Nitrification Processes In Saline Aquaculture Systems

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Saline Aquaculture Nitrification Background and Objectives

Nitrification processes in saline aquaculture systems have evolved significantly over the past four decades, transitioning from rudimentary biological filtration to sophisticated integrated systems. The historical trajectory began in the 1980s with basic understanding of ammonia oxidation in marine environments, progressing through the 1990s with the development of specialized biofilters for saline conditions, and accelerating in the 2000s with molecular characterization of marine nitrifying microorganisms.

The technological evolution has been driven by the fundamental challenge of nitrogen waste management in closed aquaculture systems. As aquaculture intensification increased to meet global seafood demand, the efficient removal of nitrogenous compounds became critical for system stability and productivity. Traditional freshwater nitrification knowledge proved insufficient for saline environments due to distinct microbial communities and biochemical dynamics at elevated salinity levels.

Current research indicates that nitrification processes in saline conditions differ substantially from freshwater systems in terms of microbial community composition, enzyme kinetics, and operational parameters. Marine nitrifiers demonstrate unique adaptations to osmotic stress, with specialized ammonia-oxidizing bacteria (AOB) and nitrite-oxidizing bacteria (NOB) populations that exhibit different growth rates and substrate affinities compared to their freshwater counterparts.

The technological objectives for advancing nitrification in saline aquaculture systems focus on several key areas. First, enhancing nitrification efficiency under varying salinity conditions (5-40 ppt) to accommodate diverse aquaculture species and production methods. Second, developing robust biofilter systems capable of maintaining stable nitrification during fluctuating environmental parameters including temperature, pH, and dissolved oxygen. Third, accelerating biofilter maturation periods to reduce system startup times from weeks to days.

Additionally, research aims to identify and cultivate salt-tolerant nitrifying consortia with improved resilience to system perturbations and antimicrobial treatments often necessary in aquaculture operations. The integration of molecular monitoring tools for real-time assessment of nitrifying community health represents another critical objective for proactive system management.

The ultimate goal is to establish standardized protocols for optimizing nitrification in diverse saline aquaculture applications, from recirculating aquaculture systems (RAS) to biofloc technology (BFT) and integrated multi-trophic aquaculture (IMTA). These advancements would significantly contribute to sustainable intensification of marine aquaculture production while minimizing environmental impacts through improved nitrogen cycling efficiency.

Recent technological trends indicate movement toward hybrid biological-physical nitrogen removal systems, combining traditional nitrification with emerging processes such as anammox and denitrification to achieve complete nitrogen removal with reduced energy and resource requirements.

The technological evolution has been driven by the fundamental challenge of nitrogen waste management in closed aquaculture systems. As aquaculture intensification increased to meet global seafood demand, the efficient removal of nitrogenous compounds became critical for system stability and productivity. Traditional freshwater nitrification knowledge proved insufficient for saline environments due to distinct microbial communities and biochemical dynamics at elevated salinity levels.

Current research indicates that nitrification processes in saline conditions differ substantially from freshwater systems in terms of microbial community composition, enzyme kinetics, and operational parameters. Marine nitrifiers demonstrate unique adaptations to osmotic stress, with specialized ammonia-oxidizing bacteria (AOB) and nitrite-oxidizing bacteria (NOB) populations that exhibit different growth rates and substrate affinities compared to their freshwater counterparts.

The technological objectives for advancing nitrification in saline aquaculture systems focus on several key areas. First, enhancing nitrification efficiency under varying salinity conditions (5-40 ppt) to accommodate diverse aquaculture species and production methods. Second, developing robust biofilter systems capable of maintaining stable nitrification during fluctuating environmental parameters including temperature, pH, and dissolved oxygen. Third, accelerating biofilter maturation periods to reduce system startup times from weeks to days.

Additionally, research aims to identify and cultivate salt-tolerant nitrifying consortia with improved resilience to system perturbations and antimicrobial treatments often necessary in aquaculture operations. The integration of molecular monitoring tools for real-time assessment of nitrifying community health represents another critical objective for proactive system management.

