Cellophane Films: Innovations in Heat Resistance

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Heat Resistance Evolution and Objectives

Cellophane, a transparent film made from regenerated cellulose, has been a staple in packaging and industrial applications since its invention in the early 20th century. The evolution of cellophane's heat resistance capabilities has been a critical factor in expanding its utility and market presence. Initially, cellophane's heat resistance was limited, restricting its use in high-temperature environments and applications involving heat sealing or sterilization processes.

The journey to improve cellophane's heat resistance began in the 1950s when researchers recognized the need for more thermally stable packaging materials. Early efforts focused on modifying the cellulose structure and incorporating heat-resistant additives. These initial improvements allowed cellophane to withstand moderate heat exposure, broadening its application in food packaging and industrial uses.

As environmental concerns grew in the late 20th century, the development of heat-resistant cellophane took on new significance. The biodegradability of cellophane made it an attractive alternative to synthetic plastics, prompting renewed interest in enhancing its thermal properties to compete with more heat-resistant synthetic films.

The 21st century has seen accelerated progress in cellophane heat resistance, driven by advances in material science and nanotechnology. Researchers have explored various approaches, including the incorporation of nanoparticles, cross-linking agents, and surface treatments to enhance the film's thermal stability without compromising its other desirable properties such as transparency and biodegradability.

Current objectives in cellophane heat resistance research are multifaceted. Primary goals include increasing the maximum temperature tolerance of cellophane films, improving their dimensional stability under heat stress, and enhancing their barrier properties at elevated temperatures. Additionally, there is a focus on developing heat-resistant cellophane that maintains its biodegradability and eco-friendly characteristics.

Another key objective is to improve the heat-sealing properties of cellophane, allowing for more efficient and reliable packaging processes in food and consumer goods industries. Researchers are also working on enhancing cellophane's resistance to thermal degradation during sterilization processes, which is crucial for medical and pharmaceutical applications.

The future trajectory of cellophane heat resistance innovations aims at creating a new generation of high-performance, sustainable packaging materials. This includes developing cellophane films that can withstand temperatures comparable to those of synthetic polymers while maintaining their biodegradability. Such advancements could potentially revolutionize the packaging industry, offering a more environmentally friendly alternative to petroleum-based plastics in high-temperature applications.

The journey to improve cellophane's heat resistance began in the 1950s when researchers recognized the need for more thermally stable packaging materials. Early efforts focused on modifying the cellulose structure and incorporating heat-resistant additives. These initial improvements allowed cellophane to withstand moderate heat exposure, broadening its application in food packaging and industrial uses.

As environmental concerns grew in the late 20th century, the development of heat-resistant cellophane took on new significance. The biodegradability of cellophane made it an attractive alternative to synthetic plastics, prompting renewed interest in enhancing its thermal properties to compete with more heat-resistant synthetic films.

The 21st century has seen accelerated progress in cellophane heat resistance, driven by advances in material science and nanotechnology. Researchers have explored various approaches, including the incorporation of nanoparticles, cross-linking agents, and surface treatments to enhance the film's thermal stability without compromising its other desirable properties such as transparency and biodegradability.

Current objectives in cellophane heat resistance research are multifaceted. Primary goals include increasing the maximum temperature tolerance of cellophane films, improving their dimensional stability under heat stress, and enhancing their barrier properties at elevated temperatures. Additionally, there is a focus on developing heat-resistant cellophane that maintains its biodegradability and eco-friendly characteristics.

Another key objective is to improve the heat-sealing properties of cellophane, allowing for more efficient and reliable packaging processes in food and consumer goods industries. Researchers are also working on enhancing cellophane's resistance to thermal degradation during sterilization processes, which is crucial for medical and pharmaceutical applications.

The future trajectory of cellophane heat resistance innovations aims at creating a new generation of high-performance, sustainable packaging materials. This includes developing cellophane films that can withstand temperatures comparable to those of synthetic polymers while maintaining their biodegradability. Such advancements could potentially revolutionize the packaging industry, offering a more environmentally friendly alternative to petroleum-based plastics in high-temperature applications.

Market Analysis for Heat-Resistant Cellophane

The market for heat-resistant cellophane films has experienced significant growth in recent years, driven by increasing demand across various industries. The food packaging sector remains the primary consumer of these films, accounting for a substantial portion of the market share. The ability of heat-resistant cellophane to withstand high temperatures while maintaining transparency and barrier properties makes it an ideal choice for microwave-safe packaging and ready-to-eat meals.

