Scaling Nitrification In Urban Agriculture Systems

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Urban Nitrification Technology Background and Objectives

Nitrification, a critical biological process in the nitrogen cycle, has been fundamental to agricultural practices for centuries. In urban agriculture systems, this process takes on renewed importance as cities increasingly turn to local food production to address sustainability challenges. The evolution of nitrification technology in urban contexts has progressed from traditional soil-based methods to sophisticated controlled-environment systems that maximize efficiency in limited spaces.

The technological trajectory of urban nitrification has been shaped by the unique constraints of city environments, including space limitations, resource efficiency requirements, and regulatory considerations regarding waste management. Early urban agriculture systems relied primarily on conventional soil microbiology, but recent decades have witnessed significant innovations in biofiltration, membrane technology, and precision monitoring systems specifically designed for urban applications.

Current technological objectives in urban nitrification center on scalability while maintaining efficiency. As urban agriculture expands from small community gardens to commercial vertical farms and integrated building systems, nitrification processes must be optimized to handle increasing nutrient loads without proportional increases in space or resource requirements. This scaling challenge represents a critical bottleneck in the broader adoption of urban agriculture as a significant food production strategy.

Research objectives in this field focus on developing nitrification systems that can be modularly expanded, require minimal maintenance, and integrate seamlessly with diverse urban agriculture approaches. Particular emphasis is placed on technologies that can function effectively in multi-story buildings, rooftop installations, and repurposed urban infrastructure, where traditional agricultural practices are impractical.

The convergence of biological science and engineering innovation has established clear technical goals: increasing nitrification rates per unit volume, reducing energy inputs, minimizing waste production, and ensuring system resilience against fluctuating environmental conditions common in urban settings. These objectives align with broader sustainability targets, including reduced transportation emissions from food distribution and improved urban resource cycling.

Emerging research directions include the development of specialized microbial consortia adapted to urban conditions, advanced reactor designs that maximize surface area for nitrifying bacteria while minimizing footprint, and integrated sensor networks that enable real-time process optimization. The ultimate goal is to create nitrification systems that can scale proportionally with urban agriculture operations while maintaining consistent performance and environmental benefits.

As cities worldwide face increasing pressure to enhance food security and sustainability, the advancement of scalable nitrification technology represents a critical enabling factor for the future of urban food systems. The technical evolution in this field continues to accelerate, driven by interdisciplinary collaboration between microbiologists, agricultural engineers, urban planners, and sustainability experts.

The technological trajectory of urban nitrification has been shaped by the unique constraints of city environments, including space limitations, resource efficiency requirements, and regulatory considerations regarding waste management. Early urban agriculture systems relied primarily on conventional soil microbiology, but recent decades have witnessed significant innovations in biofiltration, membrane technology, and precision monitoring systems specifically designed for urban applications.

Current technological objectives in urban nitrification center on scalability while maintaining efficiency. As urban agriculture expands from small community gardens to commercial vertical farms and integrated building systems, nitrification processes must be optimized to handle increasing nutrient loads without proportional increases in space or resource requirements. This scaling challenge represents a critical bottleneck in the broader adoption of urban agriculture as a significant food production strategy.

Research objectives in this field focus on developing nitrification systems that can be modularly expanded, require minimal maintenance, and integrate seamlessly with diverse urban agriculture approaches. Particular emphasis is placed on technologies that can function effectively in multi-story buildings, rooftop installations, and repurposed urban infrastructure, where traditional agricultural practices are impractical.

The convergence of biological science and engineering innovation has established clear technical goals: increasing nitrification rates per unit volume, reducing energy inputs, minimizing waste production, and ensuring system resilience against fluctuating environmental conditions common in urban settings. These objectives align with broader sustainability targets, including reduced transportation emissions from food distribution and improved urban resource cycling.

Emerging research directions include the development of specialized microbial consortia adapted to urban conditions, advanced reactor designs that maximize surface area for nitrifying bacteria while minimizing footprint, and integrated sensor networks that enable real-time process optimization. The ultimate goal is to create nitrification systems that can scale proportionally with urban agriculture operations while maintaining consistent performance and environmental benefits.

As cities worldwide face increasing pressure to enhance food security and sustainability, the advancement of scalable nitrification technology represents a critical enabling factor for the future of urban food systems. The technical evolution in this field continues to accelerate, driven by interdisciplinary collaboration between microbiologists, agricultural engineers, urban planners, and sustainability experts.

