Managing Complexities in Cellophane Flexible Applications

Cellophane Flex Tech Evolution and Objectives

Cellophane flexible applications have undergone significant evolution since their inception in the early 20th century. Initially developed as a moisture-proof packaging material, cellophane has transformed into a versatile substrate for various flexible applications. The technology's progression has been driven by the increasing demand for sustainable, biodegradable materials in packaging and other industries.

The evolution of cellophane flex technology can be traced through several key milestones. In the 1920s, the basic manufacturing process was established, involving the regeneration of cellulose from wood pulp. The 1950s saw improvements in coating technologies, enhancing cellophane's barrier properties. The 1970s and 1980s brought advancements in plasticizers and additives, expanding cellophane's flexibility and durability.

Recent developments have focused on enhancing cellophane's performance in flexible applications. This includes improving its heat-sealing properties, increasing its resistance to moisture and gases, and developing new surface treatments for better printability and adhesion. The integration of nanotechnology has also played a crucial role in enhancing cellophane's mechanical and barrier properties.

The primary objective in managing complexities in cellophane flexible applications is to optimize its performance while maintaining its eco-friendly characteristics. This involves addressing challenges such as improving its heat resistance, enhancing its barrier properties against oxygen and moisture, and increasing its overall durability without compromising its biodegradability.

Another key goal is to develop cellophane-based materials that can compete with synthetic plastics in terms of functionality and cost-effectiveness. This requires innovations in manufacturing processes to reduce production costs and improve scalability. Additionally, there is a focus on expanding cellophane's applications beyond packaging, exploring its potential in electronics, medical devices, and other high-tech fields.

The future trajectory of cellophane flex technology is likely to involve the development of smart and active packaging solutions. This includes incorporating sensors and indicators into cellophane-based materials for improved food safety and quality monitoring. Research is also being conducted on enhancing cellophane's compatibility with emerging technologies such as printed electronics and flexible displays.

Market Analysis for Cellophane Flexible Applications

The global market for cellophane flexible applications has experienced significant growth in recent years, driven by increasing demand for sustainable packaging solutions across various industries. The versatility and eco-friendly nature of cellophane have positioned it as a preferred material for flexible packaging, particularly in the food and beverage, personal care, and pharmaceutical sectors.

Market research indicates that the cellophane flexible packaging market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to exceed 5% over the next five years. This growth is primarily attributed to the rising consumer awareness of environmental issues and the subsequent shift towards biodegradable and compostable packaging materials.

The food and beverage industry remains the largest consumer of cellophane flexible applications, accounting for over 40% of the market share. The material's excellent barrier properties against moisture, gases, and odors make it ideal for preserving food quality and extending shelf life. Additionally, the transparency of cellophane allows for attractive product presentation, which is crucial in the competitive retail environment.

In the personal care and cosmetics sector, cellophane flexible packaging is gaining traction due to its ability to protect sensitive products from external contaminants while maintaining an appealing aesthetic. The pharmaceutical industry is also adopting cellophane for blister packs and sachets, leveraging its moisture resistance and compatibility with various sterilization methods.

Geographically, Asia-Pacific leads the market for cellophane flexible applications, followed by North America and Europe. The rapid industrialization and growing population in countries like China and India are driving the demand for flexible packaging solutions in the region. However, stringent regulations regarding plastic use in Europe are expected to boost the adoption of cellophane as an alternative packaging material in the coming years.

Despite the positive market outlook, challenges remain in the cellophane flexible applications industry. The complexity of managing the production process, ensuring consistent quality, and addressing the limitations of cellophane in certain high-barrier applications are areas that require ongoing innovation and technological advancements.

To capitalize on the market potential, key players in the industry are focusing on developing advanced cellophane formulations with enhanced properties, such as improved heat resistance and barrier performance. Additionally, investments in research and development are being made to optimize production processes and reduce costs, making cellophane more competitive against synthetic alternatives.

As sustainability continues to be a driving force in consumer preferences and regulatory landscapes, the market for cellophane flexible applications is poised for further expansion. The industry's ability to address the complexities in production and application while meeting the evolving demands for eco-friendly packaging will be crucial in shaping its future growth trajectory.

Cellophane Flexibility Challenges and Limitations

Cellophane, a versatile and widely used packaging material, faces several challenges and limitations in flexible applications. One of the primary issues is its sensitivity to moisture, which can significantly affect its performance. When exposed to high humidity or direct contact with water, cellophane tends to absorb moisture, leading to dimensional changes and potential loss of structural integrity. This hygroscopic nature can result in warping, wrinkling, or even tearing of the material, compromising its effectiveness as a barrier and protective layer.

Another challenge lies in cellophane's limited heat resistance. While it performs well at room temperature, exposure to high temperatures can cause the material to soften, distort, or even melt. This thermal sensitivity restricts its use in applications involving hot-filling processes or in environments with elevated temperatures, limiting its versatility in certain packaging scenarios.

