Exploring Vacuum Pump Use in High-Resolution Nanostructure Lithography

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanostructure Lithography Vacuum Pump Evolution

The evolution of vacuum pump technology in nanostructure lithography has been a critical factor in advancing high-resolution fabrication techniques. Initially, basic mechanical pumps were used to create low-pressure environments for early lithography processes. These pumps, while effective for macro-scale applications, were insufficient for the precision required in nanoscale fabrication.

As the demand for smaller feature sizes increased, the need for higher vacuum levels became apparent. This led to the introduction of turbomolecular pumps in the 1980s, which significantly improved the vacuum quality in lithography chambers. Turbomolecular pumps operate on the principle of imparting momentum to gas molecules, effectively removing them from the system at a molecular level.

The 1990s saw the integration of cryogenic pumps into lithography systems. These pumps utilize extremely low temperatures to condense and trap gas molecules, creating ultra-high vacuum environments. This development was crucial for extreme ultraviolet (EUV) lithography, which requires near-perfect vacuum conditions to prevent absorption of EUV light by residual gases.

In the early 2000s, the focus shifted towards improving pump reliability and reducing contamination. Dry pumps, which operate without oil, became increasingly popular. These pumps eliminated the risk of oil backstreaming, a significant source of contamination in nanoscale fabrication processes.

The mid-2000s brought advancements in multi-stage pumping systems. These systems combined different pump technologies in series, optimizing vacuum performance at various pressure ranges. For instance, a typical configuration might include a dry pump for rough vacuum, followed by a turbomolecular pump for high vacuum, and finally a cryogenic pump for ultra-high vacuum.

Recent years have seen the development of smart pumping systems. These incorporate sensors and control algorithms to dynamically adjust pumping parameters based on process requirements. Such systems optimize energy consumption and extend equipment lifespan while maintaining precise vacuum levels.

Looking forward, research is focused on developing pumps with even higher pumping speeds and lower ultimate pressures. There is also a growing interest in compact, integrated vacuum solutions that can be seamlessly incorporated into next-generation lithography tools, supporting the ongoing miniaturization trend in semiconductor manufacturing.

As the demand for smaller feature sizes increased, the need for higher vacuum levels became apparent. This led to the introduction of turbomolecular pumps in the 1980s, which significantly improved the vacuum quality in lithography chambers. Turbomolecular pumps operate on the principle of imparting momentum to gas molecules, effectively removing them from the system at a molecular level.

The 1990s saw the integration of cryogenic pumps into lithography systems. These pumps utilize extremely low temperatures to condense and trap gas molecules, creating ultra-high vacuum environments. This development was crucial for extreme ultraviolet (EUV) lithography, which requires near-perfect vacuum conditions to prevent absorption of EUV light by residual gases.

In the early 2000s, the focus shifted towards improving pump reliability and reducing contamination. Dry pumps, which operate without oil, became increasingly popular. These pumps eliminated the risk of oil backstreaming, a significant source of contamination in nanoscale fabrication processes.

The mid-2000s brought advancements in multi-stage pumping systems. These systems combined different pump technologies in series, optimizing vacuum performance at various pressure ranges. For instance, a typical configuration might include a dry pump for rough vacuum, followed by a turbomolecular pump for high vacuum, and finally a cryogenic pump for ultra-high vacuum.

Recent years have seen the development of smart pumping systems. These incorporate sensors and control algorithms to dynamically adjust pumping parameters based on process requirements. Such systems optimize energy consumption and extend equipment lifespan while maintaining precise vacuum levels.

Looking forward, research is focused on developing pumps with even higher pumping speeds and lower ultimate pressures. There is also a growing interest in compact, integrated vacuum solutions that can be seamlessly incorporated into next-generation lithography tools, supporting the ongoing miniaturization trend in semiconductor manufacturing.

Market Demand for High-Resolution Nanostructures

The market demand for high-resolution nanostructures has been experiencing significant growth in recent years, driven by advancements in various industries such as semiconductor manufacturing, nanotechnology, and materials science. This demand is primarily fueled by the increasing need for miniaturization and improved performance in electronic devices, as well as the development of novel materials and applications at the nanoscale.

