Innovations in Sodium Percarbonate for Cold Brew Coffee Cleanliness

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Percarbonate in Cold Brew: Background and Objectives

Sodium percarbonate has emerged as a promising cleaning agent in the cold brew coffee industry, addressing the growing demand for efficient and eco-friendly cleaning solutions. This innovative compound, also known as sodium carbonate peroxyhydrate, is a stable adduct of sodium carbonate and hydrogen peroxide. Its application in cold brew coffee cleanliness represents a significant advancement in maintaining hygiene standards while aligning with sustainability goals.

The evolution of cold brew coffee from a niche product to a mainstream beverage has necessitated the development of specialized cleaning techniques. Traditional cleaning methods often involve harsh chemicals or time-consuming processes, which are not ideal for the delicate flavor profiles of cold brew or the increasing environmental consciousness of consumers and businesses alike. Sodium percarbonate has stepped into this gap, offering a powerful yet gentle cleaning solution.

The primary objective of incorporating sodium percarbonate into cold brew coffee cleaning processes is to enhance cleanliness while minimizing environmental impact. This compound breaks down into natural, non-toxic components – sodium carbonate, water, and oxygen – making it an environmentally responsible choice. The oxygen released during decomposition acts as a potent cleaning agent, effectively removing coffee oils and residues without leaving harmful chemical traces.

Another key goal is to improve operational efficiency in cold brew production. Sodium percarbonate's rapid action and ease of use can significantly reduce cleaning time and labor costs. Its versatility allows for application in various brewing equipment and surfaces, from stainless steel tanks to plastic tubing, addressing the diverse cleaning needs of cold brew coffee producers.

The technology behind sodium percarbonate aligns with the broader trend of green chemistry in the food and beverage industry. As consumers become more environmentally conscious, there is a growing demand for products and processes that minimize ecological footprints. The adoption of sodium percarbonate in cold brew coffee cleaning is part of this larger movement towards sustainable practices in the beverage industry.

Research and development efforts in this field aim to optimize the formulation and application methods of sodium percarbonate for cold brew coffee systems. This includes investigating the ideal concentration levels, contact times, and application techniques to maximize cleaning efficacy while preserving the integrity of brewing equipment and the subtle flavors of cold brew coffee. The goal is to develop standardized protocols that can be widely adopted across the industry, ensuring consistent quality and safety standards.

The evolution of cold brew coffee from a niche product to a mainstream beverage has necessitated the development of specialized cleaning techniques. Traditional cleaning methods often involve harsh chemicals or time-consuming processes, which are not ideal for the delicate flavor profiles of cold brew or the increasing environmental consciousness of consumers and businesses alike. Sodium percarbonate has stepped into this gap, offering a powerful yet gentle cleaning solution.

The primary objective of incorporating sodium percarbonate into cold brew coffee cleaning processes is to enhance cleanliness while minimizing environmental impact. This compound breaks down into natural, non-toxic components – sodium carbonate, water, and oxygen – making it an environmentally responsible choice. The oxygen released during decomposition acts as a potent cleaning agent, effectively removing coffee oils and residues without leaving harmful chemical traces.

Another key goal is to improve operational efficiency in cold brew production. Sodium percarbonate's rapid action and ease of use can significantly reduce cleaning time and labor costs. Its versatility allows for application in various brewing equipment and surfaces, from stainless steel tanks to plastic tubing, addressing the diverse cleaning needs of cold brew coffee producers.

The technology behind sodium percarbonate aligns with the broader trend of green chemistry in the food and beverage industry. As consumers become more environmentally conscious, there is a growing demand for products and processes that minimize ecological footprints. The adoption of sodium percarbonate in cold brew coffee cleaning is part of this larger movement towards sustainable practices in the beverage industry.

Research and development efforts in this field aim to optimize the formulation and application methods of sodium percarbonate for cold brew coffee systems. This includes investigating the ideal concentration levels, contact times, and application techniques to maximize cleaning efficacy while preserving the integrity of brewing equipment and the subtle flavors of cold brew coffee. The goal is to develop standardized protocols that can be widely adopted across the industry, ensuring consistent quality and safety standards.