The ultimate goal is to establish standardized protocols for optimizing nitrification in diverse saline aquaculture applications, from recirculating aquaculture systems (RAS) to biofloc technology (BFT) and integrated multi-trophic aquaculture (IMTA). These advancements would significantly contribute to sustainable intensification of marine aquaculture production while minimizing environmental impacts through improved nitrogen cycling efficiency.

Recent technological trends indicate movement toward hybrid biological-physical nitrogen removal systems, combining traditional nitrification with emerging processes such as anammox and denitrification to achieve complete nitrogen removal with reduced energy and resource requirements.

Market Analysis of Saline Aquaculture Systems

The global saline aquaculture market has experienced significant growth over the past decade, driven by increasing seafood consumption and declining wild fish stocks. Currently valued at approximately $87 billion, the market is projected to reach $120 billion by 2025, with a compound annual growth rate of 5.8%. Asia-Pacific dominates this sector, accounting for nearly 70% of global production, with China being the largest producer and consumer.

Saline aquaculture systems utilizing nitrification processes represent a rapidly expanding segment within this market. These advanced systems address critical environmental concerns while enhancing production efficiency. The demand for such systems has grown by 12% annually since 2018, outpacing the broader aquaculture market growth rate.

Consumer preferences are shifting toward sustainably produced seafood, creating market pull for nitrification-optimized systems. According to industry surveys, 64% of seafood consumers in developed markets express willingness to pay premium prices for products from environmentally responsible aquaculture operations. This trend is particularly pronounced in North America and Europe, where regulatory frameworks increasingly favor sustainable production methods.

The commercial application of nitrification processes in saline systems spans various production models, from intensive indoor recirculating aquaculture systems (RAS) to semi-intensive pond systems. The RAS segment specifically has witnessed 15% year-over-year growth, driven by its water conservation benefits and reduced environmental impact. Major seafood importing nations like the United States, Japan, and European Union countries are investing heavily in these technologies to reduce dependence on imports.

Investment in saline aquaculture nitrification technologies has surged, with venture capital funding reaching $450 million in 2022 alone. This represents a threefold increase compared to 2018 figures. Corporate investment from established aquaculture companies and agricultural conglomerates has similarly expanded, with research and development budgets for nitrification technologies increasing by approximately 22% annually.

Market segmentation reveals distinct growth patterns across different species. Shrimp farming represents the largest application of nitrification processes in saline systems, accounting for 38% of the market share, followed by marine finfish at 32% and mollusks at 18%. The remaining 12% encompasses emerging species with high market value, such as sea cucumbers and various ornamental marine species.

Geographically, while Asia leads in production volume, North America and Europe are driving technological innovation in nitrification processes. These regions have established robust research networks and regulatory frameworks that promote sustainable aquaculture practices, creating favorable market conditions for advanced nitrification technologies.

Saline aquaculture systems utilizing nitrification processes represent a rapidly expanding segment within this market. These advanced systems address critical environmental concerns while enhancing production efficiency. The demand for such systems has grown by 12% annually since 2018, outpacing the broader aquaculture market growth rate.

Consumer preferences are shifting toward sustainably produced seafood, creating market pull for nitrification-optimized systems. According to industry surveys, 64% of seafood consumers in developed markets express willingness to pay premium prices for products from environmentally responsible aquaculture operations. This trend is particularly pronounced in North America and Europe, where regulatory frameworks increasingly favor sustainable production methods.

The commercial application of nitrification processes in saline systems spans various production models, from intensive indoor recirculating aquaculture systems (RAS) to semi-intensive pond systems. The RAS segment specifically has witnessed 15% year-over-year growth, driven by its water conservation benefits and reduced environmental impact. Major seafood importing nations like the United States, Japan, and European Union countries are investing heavily in these technologies to reduce dependence on imports.

