Leading Edge Developments in Cellophane Coatings

JUL 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Coating Evolution and Objectives

Cellophane, a transparent film made from regenerated cellulose, has been a staple in packaging and coating applications for over a century. The evolution of cellophane coatings has been driven by the need for improved barrier properties, enhanced functionality, and increased sustainability. This journey began in the early 1900s with the invention of cellophane by Jacques E. Brandenberger and has since undergone significant transformations.

In its early days, cellophane was primarily used as a moisture-resistant packaging material. However, as the demands of the packaging industry grew, so did the need for more advanced cellophane coatings. The 1950s and 1960s saw the introduction of nitrocellulose coatings, which improved the moisture barrier properties of cellophane and extended its shelf life. This development marked a significant milestone in the evolution of cellophane coatings.

The 1970s and 1980s brought about a shift towards more environmentally friendly coating options. Water-based acrylic coatings emerged as a viable alternative to solvent-based systems, addressing growing concerns about volatile organic compounds (VOCs) and their impact on the environment. This period also saw the introduction of heat-sealable coatings, which greatly expanded the applications of cellophane in the packaging industry.

In recent years, the focus has shifted towards developing bio-based and biodegradable coatings for cellophane. This trend aligns with the growing demand for sustainable packaging solutions and the global push to reduce plastic waste. Researchers are exploring novel coating materials derived from renewable resources, such as plant-based proteins, polysaccharides, and lipids, to enhance the barrier properties of cellophane while maintaining its biodegradability.

The current objectives in cellophane coating development are multifaceted. Firstly, there is a strong emphasis on improving the oxygen and moisture barrier properties of cellophane coatings to extend the shelf life of packaged products, particularly in the food industry. Secondly, researchers are working on enhancing the mechanical properties of coated cellophane to improve its durability and resistance to tearing. Thirdly, there is a growing interest in developing active and intelligent coatings that can interact with the packaged product or provide information about its condition.

Another key objective is to reduce the environmental footprint of cellophane coatings. This includes developing fully compostable coatings, reducing the thickness of coating layers without compromising performance, and exploring ways to improve the recyclability of coated cellophane products. Additionally, there is a push towards creating multifunctional coatings that can combine barrier properties with antimicrobial or antioxidant capabilities, thus adding value to the packaging material.

In its early days, cellophane was primarily used as a moisture-resistant packaging material. However, as the demands of the packaging industry grew, so did the need for more advanced cellophane coatings. The 1950s and 1960s saw the introduction of nitrocellulose coatings, which improved the moisture barrier properties of cellophane and extended its shelf life. This development marked a significant milestone in the evolution of cellophane coatings.

The 1970s and 1980s brought about a shift towards more environmentally friendly coating options. Water-based acrylic coatings emerged as a viable alternative to solvent-based systems, addressing growing concerns about volatile organic compounds (VOCs) and their impact on the environment. This period also saw the introduction of heat-sealable coatings, which greatly expanded the applications of cellophane in the packaging industry.

In recent years, the focus has shifted towards developing bio-based and biodegradable coatings for cellophane. This trend aligns with the growing demand for sustainable packaging solutions and the global push to reduce plastic waste. Researchers are exploring novel coating materials derived from renewable resources, such as plant-based proteins, polysaccharides, and lipids, to enhance the barrier properties of cellophane while maintaining its biodegradability.

The current objectives in cellophane coating development are multifaceted. Firstly, there is a strong emphasis on improving the oxygen and moisture barrier properties of cellophane coatings to extend the shelf life of packaged products, particularly in the food industry. Secondly, researchers are working on enhancing the mechanical properties of coated cellophane to improve its durability and resistance to tearing. Thirdly, there is a growing interest in developing active and intelligent coatings that can interact with the packaged product or provide information about its condition.