In the semiconductor industry, the push for smaller and more powerful chips has led to a surge in demand for high-resolution nanostructures. As transistor sizes continue to shrink, manufacturers require more precise and intricate lithography techniques to create these nanoscale features. This trend is expected to continue as the industry moves towards 3nm and beyond process nodes, driving the need for advanced lithography solutions that can produce high-resolution nanostructures.

The nanotechnology sector is another major contributor to the growing market demand. Research institutions and companies are increasingly focusing on developing nanostructures for applications in areas such as energy storage, drug delivery systems, and environmental remediation. These applications require precise control over nanostructure dimensions and properties, further driving the demand for high-resolution fabrication techniques.

Materials science is also playing a crucial role in shaping the market demand for high-resolution nanostructures. The development of metamaterials, nanocomposites, and other advanced materials relies heavily on the ability to create and manipulate structures at the nanoscale. This has led to increased investment in research and development of high-resolution fabrication methods, including advanced lithography techniques.

The healthcare and biomedical sectors are emerging as significant drivers of demand for high-resolution nanostructures. Applications such as biosensors, lab-on-a-chip devices, and targeted drug delivery systems require precise nanostructures to achieve their desired functionality. As these fields continue to advance, the demand for high-resolution fabrication techniques is expected to grow substantially.

In the optics and photonics industry, high-resolution nanostructures are becoming increasingly important for the development of advanced optical components, such as metamaterial lenses and photonic crystals. These applications require precise control over nanostructure geometry and optical properties, driving the need for high-resolution fabrication methods.

The global market for high-resolution nanostructures is projected to expand significantly in the coming years, with some estimates suggesting a compound annual growth rate (CAGR) in the double digits. This growth is expected to be driven by continued advancements in technology, increasing adoption of nanotechnology across various industries, and the development of new applications that require precise nanoscale structures.

In the semiconductor industry, the push for smaller and more powerful chips has led to a surge in demand for high-resolution nanostructures. As transistor sizes continue to shrink, manufacturers require more precise and intricate lithography techniques to create these nanoscale features. This trend is expected to continue as the industry moves towards 3nm and beyond process nodes, driving the need for advanced lithography solutions that can produce high-resolution nanostructures.

The nanotechnology sector is another major contributor to the growing market demand. Research institutions and companies are increasingly focusing on developing nanostructures for applications in areas such as energy storage, drug delivery systems, and environmental remediation. These applications require precise control over nanostructure dimensions and properties, further driving the demand for high-resolution fabrication techniques.

Materials science is also playing a crucial role in shaping the market demand for high-resolution nanostructures. The development of metamaterials, nanocomposites, and other advanced materials relies heavily on the ability to create and manipulate structures at the nanoscale. This has led to increased investment in research and development of high-resolution fabrication methods, including advanced lithography techniques.

The healthcare and biomedical sectors are emerging as significant drivers of demand for high-resolution nanostructures. Applications such as biosensors, lab-on-a-chip devices, and targeted drug delivery systems require precise nanostructures to achieve their desired functionality. As these fields continue to advance, the demand for high-resolution fabrication techniques is expected to grow substantially.

In the optics and photonics industry, high-resolution nanostructures are becoming increasingly important for the development of advanced optical components, such as metamaterial lenses and photonic crystals. These applications require precise control over nanostructure geometry and optical properties, driving the need for high-resolution fabrication methods.

The global market for high-resolution nanostructures is projected to expand significantly in the coming years, with some estimates suggesting a compound annual growth rate (CAGR) in the double digits. This growth is expected to be driven by continued advancements in technology, increasing adoption of nanotechnology across various industries, and the development of new applications that require precise nanoscale structures.

Current Vacuum Pump Challenges in Nanolithography

Vacuum pumps play a crucial role in high-resolution nanostructure lithography, yet they face several significant challenges in this advanced application. One of the primary issues is maintaining ultra-high vacuum levels consistently over extended periods. Nanolithography processes often require pressures as low as 10^-9 Torr or lower, which pushes the limits of current vacuum pump technologies.

