Vacuum Pump Design for High-Efficiency Desulfurization Processes

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Desulfurization Vacuum Pump Evolution and Objectives

Vacuum pump technology for desulfurization processes has undergone significant evolution over the past decades, driven by the increasing demand for more efficient and environmentally friendly industrial operations. The journey began with simple mechanical pumps, which were limited in their ability to handle corrosive gases and achieve high vacuum levels required for effective desulfurization.

As environmental regulations became more stringent, the need for more advanced vacuum pump designs became apparent. This led to the development of liquid ring pumps, which offered improved resistance to corrosive gases and better performance in handling two-phase flows. However, these pumps still faced challenges in terms of energy efficiency and maintenance requirements.

The next major leap came with the introduction of dry screw pumps, which eliminated the need for sealing fluids and provided better vacuum performance. These pumps offered significant advantages in terms of reduced contamination risks and lower operating costs. However, they still faced limitations in handling large volumes of gas and achieving ultra-high vacuum levels.

Recent years have seen the emergence of hybrid pump designs, combining the strengths of different technologies to address the specific challenges of desulfurization processes. These innovations have focused on improving energy efficiency, reducing maintenance needs, and enhancing the ability to handle corrosive and particulate-laden gases.

The current objectives in vacuum pump design for desulfurization processes are multifaceted. Firstly, there is a push towards even greater energy efficiency, aiming to reduce the overall environmental impact and operational costs of desulfurization plants. This includes the development of advanced motor and control systems that can optimize pump performance based on real-time process conditions.

Secondly, there is a focus on improving the durability and reliability of pump components exposed to harsh desulfurization environments. This involves research into new materials and coatings that can withstand corrosive gases and high temperatures while maintaining performance over extended periods.

Another key objective is to enhance the flexibility of vacuum pumps to handle varying gas compositions and flow rates encountered in different desulfurization applications. This requires the development of adaptive pump designs that can maintain optimal performance across a wide range of operating conditions.

Lastly, there is a growing emphasis on integrating smart technologies and predictive maintenance capabilities into vacuum pump systems. This aims to reduce downtime, optimize maintenance schedules, and improve overall plant efficiency through real-time monitoring and data analytics.

As environmental regulations became more stringent, the need for more advanced vacuum pump designs became apparent. This led to the development of liquid ring pumps, which offered improved resistance to corrosive gases and better performance in handling two-phase flows. However, these pumps still faced challenges in terms of energy efficiency and maintenance requirements.

The next major leap came with the introduction of dry screw pumps, which eliminated the need for sealing fluids and provided better vacuum performance. These pumps offered significant advantages in terms of reduced contamination risks and lower operating costs. However, they still faced limitations in handling large volumes of gas and achieving ultra-high vacuum levels.

Recent years have seen the emergence of hybrid pump designs, combining the strengths of different technologies to address the specific challenges of desulfurization processes. These innovations have focused on improving energy efficiency, reducing maintenance needs, and enhancing the ability to handle corrosive and particulate-laden gases.

The current objectives in vacuum pump design for desulfurization processes are multifaceted. Firstly, there is a push towards even greater energy efficiency, aiming to reduce the overall environmental impact and operational costs of desulfurization plants. This includes the development of advanced motor and control systems that can optimize pump performance based on real-time process conditions.

Secondly, there is a focus on improving the durability and reliability of pump components exposed to harsh desulfurization environments. This involves research into new materials and coatings that can withstand corrosive gases and high temperatures while maintaining performance over extended periods.

Another key objective is to enhance the flexibility of vacuum pumps to handle varying gas compositions and flow rates encountered in different desulfurization applications. This requires the development of adaptive pump designs that can maintain optimal performance across a wide range of operating conditions.

Lastly, there is a growing emphasis on integrating smart technologies and predictive maintenance capabilities into vacuum pump systems. This aims to reduce downtime, optimize maintenance schedules, and improve overall plant efficiency through real-time monitoring and data analytics.