Another key objective is to reduce the environmental footprint of cellophane coatings. This includes developing fully compostable coatings, reducing the thickness of coating layers without compromising performance, and exploring ways to improve the recyclability of coated cellophane products. Additionally, there is a push towards creating multifunctional coatings that can combine barrier properties with antimicrobial or antioxidant capabilities, thus adding value to the packaging material.

Market Demand Analysis for Advanced Cellophane Coatings

The market demand for advanced cellophane coatings has been experiencing significant growth in recent years, driven by various factors across multiple industries. The packaging sector, in particular, has shown a strong appetite for innovative cellophane coating solutions that offer enhanced barrier properties, improved sustainability, and extended shelf life for products.

In the food and beverage industry, there is a growing demand for cellophane coatings that provide superior moisture and oxygen barriers while maintaining the transparency and flexibility of traditional cellophane. This demand is fueled by consumer preferences for fresh, minimally processed foods with longer shelf lives and reduced food waste. The market has also seen an increased interest in coatings that offer antimicrobial properties, addressing food safety concerns and extending the usability of perishable goods.

The pharmaceutical and medical device sectors have emerged as key drivers of demand for advanced cellophane coatings. These industries require high-performance barrier materials that can protect sensitive drugs and medical equipment from moisture, oxygen, and contaminants. The need for sterile packaging solutions that can withstand various sterilization processes has further boosted the demand for specialized cellophane coatings in these sectors.

Environmental concerns and sustainability initiatives have significantly influenced market trends in cellophane coatings. There is a growing demand for bio-based and biodegradable coating solutions that can reduce the environmental impact of packaging materials. This shift is partly driven by regulatory pressures and consumer preferences for eco-friendly products, leading to increased research and development in sustainable cellophane coating technologies.

The electronics industry has also contributed to the market demand for advanced cellophane coatings. With the miniaturization of electronic components and the need for flexible displays, there is a rising interest in thin, transparent, and flexible coating materials that can provide protection against moisture and environmental factors while maintaining the functionality of electronic devices.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in demand for advanced cellophane coatings. This is attributed to the rapid industrialization, growing population, and increasing disposable income in countries like China and India. The region's expanding packaging industry and the adoption of advanced technologies in manufacturing processes are key factors driving this growth.

In terms of market size, the global cellophane coatings market is projected to reach substantial values in the coming years, with a compound annual growth rate (CAGR) that reflects the increasing adoption of these materials across various end-use industries. The market is characterized by ongoing research and development efforts aimed at improving coating performance, reducing costs, and addressing environmental concerns.

In the food and beverage industry, there is a growing demand for cellophane coatings that provide superior moisture and oxygen barriers while maintaining the transparency and flexibility of traditional cellophane. This demand is fueled by consumer preferences for fresh, minimally processed foods with longer shelf lives and reduced food waste. The market has also seen an increased interest in coatings that offer antimicrobial properties, addressing food safety concerns and extending the usability of perishable goods.

The pharmaceutical and medical device sectors have emerged as key drivers of demand for advanced cellophane coatings. These industries require high-performance barrier materials that can protect sensitive drugs and medical equipment from moisture, oxygen, and contaminants. The need for sterile packaging solutions that can withstand various sterilization processes has further boosted the demand for specialized cellophane coatings in these sectors.

Environmental concerns and sustainability initiatives have significantly influenced market trends in cellophane coatings. There is a growing demand for bio-based and biodegradable coating solutions that can reduce the environmental impact of packaging materials. This shift is partly driven by regulatory pressures and consumer preferences for eco-friendly products, leading to increased research and development in sustainable cellophane coating technologies.

The electronics industry has also contributed to the market demand for advanced cellophane coatings. With the miniaturization of electronic components and the need for flexible displays, there is a rising interest in thin, transparent, and flexible coating materials that can provide protection against moisture and environmental factors while maintaining the functionality of electronic devices.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in demand for advanced cellophane coatings. This is attributed to the rapid industrialization, growing population, and increasing disposable income in countries like China and India. The region's expanding packaging industry and the adoption of advanced technologies in manufacturing processes are key factors driving this growth.