The miniaturization trend in semiconductor manufacturing has led to increasingly stringent cleanliness requirements. Conventional oil-based pumps risk contaminating the delicate nanostructures with hydrocarbon residues, necessitating the development and implementation of oil-free pump designs. However, these oil-free alternatives often struggle to achieve the same level of vacuum performance as their oil-based counterparts.

Another challenge lies in managing pump-induced vibrations. Even minute vibrations can significantly impact the precision of nanolithography processes, potentially leading to defects in the fabricated nanostructures. This necessitates advanced vibration isolation systems and pump designs that minimize mechanical disturbances.

Heat generation and dissipation present additional hurdles. High-performance vacuum pumps generate considerable heat during operation, which can affect the stability of the lithography environment. Efficient cooling mechanisms must be integrated without compromising the pump's performance or introducing additional vibrations.

The demand for faster pump-down times to improve throughput in semiconductor manufacturing clashes with the need for stable, ultra-high vacuum conditions. Balancing these conflicting requirements poses a significant engineering challenge for vacuum pump designers and manufacturers.

Reliability and maintenance issues also come to the fore in nanolithography applications. The extreme operating conditions and the critical nature of the processes demand pumps with exceptional longevity and minimal downtime. However, achieving this level of reliability while maintaining the required performance characteristics remains a formidable task.

Lastly, the integration of vacuum pumps into increasingly complex and automated lithography systems presents its own set of challenges. Pumps must be compatible with advanced control systems, offer real-time monitoring capabilities, and seamlessly interface with other components of the lithography tool.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, precision engineering, and control systems. As the semiconductor industry continues to push the boundaries of miniaturization, overcoming these vacuum pump challenges will be crucial for enabling the next generation of high-resolution nanostructure lithography.

The miniaturization trend in semiconductor manufacturing has led to increasingly stringent cleanliness requirements. Conventional oil-based pumps risk contaminating the delicate nanostructures with hydrocarbon residues, necessitating the development and implementation of oil-free pump designs. However, these oil-free alternatives often struggle to achieve the same level of vacuum performance as their oil-based counterparts.

Another challenge lies in managing pump-induced vibrations. Even minute vibrations can significantly impact the precision of nanolithography processes, potentially leading to defects in the fabricated nanostructures. This necessitates advanced vibration isolation systems and pump designs that minimize mechanical disturbances.

Heat generation and dissipation present additional hurdles. High-performance vacuum pumps generate considerable heat during operation, which can affect the stability of the lithography environment. Efficient cooling mechanisms must be integrated without compromising the pump's performance or introducing additional vibrations.

The demand for faster pump-down times to improve throughput in semiconductor manufacturing clashes with the need for stable, ultra-high vacuum conditions. Balancing these conflicting requirements poses a significant engineering challenge for vacuum pump designers and manufacturers.

Reliability and maintenance issues also come to the fore in nanolithography applications. The extreme operating conditions and the critical nature of the processes demand pumps with exceptional longevity and minimal downtime. However, achieving this level of reliability while maintaining the required performance characteristics remains a formidable task.

Lastly, the integration of vacuum pumps into increasingly complex and automated lithography systems presents its own set of challenges. Pumps must be compatible with advanced control systems, offer real-time monitoring capabilities, and seamlessly interface with other components of the lithography tool.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, precision engineering, and control systems. As the semiconductor industry continues to push the boundaries of miniaturization, overcoming these vacuum pump challenges will be crucial for enabling the next generation of high-resolution nanostructure lithography.

Existing Vacuum Solutions for Nanostructure Fabrication

01 Improved pump design for enhanced resolution

Advanced vacuum pump designs incorporate features to improve resolution and efficiency. These may include optimized rotor configurations, precision-engineered clearances, and innovative sealing mechanisms. Such improvements result in better vacuum quality and more precise control over pressure levels.- Improved pump design for enhanced resolution: Advanced vacuum pump designs incorporate features to improve resolution and precision. These may include optimized rotor configurations, enhanced sealing mechanisms, and precise control systems. Such improvements allow for finer control of vacuum levels and more stable operation, resulting in better overall pump performance and resolution.