In the pharmaceutical industry, heat-resistant cellophane films are gaining traction for blister packaging applications, where temperature stability during sterilization processes is crucial. The cosmetics and personal care sector also shows promising growth potential, utilizing these films for packaging products that require heat protection during manufacturing or application.

The global market for heat-resistant cellophane is expected to continue its upward trajectory, with Asia-Pacific emerging as the fastest-growing region. This growth is attributed to rapid industrialization, changing consumer lifestyles, and increasing disposable incomes in countries like China and India. North America and Europe remain significant markets, driven by stringent food safety regulations and a growing preference for sustainable packaging solutions.

Environmental concerns and regulatory pressures are shaping market dynamics, with a growing emphasis on biodegradable and compostable alternatives. This trend is prompting manufacturers to invest in research and development to enhance the eco-friendly properties of heat-resistant cellophane films without compromising their performance characteristics.

The market is characterized by intense competition among key players, with companies focusing on product innovation and strategic partnerships to gain a competitive edge. Technological advancements in film manufacturing processes, such as improved heat stabilization techniques and the incorporation of nanocomposites, are expected to drive market growth and expand application areas.

Consumer preferences for convenience foods and the rise of e-commerce are creating new opportunities for heat-resistant cellophane in the packaging industry. The films' ability to withstand temperature fluctuations during transportation and storage makes them particularly suitable for online food delivery services and meal kit packaging.

As sustainability becomes increasingly important to consumers and businesses alike, there is a growing demand for heat-resistant cellophane films made from renewable resources. This shift is encouraging manufacturers to explore bio-based alternatives and circular economy models, potentially reshaping the market landscape in the coming years.

In the pharmaceutical industry, heat-resistant cellophane films are gaining traction for blister packaging applications, where temperature stability during sterilization processes is crucial. The cosmetics and personal care sector also shows promising growth potential, utilizing these films for packaging products that require heat protection during manufacturing or application.

The global market for heat-resistant cellophane is expected to continue its upward trajectory, with Asia-Pacific emerging as the fastest-growing region. This growth is attributed to rapid industrialization, changing consumer lifestyles, and increasing disposable incomes in countries like China and India. North America and Europe remain significant markets, driven by stringent food safety regulations and a growing preference for sustainable packaging solutions.

Environmental concerns and regulatory pressures are shaping market dynamics, with a growing emphasis on biodegradable and compostable alternatives. This trend is prompting manufacturers to invest in research and development to enhance the eco-friendly properties of heat-resistant cellophane films without compromising their performance characteristics.

The market is characterized by intense competition among key players, with companies focusing on product innovation and strategic partnerships to gain a competitive edge. Technological advancements in film manufacturing processes, such as improved heat stabilization techniques and the incorporation of nanocomposites, are expected to drive market growth and expand application areas.

Consumer preferences for convenience foods and the rise of e-commerce are creating new opportunities for heat-resistant cellophane in the packaging industry. The films' ability to withstand temperature fluctuations during transportation and storage makes them particularly suitable for online food delivery services and meal kit packaging.

As sustainability becomes increasingly important to consumers and businesses alike, there is a growing demand for heat-resistant cellophane films made from renewable resources. This shift is encouraging manufacturers to explore bio-based alternatives and circular economy models, potentially reshaping the market landscape in the coming years.

Current Challenges in Cellophane Heat Resistance

Despite significant advancements in cellophane film technology, several challenges persist in improving its heat resistance. One of the primary issues is the inherent thermal sensitivity of cellulose, the main component of cellophane. When exposed to high temperatures, cellophane tends to soften, deform, and lose its structural integrity, limiting its applications in high-temperature environments.

The current maximum temperature tolerance of standard cellophane films typically ranges from 150°C to 180°C, which is insufficient for many industrial and packaging applications that require higher heat resistance. This limitation restricts the use of cellophane in hot-fill packaging, microwave-safe containers, and certain food processing techniques.

Another significant challenge is maintaining the desirable properties of cellophane, such as transparency, flexibility, and barrier characteristics, while enhancing its heat resistance. Attempts to improve thermal stability often result in trade-offs, compromising other essential features that make cellophane an attractive packaging material.