Market Analysis: Cold Brew Coffee Cleanliness Demands

The cold brew coffee market has experienced significant growth in recent years, driven by consumer demand for smoother, less acidic coffee options. This trend has created a parallel need for effective cleaning solutions tailored to cold brew equipment and processes. The market for cold brew coffee cleanliness products is expanding rapidly, with a particular focus on solutions that can maintain the quality and safety of cold brew coffee without compromising its unique flavor profile.

Cold brew coffee makers, both commercial and residential, require specialized cleaning to prevent the buildup of coffee oils, residues, and potential microbial contamination. Traditional cleaning methods often involve harsh chemicals or time-consuming processes that can impact the taste of subsequent brews. This has led to a growing demand for innovative, food-safe cleaning solutions that can effectively sanitize cold brew equipment while being easy to use and environmentally friendly.

The market analysis reveals a significant opportunity for sodium percarbonate-based cleaning products specifically designed for cold brew coffee equipment. Sodium percarbonate, known for its powerful oxidizing properties and ability to break down organic compounds, aligns well with the cleanliness demands of the cold brew coffee industry. Its effectiveness in removing coffee oils and residues, combined with its ability to decompose into harmless byproducts, makes it an attractive option for both commercial and home users.

Consumer surveys indicate a strong preference for cleaning products that are both effective and eco-friendly. This aligns with the broader trend of sustainability in the coffee industry, where consumers are increasingly conscious of the environmental impact of their coffee consumption habits. Sodium percarbonate-based cleaners have the potential to meet this demand, offering a powerful cleaning solution that is biodegradable and leaves no harmful residues.

The market for cold brew coffee cleanliness products is segmented into commercial and residential sectors. The commercial sector, including cafes, restaurants, and coffee shops, represents a significant portion of the market, with a high demand for efficient, large-scale cleaning solutions. The residential sector, while smaller, is growing rapidly as more consumers adopt cold brew coffee making at home, creating a need for user-friendly cleaning products.

Industry reports suggest that the global market for specialized coffee cleaning products is expected to grow substantially in the coming years, with cold brew-specific solutions playing a significant role in this growth. The increasing popularity of cold brew coffee across different regions, particularly in North America and Europe, is driving the demand for innovative cleaning solutions.

In conclusion, the market analysis reveals a strong and growing demand for effective, safe, and environmentally friendly cleaning solutions for cold brew coffee equipment. Innovations in sodium percarbonate-based products have the potential to address this market need, offering a promising opportunity for product development and market expansion in the cold brew coffee cleanliness sector.

Cold brew coffee makers, both commercial and residential, require specialized cleaning to prevent the buildup of coffee oils, residues, and potential microbial contamination. Traditional cleaning methods often involve harsh chemicals or time-consuming processes that can impact the taste of subsequent brews. This has led to a growing demand for innovative, food-safe cleaning solutions that can effectively sanitize cold brew equipment while being easy to use and environmentally friendly.

The market analysis reveals a significant opportunity for sodium percarbonate-based cleaning products specifically designed for cold brew coffee equipment. Sodium percarbonate, known for its powerful oxidizing properties and ability to break down organic compounds, aligns well with the cleanliness demands of the cold brew coffee industry. Its effectiveness in removing coffee oils and residues, combined with its ability to decompose into harmless byproducts, makes it an attractive option for both commercial and home users.

Consumer surveys indicate a strong preference for cleaning products that are both effective and eco-friendly. This aligns with the broader trend of sustainability in the coffee industry, where consumers are increasingly conscious of the environmental impact of their coffee consumption habits. Sodium percarbonate-based cleaners have the potential to meet this demand, offering a powerful cleaning solution that is biodegradable and leaves no harmful residues.

The market for cold brew coffee cleanliness products is segmented into commercial and residential sectors. The commercial sector, including cafes, restaurants, and coffee shops, represents a significant portion of the market, with a high demand for efficient, large-scale cleaning solutions. The residential sector, while smaller, is growing rapidly as more consumers adopt cold brew coffee making at home, creating a need for user-friendly cleaning products.

Industry reports suggest that the global market for specialized coffee cleaning products is expected to grow substantially in the coming years, with cold brew-specific solutions playing a significant role in this growth. The increasing popularity of cold brew coffee across different regions, particularly in North America and Europe, is driving the demand for innovative cleaning solutions.