Investment in saline aquaculture nitrification technologies has surged, with venture capital funding reaching $450 million in 2022 alone. This represents a threefold increase compared to 2018 figures. Corporate investment from established aquaculture companies and agricultural conglomerates has similarly expanded, with research and development budgets for nitrification technologies increasing by approximately 22% annually.

Market segmentation reveals distinct growth patterns across different species. Shrimp farming represents the largest application of nitrification processes in saline systems, accounting for 38% of the market share, followed by marine finfish at 32% and mollusks at 18%. The remaining 12% encompasses emerging species with high market value, such as sea cucumbers and various ornamental marine species.

Geographically, while Asia leads in production volume, North America and Europe are driving technological innovation in nitrification processes. These regions have established robust research networks and regulatory frameworks that promote sustainable aquaculture practices, creating favorable market conditions for advanced nitrification technologies.

Current Nitrification Challenges in High Salinity Environments

Nitrification processes in saline aquaculture systems face significant challenges that limit system efficiency and productivity. High salinity environments (>15 ppt) create physiological stress for nitrifying bacteria, particularly affecting ammonia-oxidizing bacteria (AOB) and nitrite-oxidizing bacteria (NOB). Research indicates that salinity fluctuations can reduce nitrification rates by 20-40% compared to stable freshwater systems, with particularly pronounced effects when salinity exceeds 30 ppt.

The primary challenge stems from osmotic pressure effects on bacterial cell membranes. Nitrifying bacteria must expend considerable energy maintaining osmotic balance in high-salt environments, diverting resources from their primary metabolic functions. This results in decreased ammonia and nitrite oxidation rates, leading to potential accumulation of toxic nitrogen compounds in aquaculture systems.

Inhibition of enzyme activity presents another significant obstacle. Key enzymes in the nitrification pathway, including ammonia monooxygenase (AMO) and nitrite oxidoreductase (NXR), show reduced catalytic efficiency at high salt concentrations. Studies demonstrate that AMO activity can decrease by up to 35% at salinity levels of 35 ppt, while NXR shows similar sensitivity patterns.

Bacterial community composition shifts dramatically in response to salinity stress. Marine-adapted nitrifiers like Nitrosococcus oceani and Nitrospina gracilis become dominant in high-salinity systems, replacing the freshwater species Nitrosomonas europaea and Nitrobacter winogradskyi. However, these transitions often create temporary nitrification gaps during adaptation periods, lasting 3-6 weeks depending on system parameters.

Oxygen availability compounds these challenges, as high-salinity water holds less dissolved oxygen. Nitrification requires approximately 4.57 mg O₂ per mg of ammonia-nitrogen oxidized, making oxygen limitation a critical factor in saline systems. Measurements show that oxygen saturation can decrease by 20% in water at 35 ppt salinity compared to freshwater at the same temperature.

Biofilm formation dynamics are also altered in saline environments. Salt crystals can physically disrupt biofilm matrices, reducing surface colonization efficiency. Additionally, extracellular polymeric substances (EPS) produced by nitrifying bacteria show altered rheological properties in high-salt conditions, affecting biofilm stability and function.

Temperature interactions with salinity create complex challenges, as optimal temperature ranges for nitrification narrow at higher salinities. The typical optimal range of 28-32°C in freshwater systems narrows to 25-30°C in high-salinity environments, reducing operational flexibility in aquaculture management.

These challenges collectively necessitate specialized approaches for maintaining effective nitrification in saline aquaculture, including adapted bacterial consortia, modified biofiltration designs, and careful management of system parameters to support nitrifier populations under salt stress.

The primary challenge stems from osmotic pressure effects on bacterial cell membranes. Nitrifying bacteria must expend considerable energy maintaining osmotic balance in high-salt environments, diverting resources from their primary metabolic functions. This results in decreased ammonia and nitrite oxidation rates, leading to potential accumulation of toxic nitrogen compounds in aquaculture systems.