The moisture sensitivity of cellophane also poses a challenge in heat-resistant applications. When exposed to high temperatures, the moisture content in cellophane can lead to dimensional instability, affecting its performance and appearance. This issue is particularly problematic in environments with fluctuating humidity levels.

Furthermore, the development of heat-resistant coatings for cellophane presents its own set of challenges. While coatings can enhance heat resistance, they often affect the film's recyclability and biodegradability, two key environmental advantages of cellophane. Balancing improved heat performance with sustainability goals remains a significant hurdle.

The cost-effectiveness of producing heat-resistant cellophane is another obstacle. Current methods to enhance thermal stability, such as chemical modifications or the addition of heat-resistant polymers, can significantly increase production costs, making the final product less competitive in the market.

Lastly, achieving consistent heat resistance across large-scale production runs poses a technical challenge. Variations in raw materials, processing conditions, and film thickness can lead to inconsistencies in thermal performance, necessitating stringent quality control measures.

Addressing these challenges requires innovative approaches in material science, polymer chemistry, and manufacturing processes. Research efforts are focused on developing novel cellulose derivatives, exploring bio-based additives, and optimizing film structure at the molecular level to enhance heat resistance without compromising other desirable properties of cellophane.

The current maximum temperature tolerance of standard cellophane films typically ranges from 150°C to 180°C, which is insufficient for many industrial and packaging applications that require higher heat resistance. This limitation restricts the use of cellophane in hot-fill packaging, microwave-safe containers, and certain food processing techniques.

Another significant challenge is maintaining the desirable properties of cellophane, such as transparency, flexibility, and barrier characteristics, while enhancing its heat resistance. Attempts to improve thermal stability often result in trade-offs, compromising other essential features that make cellophane an attractive packaging material.

The moisture sensitivity of cellophane also poses a challenge in heat-resistant applications. When exposed to high temperatures, the moisture content in cellophane can lead to dimensional instability, affecting its performance and appearance. This issue is particularly problematic in environments with fluctuating humidity levels.

Furthermore, the development of heat-resistant coatings for cellophane presents its own set of challenges. While coatings can enhance heat resistance, they often affect the film's recyclability and biodegradability, two key environmental advantages of cellophane. Balancing improved heat performance with sustainability goals remains a significant hurdle.

The cost-effectiveness of producing heat-resistant cellophane is another obstacle. Current methods to enhance thermal stability, such as chemical modifications or the addition of heat-resistant polymers, can significantly increase production costs, making the final product less competitive in the market.

Lastly, achieving consistent heat resistance across large-scale production runs poses a technical challenge. Variations in raw materials, processing conditions, and film thickness can lead to inconsistencies in thermal performance, necessitating stringent quality control measures.

Addressing these challenges requires innovative approaches in material science, polymer chemistry, and manufacturing processes. Research efforts are focused on developing novel cellulose derivatives, exploring bio-based additives, and optimizing film structure at the molecular level to enhance heat resistance without compromising other desirable properties of cellophane.

Existing Heat Resistance Enhancement Methods

01 Heat-resistant polymer blends for cellophane films

Incorporating heat-resistant polymers or polymer blends into cellophane films can significantly improve their thermal stability. These blends often include materials such as polyesters, polyamides, or specialized copolymers that maintain structural integrity at elevated temperatures. The resulting films exhibit enhanced resistance to deformation and degradation when exposed to heat.- Heat-resistant polymer blends for cellophane films: Incorporating heat-resistant polymers into cellophane film formulations can significantly improve their thermal stability. These blends often include materials like polyesters, polyamides, or specialty copolymers that maintain structural integrity at elevated temperatures. The resulting films exhibit enhanced resistance to deformation and degradation when exposed to heat, making them suitable for high-temperature applications.

- Surface treatments for improved heat resistance: Applying surface treatments or coatings to cellophane films can enhance their heat resistance. These treatments may include the application of heat-resistant resins, inorganic compounds, or specialized coatings that form a protective layer on the film surface. Such modifications can increase the film's ability to withstand high temperatures without compromising its other properties.

- Nanocomposite reinforcement for thermal stability: Incorporating nanoparticles or nanocomposites into cellophane films can significantly improve their heat resistance. These nanomaterials, such as clay platelets or metal oxide nanoparticles, can be dispersed throughout the film matrix, creating a tortuous path for heat transfer and enhancing the overall thermal stability of the material.

