Nanocomposite design using MSH for pollutant capture.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocomposite MSH Background and Objectives

Nanocomposite materials have emerged as a promising solution for environmental remediation, particularly in the field of pollutant capture. The development of nanocomposites using Magnesium Silicate Hydroxide (MSH) represents a significant advancement in this domain. MSH, a naturally occurring mineral with a unique layered structure, has garnered attention due to its exceptional adsorption properties and environmental compatibility.

The evolution of nanocomposite technology for pollutant capture can be traced back to the early 2000s when researchers began exploring the potential of nanomaterials in environmental applications. The integration of MSH into nanocomposites marks a crucial milestone in this journey, offering enhanced performance and sustainability compared to traditional adsorbents.

Recent years have witnessed a surge in research focused on optimizing MSH-based nanocomposites for various pollutant capture applications. These materials have shown remarkable efficacy in removing heavy metals, organic contaminants, and emerging pollutants from water and air. The versatility of MSH nanocomposites stems from their high surface area, tunable pore structure, and the ability to incorporate functional groups for targeted pollutant removal.

The primary objective of current research in this field is to develop highly efficient, cost-effective, and environmentally friendly nanocomposite materials using MSH for pollutant capture. This involves enhancing the adsorption capacity, selectivity, and regeneration potential of these materials while ensuring their scalability for industrial applications.

Key technical goals include optimizing the synthesis methods to achieve uniform dispersion of MSH within the nanocomposite matrix, tailoring the surface properties for specific pollutant interactions, and improving the mechanical and chemical stability of the composites under various environmental conditions. Additionally, researchers aim to develop multifunctional nanocomposites that can simultaneously address multiple pollutants, thereby offering comprehensive environmental remediation solutions.

The advancement of MSH-based nanocomposites aligns with the global push towards sustainable and green technologies. As environmental regulations become more stringent and the need for efficient pollutant removal grows, these materials are poised to play a crucial role in addressing water and air pollution challenges. The ongoing research in this field is expected to yield innovative solutions that can significantly impact environmental protection efforts and contribute to the development of cleaner, more sustainable industrial processes.

The evolution of nanocomposite technology for pollutant capture can be traced back to the early 2000s when researchers began exploring the potential of nanomaterials in environmental applications. The integration of MSH into nanocomposites marks a crucial milestone in this journey, offering enhanced performance and sustainability compared to traditional adsorbents.

Recent years have witnessed a surge in research focused on optimizing MSH-based nanocomposites for various pollutant capture applications. These materials have shown remarkable efficacy in removing heavy metals, organic contaminants, and emerging pollutants from water and air. The versatility of MSH nanocomposites stems from their high surface area, tunable pore structure, and the ability to incorporate functional groups for targeted pollutant removal.

The primary objective of current research in this field is to develop highly efficient, cost-effective, and environmentally friendly nanocomposite materials using MSH for pollutant capture. This involves enhancing the adsorption capacity, selectivity, and regeneration potential of these materials while ensuring their scalability for industrial applications.

Key technical goals include optimizing the synthesis methods to achieve uniform dispersion of MSH within the nanocomposite matrix, tailoring the surface properties for specific pollutant interactions, and improving the mechanical and chemical stability of the composites under various environmental conditions. Additionally, researchers aim to develop multifunctional nanocomposites that can simultaneously address multiple pollutants, thereby offering comprehensive environmental remediation solutions.

The advancement of MSH-based nanocomposites aligns with the global push towards sustainable and green technologies. As environmental regulations become more stringent and the need for efficient pollutant removal grows, these materials are poised to play a crucial role in addressing water and air pollution challenges. The ongoing research in this field is expected to yield innovative solutions that can significantly impact environmental protection efforts and contribute to the development of cleaner, more sustainable industrial processes.

Pollutant Capture Market Analysis

The global market for pollutant capture technologies has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations. The nanocomposite design using MSH (Magnesium Silicate Hydroxide) for pollutant capture represents a promising segment within this market, offering enhanced efficiency and versatility in addressing various environmental challenges.