Inhibition of enzyme activity presents another significant obstacle. Key enzymes in the nitrification pathway, including ammonia monooxygenase (AMO) and nitrite oxidoreductase (NXR), show reduced catalytic efficiency at high salt concentrations. Studies demonstrate that AMO activity can decrease by up to 35% at salinity levels of 35 ppt, while NXR shows similar sensitivity patterns.

Bacterial community composition shifts dramatically in response to salinity stress. Marine-adapted nitrifiers like Nitrosococcus oceani and Nitrospina gracilis become dominant in high-salinity systems, replacing the freshwater species Nitrosomonas europaea and Nitrobacter winogradskyi. However, these transitions often create temporary nitrification gaps during adaptation periods, lasting 3-6 weeks depending on system parameters.

Oxygen availability compounds these challenges, as high-salinity water holds less dissolved oxygen. Nitrification requires approximately 4.57 mg O₂ per mg of ammonia-nitrogen oxidized, making oxygen limitation a critical factor in saline systems. Measurements show that oxygen saturation can decrease by 20% in water at 35 ppt salinity compared to freshwater at the same temperature.

Biofilm formation dynamics are also altered in saline environments. Salt crystals can physically disrupt biofilm matrices, reducing surface colonization efficiency. Additionally, extracellular polymeric substances (EPS) produced by nitrifying bacteria show altered rheological properties in high-salt conditions, affecting biofilm stability and function.

Temperature interactions with salinity create complex challenges, as optimal temperature ranges for nitrification narrow at higher salinities. The typical optimal range of 28-32°C in freshwater systems narrows to 25-30°C in high-salinity environments, reducing operational flexibility in aquaculture management.

These challenges collectively necessitate specialized approaches for maintaining effective nitrification in saline aquaculture, including adapted bacterial consortia, modified biofiltration designs, and careful management of system parameters to support nitrifier populations under salt stress.

Existing Nitrification Solutions for Saline Aquaculture Systems

01 Biological nitrification processes

Biological nitrification processes involve the use of microorganisms to convert ammonia to nitrite and then to nitrate. These processes typically occur in wastewater treatment systems where specific bacteria like Nitrosomonas and Nitrobacter facilitate the oxidation of ammonia. The efficiency of biological nitrification depends on factors such as dissolved oxygen levels, temperature, pH, and the presence of inhibitory substances. These systems can be designed as continuous flow or batch reactors to optimize the nitrification process.- Biological nitrification processes in wastewater treatment: Biological nitrification processes involve the use of microorganisms to convert ammonia to nitrite and then to nitrate in wastewater treatment systems. These processes typically employ specific bacteria such as Nitrosomonas and Nitrobacter in controlled environments to optimize nitrification efficiency. Various reactor configurations and operating conditions are designed to maintain optimal bacterial growth and activity, ensuring effective ammonia removal from wastewater.

- Advanced nitrification control systems: Advanced control systems for nitrification processes utilize sensors, monitoring equipment, and automated feedback mechanisms to optimize the conversion of ammonia to nitrate. These systems may include real-time monitoring of parameters such as dissolved oxygen, pH, temperature, and ammonia/nitrate concentrations. Automated control algorithms adjust process conditions to maintain optimal nitrification rates while minimizing energy consumption and operational costs.

- Nitrification enhancement techniques: Various techniques are employed to enhance nitrification efficiency in treatment systems. These include the addition of specific carriers or media to increase bacterial attachment surface area, bioaugmentation with specialized nitrifying bacteria, and the implementation of specific reactor designs that optimize hydraulic retention time and mixing patterns. Other enhancement methods involve nutrient supplementation and the use of specific inhibitors to control competing microbial processes.