- Cross-linking techniques for improved heat resistance: Employing cross-linking techniques during the manufacturing process can enhance the heat resistance of cellophane films. This may involve the use of chemical cross-linking agents or radiation-induced cross-linking. The resulting interconnected polymer network exhibits improved thermal stability and mechanical properties at elevated temperatures.

- Multilayer structures for enhanced thermal performance: Developing multilayer film structures that combine cellophane with other heat-resistant materials can improve overall thermal performance. These composite films may include layers of high-temperature-resistant polymers or inorganic materials that provide additional protection against heat. The layered structure allows for the optimization of different properties, including heat resistance, barrier properties, and mechanical strength.

02 Surface treatments for improved heat resistance

Applying surface treatments or coatings to cellophane films can enhance their heat resistance. These treatments may include the application of heat-resistant resins, inorganic compounds, or specialized coatings that form a protective layer on the film surface. Such modifications can increase the film's ability to withstand high temperatures without compromising its structural integrity or optical properties.Expand Specific Solutions03 Nanocomposite reinforcement for thermal stability

Incorporating nanoparticles or nanocomposites into cellophane films can significantly improve their heat resistance. These nanomaterials, such as clay nanoparticles or carbon nanotubes, can be dispersed throughout the film matrix, enhancing its thermal stability and mechanical properties at high temperatures. This approach can lead to films with superior heat resistance while maintaining flexibility and transparency.Expand Specific Solutions04 Cross-linking techniques for improved thermal properties

Employing cross-linking techniques can enhance the heat resistance of cellophane films. This process involves creating chemical bonds between polymer chains, resulting in a more stable and heat-resistant structure. Various methods, such as radiation-induced cross-linking or chemical cross-linking agents, can be used to achieve this effect, leading to films with improved thermal stability and mechanical strength at elevated temperatures.Expand Specific Solutions05 Multilayer film structures for enhanced heat resistance

Developing multilayer film structures can significantly improve the heat resistance of cellophane-based products. By combining layers of cellophane with other heat-resistant materials or specialized barrier layers, the overall thermal stability of the film can be enhanced. This approach allows for the creation of films that maintain their properties and performance under high-temperature conditions while retaining the desirable characteristics of cellophane.Expand Specific Solutions

Key Players in Heat-Resistant Cellophane Industry

The heat resistance innovation in cellophane films market is in a growth phase, driven by increasing demand for sustainable packaging solutions. The global market size for heat-resistant cellophane films is projected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with companies like FUJIFILM Corp., Toyobo Co., Ltd., and Rengo Co., Ltd. leading innovation. These firms are developing enhanced formulations and manufacturing processes to improve the heat resistance of cellophane films. While the technology is maturing, there's still room for breakthrough innovations, particularly in areas like bio-based materials and nano-coatings to further enhance heat resistance properties.

FUJIFILM Corp.

Technical Solution: FUJIFILM has developed innovative heat-resistant cellophane films using their proprietary technology. Their approach involves incorporating nanoparticles into the cellulose matrix, which significantly enhances the film's thermal stability. The company has achieved a breakthrough by creating cellophane films that can withstand temperatures up to 230°C for short periods, a substantial improvement over conventional cellophane[1]. FUJIFILM's process also includes a unique cross-linking method that further improves the film's heat resistance without compromising its biodegradability[2]. The company has implemented a multi-layer structure in their films, with each layer optimized for different properties such as heat resistance, barrier properties, and mechanical strength[3].

Strengths: Superior heat resistance, maintained biodegradability, versatile multi-layer structure. Weaknesses: Potentially higher production costs, limited to specific applications due to specialized properties.

Toyobo Co., Ltd.

Technical Solution: Toyobo has developed a novel approach to heat-resistant cellophane films by focusing on molecular orientation and crystallinity control. Their process involves a specialized stretching technique that aligns cellulose molecules in a way that enhances thermal stability[4]. The company has also introduced a proprietary coating technology that creates a thin, heat-resistant layer on the cellophane surface without affecting its transparency or flexibility[5]. Toyobo's cellophane films can maintain their integrity at temperatures up to 200°C, making them suitable for various high-temperature packaging applications[6]. Additionally, they have incorporated flame-retardant additives that further enhance the film's resistance to heat and fire, expanding its potential uses in safety-critical environments[7].

