintenance strategies tailored for coastal environments are essential for preserving the integrity of vacuum systems. Regular cleaning and flushing procedures using demineralized water or specialized cleaning agents help remove salt deposits and other corrosive substances. Implementing rigorous maintenance schedules and conducting frequent inspections can identify early signs of corrosion, allowing for timely intervention and prevention of more severe damage.

Research into advanced materials and coatings continues to drive improvements in corrosion resistance. Nanotechnology-based solutions, such as self-healing coatings and nanocomposite materials, show promise in providing superior protection against corrosion in coastal environments. These innovations aim to extend the operational life of vacuum systems and reduce maintenance requirements, ultimately enhancing the reliability and efficiency of coastal research instruments.

To address these challenges, manufacturers and researchers have developed various strategies to enhance corrosion resistance in coastal vacuum systems. One primary approach involves the use of corrosion-resistant materials in the construction of pump components. Stainless steel alloys, such as 316L and duplex grades, have proven effective due to their high resistance to chloride-induced corrosion. Additionally, titanium and its alloys are increasingly utilized for their exceptional corrosion resistance in marine environments.

Surface treatments and coatings play a crucial role in protecting vacuum system components from corrosive elements. Advanced coating technologies, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), are employed to apply thin, protective layers of materials like titanium nitride or diamond-like carbon. These coatings not only enhance corrosion resistance but also improve wear resistance and reduce friction, contributing to overall system efficiency.

Innovative design features have been incorporated to minimize exposure to corrosive agents. For instance, sealed bearing systems and labyrinth seals help prevent the ingress of salt-laden air into critical components. Some manufacturers have developed specialized "coastal packages" for their vacuum pumps, which include additional protective measures such as corrosion-resistant paint finishes and enhanced sealing systems.

Maintenance strategies tailored for coastal environments are essential for preserving the integrity of vacuum systems. Regular cleaning and flushing procedures using demineralized water or specialized cleaning agents help remove salt deposits and other corrosive substances. Implementing rigorous maintenance schedules and conducting frequent inspections can identify early signs of corrosion, allowing for timely intervention and prevention of more severe damage.

Research into advanced materials and coatings continues to drive improvements in corrosion resistance. Nanotechnology-based solutions, such as self-healing coatings and nanocomposite materials, show promise in providing superior protection against corrosion in coastal environments. These innovations aim to extend the operational life of vacuum systems and reduce maintenance requirements, ultimately enhancing the reliability and efficiency of coastal research instruments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!