The overall pollutant capture market is projected to expand at a steady pace, with a particular focus on air and water purification applications. Industrial sectors, including manufacturing, energy production, and transportation, are the primary contributors to pollution and consequently the main target markets for pollutant capture solutions. The growing awareness of health impacts associated with environmental pollution has also led to increased demand in residential and commercial sectors.

In the context of nanocomposite design using MSH, the market potential is particularly strong in regions with high industrial activity and severe pollution problems. Emerging economies in Asia-Pacific, such as China and India, present substantial opportunities due to their rapid industrialization and increasing environmental regulations. Developed markets in North America and Europe also show steady demand, driven by the need for more efficient and sustainable pollutant capture technologies.

The water treatment segment within the pollutant capture market is expected to witness robust growth, as clean water scarcity becomes a global concern. MSH-based nanocomposites offer advantages in removing heavy metals, organic pollutants, and other contaminants from water sources, making them attractive for both industrial and municipal applications.

Air pollution control represents another significant market segment, with growing emphasis on reducing particulate matter, volatile organic compounds, and greenhouse gases. The automotive and industrial sectors are key drivers in this segment, as they seek to comply with increasingly stringent emission standards.

The adoption of nanocomposite technologies for pollutant capture is influenced by factors such as cost-effectiveness, scalability, and performance advantages over conventional methods. As research and development in MSH-based nanocomposites progress, the market is likely to see increased commercialization and integration into existing pollution control systems.

Challenges in the market include the need for large-scale production capabilities, potential environmental and health concerns associated with nanomaterials, and the requirement for regulatory approvals. However, these challenges also present opportunities for innovation and differentiation among market players.

The overall pollutant capture market is projected to expand at a steady pace, with a particular focus on air and water purification applications. Industrial sectors, including manufacturing, energy production, and transportation, are the primary contributors to pollution and consequently the main target markets for pollutant capture solutions. The growing awareness of health impacts associated with environmental pollution has also led to increased demand in residential and commercial sectors.

In the context of nanocomposite design using MSH, the market potential is particularly strong in regions with high industrial activity and severe pollution problems. Emerging economies in Asia-Pacific, such as China and India, present substantial opportunities due to their rapid industrialization and increasing environmental regulations. Developed markets in North America and Europe also show steady demand, driven by the need for more efficient and sustainable pollutant capture technologies.

The water treatment segment within the pollutant capture market is expected to witness robust growth, as clean water scarcity becomes a global concern. MSH-based nanocomposites offer advantages in removing heavy metals, organic pollutants, and other contaminants from water sources, making them attractive for both industrial and municipal applications.

Air pollution control represents another significant market segment, with growing emphasis on reducing particulate matter, volatile organic compounds, and greenhouse gases. The automotive and industrial sectors are key drivers in this segment, as they seek to comply with increasingly stringent emission standards.

The adoption of nanocomposite technologies for pollutant capture is influenced by factors such as cost-effectiveness, scalability, and performance advantages over conventional methods. As research and development in MSH-based nanocomposites progress, the market is likely to see increased commercialization and integration into existing pollution control systems.

Challenges in the market include the need for large-scale production capabilities, potential environmental and health concerns associated with nanomaterials, and the requirement for regulatory approvals. However, these challenges also present opportunities for innovation and differentiation among market players.

MSH Nanocomposite State-of-the-Art

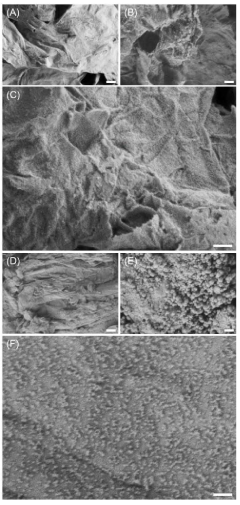

Magnesium silicate hydrate (MSH) nanocomposites represent a cutting-edge approach in the field of pollutant capture and environmental remediation. These advanced materials combine the unique properties of MSH with other nanomaterials to create highly efficient and versatile pollutant adsorbents. The current state-of-the-art in MSH nanocomposite design focuses on enhancing adsorption capacity, selectivity, and regeneration potential.