Strengths: High heat resistance, maintained transparency and flexibility, added flame-retardant properties. Weaknesses: Potential increase in production complexity, may require specialized equipment for manufacturing.

Core Innovations in Cellophane Heat Resistance

Cellophane laminate

PatentPendingJP2024001514A

Innovation

- A cellophane laminate with moisture-resistant layers of specific thickness and composition, made from olefin, aliphatic, or alicyclic hydrocarbon resins, applied directly to both surfaces without an anchor coat or adhesive, providing heat-sealability and moisture resistance.

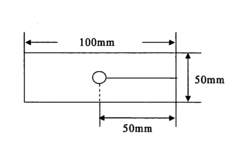

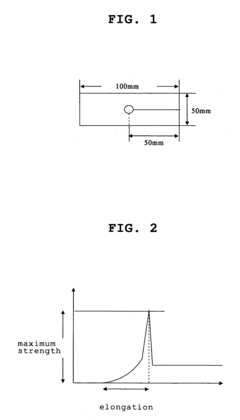

Easy-to-tear stretched aliphatic-polyester film

PatentInactiveUS20050106345A1

Innovation

- A stretched aliphatic polyester film is developed with improved tearability, tensile impact strength, and biodegradability through actinic ray irradiation and a three-layer laminating process using lactic acid-based polyester resins with different melting points, enhancing moisture resistance and twist fixability.

Environmental Impact of Heat-Resistant Cellophane

The environmental impact of heat-resistant cellophane is a critical consideration in the development and application of this innovative material. As the demand for more durable and versatile packaging solutions grows, it is essential to assess the ecological footprint of these advanced cellophane films throughout their lifecycle.

Heat-resistant cellophane production typically involves additional chemical treatments or coatings to enhance its thermal stability. These processes may require increased energy consumption and the use of specialized additives, potentially leading to a higher carbon footprint compared to conventional cellophane manufacturing. However, the extended durability and heat resistance of these films can offset some of these environmental costs by reducing the need for frequent replacements and minimizing food waste due to packaging failures.

The disposal and recycling of heat-resistant cellophane present both challenges and opportunities. While the enhanced properties of these films may complicate traditional recycling processes, their increased durability could lead to extended use cycles, reducing overall waste generation. Some heat-resistant cellophane formulations incorporate biodegradable components, which can mitigate long-term environmental impacts if properly managed in industrial composting facilities.

Water consumption and potential chemical runoff during the production of heat-resistant cellophane are areas of environmental concern. Advanced water treatment systems and closed-loop manufacturing processes are being developed to address these issues, aiming to minimize water usage and prevent the release of harmful substances into ecosystems.

The use of heat-resistant cellophane in food packaging applications can contribute to food preservation and reduced spoilage, indirectly benefiting the environment by decreasing food waste. This positive impact must be weighed against the potential increase in packaging material complexity and its effects on recycling streams.

As regulations on single-use plastics and packaging materials become more stringent, the development of heat-resistant cellophane must align with circular economy principles. Innovations in bio-based and recyclable heat-resistant films are emerging, offering promising alternatives that could significantly reduce the environmental footprint of these materials.

The life cycle assessment (LCA) of heat-resistant cellophane is crucial for understanding its true environmental impact. Comprehensive studies comparing these advanced films to traditional packaging materials across various metrics, including greenhouse gas emissions, water usage, and end-of-life scenarios, are necessary to guide sustainable development in this field.

Heat-resistant cellophane production typically involves additional chemical treatments or coatings to enhance its thermal stability. These processes may require increased energy consumption and the use of specialized additives, potentially leading to a higher carbon footprint compared to conventional cellophane manufacturing. However, the extended durability and heat resistance of these films can offset some of these environmental costs by reducing the need for frequent replacements and minimizing food waste due to packaging failures.

The disposal and recycling of heat-resistant cellophane present both challenges and opportunities. While the enhanced properties of these films may complicate traditional recycling processes, their increased durability could lead to extended use cycles, reducing overall waste generation. Some heat-resistant cellophane formulations incorporate biodegradable components, which can mitigate long-term environmental impacts if properly managed in industrial composting facilities.

Water consumption and potential chemical runoff during the production of heat-resistant cellophane are areas of environmental concern. Advanced water treatment systems and closed-loop manufacturing processes are being developed to address these issues, aiming to minimize water usage and prevent the release of harmful substances into ecosystems.