Cellophane also exhibits relatively low tear resistance compared to some synthetic polymers. This characteristic makes it more susceptible to damage during handling, transportation, or use, potentially compromising the integrity of the packaged contents. The material's brittleness at low temperatures further exacerbates this issue, making it less suitable for cold storage or freezer applications.

The material's permeability to certain gases, particularly oxygen, poses another limitation. While cellophane provides a good barrier against water vapor, its oxygen transmission rate is higher than some alternative packaging materials. This property can be problematic for products sensitive to oxidation, such as certain foods or pharmaceuticals, potentially reducing shelf life or product quality.

Cellophane's limited stretchability and elasticity present challenges in applications requiring high flexibility or conformability. Unlike some plastic films, cellophane does not easily conform to irregular shapes or stretch to accommodate product expansion, which can restrict its use in certain packaging designs or for specific product types.

The material's sensitivity to UV light is another concern, as prolonged exposure can lead to degradation, discoloration, and loss of mechanical properties. This limitation necessitates additional protective measures or restricts its use in applications with significant UV exposure.

Lastly, the production of cellophane involves the use of chemicals and processes that can be environmentally challenging. While cellophane is biodegradable, the manufacturing process can have a higher environmental impact compared to some synthetic alternatives, raising sustainability concerns in an increasingly eco-conscious market.

Current Solutions for Cellophane Flexibility Management

01 Cellophane production and processing methods

Various techniques for producing and processing cellophane, including improvements in manufacturing processes, chemical treatments, and modifications to enhance its properties. These methods aim to optimize the production of cellophane for different applications and improve its overall quality and performance.- Cellophane manufacturing processes: Various methods and improvements in the production of cellophane, including chemical treatments, extrusion techniques, and modifications to enhance properties such as strength, transparency, and barrier characteristics.

- Cellophane packaging applications: Innovative uses of cellophane in packaging, including food wrapping, consumer goods packaging, and specialized industrial applications. This includes developments in heat-sealable cellophane and biodegradable variants.

- Cellophane surface treatments and coatings: Techniques for modifying cellophane surfaces to enhance properties such as adhesion, printability, and moisture resistance. This includes the application of various coatings and surface treatments to improve functionality.

- Cellophane-based composite materials: Development of composite materials incorporating cellophane, combining it with other materials to create products with enhanced properties such as improved strength, flexibility, or specific functional characteristics.

- Cellophane recycling and environmental considerations: Advancements in cellophane recycling processes and the development of more environmentally friendly cellophane variants. This includes biodegradable formulations and methods to reduce the environmental impact of cellophane production and disposal.

02 Cellophane packaging solutions

Innovative packaging solutions utilizing cellophane, including designs for food packaging, consumer goods, and industrial applications. These solutions focus on improving the functionality, aesthetics, and sustainability of cellophane-based packaging materials.Expand Specific Solutions03 Cellophane-based composite materials

Development of composite materials incorporating cellophane, combining it with other substances to create new materials with enhanced properties. These composites aim to leverage the unique characteristics of cellophane while addressing its limitations through synergistic combinations with other materials.Expand Specific Solutions04 Cellophane modification techniques

Methods for modifying cellophane to enhance its properties, such as improving barrier properties, increasing strength, or adding functionality. These techniques involve chemical treatments, surface modifications, or the incorporation of additives to tailor cellophane for specific applications.Expand Specific Solutions05 Cellophane analysis and quality control

Techniques and systems for analyzing cellophane properties, ensuring quality control in production, and characterizing its behavior under various conditions. These methods help in maintaining consistency in cellophane production and optimizing its performance for different applications.Expand Specific Solutions

Key Players in Cellophane Flexible Industry

The market for managing complexities in cellophane flexible applications is in a growth phase, driven by increasing demand for advanced packaging solutions across various industries. The global market size is expanding, with a projected CAGR of 4-5% over the next five years. Technologically, the field is moderately mature but continues to evolve, with companies like China National Building Material Group, Samsung Electronics, and Huawei Technologies leading innovation. These firms are investing in R&D to enhance cellophane's properties, such as improved barrier functions and sustainability. Emerging players like Tunghsu Optoelectronic and Triumph Science & Technology are also contributing to technological advancements, particularly in areas of flexible electronics and eco-friendly materials.

Samsung Electronics Co., Ltd.

Huawei Technologies Co., Ltd.

Innovative Approaches in Cellophane Flexibility

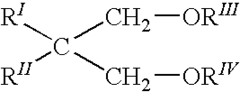

- A polyolefin composition comprising a crystalline polymer fraction and an elastomeric fraction, prepared through sequential polymerization stages using specific catalysts, achieving a flexural modulus below 60 MPa, Shore A hardness below 90, and tension set at 100% lower than 35%, while maintaining transparency and chemical inertia.