Market Analysis for Advanced Desulfurization Technologies

The global market for advanced desulfurization technologies is experiencing significant growth, driven by stringent environmental regulations and increasing awareness of air pollution's impact on public health. The desulfurization market, particularly in the power generation and industrial sectors, is projected to expand substantially over the next decade. This growth is primarily attributed to the rising demand for cleaner energy production and the need to comply with stricter emission standards worldwide.

In the power generation sector, coal-fired power plants remain a significant contributor to sulfur dioxide emissions. However, the implementation of flue gas desulfurization (FGD) systems has become increasingly prevalent. The market for FGD technologies is expected to grow as developing countries modernize their power infrastructure and developed nations upgrade existing facilities to meet more stringent environmental standards.

The industrial sector, including oil refineries, chemical plants, and metal processing facilities, represents another major market for desulfurization technologies. As these industries face mounting pressure to reduce their environmental footprint, the demand for efficient and cost-effective desulfurization solutions continues to rise.

Geographically, Asia-Pacific is emerging as the largest market for desulfurization technologies, with China and India leading the way due to their rapid industrialization and increasing focus on environmental protection. North America and Europe, while more mature markets, are still seeing steady growth as they transition towards cleaner energy sources and implement stricter emission controls.

The market is characterized by a mix of established players and innovative startups. Large industrial conglomerates with diversified portfolios often dominate the market, leveraging their extensive resources and established customer bases. However, there is a growing trend of specialized companies focusing on niche desulfurization technologies, particularly in areas such as catalytic processes and advanced sorbent materials.

Technological advancements are driving market dynamics, with a focus on improving efficiency, reducing operational costs, and minimizing waste generation. Innovations in areas such as regenerative processes, nanocatalysts, and membrane-based separation are opening new opportunities for market growth and differentiation.

The economic viability of desulfurization technologies remains a critical factor influencing market adoption. While the initial capital investment for advanced systems can be substantial, the long-term benefits in terms of regulatory compliance, operational efficiency, and potential for byproduct recovery are increasingly recognized by industry stakeholders.

In the power generation sector, coal-fired power plants remain a significant contributor to sulfur dioxide emissions. However, the implementation of flue gas desulfurization (FGD) systems has become increasingly prevalent. The market for FGD technologies is expected to grow as developing countries modernize their power infrastructure and developed nations upgrade existing facilities to meet more stringent environmental standards.

The industrial sector, including oil refineries, chemical plants, and metal processing facilities, represents another major market for desulfurization technologies. As these industries face mounting pressure to reduce their environmental footprint, the demand for efficient and cost-effective desulfurization solutions continues to rise.

Geographically, Asia-Pacific is emerging as the largest market for desulfurization technologies, with China and India leading the way due to their rapid industrialization and increasing focus on environmental protection. North America and Europe, while more mature markets, are still seeing steady growth as they transition towards cleaner energy sources and implement stricter emission controls.

The market is characterized by a mix of established players and innovative startups. Large industrial conglomerates with diversified portfolios often dominate the market, leveraging their extensive resources and established customer bases. However, there is a growing trend of specialized companies focusing on niche desulfurization technologies, particularly in areas such as catalytic processes and advanced sorbent materials.

Technological advancements are driving market dynamics, with a focus on improving efficiency, reducing operational costs, and minimizing waste generation. Innovations in areas such as regenerative processes, nanocatalysts, and membrane-based separation are opening new opportunities for market growth and differentiation.

The economic viability of desulfurization technologies remains a critical factor influencing market adoption. While the initial capital investment for advanced systems can be substantial, the long-term benefits in terms of regulatory compliance, operational efficiency, and potential for byproduct recovery are increasingly recognized by industry stakeholders.

Current Challenges in High-Efficiency Vacuum Pump Design

The design of high-efficiency vacuum pumps for desulfurization processes faces several significant challenges. One of the primary issues is the corrosive nature of the gases involved in the desulfurization process. Sulfur-containing compounds can be highly reactive and corrosive, leading to accelerated wear and degradation of pump components. This necessitates the use of specialized materials and coatings that can withstand these harsh conditions, which often comes at a higher cost and may impact overall pump efficiency.