- Sensor integration for accurate pressure monitoring: Integration of high-precision sensors within vacuum pump systems enables real-time monitoring of pressure levels. These sensors provide accurate feedback, allowing for dynamic adjustments to maintain desired vacuum levels. This technology contributes to improved resolution by enabling more responsive and precise control of the pumping process.

- Advanced control algorithms for pump operation: Sophisticated control algorithms are implemented to optimize vacuum pump operation. These algorithms process sensor data and adjust pump parameters in real-time, ensuring stable and precise vacuum levels. By continuously fine-tuning the pump's performance, these control systems significantly enhance the overall resolution and efficiency of the vacuum system.

- Multi-stage pump configurations for higher resolution: Multi-stage vacuum pump configurations are utilized to achieve higher resolution and lower ultimate pressures. By combining different pump types or stages, each optimized for specific pressure ranges, these systems can maintain precise vacuum levels across a wide operating range. This approach allows for more accurate and stable vacuum control in various applications.

- Noise reduction techniques for improved sensitivity: Various noise reduction techniques are employed to enhance the sensitivity and resolution of vacuum pump systems. These may include vibration isolation, acoustic dampening, and electronic noise filtering. By minimizing interference from mechanical and electrical sources, these methods allow for more precise measurement and control of vacuum levels, particularly in high-sensitivity applications.

02 Sensor integration for accurate pressure monitoring

Integration of high-precision sensors within vacuum pump systems allows for real-time monitoring and adjustment of pressure levels. This enables finer control over the vacuum environment, leading to improved resolution in various applications such as scientific instruments and semiconductor manufacturing processes.Expand Specific Solutions03 Advanced control systems for pump operation

Sophisticated control systems, often incorporating microprocessors and adaptive algorithms, are employed to optimize vacuum pump performance. These systems can adjust pump speed, flow rates, and other parameters in response to changing conditions, resulting in more stable and precise vacuum levels.Expand Specific Solutions04 Multi-stage pump configurations for higher resolution

Utilizing multi-stage pump configurations allows for achieving higher vacuum levels and finer resolution. By combining different pump types or multiple pumps in series, these systems can effectively remove gases across a wide pressure range, enabling more precise control over the final vacuum state.Expand Specific Solutions05 Noise reduction techniques for improved sensitivity

Implementing various noise reduction techniques in vacuum pump design and operation contributes to improved resolution and sensitivity. These may include vibration isolation, acoustic dampening, and electronic noise filtering, allowing for more accurate measurements and better performance in noise-sensitive applications.Expand Specific Solutions

Key Players in Nanolithography Vacuum Systems

The field of high-resolution nanostructure lithography using vacuum pumps is in a mature stage of development, with significant market growth potential. The global market for this technology is estimated to be in the billions of dollars, driven by increasing demand for advanced semiconductor devices. Companies like ASML Netherlands BV and Edwards Ltd. are at the forefront, leveraging their expertise in lithography systems and vacuum technology. The technology's maturity is evident in the involvement of major players such as Taiwan Semiconductor Manufacturing Co., Ltd. and Illumina, Inc., who are applying these advanced lithography techniques in their manufacturing processes. Research institutions like Korea Institute of Machinery & Materials and Suzhou Institute of Nano-Tech & Nano-Bionics are also contributing to further advancements in this field, indicating ongoing innovation and refinement of the technology.

ASML Netherlands BV

Technical Solution: ASML has developed advanced vacuum systems for their extreme ultraviolet (EUV) lithography machines, which are crucial for high-resolution nanostructure fabrication. Their technology utilizes a high-vacuum environment to enable the propagation of EUV light and precise pattern transfer. ASML's vacuum pumps are designed to maintain ultra-clean conditions, with specialized multi-stage pumping systems that can achieve pressures as low as 10^-9 mbar in the main chamber[1]. This allows for contamination-free lithography processes at the nanoscale. The company has also implemented innovative sealing technologies and advanced vacuum control systems to ensure stable pressure conditions during the entire lithography process[2].