In terms of market size, the global cellophane coatings market is projected to reach substantial values in the coming years, with a compound annual growth rate (CAGR) that reflects the increasing adoption of these materials across various end-use industries. The market is characterized by ongoing research and development efforts aimed at improving coating performance, reducing costs, and addressing environmental concerns.

Current Challenges in Cellophane Coating Technology

Cellophane coating technology, while well-established, faces several significant challenges in the current landscape. One of the primary issues is the environmental impact of traditional cellophane production and coating processes. The use of carbon disulfide in the manufacturing of cellophane raises concerns about toxicity and environmental pollution. This has led to increased pressure from regulatory bodies and consumers for more sustainable alternatives.

Another challenge lies in improving the barrier properties of cellophane coatings. While cellophane offers good moisture resistance, its gas barrier properties, particularly against oxygen, are limited. This restricts its use in certain packaging applications, especially for products requiring extended shelf life. The industry is actively seeking ways to enhance these barrier properties without compromising the material's inherent biodegradability and transparency.

The cost-effectiveness of cellophane coatings is also a significant hurdle. With the rise of synthetic polymers that offer similar or superior properties at lower costs, cellophane faces stiff competition in various market segments. Manufacturers are challenged to develop more economical production methods and coating techniques to maintain cellophane's competitiveness.

Adhesion issues present another technical challenge in cellophane coating technology. Ensuring strong and durable adhesion between the cellophane substrate and various coating materials across different environmental conditions remains a complex task. This is particularly crucial for applications requiring resistance to moisture, heat, or mechanical stress.

The demand for enhanced functionality in packaging materials is pushing the boundaries of cellophane coating technology. There is a growing need for coatings that provide not just barrier properties but also active functions such as antimicrobial activity, controlled release of preservatives, or indicators for food freshness. Developing such multifunctional coatings while maintaining the core properties of cellophane is a significant challenge.

Scalability and process efficiency in coating application represent another area of concern. As the packaging industry moves towards higher production speeds and larger volumes, coating technologies need to keep pace. Achieving uniform and defect-free coatings at high speeds, while minimizing waste and energy consumption, remains a technical hurdle.

Lastly, the recyclability and end-of-life management of coated cellophane products pose challenges. While uncoated cellophane is biodegradable, certain coatings can interfere with this property. Developing coating solutions that do not impede the biodegradability or recyclability of cellophane, while still providing the desired functional properties, is a complex balancing act that the industry continues to grapple with.

Another challenge lies in improving the barrier properties of cellophane coatings. While cellophane offers good moisture resistance, its gas barrier properties, particularly against oxygen, are limited. This restricts its use in certain packaging applications, especially for products requiring extended shelf life. The industry is actively seeking ways to enhance these barrier properties without compromising the material's inherent biodegradability and transparency.

The cost-effectiveness of cellophane coatings is also a significant hurdle. With the rise of synthetic polymers that offer similar or superior properties at lower costs, cellophane faces stiff competition in various market segments. Manufacturers are challenged to develop more economical production methods and coating techniques to maintain cellophane's competitiveness.

Adhesion issues present another technical challenge in cellophane coating technology. Ensuring strong and durable adhesion between the cellophane substrate and various coating materials across different environmental conditions remains a complex task. This is particularly crucial for applications requiring resistance to moisture, heat, or mechanical stress.

The demand for enhanced functionality in packaging materials is pushing the boundaries of cellophane coating technology. There is a growing need for coatings that provide not just barrier properties but also active functions such as antimicrobial activity, controlled release of preservatives, or indicators for food freshness. Developing such multifunctional coatings while maintaining the core properties of cellophane is a significant challenge.