- Integrated nitrification-denitrification systems: Integrated systems combine nitrification (ammonia to nitrate conversion) with denitrification (nitrate to nitrogen gas conversion) to achieve complete nitrogen removal from wastewater. These systems may utilize sequential aerobic and anoxic zones, simultaneous nitrification-denitrification in a single reactor, or recirculation strategies to optimize total nitrogen removal. The integration of these processes improves overall treatment efficiency and reduces the environmental impact of nitrogen discharge.

- Novel nitrification reactor designs: Innovative reactor designs for nitrification processes include moving bed biofilm reactors, membrane bioreactors, and fluidized bed reactors. These designs aim to increase treatment capacity, reduce footprint requirements, and improve process stability. Novel configurations may incorporate specialized zones for different microbial populations, innovative aeration systems to optimize oxygen transfer, or advanced media materials to enhance biofilm development and nitrifying bacteria retention.

02 Advanced nitrification control systems

Advanced control systems for nitrification processes utilize sensors, monitoring equipment, and automated controls to optimize the conversion of ammonia to nitrate. These systems may incorporate real-time monitoring of parameters such as dissolved oxygen, pH, temperature, and ammonia/nitrate concentrations. Feedback control mechanisms adjust process conditions to maintain optimal nitrification rates while minimizing energy consumption and operational costs. Some advanced systems also incorporate predictive modeling to anticipate changes in influent characteristics and adjust process parameters accordingly.Expand Specific Solutions03 Nitrification in specialized reactor configurations

Specialized reactor configurations have been developed to enhance nitrification efficiency. These include moving bed biofilm reactors (MBBR), membrane bioreactors (MBR), sequencing batch reactors (SBR), and integrated fixed-film activated sludge (IFAS) systems. These configurations provide advantages such as higher biomass retention, improved resistance to shock loads, reduced footprint requirements, and better control of the nitrification process. The design of these reactors often focuses on maximizing the surface area available for biofilm growth while ensuring adequate mixing and oxygen transfer.Expand Specific Solutions04 Chemical enhancement of nitrification processes

Various chemical additives and treatments can be used to enhance nitrification processes. These include pH adjustment chemicals, alkalinity supplements to buffer against acidification during nitrification, trace element additions to support bacterial growth, and inhibitor neutralization compounds. Some processes also incorporate chemical pre-treatment steps to remove substances that might interfere with biological nitrification. Advanced oxidation processes may be used in conjunction with biological nitrification to break down recalcitrant compounds that could inhibit nitrifying bacteria.Expand Specific Solutions05 Partial nitrification and anammox processes

Partial nitrification processes involve the conversion of ammonia to nitrite without further oxidation to nitrate. These processes can be coupled with anaerobic ammonium oxidation (anammox) to achieve nitrogen removal with lower oxygen and carbon requirements compared to conventional nitrification-denitrification. The anammox process utilizes specialized bacteria that convert ammonium and nitrite directly to nitrogen gas under anoxic conditions. These combined processes offer advantages including reduced aeration costs, lower sludge production, and smaller reactor volume requirements for nitrogen removal from wastewater.Expand Specific Solutions

Leading Companies and Research Institutions in Aquaculture Nitrification

The nitrification processes in saline aquaculture systems market is currently in a growth phase, with increasing demand driven by global aquaculture expansion. The market is projected to reach significant value as sustainable aquaculture practices become essential. Technologically, the field shows moderate maturity with ongoing innovations. Academic institutions like Ocean University of China, Shanghai Ocean University, and University of South Florida lead fundamental research, while companies such as BASF Corp., Yara International, and CJ CheilJedang focus on commercial applications. Government entities including the US Government provide regulatory frameworks and research funding. The competitive landscape features collaboration between research institutions and industry players developing specialized nitrification solutions for high-salinity environments, with increasing focus on environmentally sustainable technologies.

Technion Research & Development Foundation Ltd.