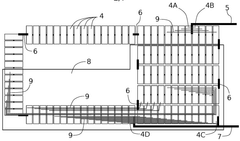

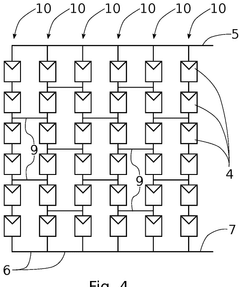

- A flexible interconnection structure is implemented in photovoltaic modules, featuring a structural film with conductive tracks and connection zones that can be folded to facilitate electrical connections, allowing for complex electrical architectures without increasing costs or reducing cell density.

Environmental Impact of Cellophane Flex Applications

The environmental impact of cellophane flexible applications is a critical consideration in the modern packaging industry. Cellophane, a biodegradable material derived from cellulose, offers several advantages over traditional plastic packaging. However, its production and disposal still pose significant environmental challenges that must be addressed.

The manufacturing process of cellophane involves the use of chemicals and energy-intensive procedures, which contribute to carbon emissions and potential water pollution. The production requires large amounts of wood pulp, raising concerns about deforestation and habitat destruction. Additionally, the chemical treatments used to enhance cellophane's properties can introduce harmful substances into the environment if not properly managed.

Despite these concerns, cellophane's biodegradability gives it an edge over conventional plastics in terms of end-of-life environmental impact. When disposed of in appropriate conditions, cellophane can decompose within a few months to a few years, significantly reducing long-term pollution compared to petroleum-based plastics that persist for centuries.

The recyclability of cellophane presents both opportunities and challenges. While technically recyclable, the infrastructure for collecting and processing cellophane waste is not as well-established as that for other materials. This limitation often results in cellophane ending up in landfills or incineration facilities, negating its potential environmental benefits.

Water usage in cellophane production is another area of environmental concern. The manufacturing process requires substantial amounts of water, which can strain local water resources in areas where production facilities are located. Implementing water recycling systems and improving production efficiency can help mitigate this impact.

The carbon footprint of cellophane throughout its lifecycle, from raw material extraction to disposal, is an important factor to consider. While lower than many synthetic alternatives, the carbon emissions associated with cellophane production and transportation still contribute to global warming. Efforts to reduce this footprint through renewable energy use and optimized logistics are crucial for improving the overall environmental profile of cellophane applications.

As the demand for sustainable packaging solutions grows, innovations in cellophane production and application are emerging. These include the development of bio-based additives to enhance performance without compromising biodegradability, and the exploration of alternative raw materials that reduce reliance on wood pulp. Such advancements hold promise for further reducing the environmental impact of cellophane flexible applications in the future.

Regulatory Framework for Cellophane Flexible Products

The regulatory framework for cellophane flexible products is a complex and evolving landscape that significantly impacts the development, production, and distribution of these materials. At the global level, organizations such as the World Health Organization (WHO) and the Food and Agriculture Organization (FAO) provide guidelines that influence national regulations. These guidelines often focus on food safety, as cellophane is frequently used in food packaging applications.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating cellophane products, particularly those intended for food contact. The FDA's regulations are outlined in the Code of Federal Regulations (CFR), specifically in 21 CFR 177.1200, which details the requirements for cellophane as an indirect food additive. This regulation covers aspects such as composition, manufacturing processes, and permissible additives.

The European Union has established a comprehensive regulatory framework for food contact materials, including cellophane, through Regulation (EC) No 1935/2004. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, Commission Regulation (EU) No 10/2011 provides specific requirements for plastic materials and articles intended to come into contact with food, which may apply to certain cellophane products.

Environmental considerations are increasingly shaping the regulatory landscape for cellophane flexible products. Many jurisdictions are implementing regulations aimed at reducing plastic waste and promoting sustainable packaging solutions. For instance, the EU's Single-Use Plastics Directive, while primarily targeting conventional plastics, may indirectly affect cellophane products depending on their specific applications and disposal methods.

Manufacturers of cellophane flexible products must also navigate regulations related to chemical safety. The Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation in the EU and the Toxic Substances Control Act (TSCA) in the US impose requirements on the use of certain chemicals in manufacturing processes and final products.

As sustainability becomes a greater focus, regulations are evolving to address the entire lifecycle of cellophane products. This includes considerations for raw material sourcing, production processes, and end-of-life management. Some jurisdictions are implementing extended producer responsibility (EPR) schemes, which may require manufacturers to take responsibility for the collection and recycling of their products after use.

Compliance with these diverse regulatory requirements presents significant challenges for manufacturers in managing the complexities of cellophane flexible applications. It necessitates ongoing monitoring of regulatory developments, investment in research and development to meet evolving standards, and the implementation of robust quality control and traceability systems throughout the supply chain.