Scalability and process efficiency in coating application represent another area of concern. As the packaging industry moves towards higher production speeds and larger volumes, coating technologies need to keep pace. Achieving uniform and defect-free coatings at high speeds, while minimizing waste and energy consumption, remains a technical hurdle.

Lastly, the recyclability and end-of-life management of coated cellophane products pose challenges. While uncoated cellophane is biodegradable, certain coatings can interfere with this property. Developing coating solutions that do not impede the biodegradability or recyclability of cellophane, while still providing the desired functional properties, is a complex balancing act that the industry continues to grapple with.

State-of-the-Art Cellophane Coating Solutions

01 Cellophane coatings for food packaging

Cellophane coatings are widely used in food packaging applications due to their excellent barrier properties against moisture and gases. These coatings help extend the shelf life of food products by preventing oxidation and moisture loss. The transparent nature of cellophane also allows for visual inspection of the packaged food items.- Cellophane coatings for food packaging: Cellophane coatings are widely used in food packaging applications due to their barrier properties and transparency. These coatings can be modified to enhance moisture resistance, oxygen barrier properties, and overall shelf life of food products. The coatings can be applied to various substrates and may incorporate additional functional additives.

- Biodegradable cellophane coatings: Development of biodegradable cellophane coatings addresses environmental concerns associated with traditional packaging materials. These coatings are derived from renewable resources and can be engineered to maintain desired barrier properties while being compostable or easily degradable in natural environments.

- Cellophane coatings with antimicrobial properties: Incorporation of antimicrobial agents into cellophane coatings enhances food safety and extends product shelf life. These coatings can inhibit the growth of bacteria, fungi, and other microorganisms on the surface of packaged goods, reducing the risk of contamination and spoilage.

- Cellophane coatings for electronic applications: Cellophane coatings find applications in electronic devices and components. These coatings can provide insulation, protection against moisture and dust, and improve the overall durability of electronic products. Modified cellophane coatings may also offer specific electrical or thermal properties for specialized applications.

- Cellophane coating processes and equipment: Advancements in coating processes and equipment for applying cellophane coatings to various substrates. This includes innovations in coating techniques, drying methods, and machinery designed specifically for cellophane coating applications. These developments aim to improve coating uniformity, efficiency, and overall product quality.

02 Biodegradable cellophane coatings

Researchers are developing biodegradable cellophane coatings to address environmental concerns associated with traditional packaging materials. These eco-friendly coatings are derived from renewable resources and can decompose naturally, reducing the environmental impact of packaging waste.Expand Specific Solutions03 Cellophane coatings with enhanced properties

Advanced cellophane coatings are being developed with improved properties such as increased strength, better heat resistance, and enhanced barrier functions. These coatings may incorporate additives or undergo special treatments to achieve desired characteristics for specific applications.Expand Specific Solutions04 Cellophane coatings for medical applications

Cellophane coatings are being explored for various medical applications, including wound dressings and drug delivery systems. These coatings can provide a protective barrier while allowing for controlled release of medications or maintaining a moist environment for wound healing.Expand Specific Solutions05 Cellophane coating processes and equipment

Various processes and equipment have been developed for applying cellophane coatings efficiently and uniformly. These may include specialized coating machines, drying systems, and quality control measures to ensure consistent coating thickness and performance across different substrates.Expand Specific Solutions

Key Players in Cellophane Coating Industry

The market for cellophane coatings is in a mature stage, with established players and steady demand. The global market size is estimated to be in the billions of dollars, driven by applications in packaging, electronics, and other industries. Technologically, cellophane coatings are well-developed, but innovation continues in areas like sustainability and performance enhancement. Key players like 3M, Hempel, and BASF Coatings are leading research efforts, while academic institutions such as South China University of Technology and Nanjing Tech University contribute to advancing the field. Emerging trends include bio-based materials and nanotechnology applications, indicating potential for future growth and technological advancements in this sector.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced cellophane coatings with enhanced barrier properties. Their technology involves a multi-layer coating system that combines cellulose-based materials with synthetic polymers. This approach results in a biodegradable film with improved moisture resistance and oxygen barrier properties[1]. The company has also introduced nanotechnology in their cellophane coatings, incorporating nanoparticles to enhance mechanical strength and thermal stability[3]. 3M's coatings are designed to be compatible with various substrates, allowing for versatile applications in food packaging, electronics, and medical devices[5].