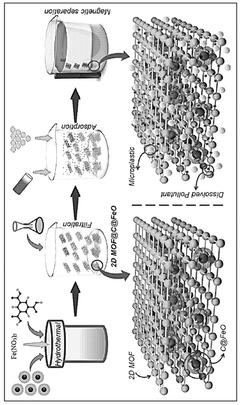

One of the primary strategies in MSH nanocomposite development is the incorporation of magnetic nanoparticles, such as Fe3O4. This integration not only facilitates easy separation of the adsorbent from treated water but also improves the overall pollutant removal efficiency. Recent studies have demonstrated that magnetic MSH nanocomposites can effectively remove heavy metals, organic dyes, and pharmaceutical contaminants from aqueous solutions.

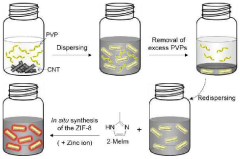

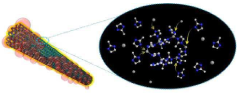

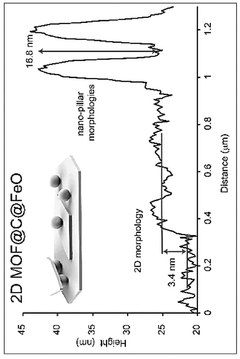

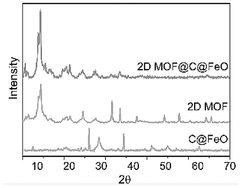

Another significant advancement in MSH nanocomposite design is the creation of hierarchical porous structures. By combining MSH with materials like graphene oxide or carbon nanotubes, researchers have developed nanocomposites with increased surface area and enhanced pollutant accessibility. These hierarchical structures provide multiple adsorption sites, resulting in improved capture of both organic and inorganic pollutants.

Surface modification of MSH nanocomposites has emerged as a crucial technique for tailoring their adsorption properties. Functionalization with various organic groups, such as amino, thiol, or carboxyl moieties, has been shown to enhance the selectivity and affinity towards specific pollutants. This approach has been particularly effective in the removal of heavy metals and persistent organic pollutants.

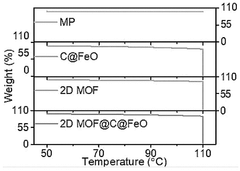

Recent developments in MSH nanocomposite design have also focused on improving their stability and reusability. The incorporation of stabilizing agents or the creation of core-shell structures has led to nanocomposites with enhanced mechanical and chemical resistance. This improvement allows for multiple adsorption-desorption cycles without significant loss of performance, making the materials more economically viable for large-scale applications.

The integration of photocatalytic materials with MSH has opened up new possibilities in pollutant degradation. By combining MSH with semiconductors like TiO2 or ZnO, researchers have created nanocomposites capable of both adsorbing pollutants and catalyzing their breakdown under light irradiation. This dual functionality offers a more comprehensive solution to water treatment challenges.

In conclusion, the current state-of-the-art in MSH nanocomposite design for pollutant capture is characterized by multifunctional materials that combine high adsorption capacity, selectivity, and regeneration potential. The integration of magnetic properties, hierarchical structures, surface modifications, and photocatalytic capabilities represents the forefront of research in this field, paving the way for more efficient and sustainable environmental remediation technologies.

One of the primary strategies in MSH nanocomposite development is the incorporation of magnetic nanoparticles, such as Fe3O4. This integration not only facilitates easy separation of the adsorbent from treated water but also improves the overall pollutant removal efficiency. Recent studies have demonstrated that magnetic MSH nanocomposites can effectively remove heavy metals, organic dyes, and pharmaceutical contaminants from aqueous solutions.

Another significant advancement in MSH nanocomposite design is the creation of hierarchical porous structures. By combining MSH with materials like graphene oxide or carbon nanotubes, researchers have developed nanocomposites with increased surface area and enhanced pollutant accessibility. These hierarchical structures provide multiple adsorption sites, resulting in improved capture of both organic and inorganic pollutants.