Strengths: Unparalleled expertise in EUV lithography, cutting-edge vacuum technology integration, and ability to achieve extreme cleanliness. Weaknesses: High cost of implementation and complexity of maintenance.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed specialized vacuum pumps tailored for semiconductor manufacturing and nanostructure lithography. Their product line includes dry pumps and turbomolecular pumps designed to maintain high vacuum levels required for precise nanoscale fabrication. Edwards' vacuum solutions incorporate advanced features such as contamination management systems and intelligent control interfaces. The company's iXH series dry pumps, for instance, can achieve ultimate pressures below 5 × 10^-3 mbar and offer high pumping speeds of up to 3400 m³/h[3]. These pumps are engineered to handle corrosive process gases and particles common in lithography processes. Edwards also provides integrated abatement systems to manage exhaust gases, ensuring environmental compliance in nanostructure fabrication facilities[4].

Strengths: Wide range of specialized vacuum solutions, robust design for harsh semiconductor environments, and integrated abatement capabilities. Weaknesses: May require frequent maintenance in high-throughput manufacturing settings.

Innovative Vacuum Pump Designs for Nanolithography

Vacuum pumping system

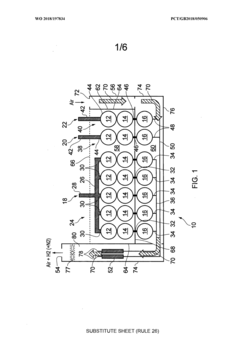

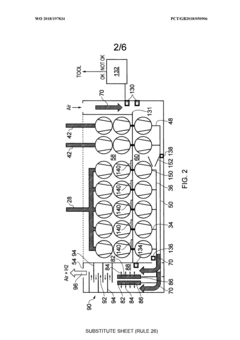

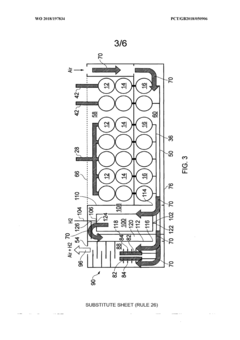

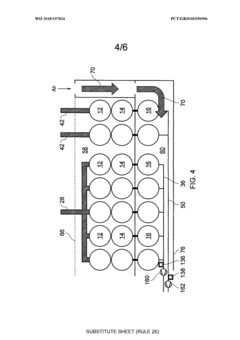

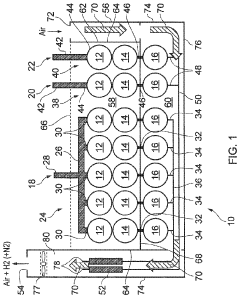

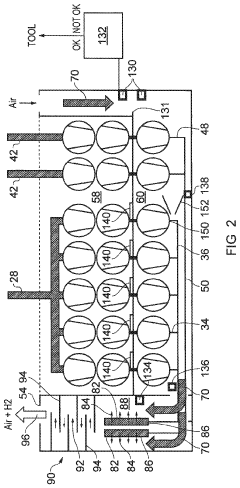

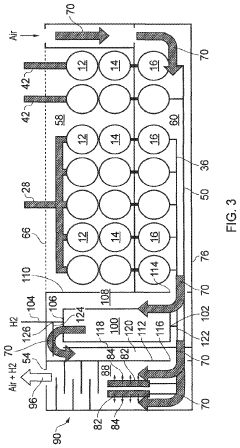

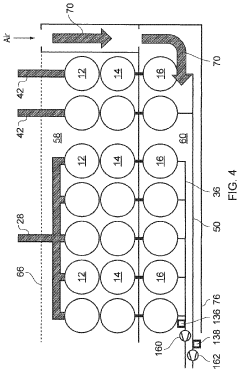

PatentWO2018197834A1

Innovation

- A vacuum pumping system that dilutes flammable gases with air to below their lower flammability limit, using a housing with distinct pressure regions and airflow generators to mix air with the gas stream, preventing ignition and allowing safe emission, and incorporating hydrogen recovery systems to recycle valuable gases.