In conclusion, the market analysis reveals a strong and growing demand for effective, safe, and environmentally friendly cleaning solutions for cold brew coffee equipment. Innovations in sodium percarbonate-based products have the potential to address this market need, offering a promising opportunity for product development and market expansion in the cold brew coffee cleanliness sector.

Current Challenges in Cold Brew Sanitation

Cold brew coffee has gained significant popularity in recent years, but with its rise comes a set of unique sanitation challenges. The extended brewing process at room temperature creates an environment conducive to microbial growth, posing potential food safety risks. Traditional hot brewing methods naturally inhibit bacterial proliferation, but cold brew lacks this inherent safeguard.

One of the primary challenges in cold brew sanitation is the prevention of bacterial contamination during the lengthy steeping process, which can last anywhere from 12 to 24 hours. This extended contact time between water and coffee grounds at ambient temperatures provides an ideal breeding ground for microorganisms. Ensuring the cleanliness of brewing equipment, water quality, and coffee beans becomes paramount in mitigating these risks.

Another significant hurdle is the difficulty in implementing effective sanitization procedures without compromising the delicate flavor profile of cold brew coffee. Harsh chemical sanitizers can impart unwanted flavors or aromas, while heat-based sterilization methods are incompatible with the cold brewing process. This necessitates the development of gentle yet effective sanitation solutions that maintain the integrity of the final product.

The lack of standardized sanitation protocols specific to cold brew production further complicates the issue. Unlike hot brewing methods, which have well-established food safety guidelines, cold brew is a relatively new commercial product with evolving best practices. This regulatory gap leaves many producers uncertain about the most effective ways to ensure product safety and consistency.

Scale-up challenges also present themselves as cold brew production moves from small-batch to industrial levels. Maintaining sanitary conditions in larger brewing vessels and ensuring uniform cleanliness across increased production volumes require innovative approaches to equipment design and cleaning procedures.

Additionally, the shelf life of cold brew coffee is a concern closely tied to sanitation practices. Inadequate cleaning and sanitization can lead to rapid spoilage, reducing product viability and increasing waste. Balancing extended shelf life with minimal use of preservatives while maintaining product safety is an ongoing challenge for producers.

The need for sustainable sanitation solutions adds another layer of complexity. As the industry moves towards more environmentally friendly practices, finding eco-conscious cleaning and sanitizing methods that are both effective and aligned with sustainability goals becomes increasingly important.

Addressing these challenges requires a multifaceted approach, combining innovative cleaning technologies, rigorous quality control measures, and ongoing research into safe, flavor-neutral sanitization methods. The development of new sanitizing agents, such as those based on sodium percarbonate, offers promising avenues for overcoming these hurdles in cold brew coffee production.

One of the primary challenges in cold brew sanitation is the prevention of bacterial contamination during the lengthy steeping process, which can last anywhere from 12 to 24 hours. This extended contact time between water and coffee grounds at ambient temperatures provides an ideal breeding ground for microorganisms. Ensuring the cleanliness of brewing equipment, water quality, and coffee beans becomes paramount in mitigating these risks.

Another significant hurdle is the difficulty in implementing effective sanitization procedures without compromising the delicate flavor profile of cold brew coffee. Harsh chemical sanitizers can impart unwanted flavors or aromas, while heat-based sterilization methods are incompatible with the cold brewing process. This necessitates the development of gentle yet effective sanitation solutions that maintain the integrity of the final product.

The lack of standardized sanitation protocols specific to cold brew production further complicates the issue. Unlike hot brewing methods, which have well-established food safety guidelines, cold brew is a relatively new commercial product with evolving best practices. This regulatory gap leaves many producers uncertain about the most effective ways to ensure product safety and consistency.

Scale-up challenges also present themselves as cold brew production moves from small-batch to industrial levels. Maintaining sanitary conditions in larger brewing vessels and ensuring uniform cleanliness across increased production volumes require innovative approaches to equipment design and cleaning procedures.

Additionally, the shelf life of cold brew coffee is a concern closely tied to sanitation practices. Inadequate cleaning and sanitization can lead to rapid spoilage, reducing product viability and increasing waste. Balancing extended shelf life with minimal use of preservatives while maintaining product safety is an ongoing challenge for producers.