Another challenge lies in maintaining consistent performance across varying operating conditions. Desulfurization processes can experience fluctuations in gas composition, temperature, and pressure. Vacuum pumps must be designed to operate efficiently and reliably across this range of conditions, which requires sophisticated control systems and adaptive technologies. This adaptability often comes at the expense of increased complexity and potential reliability issues.

Energy efficiency remains a critical concern in vacuum pump design for desulfurization. The process typically requires high vacuum levels, which demands significant energy input. Improving the energy efficiency of these pumps without compromising their performance is a delicate balance that engineers continue to grapple with. This challenge is further compounded by the need to meet increasingly stringent environmental regulations and reduce overall energy consumption in industrial processes.

Sealing technology presents another hurdle in high-efficiency vacuum pump design. Effective seals are crucial to maintain the required vacuum levels and prevent contamination. However, traditional sealing methods often introduce friction, which can reduce pump efficiency and increase wear. Developing advanced sealing solutions that minimize friction while ensuring a tight seal under varying conditions is an ongoing challenge for pump designers.

The handling of particulate matter in the gas stream poses additional difficulties. Desulfurization processes can generate fine particles that may enter the vacuum system. These particles can cause abrasion, clog small passages, and reduce overall pump efficiency. Designing pumps with effective filtration systems or particle-tolerant mechanisms without significantly impacting pumping speed or efficiency is a complex engineering task.

Lastly, the integration of smart technologies and predictive maintenance capabilities into vacuum pump systems presents both opportunities and challenges. While these technologies can potentially improve pump performance and longevity, they also introduce new complexities in terms of data management, sensor reliability, and system integration. Balancing the benefits of these advanced features with the need for robust, reliable operation in industrial settings remains a significant challenge in the field of vacuum pump design for desulfurization processes.

Another challenge lies in maintaining consistent performance across varying operating conditions. Desulfurization processes can experience fluctuations in gas composition, temperature, and pressure. Vacuum pumps must be designed to operate efficiently and reliably across this range of conditions, which requires sophisticated control systems and adaptive technologies. This adaptability often comes at the expense of increased complexity and potential reliability issues.

Energy efficiency remains a critical concern in vacuum pump design for desulfurization. The process typically requires high vacuum levels, which demands significant energy input. Improving the energy efficiency of these pumps without compromising their performance is a delicate balance that engineers continue to grapple with. This challenge is further compounded by the need to meet increasingly stringent environmental regulations and reduce overall energy consumption in industrial processes.

Sealing technology presents another hurdle in high-efficiency vacuum pump design. Effective seals are crucial to maintain the required vacuum levels and prevent contamination. However, traditional sealing methods often introduce friction, which can reduce pump efficiency and increase wear. Developing advanced sealing solutions that minimize friction while ensuring a tight seal under varying conditions is an ongoing challenge for pump designers.

The handling of particulate matter in the gas stream poses additional difficulties. Desulfurization processes can generate fine particles that may enter the vacuum system. These particles can cause abrasion, clog small passages, and reduce overall pump efficiency. Designing pumps with effective filtration systems or particle-tolerant mechanisms without significantly impacting pumping speed or efficiency is a complex engineering task.

Lastly, the integration of smart technologies and predictive maintenance capabilities into vacuum pump systems presents both opportunities and challenges. While these technologies can potentially improve pump performance and longevity, they also introduce new complexities in terms of data management, sensor reliability, and system integration. Balancing the benefits of these advanced features with the need for robust, reliable operation in industrial settings remains a significant challenge in the field of vacuum pump design for desulfurization processes.