Strengths: Excellent barrier properties, biodegradability, versatility across industries. Weaknesses: Potentially higher production costs, complexity in manufacturing multi-layer systems.

Daicel Corp.

Technical Solution: Daicel Corporation has made significant strides in cellophane coating technology, focusing on eco-friendly solutions. Their approach involves using cellulose derivatives and bio-based plasticizers to create high-performance, sustainable coatings[2]. Daicel has developed a proprietary process for producing cellulose nanofibers, which are incorporated into their cellophane coatings to enhance strength and flexibility[4]. The company has also introduced antimicrobial additives to their coatings, addressing growing demand for hygienic packaging solutions[6]. Daicel's coatings are particularly noted for their excellent printability and heat-sealability, making them ideal for flexible packaging applications.

Strengths: Eco-friendly formulations, enhanced mechanical properties, antimicrobial features. Weaknesses: May have limitations in extreme temperature applications, potentially higher cost compared to traditional coatings.

Innovative Cellophane Coating Patents and Research

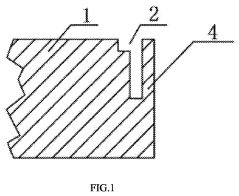

Protective coating material on side edge for capacitive touch screen panel

PatentActiveKR1020150053111A

Innovation

- A side-reinforced resin composition is used, incorporating pigments to match the color of the printed layer, which is applied to the cut surfaces of the glass substrate, enhancing the adhesion and strength of the side surfaces through ultraviolet curing and mixing with silane coupling agents.

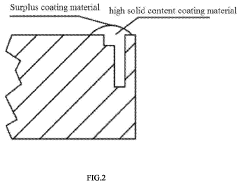

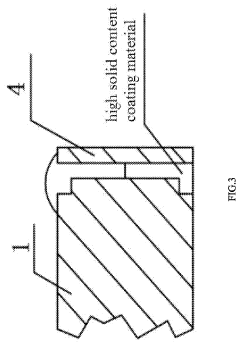

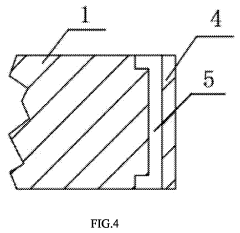

Board edge casting process and application thereof

PatentActiveUS20230241800A1

Innovation

- An edge-casting process involving grooving, casting high solid content coating material, and milling to create seamless cast edges that integrate with the sheet material, allowing for diverse shapes and improved adhesion, and applying this process to melamine veneers with 3D printing for enhanced waterproofness and surface integration.

Environmental Impact of Cellophane Coatings

The environmental impact of cellophane coatings has become a significant concern in recent years, as the widespread use of these materials in packaging and other applications has raised questions about their sustainability and long-term effects on ecosystems. Cellophane, a biodegradable material derived from cellulose, has traditionally been viewed as a more environmentally friendly alternative to petroleum-based plastics. However, the coatings applied to cellophane to enhance its properties often introduce complexities in terms of environmental impact.

One of the primary environmental concerns associated with cellophane coatings is their potential to hinder the biodegradability of the base material. While uncoated cellophane can decompose naturally in a relatively short time, certain coatings may significantly extend this process or render the material non-biodegradable. This can lead to accumulation in landfills or natural environments, contributing to pollution and habitat disruption.

Water pollution is another critical issue related to cellophane coatings. Some coating materials, particularly those containing synthetic chemicals or heavy metals, can leach into water systems during the degradation process. This contamination poses risks to aquatic ecosystems and potentially to human health if it enters drinking water supplies. Additionally, the production processes for certain coatings may involve the use of harmful chemicals, which can result in industrial wastewater pollution if not properly managed.