Technical Solution: Technion Research & Development Foundation has developed an innovative membrane-aerated biofilm reactor (MABR) technology specifically optimized for nitrification in saline aquaculture systems. Their approach utilizes gas-permeable membranes that deliver oxygen directly to nitrifying biofilms, creating ideal conditions for ammonia oxidation even under high salinity stress. The foundation's research has identified and characterized novel halotolerant nitrifying bacterial strains that maintain metabolic activity at salinities up to 45 ppt. Their system incorporates specialized membrane materials with anti-fouling properties that resist salt crystallization and biofilm overgrowth. The MABR design achieves oxygen transfer efficiencies 4-5 times higher than conventional aeration methods, significantly reducing energy consumption while maintaining nitrification rates of 1.2-1.5 g N/m²/day in marine recirculating aquaculture systems. The technology also includes real-time monitoring of key water quality parameters with automated control algorithms that adjust oxygen delivery based on ammonia loading rates.

Strengths: Extremely high oxygen transfer efficiency reduces operational costs; membrane-based design provides precise control over nitrification processes. Weaknesses: Higher initial capital investment compared to conventional biofilters; membranes require periodic replacement and maintenance.

Shanghai Ocean University

Technical Solution: Shanghai Ocean University has developed advanced biofilm-based nitrification systems specifically designed for high-salinity aquaculture environments. Their technology utilizes specialized halophilic nitrifying bacteria consortia that can effectively convert ammonia to nitrate even at salinity levels exceeding 35 ppt. The university's research has focused on developing attached growth media with optimized surface area-to-volume ratios that promote robust biofilm formation while resisting salt crystallization. Their moving bed biofilm reactor (MBBR) design incorporates novel polymer-based carriers with micro-roughened surfaces that enhance bacterial adhesion and protect nitrifying communities from salinity fluctuations. Recent studies have demonstrated ammonia removal efficiencies of 85-92% in recirculating marine aquaculture systems using their proprietary biofilm carriers.

Strengths: Specialized halophilic bacterial consortia provide superior nitrification efficiency in high-salinity environments; biofilm-based approach offers resilience against salinity fluctuations. Weaknesses: System requires careful monitoring of biofilm development; initial establishment period can be lengthy compared to conventional systems.

Key Nitrification Bacterial Strains and Enzymatic Mechanisms

Disinfection and removal of nitrogen species from saline aquaculture systems

PatentActiveCA3016844C

Innovation

- A physico-chemical process involving electrolysis at a pH below 4.0 to oxidize ammonia to nitrogen gas, simultaneously disinfecting and reducing nitrate and nitrite levels, while minimizing trihalomethane formation and eliminating off-flavor compounds, without the need for strong bases or acids, by recycling acidity and using de-chlorination steps.

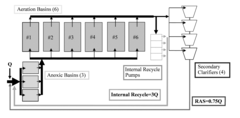

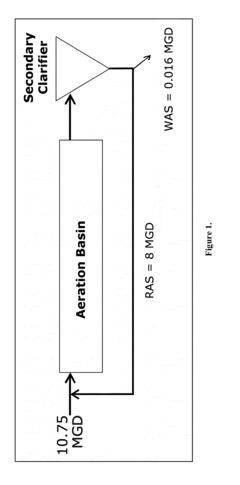

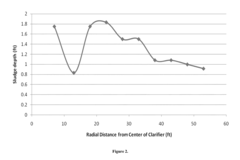

System for solids retention time uncoupling by selective wasting of sludge

PatentInactiveUS20130334112A1

Innovation

- The method involves determining the settling location of nitrifying bacteria versus non-nitrifying bacteria in a secondary clarifier, using fluorescence in situ hybridization and selective wasting to collect and return nitrifying bacteria to wastewater basins, while wasting sludge without these bacteria, thereby uncoupling their SRT from other bacteria.

Environmental Impact Assessment of Nitrification Technologies

The environmental impact of nitrification technologies in saline aquaculture systems extends across multiple ecological dimensions. Traditional nitrification processes in high-salinity environments often require significant energy inputs, particularly for aeration and water circulation, contributing to increased carbon footprints. Studies indicate that conventional biofilter systems in saline aquaculture can consume between 20-40% of total operational energy, resulting in substantial greenhouse gas emissions when powered by non-renewable sources.