State-of-the-Art Vacuum Pump Solutions for Desulfurization

01 Improved rotor design for vacuum pumps

Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping capacity. Advanced rotor designs can also contribute to better sealing and reduced wear, leading to improved overall pump performance and longevity.- Improved rotor design for enhanced efficiency: Vacuum pump efficiency can be increased through optimized rotor designs. This includes modifications to rotor geometry, surface treatments, and material selection to reduce friction and improve sealing. Advanced rotor configurations can lead to better compression ratios and reduced power consumption.

- Multi-stage pump systems for higher efficiency: Implementing multi-stage pump designs can significantly improve overall vacuum pump efficiency. By combining different pump types or multiple stages of the same pump type, these systems can achieve higher vacuum levels and better performance across a wider range of operating conditions.

- Advanced control systems and variable speed drives: Incorporating sophisticated control systems and variable speed drives can optimize vacuum pump operation. These technologies allow for real-time adjustments to pump speed and performance based on demand, resulting in improved energy efficiency and reduced wear on components.

- Heat management and recovery systems: Efficient heat management and recovery systems can significantly enhance vacuum pump efficiency. This includes improved cooling mechanisms, thermal insulation, and the integration of heat recovery systems to utilize waste heat for other processes, thereby increasing overall system efficiency.

- Novel sealing and lubrication technologies: Developing and implementing advanced sealing and lubrication technologies can boost vacuum pump efficiency. This includes the use of innovative materials and designs for seals, as well as optimized lubrication systems that reduce friction and extend component life while maintaining high performance.

02 Innovative sealing mechanisms

Developing new sealing mechanisms or improving existing ones can greatly enhance vacuum pump efficiency. This involves creating better seals between moving parts, reducing leakage, and maintaining optimal pressure differentials. Advanced sealing technologies can minimize power consumption, increase pumping speed, and improve the overall vacuum quality achieved by the pump.Expand Specific Solutions03 Integration of smart control systems

Incorporating intelligent control systems and sensors into vacuum pumps can optimize their operation in real-time. These systems can adjust pump parameters based on changing conditions, manage power consumption, and predict maintenance needs. Smart controls contribute to improved efficiency by ensuring the pump operates at its optimal point under various conditions.Expand Specific Solutions04 Advanced cooling and heat management

Implementing sophisticated cooling systems and heat management techniques can significantly enhance vacuum pump efficiency. This includes designing better heat dissipation mechanisms, using advanced materials with superior thermal properties, and optimizing the pump's internal flow to reduce heat generation. Effective heat management allows the pump to operate at higher speeds and for longer durations without performance degradation.Expand Specific Solutions05 Multi-stage and hybrid pump designs

Developing multi-stage or hybrid vacuum pump designs can offer improved efficiency across a wider range of operating conditions. These designs combine different pumping mechanisms or stages to optimize performance at various pressure levels. By leveraging the strengths of different pump types, these innovative designs can achieve higher efficiency and broader applicability in various industrial processes.Expand Specific Solutions

Key Manufacturers in Desulfurization Equipment Industry

The vacuum pump design for high-efficiency desulfurization processes is in a mature stage of development, with a competitive market dominated by established players. The global desulfurization market is projected to reach significant size, driven by stringent environmental regulations and increasing industrial applications. Key players like Edwards Vacuum, ExxonMobil Technology & Engineering, and Mitsubishi Power are at the forefront of technological advancements. These companies, along with others such as Haldor Topsøe and China Petroleum & Chemical Corp., are investing heavily in R&D to improve pump efficiency and reduce operational costs. The technology's maturity is evident in the diverse range of solutions offered by companies across different industries, from oil and gas to power generation.

Haldor Topsøe A/S

Technical Solution: Haldor Topsøe A/S has developed innovative vacuum pump solutions tailored for high-efficiency desulfurization processes. Their technology focuses on hybrid vacuum systems that combine the benefits of liquid ring and dry screw pumps. These pumps feature a unique two-stage design with an optimized liquid ring first stage for handling wet gases and a dry screw second stage for achieving deep vacuum levels. Haldor Topsøe's pumps incorporate advanced materials such as silicon carbide and specialized coatings to resist corrosion from sulfur compounds[7]. The company has also implemented a smart lubrication system that extends pump life and reduces maintenance requirements[8].