Surface modification of MSH nanocomposites has emerged as a crucial technique for tailoring their adsorption properties. Functionalization with various organic groups, such as amino, thiol, or carboxyl moieties, has been shown to enhance the selectivity and affinity towards specific pollutants. This approach has been particularly effective in the removal of heavy metals and persistent organic pollutants.

Recent developments in MSH nanocomposite design have also focused on improving their stability and reusability. The incorporation of stabilizing agents or the creation of core-shell structures has led to nanocomposites with enhanced mechanical and chemical resistance. This improvement allows for multiple adsorption-desorption cycles without significant loss of performance, making the materials more economically viable for large-scale applications.

The integration of photocatalytic materials with MSH has opened up new possibilities in pollutant degradation. By combining MSH with semiconductors like TiO2 or ZnO, researchers have created nanocomposites capable of both adsorbing pollutants and catalyzing their breakdown under light irradiation. This dual functionality offers a more comprehensive solution to water treatment challenges.

In conclusion, the current state-of-the-art in MSH nanocomposite design for pollutant capture is characterized by multifunctional materials that combine high adsorption capacity, selectivity, and regeneration potential. The integration of magnetic properties, hierarchical structures, surface modifications, and photocatalytic capabilities represents the forefront of research in this field, paving the way for more efficient and sustainable environmental remediation technologies.

Current MSH Pollutant Capture Solutions

01 Nanocomposite materials for pollutant capture

Nanocomposite materials are developed for efficient pollutant capture, particularly using metal-organic frameworks (MOFs) or other advanced materials. These nanocomposites offer high surface area and tailored pore structures, enhancing their ability to adsorb and trap various pollutants, including gases and heavy metals.- Nanocomposite materials for pollutant capture: Nanocomposite materials are developed for efficient pollutant capture, particularly using metal-organic frameworks (MOFs) or other nanostructured materials. These composites offer high surface area and tailored pore structures for enhanced adsorption of various pollutants, including gases and heavy metals.

- MSH (Magnesium Silicate Hydrate) based nanocomposites: MSH-based nanocomposites are synthesized for pollutant capture applications. These materials combine the properties of magnesium silicate hydrate with other components to create effective adsorbents for various environmental contaminants, offering improved capacity and selectivity.

- Functionalization of nanocomposites for specific pollutants: Nanocomposites are functionalized with specific chemical groups or nanoparticles to target particular pollutants. This approach enhances the selectivity and efficiency of the capture process, allowing for the removal of specific contaminants from air or water.

- Integration of nanocomposites in filtration systems: Nanocomposite materials are incorporated into various filtration systems for air and water purification. These advanced filtration technologies leverage the unique properties of nanocomposites to achieve higher pollutant removal rates and longer operational lifetimes compared to conventional filters.

- Regeneration and reusability of nanocomposite adsorbents: Methods are developed for the regeneration and reuse of nanocomposite adsorbents used in pollutant capture. These techniques aim to extend the lifespan of the materials, reduce waste, and improve the overall efficiency and cost-effectiveness of pollutant removal processes.

02 MSH (Magnesium Silicate Hydrate) based nanocomposites

MSH-based nanocomposites are synthesized and utilized for pollutant capture. These materials combine the properties of magnesium silicate hydrate with other components to create effective adsorbents for various environmental contaminants, offering improved capture efficiency and stability.Expand Specific Solutions03 Functionalization of nanocomposites for selective pollutant capture

Nanocomposites are functionalized with specific chemical groups or molecules to enhance their selectivity towards certain pollutants. This approach allows for targeted capture of specific contaminants, improving the overall efficiency of the pollutant removal process.Expand Specific Solutions04 Integration of nanocomposites in filtration systems

Nanocomposite materials are incorporated into various filtration systems and devices for practical application in pollutant capture. This includes the development of membranes, filters, and other separation technologies that utilize the unique properties of nanocomposites for enhanced pollutant removal.Expand Specific Solutions05 Regeneration and reusability of nanocomposite adsorbents