The need for sustainable sanitation solutions adds another layer of complexity. As the industry moves towards more environmentally friendly practices, finding eco-conscious cleaning and sanitizing methods that are both effective and aligned with sustainability goals becomes increasingly important.

Addressing these challenges requires a multifaceted approach, combining innovative cleaning technologies, rigorous quality control measures, and ongoing research into safe, flavor-neutral sanitization methods. The development of new sanitizing agents, such as those based on sodium percarbonate, offers promising avenues for overcoming these hurdles in cold brew coffee production.

Existing Sodium Percarbonate Solutions for Cold Brew

01 Sodium percarbonate as a cleaning agent

Sodium percarbonate is widely used as an effective cleaning agent in various applications. It releases hydrogen peroxide when dissolved in water, providing powerful oxidizing and bleaching properties. This makes it suitable for removing stains, disinfecting surfaces, and general cleaning purposes.- Sodium percarbonate as a cleaning agent: Sodium percarbonate is widely used as an effective cleaning agent in various applications. It releases hydrogen peroxide when dissolved in water, providing powerful oxidizing and bleaching properties. This makes it suitable for removing stains, disinfecting surfaces, and general cleaning purposes.

- Stabilization of sodium percarbonate: Various methods and additives are used to stabilize sodium percarbonate, improving its shelf life and effectiveness. These may include coating the particles, adding stabilizing agents, or modifying the manufacturing process to enhance the stability of the compound in storage and during use.

- Formulation of cleaning products with sodium percarbonate: Sodium percarbonate is incorporated into various cleaning product formulations, including laundry detergents, dishwashing agents, and all-purpose cleaners. The formulations often include other ingredients to enhance cleaning performance, such as surfactants, enzymes, and builders.

- Environmental and safety aspects of sodium percarbonate: Sodium percarbonate is considered an environmentally friendly cleaning agent as it breaks down into harmless substances (sodium carbonate and hydrogen peroxide). Its use in cleaning products can reduce the need for harsher chemicals, making it a safer alternative for both users and the environment.

- Manufacturing processes for sodium percarbonate: Various manufacturing processes are employed to produce sodium percarbonate with desired properties. These may include spray drying, fluidized bed processes, or other methods to create particles with specific characteristics such as size, shape, and stability.

02 Stabilization of sodium percarbonate

Various methods and additives are used to stabilize sodium percarbonate, improving its shelf life and effectiveness. These may include coating the particles, adding stabilizing agents, or modifying the manufacturing process to enhance the stability of the compound in storage and during use.Expand Specific Solutions03 Sodium percarbonate in laundry applications

Sodium percarbonate is commonly used in laundry detergents and stain removers. It acts as a bleaching agent and helps to remove tough stains from fabrics. The oxygen released during the cleaning process also helps to brighten and freshen clothes.Expand Specific Solutions04 Environmental and safety aspects

Sodium percarbonate is considered an environmentally friendly cleaning agent as it breaks down into harmless substances (sodium carbonate and water) after use. It is also generally safe for use on various surfaces and materials when used as directed, making it a popular choice for eco-conscious consumers.Expand Specific Solutions05 Formulations and combinations with other cleaning agents

Sodium percarbonate is often combined with other cleaning agents and additives to enhance its effectiveness or provide additional benefits. These formulations may include surfactants, enzymes, or other oxidizing agents to create more comprehensive cleaning solutions for various applications.Expand Specific Solutions

Key Players in Sodium Percarbonate and Coffee Cleaning

The market for sodium percarbonate innovations in cold brew coffee cleanliness is in its growth stage, with increasing demand driven by the rising popularity of cold brew coffee. The global market size is expanding, though exact figures are not readily available. Technologically, the field is moderately mature, with established players like Solvay SA and Ecolab, Inc. leading research and development efforts. However, there's room for innovation, particularly in enhancing efficiency and sustainability. Companies such as Zhejiang Jinke Daily Chemical Co. Ltd. and Puyang Hongye Environment Protection New Materials Co., Ltd. are emerging as significant contributors, especially in the Asian market. The competitive landscape is diverse, with a mix of chemical giants and specialized manufacturers vying for market share and technological breakthroughs.