The use of heat-resistant cellophane in food packaging applications can contribute to food preservation and reduced spoilage, indirectly benefiting the environment by decreasing food waste. This positive impact must be weighed against the potential increase in packaging material complexity and its effects on recycling streams.

As regulations on single-use plastics and packaging materials become more stringent, the development of heat-resistant cellophane must align with circular economy principles. Innovations in bio-based and recyclable heat-resistant films are emerging, offering promising alternatives that could significantly reduce the environmental footprint of these materials.

The life cycle assessment (LCA) of heat-resistant cellophane is crucial for understanding its true environmental impact. Comprehensive studies comparing these advanced films to traditional packaging materials across various metrics, including greenhouse gas emissions, water usage, and end-of-life scenarios, are necessary to guide sustainable development in this field.

Regulatory Framework for Food Packaging Materials

The regulatory framework for food packaging materials plays a crucial role in ensuring the safety and quality of packaged foods, including those utilizing cellophane films with enhanced heat resistance. In the context of innovations in heat-resistant cellophane films, regulatory bodies worldwide have established comprehensive guidelines and standards to govern their use in food packaging applications.

The United States Food and Drug Administration (FDA) has set forth specific regulations under the Code of Federal Regulations (CFR) Title 21, particularly in parts 174-179, which address food contact substances and packaging materials. These regulations outline the requirements for the composition, manufacturing processes, and intended use of cellophane films in food packaging, including those with improved heat resistance properties.

In the European Union, the European Food Safety Authority (EFSA) oversees the safety assessment of food contact materials, including cellophane films. The EU Regulation No. 10/2011 on plastic materials and articles intended to come into contact with food provides a harmonized framework for the evaluation and authorization of substances used in food packaging materials, including those designed for heat-resistant applications.

The regulatory landscape also encompasses specific migration limits (SMLs) for various substances that may be present in cellophane films. These limits are established to ensure that any potential migration of chemicals from the packaging material to the food remains within safe levels, even under elevated temperature conditions.

Additionally, international standards such as those developed by the International Organization for Standardization (ISO) provide guidelines for testing and evaluating the performance of food packaging materials, including heat-resistant cellophane films. ISO 22000 series standards, for instance, address food safety management systems and include considerations for packaging materials used in the food industry.

Regulatory bodies also require manufacturers to demonstrate compliance with Good Manufacturing Practices (GMPs) in the production of food packaging materials. This ensures that the manufacturing processes for heat-resistant cellophane films meet stringent quality and safety standards throughout the production chain.

As innovations in heat-resistant cellophane films continue to evolve, regulatory frameworks are adapting to address new technologies and materials. This includes the development of guidelines for novel additives or manufacturing processes that enhance the heat resistance of cellophane films while maintaining their safety for food contact applications.

The United States Food and Drug Administration (FDA) has set forth specific regulations under the Code of Federal Regulations (CFR) Title 21, particularly in parts 174-179, which address food contact substances and packaging materials. These regulations outline the requirements for the composition, manufacturing processes, and intended use of cellophane films in food packaging, including those with improved heat resistance properties.

In the European Union, the European Food Safety Authority (EFSA) oversees the safety assessment of food contact materials, including cellophane films. The EU Regulation No. 10/2011 on plastic materials and articles intended to come into contact with food provides a harmonized framework for the evaluation and authorization of substances used in food packaging materials, including those designed for heat-resistant applications.

The regulatory landscape also encompasses specific migration limits (SMLs) for various substances that may be present in cellophane films. These limits are established to ensure that any potential migration of chemicals from the packaging material to the food remains within safe levels, even under elevated temperature conditions.

Additionally, international standards such as those developed by the International Organization for Standardization (ISO) provide guidelines for testing and evaluating the performance of food packaging materials, including heat-resistant cellophane films. ISO 22000 series standards, for instance, address food safety management systems and include considerations for packaging materials used in the food industry.

Regulatory bodies also require manufacturers to demonstrate compliance with Good Manufacturing Practices (GMPs) in the production of food packaging materials. This ensures that the manufacturing processes for heat-resistant cellophane films meet stringent quality and safety standards throughout the production chain.

As innovations in heat-resistant cellophane films continue to evolve, regulatory frameworks are adapting to address new technologies and materials. This includes the development of guidelines for novel additives or manufacturing processes that enhance the heat resistance of cellophane films while maintaining their safety for food contact applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!