Strengths: Versatile performance in wet and dry conditions, corrosion-resistant design, and low maintenance requirements. Weaknesses: Potentially complex system integration, may have higher upfront costs compared to single-technology pumps.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach to vacuum pump design for desulfurization processes. Their technology integrates high-efficiency liquid ring vacuum pumps with advanced materials resistant to sulfur compounds. Sinopec's pumps feature innovative impeller designs that enhance gas handling capacity while reducing power consumption. The company has also implemented a dual-stage system that combines liquid ring and dry screw technologies, allowing for better performance across a wide range of operating conditions[2]. Additionally, Sinopec has developed a heat recovery system that utilizes waste heat from the vacuum pumps to improve overall process efficiency[5].

Strengths: Integrated approach combining multiple technologies, high efficiency in varied conditions, and effective heat recovery. Weaknesses: Complex system may require more maintenance, potentially higher capital costs.

Innovative Patents in High-Efficiency Desulfurization Pumps

DESULFURIZATION SYSTEM

PatentActiveID2021PID00296A

Innovation

- A desulfurization system design with an inlet wider than the absorption column diameter and a flow control member to divert gas flow towards the center, using materials resistant to corrosion and abrasion only where necessary, thereby maintaining high liquid density and reducing the absorption column's height and pump power.

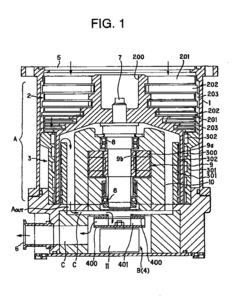

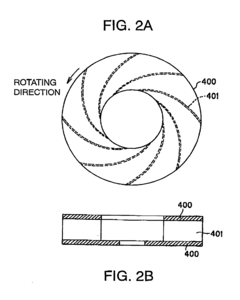

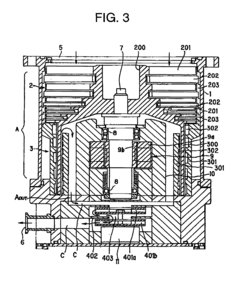

Vacuum pump

PatentInactiveUS20020098092A1

Innovation

- A vacuum pump design featuring a compound-type pump construction with a turbo molecular pump mechanism and a spiral pump mechanism, where the spiral pump mechanism can independently control its rotation speed to adjust the backing pressure and process pressure in the chamber, eliminating the need for conductance valves and nitrogen gas introduction systems.

Environmental Regulations Impacting Desulfurization Processes

Environmental regulations play a crucial role in shaping the landscape of desulfurization processes, including the design and implementation of vacuum pump systems for high-efficiency operations. These regulations are continuously evolving to address the growing concerns over air quality and environmental protection.

In the United States, the Environmental Protection Agency (EPA) has established stringent standards for sulfur dioxide (SO2) emissions under the Clean Air Act. The National Ambient Air Quality Standards (NAAQS) for SO2 have been progressively tightened, with the current 1-hour standard set at 75 parts per billion (ppb). This has led to increased pressure on industries to adopt more effective desulfurization technologies, including advanced vacuum pump designs.

The European Union has implemented similar regulations through its Industrial Emissions Directive (IED). This directive sets emission limit values for various pollutants, including SO2, and requires the use of Best Available Techniques (BAT) in industrial processes. For large combustion plants, the SO2 emission limit can be as low as 200 mg/Nm³, depending on the fuel type and plant capacity.

In China, the government has introduced the "Blue Sky Defense" action plan, which aims to significantly reduce air pollution. This plan includes strict emission standards for SO2, with some regions implementing even more stringent local regulations. The national standard for thermal power plants, for instance, limits SO2 emissions to 35 mg/m³.

These regulations have a direct impact on vacuum pump design for desulfurization processes. Manufacturers are now required to develop pumps that can achieve higher removal efficiencies while maintaining operational stability and energy efficiency. This has led to innovations in materials science, with corrosion-resistant alloys being developed to withstand the harsh chemical environment of desulfurization systems.