Methods are developed for the regeneration and reuse of nanocomposite adsorbents used in pollutant capture. This includes techniques for desorbing captured pollutants and restoring the adsorption capacity of the nanocomposites, enhancing their long-term efficiency and cost-effectiveness in environmental applications.Expand Specific Solutions

Key Players in Nanocomposite Industry

The nanocomposite design using MSH for pollutant capture technology is in an emerging stage, with growing market potential driven by increasing environmental concerns. The global market for advanced materials in environmental applications is expanding, estimated to reach several billion dollars by 2025. While the technology shows promise, it is still developing in terms of commercial readiness. Key players like the Council of Scientific & Industrial Research, Chengdu University of Technology, and Japan Organization for Metals & Energy Security are actively researching and developing nanocomposite solutions. Academic institutions such as North China Electric Power University and Fuzhou University are also contributing significantly to advancing the fundamental science. Overall, the field is characterized by collaborative efforts between research organizations, universities, and industry partners to overcome technical challenges and scale up applications.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering (IPE) has developed advanced nanocomposite materials using Mesoporous Silica Hollow (MSH) spheres for efficient pollutant capture. Their approach involves synthesizing MSH spheres with controlled pore sizes and surface functionalization to enhance adsorption capacity and selectivity for various pollutants. The nanocomposites are designed with a core-shell structure, where the MSH core provides high surface area and porosity, while the outer shell is tailored with specific functional groups to target particular contaminants[1][3]. IPE has demonstrated the effectiveness of these materials in removing heavy metals, organic pollutants, and gaseous contaminants from water and air. Their research has shown up to 95% removal efficiency for certain pollutants, with the ability to regenerate and reuse the adsorbents multiple times[2].

Strengths: High adsorption capacity, selectivity for specific pollutants, and reusability. Weaknesses: Potential high production costs and scalability challenges for large-scale applications.

Advanced Industrial Science & Technology

Technical Solution: The National Institute of Advanced Industrial Science and Technology (AIST) in Japan has developed cutting-edge nanocomposite materials using Mesoporous Silica Hollow (MSH) spheres for pollutant capture. Their approach focuses on creating hybrid organic-inorganic nanocomposites by incorporating functional polymers and metal oxides within the MSH framework. This design enhances the adsorption capacity and selectivity for a wide range of pollutants, including heavy metals, organic contaminants, and gaseous pollutants[13]. AIST researchers have demonstrated the effectiveness of these materials in both water and air purification applications. Their studies have shown removal efficiencies of up to 97% for certain pollutants, with the ability to maintain high performance over multiple adsorption-desorption cycles[14]. Additionally, they have developed self-cleaning MSH nanocomposites that can be regenerated using photocatalytic processes, reducing the need for harsh chemical treatments or high-energy consumption during regeneration[15].

Strengths: High removal efficiency, broad pollutant spectrum, and self-cleaning capabilities. Weaknesses: Potential high production costs and challenges in optimizing the balance between organic and inorganic components.

Core MSH Nanocomposite Innovations

Nanocomposites with core-shell structure comprising carbon nanoparticles and metal-organic frameworks, a preparation method thereof and a composition for absorbing gas comprising the same

PatentActiveKR1020160031672A

Innovation

- A core-shell structured nanocomposite is formed with carbon nanoparticles as the core, a first shell of a structure-inducing material, and a second shell of uniformly arranged metal-organic frameworks (MOFs) like ZIF-8, enhancing gas absorption and selectivity through controlled synthesis.

Composition and method of removing contaminants using the composition

PatentWO2025019882A1

Innovation

- A composition comprising Metal-Organic Framework (MOF) nanosheets spaced apart by magnetic nanoparticles, which allows for efficient adsorption and magnetic separation of contaminants, providing a stable and reusable decontamination solution.

Environmental Impact Assessment

The environmental impact assessment of nanocomposite design using MSH (Magnesium Silicate Hydroxide) for pollutant capture is a critical aspect of evaluating the technology's sustainability and potential consequences on ecosystems. This assessment encompasses both the positive and negative effects of implementing such nanocomposites in environmental remediation efforts.