Solvay SA

Technical Solution: Solvay SA has developed innovative sodium percarbonate solutions for cold brew coffee cleanliness. Their approach involves a stabilized sodium percarbonate formulation that maintains its effectiveness in cold water environments. The company has engineered particles with a protective coating that prevents premature decomposition, ensuring a sustained release of active oxygen for improved cleaning performance[1]. This technology allows for effective sanitization of cold brew equipment without the need for hot water, addressing the unique challenges of cold brew coffee production. Solvay's sodium percarbonate solutions also incorporate eco-friendly additives that enhance its biodegradability, aligning with the growing demand for sustainable cleaning products in the food and beverage industry[3].

Strengths: Effective in cold water, sustained release of active oxygen, eco-friendly formulation. Weaknesses: May require higher concentrations compared to hot water applications, potentially higher cost due to specialized coating technology.

Ecolab GmbH & Co. oHG

Technical Solution: Ecolab has developed a comprehensive cleaning solution for cold brew coffee equipment utilizing sodium percarbonate as a key component. Their system combines a specially formulated sodium percarbonate-based cleaner with proprietary dispensing technology to ensure optimal cleaning efficacy in cold water conditions. The company's approach includes a multi-step process that first removes coffee oils and residues, followed by a sanitization phase using the sodium percarbonate solution[2]. Ecolab's innovation lies in the precise control of the cleaning chemistry, which is tailored to the specific needs of cold brew coffee equipment. Their system also incorporates real-time monitoring and data analytics to optimize the cleaning process and reduce water and chemical usage[4].

Strengths: Comprehensive cleaning system, tailored for cold brew equipment, incorporates data analytics for optimization. Weaknesses: May require specialized equipment, potentially higher initial investment for implementation.

Innovative Sodium Percarbonate Formulations

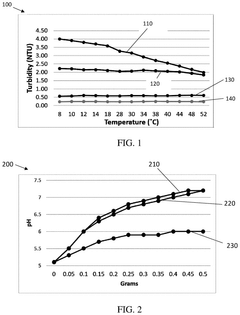

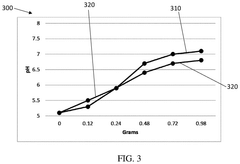

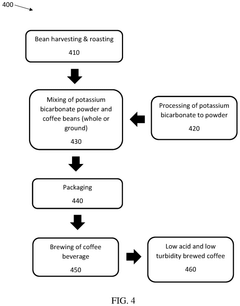

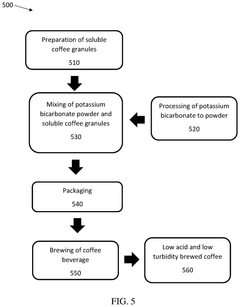

Process for decreasing turbidity and acidity in a coffee beverage

PatentPendingUS20240315271A1

Innovation

- Incorporating potassium bicarbonate into coffee beans, soluble coffee granules, or brewed coffee to neutralize acidity and reduce turbidity, utilizing its solubility and safety as a GRAS substance to adjust pH and clarity without adverse effects on taste.

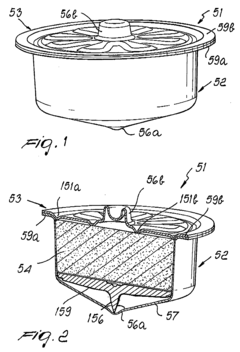

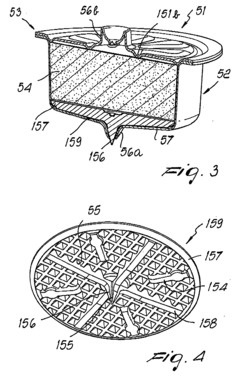

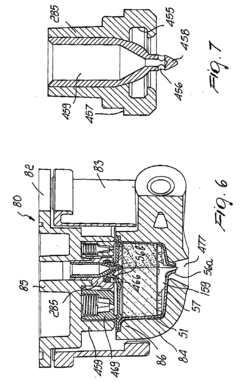

Integrated cartridge for extracting a beverage from a particulate substance

PatentInactiveEP1580144B1

Innovation

- An integrated cartridge with a cup and lid portion, featuring a tappet that automatically pierces the base to create an outlet for beverage extraction and an injection nozzle that spreads water evenly, ensuring air-tight preservation and easy installation, reducing contamination and manual handling.