Furthermore, regulations are increasingly focusing on the overall environmental impact of desulfurization processes. This includes not only the direct emissions but also the energy consumption and waste generation associated with these systems. As a result, vacuum pump designs are now being optimized for energy efficiency, with variable speed drives and advanced control systems becoming more common.

The regulatory landscape also influences the choice of desulfurization technologies. While wet scrubbers have been the traditional choice, dry and semi-dry systems are gaining popularity due to their lower water consumption and reduced wastewater generation. This shift is partly driven by water conservation regulations, which indirectly affect vacuum pump design considerations.

As global efforts to combat climate change intensify, future regulations are likely to become even more stringent. This may include the integration of carbon capture technologies with desulfurization processes, potentially leading to new challenges and opportunities in vacuum pump design. The industry must therefore remain agile and innovative to meet these evolving regulatory demands while maintaining operational efficiency and cost-effectiveness.

In the United States, the Environmental Protection Agency (EPA) has established stringent standards for sulfur dioxide (SO2) emissions under the Clean Air Act. The National Ambient Air Quality Standards (NAAQS) for SO2 have been progressively tightened, with the current 1-hour standard set at 75 parts per billion (ppb). This has led to increased pressure on industries to adopt more effective desulfurization technologies, including advanced vacuum pump designs.

The European Union has implemented similar regulations through its Industrial Emissions Directive (IED). This directive sets emission limit values for various pollutants, including SO2, and requires the use of Best Available Techniques (BAT) in industrial processes. For large combustion plants, the SO2 emission limit can be as low as 200 mg/Nm³, depending on the fuel type and plant capacity.

In China, the government has introduced the "Blue Sky Defense" action plan, which aims to significantly reduce air pollution. This plan includes strict emission standards for SO2, with some regions implementing even more stringent local regulations. The national standard for thermal power plants, for instance, limits SO2 emissions to 35 mg/m³.

These regulations have a direct impact on vacuum pump design for desulfurization processes. Manufacturers are now required to develop pumps that can achieve higher removal efficiencies while maintaining operational stability and energy efficiency. This has led to innovations in materials science, with corrosion-resistant alloys being developed to withstand the harsh chemical environment of desulfurization systems.

Furthermore, regulations are increasingly focusing on the overall environmental impact of desulfurization processes. This includes not only the direct emissions but also the energy consumption and waste generation associated with these systems. As a result, vacuum pump designs are now being optimized for energy efficiency, with variable speed drives and advanced control systems becoming more common.

The regulatory landscape also influences the choice of desulfurization technologies. While wet scrubbers have been the traditional choice, dry and semi-dry systems are gaining popularity due to their lower water consumption and reduced wastewater generation. This shift is partly driven by water conservation regulations, which indirectly affect vacuum pump design considerations.

As global efforts to combat climate change intensify, future regulations are likely to become even more stringent. This may include the integration of carbon capture technologies with desulfurization processes, potentially leading to new challenges and opportunities in vacuum pump design. The industry must therefore remain agile and innovative to meet these evolving regulatory demands while maintaining operational efficiency and cost-effectiveness.

Energy Efficiency Considerations in Vacuum Pump Design

Energy efficiency is a critical consideration in the design of vacuum pumps for high-efficiency desulfurization processes. The optimization of energy consumption in these systems directly impacts operational costs and overall process efficiency. Vacuum pump design for desulfurization applications must balance the need for high performance with energy conservation to achieve sustainable and cost-effective operations.

One of the primary factors influencing energy efficiency in vacuum pump design is the selection of appropriate pump technology. Different types of vacuum pumps, such as liquid ring, dry screw, and rotary vane pumps, offer varying levels of energy efficiency depending on the specific requirements of the desulfurization process. For instance, dry screw pumps often provide higher energy efficiency compared to liquid ring pumps in certain applications due to their ability to operate without sealing fluid, reducing power consumption associated with fluid handling.