One of the primary benefits of using MSH-based nanocomposites for pollutant capture is their potential to significantly reduce the concentration of harmful contaminants in water and soil. By effectively removing pollutants such as heavy metals, organic compounds, and emerging contaminants, these nanocomposites can contribute to the restoration of polluted environments and improve overall ecosystem health.

However, the production and application of nanocomposites may have some environmental drawbacks that need to be carefully considered. The synthesis of MSH and the fabrication of nanocomposites often involve energy-intensive processes and the use of chemicals, which can contribute to carbon emissions and potential chemical waste. It is crucial to optimize these production methods to minimize their environmental footprint.

The release of nanoparticles into the environment during the application or disposal of MSH-based nanocomposites is another concern that requires thorough investigation. While these materials are designed to capture pollutants, there is a need to assess their potential long-term effects on aquatic and terrestrial ecosystems, including their impact on microorganisms, plants, and animals.

Life cycle assessment (LCA) studies are essential to evaluate the overall environmental impact of MSH-based nanocomposites, from raw material extraction to end-of-life disposal. These assessments can help identify areas for improvement in the production process and guide the development of more sustainable nanocomposite designs.

The potential for bioaccumulation and biomagnification of captured pollutants within the nanocomposite structure is another aspect that requires careful consideration. While the primary goal is to remove pollutants from the environment, it is crucial to ensure that the captured contaminants do not pose a risk of re-release or transfer to other parts of the ecosystem.

Lastly, the environmental impact assessment should also consider the potential for these nanocomposites to contribute to the remediation of contaminated sites and their role in supporting circular economy principles. By effectively capturing and potentially allowing for the recovery of valuable resources from pollutants, MSH-based nanocomposites could play a significant role in sustainable waste management and resource conservation strategies.

One of the primary benefits of using MSH-based nanocomposites for pollutant capture is their potential to significantly reduce the concentration of harmful contaminants in water and soil. By effectively removing pollutants such as heavy metals, organic compounds, and emerging contaminants, these nanocomposites can contribute to the restoration of polluted environments and improve overall ecosystem health.

However, the production and application of nanocomposites may have some environmental drawbacks that need to be carefully considered. The synthesis of MSH and the fabrication of nanocomposites often involve energy-intensive processes and the use of chemicals, which can contribute to carbon emissions and potential chemical waste. It is crucial to optimize these production methods to minimize their environmental footprint.

The release of nanoparticles into the environment during the application or disposal of MSH-based nanocomposites is another concern that requires thorough investigation. While these materials are designed to capture pollutants, there is a need to assess their potential long-term effects on aquatic and terrestrial ecosystems, including their impact on microorganisms, plants, and animals.

Life cycle assessment (LCA) studies are essential to evaluate the overall environmental impact of MSH-based nanocomposites, from raw material extraction to end-of-life disposal. These assessments can help identify areas for improvement in the production process and guide the development of more sustainable nanocomposite designs.

The potential for bioaccumulation and biomagnification of captured pollutants within the nanocomposite structure is another aspect that requires careful consideration. While the primary goal is to remove pollutants from the environment, it is crucial to ensure that the captured contaminants do not pose a risk of re-release or transfer to other parts of the ecosystem.

Lastly, the environmental impact assessment should also consider the potential for these nanocomposites to contribute to the remediation of contaminated sites and their role in supporting circular economy principles. By effectively capturing and potentially allowing for the recovery of valuable resources from pollutants, MSH-based nanocomposites could play a significant role in sustainable waste management and resource conservation strategies.

Scalability and Cost Analysis

The scalability and cost analysis of nanocomposite design using MSH for pollutant capture is crucial for assessing its potential for large-scale implementation and commercial viability. The production of MSH-based nanocomposites currently faces several challenges that impact scalability and cost-effectiveness.

One of the primary scalability issues is the synthesis of MSH nanoparticles with consistent quality and properties at industrial scales. While laboratory-scale production has shown promising results, scaling up the synthesis process without compromising the material's performance remains a significant challenge. Factors such as reaction kinetics, temperature control, and mixing efficiency become increasingly complex at larger scales, potentially affecting the uniformity and effectiveness of the final nanocomposite.