Environmental Impact of Sodium Percarbonate Use

The use of sodium percarbonate in cold brew coffee cleaning processes has significant environmental implications that warrant careful consideration. As an oxidizing agent, sodium percarbonate breaks down into hydrogen peroxide and sodium carbonate when dissolved in water, providing an effective cleaning solution. However, its environmental impact extends beyond its primary cleaning function.

One of the key environmental benefits of sodium percarbonate is its biodegradability. Unlike some harsh chemical cleaners, sodium percarbonate decomposes into harmless substances: water, oxygen, and sodium carbonate. This natural breakdown process minimizes long-term environmental contamination and reduces the burden on wastewater treatment systems. Additionally, the oxygen released during decomposition can have a positive effect on aquatic ecosystems by increasing dissolved oxygen levels in water bodies.

However, the production and use of sodium percarbonate are not without environmental concerns. The manufacturing process requires energy and resources, contributing to carbon emissions and resource depletion. The mining and processing of raw materials, such as sodium carbonate and hydrogen peroxide, can have localized environmental impacts, including habitat disruption and potential water pollution if not properly managed.

In the context of cold brew coffee cleaning, the concentration and frequency of sodium percarbonate use are crucial factors in determining its overall environmental impact. Overuse or improper disposal of cleaning solutions containing sodium percarbonate can lead to excessive alkalinity in water systems, potentially harming aquatic life and altering ecosystem balance. Therefore, it is essential to optimize dosage and implement proper waste management practices to mitigate these risks.

The environmental footprint of sodium percarbonate extends to packaging and transportation. The production of plastic containers and the fuel consumed in distribution contribute to the overall environmental impact. Innovations in packaging, such as the use of recycled materials or concentrated formulations, can help reduce this aspect of the environmental burden.

When comparing sodium percarbonate to alternative cleaning agents, its environmental profile is generally favorable. Many traditional cleaners contain chlorine-based compounds or phosphates, which can have more severe and persistent environmental effects. Sodium percarbonate's ability to effectively clean at lower temperatures also offers energy-saving potential, indirectly reducing the carbon footprint associated with hot water usage in cleaning processes.

To further improve the environmental performance of sodium percarbonate in cold brew coffee cleaning, research is ongoing into more sustainable production methods, such as using renewable energy sources in manufacturing or developing bio-based alternatives. Additionally, efforts to educate users on proper application and disposal techniques can help minimize unnecessary environmental impact and promote responsible use of this cleaning agent in the coffee industry.

One of the key environmental benefits of sodium percarbonate is its biodegradability. Unlike some harsh chemical cleaners, sodium percarbonate decomposes into harmless substances: water, oxygen, and sodium carbonate. This natural breakdown process minimizes long-term environmental contamination and reduces the burden on wastewater treatment systems. Additionally, the oxygen released during decomposition can have a positive effect on aquatic ecosystems by increasing dissolved oxygen levels in water bodies.

However, the production and use of sodium percarbonate are not without environmental concerns. The manufacturing process requires energy and resources, contributing to carbon emissions and resource depletion. The mining and processing of raw materials, such as sodium carbonate and hydrogen peroxide, can have localized environmental impacts, including habitat disruption and potential water pollution if not properly managed.

In the context of cold brew coffee cleaning, the concentration and frequency of sodium percarbonate use are crucial factors in determining its overall environmental impact. Overuse or improper disposal of cleaning solutions containing sodium percarbonate can lead to excessive alkalinity in water systems, potentially harming aquatic life and altering ecosystem balance. Therefore, it is essential to optimize dosage and implement proper waste management practices to mitigate these risks.

The environmental footprint of sodium percarbonate extends to packaging and transportation. The production of plastic containers and the fuel consumed in distribution contribute to the overall environmental impact. Innovations in packaging, such as the use of recycled materials or concentrated formulations, can help reduce this aspect of the environmental burden.