Vacuum pumping system

PatentActiveUS11839903B2

Innovation

- A vacuum pumping system that dilutes flammable gases with air to below their lower flammability limit, using a housing with distinct pressure regions and an air flow duct to mix air with the gas stream, ensuring safe emission without combustion, and incorporating sensors to monitor and control the air flow for effective dilution.

Environmental Impact of Nanolithography Processes

Nanolithography processes, while essential for advancing semiconductor technology, have significant environmental implications that warrant careful consideration. The use of vacuum pumps in high-resolution nanostructure lithography contributes to these impacts in several ways. Firstly, the energy consumption of vacuum pumps is substantial, often requiring continuous operation to maintain the necessary ultra-high vacuum conditions. This energy demand translates into increased carbon emissions, particularly in regions where electricity generation relies heavily on fossil fuels.

Moreover, the production and disposal of vacuum pumps used in nanolithography involve the use of rare earth elements and specialized materials. The extraction and processing of these materials can lead to environmental degradation, including habitat destruction and water pollution in mining areas. Additionally, the disposal of used pumps and their components presents challenges in terms of electronic waste management and potential release of hazardous substances.

The chemicals used in nanolithography processes, including photoresists and developers, pose environmental risks through potential air and water pollution. Vacuum pumps play a role in managing these chemicals, but improper handling or disposal can lead to contamination of soil and water resources. Furthermore, the ultra-pure water required for cleaning processes in nanolithography contributes to water scarcity issues in regions where semiconductor manufacturing is concentrated.

Nanoparticle emissions are another environmental concern associated with nanolithography. While vacuum pumps help contain these particles within the manufacturing environment, there is still potential for release during maintenance or equipment failures. These nanoparticles can have unpredictable effects on ecosystems and human health if they enter the broader environment.

The cleanroom environments necessary for high-resolution nanostructure lithography also have environmental implications. The extensive filtration and climate control systems required to maintain these environments consume significant energy and resources. Vacuum pumps are integral to these systems, contributing to their overall environmental footprint.

Efforts to mitigate the environmental impact of nanolithography processes, including vacuum pump use, are ongoing. These include the development of more energy-efficient pump designs, improved recycling and waste management practices for specialized materials, and the exploration of alternative lithography techniques that may reduce reliance on vacuum systems. However, as the demand for smaller and more complex nanostructures grows, balancing technological advancement with environmental sustainability remains a significant challenge for the semiconductor industry.

Moreover, the production and disposal of vacuum pumps used in nanolithography involve the use of rare earth elements and specialized materials. The extraction and processing of these materials can lead to environmental degradation, including habitat destruction and water pollution in mining areas. Additionally, the disposal of used pumps and their components presents challenges in terms of electronic waste management and potential release of hazardous substances.

The chemicals used in nanolithography processes, including photoresists and developers, pose environmental risks through potential air and water pollution. Vacuum pumps play a role in managing these chemicals, but improper handling or disposal can lead to contamination of soil and water resources. Furthermore, the ultra-pure water required for cleaning processes in nanolithography contributes to water scarcity issues in regions where semiconductor manufacturing is concentrated.

Nanoparticle emissions are another environmental concern associated with nanolithography. While vacuum pumps help contain these particles within the manufacturing environment, there is still potential for release during maintenance or equipment failures. These nanoparticles can have unpredictable effects on ecosystems and human health if they enter the broader environment.

The cleanroom environments necessary for high-resolution nanostructure lithography also have environmental implications. The extensive filtration and climate control systems required to maintain these environments consume significant energy and resources. Vacuum pumps are integral to these systems, contributing to their overall environmental footprint.

Efforts to mitigate the environmental impact of nanolithography processes, including vacuum pump use, are ongoing. These include the development of more energy-efficient pump designs, improved recycling and waste management practices for specialized materials, and the exploration of alternative lithography techniques that may reduce reliance on vacuum systems. However, as the demand for smaller and more complex nanostructures grows, balancing technological advancement with environmental sustainability remains a significant challenge for the semiconductor industry.