Water discharge from saline nitrification systems presents another significant environmental concern. Effluents containing elevated levels of nitrates, phosphates, and dissolved organic compounds can trigger eutrophication in receiving water bodies. Research conducted across multiple coastal aquaculture operations demonstrates that inadequately treated discharge from intensive saline systems can affect marine ecosystems within a 2-5 kilometer radius, potentially altering local biodiversity patterns.

Land use implications vary considerably between different nitrification technologies. While traditional biofilter systems require substantial physical space, newer membrane bioreactor technologies have reduced spatial footprints by 40-60%. This reduction becomes particularly significant in coastal areas where land availability is limited and ecosystems are sensitive to development.

Chemical inputs associated with maintaining nitrification efficiency in saline conditions present additional environmental considerations. Alkalinity supplements and pH buffers commonly used in these systems can alter local water chemistry when discharged. Furthermore, the periodic cleaning of biofilters often involves chemical disinfectants that may impact non-target organisms if not properly neutralized before release.

Recent life cycle assessments comparing various nitrification technologies reveal significant differences in overall environmental impact. Recirculating aquaculture systems (RAS) with integrated denitrification capabilities demonstrate 30-45% lower environmental footprints compared to flow-through systems when measured across categories including global warming potential, acidification, and resource depletion. Moving bed biofilm reactors (MBBR) specifically adapted for saline conditions show promising environmental performance, with reduced energy requirements and improved nitrogen removal efficiency.

Emerging technologies such as algae-based nutrient removal systems and microbial fuel cells integrated with nitrification processes offer potential pathways toward more environmentally sustainable approaches. These systems can transform nitrogenous waste into valuable biomass while simultaneously reducing energy demands and minimizing harmful discharges. Pilot implementations suggest potential energy savings of 25-35% compared to conventional nitrification systems in saline environments.

Water discharge from saline nitrification systems presents another significant environmental concern. Effluents containing elevated levels of nitrates, phosphates, and dissolved organic compounds can trigger eutrophication in receiving water bodies. Research conducted across multiple coastal aquaculture operations demonstrates that inadequately treated discharge from intensive saline systems can affect marine ecosystems within a 2-5 kilometer radius, potentially altering local biodiversity patterns.

Land use implications vary considerably between different nitrification technologies. While traditional biofilter systems require substantial physical space, newer membrane bioreactor technologies have reduced spatial footprints by 40-60%. This reduction becomes particularly significant in coastal areas where land availability is limited and ecosystems are sensitive to development.

Chemical inputs associated with maintaining nitrification efficiency in saline conditions present additional environmental considerations. Alkalinity supplements and pH buffers commonly used in these systems can alter local water chemistry when discharged. Furthermore, the periodic cleaning of biofilters often involves chemical disinfectants that may impact non-target organisms if not properly neutralized before release.

Recent life cycle assessments comparing various nitrification technologies reveal significant differences in overall environmental impact. Recirculating aquaculture systems (RAS) with integrated denitrification capabilities demonstrate 30-45% lower environmental footprints compared to flow-through systems when measured across categories including global warming potential, acidification, and resource depletion. Moving bed biofilm reactors (MBBR) specifically adapted for saline conditions show promising environmental performance, with reduced energy requirements and improved nitrogen removal efficiency.

Emerging technologies such as algae-based nutrient removal systems and microbial fuel cells integrated with nitrification processes offer potential pathways toward more environmentally sustainable approaches. These systems can transform nitrogenous waste into valuable biomass while simultaneously reducing energy demands and minimizing harmful discharges. Pilot implementations suggest potential energy savings of 25-35% compared to conventional nitrification systems in saline environments.