The carbon footprint associated with the production and disposal of cellophane coatings is also a significant environmental consideration. The energy-intensive manufacturing processes for some advanced coatings contribute to greenhouse gas emissions, exacerbating climate change concerns. Furthermore, the end-of-life disposal of coated cellophane products often requires specialized recycling or waste management processes, which can be energy-intensive and may not be widely available in all regions.

On a positive note, recent advancements in coating technologies have led to the development of more environmentally friendly options. Bio-based coatings derived from renewable resources are emerging as promising alternatives, offering improved biodegradability and reduced environmental impact. Additionally, some innovative coating techniques are focusing on enhancing the recyclability of cellophane products, aiming to create a more circular economy approach to packaging materials.

The environmental impact of cellophane coatings extends beyond their direct effects on ecosystems. The use of these materials in food packaging, for instance, can have indirect environmental benefits by reducing food waste through improved preservation. However, this must be balanced against the potential risks of chemical migration from coatings into food products, which remains an area of ongoing research and regulatory scrutiny.

As awareness of environmental issues grows, there is increasing pressure on manufacturers to develop and adopt more sustainable coating technologies for cellophane. This has spurred research into novel materials and processes that aim to minimize environmental impact while maintaining or improving the functional properties of coated cellophane products. The challenge lies in finding solutions that are not only environmentally sound but also economically viable and capable of meeting the performance requirements of various applications.

One of the primary environmental concerns associated with cellophane coatings is their potential to hinder the biodegradability of the base material. While uncoated cellophane can decompose naturally in a relatively short time, certain coatings may significantly extend this process or render the material non-biodegradable. This can lead to accumulation in landfills or natural environments, contributing to pollution and habitat disruption.

Water pollution is another critical issue related to cellophane coatings. Some coating materials, particularly those containing synthetic chemicals or heavy metals, can leach into water systems during the degradation process. This contamination poses risks to aquatic ecosystems and potentially to human health if it enters drinking water supplies. Additionally, the production processes for certain coatings may involve the use of harmful chemicals, which can result in industrial wastewater pollution if not properly managed.

The carbon footprint associated with the production and disposal of cellophane coatings is also a significant environmental consideration. The energy-intensive manufacturing processes for some advanced coatings contribute to greenhouse gas emissions, exacerbating climate change concerns. Furthermore, the end-of-life disposal of coated cellophane products often requires specialized recycling or waste management processes, which can be energy-intensive and may not be widely available in all regions.

On a positive note, recent advancements in coating technologies have led to the development of more environmentally friendly options. Bio-based coatings derived from renewable resources are emerging as promising alternatives, offering improved biodegradability and reduced environmental impact. Additionally, some innovative coating techniques are focusing on enhancing the recyclability of cellophane products, aiming to create a more circular economy approach to packaging materials.

The environmental impact of cellophane coatings extends beyond their direct effects on ecosystems. The use of these materials in food packaging, for instance, can have indirect environmental benefits by reducing food waste through improved preservation. However, this must be balanced against the potential risks of chemical migration from coatings into food products, which remains an area of ongoing research and regulatory scrutiny.

As awareness of environmental issues grows, there is increasing pressure on manufacturers to develop and adopt more sustainable coating technologies for cellophane. This has spurred research into novel materials and processes that aim to minimize environmental impact while maintaining or improving the functional properties of coated cellophane products. The challenge lies in finding solutions that are not only environmentally sound but also economically viable and capable of meeting the performance requirements of various applications.