Cleanroom Integration of Advanced Vacuum Systems

The integration of advanced vacuum systems into cleanroom environments is a critical aspect of high-resolution nanostructure lithography. These systems play a pivotal role in maintaining the ultra-clean conditions necessary for precise nanofabrication processes. The primary function of vacuum pumps in this context is to create and maintain low-pressure environments, which are essential for minimizing contamination and ensuring the accuracy of nanoscale features.

In cleanroom settings, vacuum systems are typically incorporated into various lithography tools, such as electron beam lithography (EBL) systems, extreme ultraviolet (EUV) lithography machines, and focused ion beam (FIB) instruments. These tools require stringent vacuum conditions to operate effectively and produce high-quality nanostructures. The integration process involves careful consideration of several factors, including pump selection, placement, and isolation from vibration sources.

One of the key challenges in integrating vacuum systems into cleanrooms is managing the potential for contamination. Vacuum pumps, particularly oil-based models, can be sources of particulates and hydrocarbons that may compromise the cleanliness of the environment. To address this issue, cleanroom-compatible dry pumps and turbomolecular pumps are often employed. These pumps are designed to operate without oil, significantly reducing the risk of contamination.

Another crucial aspect of vacuum system integration is the management of vibration and noise. High-resolution lithography processes are extremely sensitive to mechanical disturbances, which can lead to pattern distortion and reduced feature quality. To mitigate these effects, vacuum pumps are typically installed in separate rooms or enclosures, with vibration-isolating mounts and acoustic barriers. Additionally, flexible connections and bellows are used to decouple the pumps from the lithography tools, further reducing the transmission of vibrations.

The layout and design of vacuum lines within the cleanroom require careful planning to ensure optimal performance and maintainability. Vacuum lines are often routed through dedicated service chases or under raised floors to minimize their impact on cleanroom operations. The use of ultra-high vacuum (UHV) compatible materials and fittings is essential to maintain the integrity of the vacuum system and prevent outgassing, which could introduce contaminants into the process chamber.

Furthermore, the integration of advanced vacuum systems in cleanrooms often includes sophisticated control and monitoring systems. These systems allow for real-time tracking of pressure levels, pump performance, and potential leaks. Many modern setups incorporate automated pressure control mechanisms and failsafe systems to protect sensitive equipment and maintain process stability.

In cleanroom settings, vacuum systems are typically incorporated into various lithography tools, such as electron beam lithography (EBL) systems, extreme ultraviolet (EUV) lithography machines, and focused ion beam (FIB) instruments. These tools require stringent vacuum conditions to operate effectively and produce high-quality nanostructures. The integration process involves careful consideration of several factors, including pump selection, placement, and isolation from vibration sources.

One of the key challenges in integrating vacuum systems into cleanrooms is managing the potential for contamination. Vacuum pumps, particularly oil-based models, can be sources of particulates and hydrocarbons that may compromise the cleanliness of the environment. To address this issue, cleanroom-compatible dry pumps and turbomolecular pumps are often employed. These pumps are designed to operate without oil, significantly reducing the risk of contamination.

Another crucial aspect of vacuum system integration is the management of vibration and noise. High-resolution lithography processes are extremely sensitive to mechanical disturbances, which can lead to pattern distortion and reduced feature quality. To mitigate these effects, vacuum pumps are typically installed in separate rooms or enclosures, with vibration-isolating mounts and acoustic barriers. Additionally, flexible connections and bellows are used to decouple the pumps from the lithography tools, further reducing the transmission of vibrations.

The layout and design of vacuum lines within the cleanroom require careful planning to ensure optimal performance and maintainability. Vacuum lines are often routed through dedicated service chases or under raised floors to minimize their impact on cleanroom operations. The use of ultra-high vacuum (UHV) compatible materials and fittings is essential to maintain the integrity of the vacuum system and prevent outgassing, which could introduce contaminants into the process chamber.

Furthermore, the integration of advanced vacuum systems in cleanrooms often includes sophisticated control and monitoring systems. These systems allow for real-time tracking of pressure levels, pump performance, and potential leaks. Many modern setups incorporate automated pressure control mechanisms and failsafe systems to protect sensitive equipment and maintain process stability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!