When comparing sodium percarbonate to alternative cleaning agents, its environmental profile is generally favorable. Many traditional cleaners contain chlorine-based compounds or phosphates, which can have more severe and persistent environmental effects. Sodium percarbonate's ability to effectively clean at lower temperatures also offers energy-saving potential, indirectly reducing the carbon footprint associated with hot water usage in cleaning processes.

To further improve the environmental performance of sodium percarbonate in cold brew coffee cleaning, research is ongoing into more sustainable production methods, such as using renewable energy sources in manufacturing or developing bio-based alternatives. Additionally, efforts to educate users on proper application and disposal techniques can help minimize unnecessary environmental impact and promote responsible use of this cleaning agent in the coffee industry.

Food Safety Regulations for Coffee Cleaning Agents

The regulatory landscape for coffee cleaning agents, particularly those used in cold brew processes, is governed by a complex web of food safety regulations. These regulations are designed to ensure that cleaning agents used in food and beverage production do not pose health risks to consumers. In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing the safety of food contact substances, including cleaning agents used in coffee production.

Under the Federal Food, Drug, and Cosmetic Act, any substance that may become a component of food through its use in processing must be deemed safe for its intended use. This applies to sodium percarbonate and other cleaning agents used in cold brew coffee production. The FDA maintains a list of substances Generally Recognized as Safe (GRAS), which includes certain cleaning agents that have been proven safe through scientific procedures or long-standing use in food.

For innovative cleaning solutions like sodium percarbonate in cold brew coffee production, manufacturers must ensure compliance with FDA regulations. This includes providing evidence of safety through toxicological studies and demonstrating that the cleaning agent does not leave harmful residues on food contact surfaces. The FDA's Food Contact Notification (FCN) program is often utilized for new food contact substances, requiring manufacturers to submit detailed information about the chemical composition, intended use, and safety data of the cleaning agent.

In the European Union, the European Food Safety Authority (EFSA) sets guidelines for food contact materials, including cleaning agents. The EU's Regulation (EC) No 1935/2004 provides a harmonized legal framework for all materials and articles intended to come into contact with food. Manufacturers of cleaning agents for cold brew coffee equipment must ensure their products comply with these regulations, which may involve migration testing to ensure no harmful substances leach into the coffee.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a basis for their national regulations. These standards include guidelines for the safe use of food additives and processing aids, which can be applied to cleaning agents in coffee production.

As innovations in sodium percarbonate and other cleaning agents for cold brew coffee continue to emerge, manufacturers must navigate these regulatory frameworks to ensure their products meet all safety requirements. This often involves ongoing research, testing, and documentation to demonstrate compliance with evolving food safety standards across different markets and jurisdictions.

Under the Federal Food, Drug, and Cosmetic Act, any substance that may become a component of food through its use in processing must be deemed safe for its intended use. This applies to sodium percarbonate and other cleaning agents used in cold brew coffee production. The FDA maintains a list of substances Generally Recognized as Safe (GRAS), which includes certain cleaning agents that have been proven safe through scientific procedures or long-standing use in food.

For innovative cleaning solutions like sodium percarbonate in cold brew coffee production, manufacturers must ensure compliance with FDA regulations. This includes providing evidence of safety through toxicological studies and demonstrating that the cleaning agent does not leave harmful residues on food contact surfaces. The FDA's Food Contact Notification (FCN) program is often utilized for new food contact substances, requiring manufacturers to submit detailed information about the chemical composition, intended use, and safety data of the cleaning agent.

In the European Union, the European Food Safety Authority (EFSA) sets guidelines for food contact materials, including cleaning agents. The EU's Regulation (EC) No 1935/2004 provides a harmonized legal framework for all materials and articles intended to come into contact with food. Manufacturers of cleaning agents for cold brew coffee equipment must ensure their products comply with these regulations, which may involve migration testing to ensure no harmful substances leach into the coffee.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a basis for their national regulations. These standards include guidelines for the safe use of food additives and processing aids, which can be applied to cleaning agents in coffee production.

As innovations in sodium percarbonate and other cleaning agents for cold brew coffee continue to emerge, manufacturers must navigate these regulatory frameworks to ensure their products meet all safety requirements. This often involves ongoing research, testing, and documentation to demonstrate compliance with evolving food safety standards across different markets and jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!