The integration of MSH nanoparticles into various matrices to form nanocomposites presents another scalability hurdle. Ensuring uniform dispersion and preventing agglomeration of nanoparticles within the matrix material becomes more challenging as production volumes increase. This can impact the overall pollutant capture efficiency and durability of the nanocomposite.

From a cost perspective, the production of MSH nanoparticles involves specialized equipment and precise control of reaction conditions, which can be capital-intensive. The raw materials required for MSH synthesis, while not necessarily rare, may become more expensive when sourced in large quantities due to increased demand. Additionally, the energy consumption associated with nanoparticle synthesis and nanocomposite fabrication processes contributes significantly to the overall production costs.

The potential for recycling and regeneration of MSH-based nanocomposites after pollutant capture is an important factor in long-term cost analysis. If effective regeneration methods can be developed, it could significantly reduce the lifecycle costs of these materials and improve their economic viability for large-scale applications.

Regulatory compliance and safety measures for handling nanomaterials at industrial scales also add to the overall cost structure. As production scales up, more stringent environmental and worker safety protocols may be required, potentially increasing operational expenses.

Despite these challenges, ongoing research and development efforts are focused on optimizing production processes and exploring alternative synthesis methods to enhance scalability and reduce costs. Innovations in continuous flow reactors and microfluidic systems show promise for more efficient and scalable nanoparticle synthesis. Furthermore, advancements in polymer science and materials engineering are contributing to improved nanocomposite fabrication techniques that could address dispersion issues at larger scales.

The economic viability of MSH-based nanocomposites for pollutant capture will ultimately depend on their performance advantages over existing technologies and the potential for cost reductions through economies of scale and technological improvements. As research progresses and pilot-scale demonstrations prove successful, the path to commercial-scale production and implementation will become clearer, potentially opening new opportunities for environmental remediation and pollution control industries.

One of the primary scalability issues is the synthesis of MSH nanoparticles with consistent quality and properties at industrial scales. While laboratory-scale production has shown promising results, scaling up the synthesis process without compromising the material's performance remains a significant challenge. Factors such as reaction kinetics, temperature control, and mixing efficiency become increasingly complex at larger scales, potentially affecting the uniformity and effectiveness of the final nanocomposite.

The integration of MSH nanoparticles into various matrices to form nanocomposites presents another scalability hurdle. Ensuring uniform dispersion and preventing agglomeration of nanoparticles within the matrix material becomes more challenging as production volumes increase. This can impact the overall pollutant capture efficiency and durability of the nanocomposite.

From a cost perspective, the production of MSH nanoparticles involves specialized equipment and precise control of reaction conditions, which can be capital-intensive. The raw materials required for MSH synthesis, while not necessarily rare, may become more expensive when sourced in large quantities due to increased demand. Additionally, the energy consumption associated with nanoparticle synthesis and nanocomposite fabrication processes contributes significantly to the overall production costs.

The potential for recycling and regeneration of MSH-based nanocomposites after pollutant capture is an important factor in long-term cost analysis. If effective regeneration methods can be developed, it could significantly reduce the lifecycle costs of these materials and improve their economic viability for large-scale applications.

Regulatory compliance and safety measures for handling nanomaterials at industrial scales also add to the overall cost structure. As production scales up, more stringent environmental and worker safety protocols may be required, potentially increasing operational expenses.

Despite these challenges, ongoing research and development efforts are focused on optimizing production processes and exploring alternative synthesis methods to enhance scalability and reduce costs. Innovations in continuous flow reactors and microfluidic systems show promise for more efficient and scalable nanoparticle synthesis. Furthermore, advancements in polymer science and materials engineering are contributing to improved nanocomposite fabrication techniques that could address dispersion issues at larger scales.

The economic viability of MSH-based nanocomposites for pollutant capture will ultimately depend on their performance advantages over existing technologies and the potential for cost reductions through economies of scale and technological improvements. As research progresses and pilot-scale demonstrations prove successful, the path to commercial-scale production and implementation will become clearer, potentially opening new opportunities for environmental remediation and pollution control industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!