The sizing and capacity of the vacuum pump system also play a crucial role in energy efficiency. Oversized pumps can lead to unnecessary energy consumption, while undersized pumps may struggle to maintain the required vacuum levels, resulting in process inefficiencies. Proper sizing based on accurate process flow calculations and consideration of potential fluctuations in demand is essential for optimizing energy usage.

Advanced control systems and variable speed drives (VSDs) have emerged as key technologies for enhancing energy efficiency in vacuum pump operations. VSDs allow pumps to adjust their speed and power consumption based on real-time process demands, avoiding the energy waste associated with constant-speed operation. Intelligent control algorithms can further optimize pump performance by predicting and responding to changes in process conditions, ensuring that energy is used only when and where it is needed.

Heat recovery systems present another opportunity for improving overall energy efficiency in vacuum pump design for desulfurization processes. The heat generated during pump operation can be captured and repurposed for other process needs, such as preheating feed streams or supporting auxiliary heating requirements. This approach not only reduces energy waste but also contributes to the overall thermal efficiency of the desulfurization plant.

Material selection and component design also contribute to energy efficiency in vacuum pumps. Low-friction materials and advanced bearing technologies can reduce mechanical losses, while optimized impeller designs can improve gas handling efficiency. Additionally, the integration of high-efficiency motors, such as IE4 or IE5 rated units, can significantly reduce electrical energy consumption compared to standard motor options.

In conclusion, energy efficiency considerations in vacuum pump design for high-efficiency desulfurization processes encompass a wide range of factors, from fundamental technology selection to advanced control strategies and heat recovery systems. By addressing these aspects comprehensively, designers can create vacuum pump solutions that not only meet the demanding requirements of desulfurization processes but also contribute to sustainable and economically viable operations.

One of the primary factors influencing energy efficiency in vacuum pump design is the selection of appropriate pump technology. Different types of vacuum pumps, such as liquid ring, dry screw, and rotary vane pumps, offer varying levels of energy efficiency depending on the specific requirements of the desulfurization process. For instance, dry screw pumps often provide higher energy efficiency compared to liquid ring pumps in certain applications due to their ability to operate without sealing fluid, reducing power consumption associated with fluid handling.

The sizing and capacity of the vacuum pump system also play a crucial role in energy efficiency. Oversized pumps can lead to unnecessary energy consumption, while undersized pumps may struggle to maintain the required vacuum levels, resulting in process inefficiencies. Proper sizing based on accurate process flow calculations and consideration of potential fluctuations in demand is essential for optimizing energy usage.

Advanced control systems and variable speed drives (VSDs) have emerged as key technologies for enhancing energy efficiency in vacuum pump operations. VSDs allow pumps to adjust their speed and power consumption based on real-time process demands, avoiding the energy waste associated with constant-speed operation. Intelligent control algorithms can further optimize pump performance by predicting and responding to changes in process conditions, ensuring that energy is used only when and where it is needed.

Heat recovery systems present another opportunity for improving overall energy efficiency in vacuum pump design for desulfurization processes. The heat generated during pump operation can be captured and repurposed for other process needs, such as preheating feed streams or supporting auxiliary heating requirements. This approach not only reduces energy waste but also contributes to the overall thermal efficiency of the desulfurization plant.

Material selection and component design also contribute to energy efficiency in vacuum pumps. Low-friction materials and advanced bearing technologies can reduce mechanical losses, while optimized impeller designs can improve gas handling efficiency. Additionally, the integration of high-efficiency motors, such as IE4 or IE5 rated units, can significantly reduce electrical energy consumption compared to standard motor options.

In conclusion, energy efficiency considerations in vacuum pump design for high-efficiency desulfurization processes encompass a wide range of factors, from fundamental technology selection to advanced control strategies and heat recovery systems. By addressing these aspects comprehensively, designers can create vacuum pump solutions that not only meet the demanding requirements of desulfurization processes but also contribute to sustainable and economically viable operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!