Biosecurity Protocols for Nitrifying Biofilters in Saline Systems

Biosecurity protocols for nitrifying biofilters in saline aquaculture systems are critical for maintaining system health and preventing disease outbreaks. These protocols must address the unique challenges posed by saline environments, where nitrifying bacteria operate under different conditions compared to freshwater systems.

Effective biosecurity begins with proper biofilter design that minimizes contamination risks. Physical barriers should be implemented to prevent unauthorized access to biofilter components, with dedicated equipment for maintenance operations to avoid cross-contamination. Regular sanitization of peripheral equipment using appropriate disinfectants that won't compromise the nitrifying bacterial communities is essential.

Water quality monitoring represents a cornerstone of biosecurity management. Parameters including ammonia, nitrite, nitrate, pH, salinity, and dissolved oxygen should be monitored continuously or at minimum daily. Deviations from optimal ranges may indicate compromised biofilter function and potential biosecurity breaches. Advanced monitoring systems with real-time alerts can provide early warning of developing problems.

Quarantine procedures must be established for new biological materials entering the system. All incoming organisms, substrates, or water should undergo thorough screening and quarantine periods before introduction to the main system. This prevents potential pathogens from compromising established nitrifying communities.

Biofilter media management requires special attention in saline systems. Regular inspection for biofilm integrity, clogging, or unusual growth patterns can identify early signs of contamination. Cleaning protocols must balance the removal of excess organic matter without disrupting the essential nitrifying bacterial colonies. Techniques such as gentle backwashing or controlled air scouring are preferable to harsh chemical treatments.

Emergency response protocols should be developed for biosecurity breaches. These include isolation procedures for affected system components, remediation strategies for contaminated biofilters, and backup systems to maintain nitrification during recovery periods. Staff should be trained in recognizing early warning signs of biofilter compromise and implementing appropriate response measures.

Documentation and traceability systems form the final component of comprehensive biosecurity protocols. All maintenance activities, water quality parameters, and interventions should be recorded in detail. This creates an audit trail that can help identify the source of potential biosecurity breaches and improve future preventive measures. Regular review of these records enables continuous improvement of biosecurity protocols based on operational experience.

Effective biosecurity begins with proper biofilter design that minimizes contamination risks. Physical barriers should be implemented to prevent unauthorized access to biofilter components, with dedicated equipment for maintenance operations to avoid cross-contamination. Regular sanitization of peripheral equipment using appropriate disinfectants that won't compromise the nitrifying bacterial communities is essential.

Water quality monitoring represents a cornerstone of biosecurity management. Parameters including ammonia, nitrite, nitrate, pH, salinity, and dissolved oxygen should be monitored continuously or at minimum daily. Deviations from optimal ranges may indicate compromised biofilter function and potential biosecurity breaches. Advanced monitoring systems with real-time alerts can provide early warning of developing problems.

Quarantine procedures must be established for new biological materials entering the system. All incoming organisms, substrates, or water should undergo thorough screening and quarantine periods before introduction to the main system. This prevents potential pathogens from compromising established nitrifying communities.

Biofilter media management requires special attention in saline systems. Regular inspection for biofilm integrity, clogging, or unusual growth patterns can identify early signs of contamination. Cleaning protocols must balance the removal of excess organic matter without disrupting the essential nitrifying bacterial colonies. Techniques such as gentle backwashing or controlled air scouring are preferable to harsh chemical treatments.

Emergency response protocols should be developed for biosecurity breaches. These include isolation procedures for affected system components, remediation strategies for contaminated biofilters, and backup systems to maintain nitrification during recovery periods. Staff should be trained in recognizing early warning signs of biofilter compromise and implementing appropriate response measures.

Documentation and traceability systems form the final component of comprehensive biosecurity protocols. All maintenance activities, water quality parameters, and interventions should be recorded in detail. This creates an audit trail that can help identify the source of potential biosecurity breaches and improve future preventive measures. Regular review of these records enables continuous improvement of biosecurity protocols based on operational experience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!