Regulatory Framework for Cellophane Coating Applications

The regulatory framework for cellophane coating applications is a complex and evolving landscape that significantly impacts the development and implementation of new technologies in this field. As cellophane coatings continue to advance, regulatory bodies worldwide are adapting their guidelines to ensure safety, environmental protection, and quality standards are met.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating cellophane coatings, particularly for food packaging applications. The FDA's regulations focus on the safety of materials that come into contact with food, including cellophane coatings. Manufacturers must comply with the FDA's Food Contact Substance Notification (FCN) program, which requires thorough testing and documentation of the safety of new coating materials.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects cellophane coating manufacturers and users. REACH mandates the registration of chemical substances and promotes the use of safer alternatives. Additionally, the EU's Plastic Materials and Articles in Contact with Food Regulation (EU) No 10/2011 sets specific requirements for plastic materials used in food contact applications, including certain cellophane coatings.

Environmental regulations are becoming increasingly stringent, with many countries implementing policies to reduce plastic waste and promote sustainable packaging solutions. This has led to a growing emphasis on biodegradable and compostable cellophane coatings. Manufacturers must navigate these regulations and obtain appropriate certifications to market their products as environmentally friendly.

In Asia, countries like China and Japan have their own regulatory frameworks for cellophane coatings. China's GB standards, administered by the Standardization Administration of China (SAC), cover various aspects of cellophane coating production and use. Japan's Ministry of Health, Labour and Welfare enforces strict regulations on food packaging materials, including cellophane coatings.

International standards organizations, such as the International Organization for Standardization (ISO), provide guidelines that influence regulatory frameworks globally. ISO standards related to packaging materials and food safety management systems often inform national regulations and industry best practices for cellophane coatings.

As nanotechnology becomes more prevalent in cellophane coating applications, regulatory bodies are developing new guidelines to address potential risks. The Organization for Economic Co-operation and Development (OECD) has been working on harmonizing international approaches to the safety assessment of nanomaterials, which may impact future regulations for advanced cellophane coatings.

Compliance with these diverse regulatory requirements presents both challenges and opportunities for companies involved in cellophane coating development. Staying abreast of regulatory changes and proactively adapting to new standards is essential for success in this rapidly evolving field.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating cellophane coatings, particularly for food packaging applications. The FDA's regulations focus on the safety of materials that come into contact with food, including cellophane coatings. Manufacturers must comply with the FDA's Food Contact Substance Notification (FCN) program, which requires thorough testing and documentation of the safety of new coating materials.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects cellophane coating manufacturers and users. REACH mandates the registration of chemical substances and promotes the use of safer alternatives. Additionally, the EU's Plastic Materials and Articles in Contact with Food Regulation (EU) No 10/2011 sets specific requirements for plastic materials used in food contact applications, including certain cellophane coatings.

Environmental regulations are becoming increasingly stringent, with many countries implementing policies to reduce plastic waste and promote sustainable packaging solutions. This has led to a growing emphasis on biodegradable and compostable cellophane coatings. Manufacturers must navigate these regulations and obtain appropriate certifications to market their products as environmentally friendly.

In Asia, countries like China and Japan have their own regulatory frameworks for cellophane coatings. China's GB standards, administered by the Standardization Administration of China (SAC), cover various aspects of cellophane coating production and use. Japan's Ministry of Health, Labour and Welfare enforces strict regulations on food packaging materials, including cellophane coatings.

International standards organizations, such as the International Organization for Standardization (ISO), provide guidelines that influence regulatory frameworks globally. ISO standards related to packaging materials and food safety management systems often inform national regulations and industry best practices for cellophane coatings.

As nanotechnology becomes more prevalent in cellophane coating applications, regulatory bodies are developing new guidelines to address potential risks. The Organization for Economic Co-operation and Development (OECD) has been working on harmonizing international approaches to the safety assessment of nanomaterials, which may impact future regulations for advanced cellophane coatings.

Compliance with these diverse regulatory requirements presents both challenges and opportunities for companies involved in cellophane coating development. Staying abreast of regulatory changes and proactively adapting to new standards is essential for success in this rapidly evolving field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!