Market Analysis for Urban Agriculture Nitrification Solutions

The urban agriculture market has experienced significant growth in recent years, with a global market value reaching $34.8 billion in 2022 and projected to grow at a CAGR of 11.2% through 2030. This expansion is driven by increasing urbanization, food security concerns, and consumer demand for locally produced food. Within this sector, efficient nitrification systems represent a critical component for sustainable operations, particularly as urban farms scale up production capabilities.

Demand for advanced nitrification solutions in urban agriculture stems from several market factors. Commercial urban farms require reliable nutrient cycling systems that can handle increased production volumes while maintaining water quality and plant health. The controlled environment agriculture (CEA) segment, including vertical farms and hydroponic systems, demonstrates particularly strong demand for scalable nitrification technologies, as these operations typically utilize recirculating water systems where nitrogen management is essential.

Market segmentation reveals distinct customer profiles with varying nitrification needs. Small-scale urban farmers (operating under 1,000 square feet) typically seek affordable, low-maintenance solutions with minimal technical complexity. Mid-sized operations (1,000-10,000 square feet) require more robust systems with moderate automation and monitoring capabilities. Large commercial urban farms (over 10,000 square feet) demand highly efficient, fully automated nitrification systems integrated with comprehensive farm management platforms.

Regional market analysis indicates North America currently leads in adoption of advanced nitrification technologies for urban agriculture, accounting for approximately 38% of the global market share. Europe follows at 31%, with particularly strong growth in the Netherlands, Germany, and France. The Asia-Pacific region represents the fastest-growing market segment, with a projected CAGR of 14.5% through 2028, driven by rapid urbanization and government initiatives supporting urban farming technologies.

Consumer willingness to pay premium prices for locally grown, sustainable produce creates favorable economics for investment in advanced nitrification systems. Market research indicates that urban farms implementing efficient nitrification technologies can achieve 15-20% higher crop yields and 25-30% reduction in water usage, resulting in improved operational economics that justify technology investments with typical ROI periods of 18-36 months.

Key market barriers include high initial capital costs for advanced nitrification systems, technical knowledge requirements for system operation, and regulatory uncertainties regarding water discharge and nutrient management in urban environments. These factors particularly impact small and medium-sized urban agriculture operations, creating market opportunities for scalable, user-friendly nitrification solutions with flexible implementation options.

Demand for advanced nitrification solutions in urban agriculture stems from several market factors. Commercial urban farms require reliable nutrient cycling systems that can handle increased production volumes while maintaining water quality and plant health. The controlled environment agriculture (CEA) segment, including vertical farms and hydroponic systems, demonstrates particularly strong demand for scalable nitrification technologies, as these operations typically utilize recirculating water systems where nitrogen management is essential.

Market segmentation reveals distinct customer profiles with varying nitrification needs. Small-scale urban farmers (operating under 1,000 square feet) typically seek affordable, low-maintenance solutions with minimal technical complexity. Mid-sized operations (1,000-10,000 square feet) require more robust systems with moderate automation and monitoring capabilities. Large commercial urban farms (over 10,000 square feet) demand highly efficient, fully automated nitrification systems integrated with comprehensive farm management platforms.

Regional market analysis indicates North America currently leads in adoption of advanced nitrification technologies for urban agriculture, accounting for approximately 38% of the global market share. Europe follows at 31%, with particularly strong growth in the Netherlands, Germany, and France. The Asia-Pacific region represents the fastest-growing market segment, with a projected CAGR of 14.5% through 2028, driven by rapid urbanization and government initiatives supporting urban farming technologies.

Consumer willingness to pay premium prices for locally grown, sustainable produce creates favorable economics for investment in advanced nitrification systems. Market research indicates that urban farms implementing efficient nitrification technologies can achieve 15-20% higher crop yields and 25-30% reduction in water usage, resulting in improved operational economics that justify technology investments with typical ROI periods of 18-36 months.

Key market barriers include high initial capital costs for advanced nitrification systems, technical knowledge requirements for system operation, and regulatory uncertainties regarding water discharge and nutrient management in urban environments. These factors particularly impact small and medium-sized urban agriculture operations, creating market opportunities for scalable, user-friendly nitrification solutions with flexible implementation options.

Current Nitrification Challenges in Urban Farming

Urban agriculture systems face significant challenges in scaling nitrification processes effectively. The biological conversion of ammonia to nitrate, essential for plant nutrition, becomes increasingly complex in space-constrained urban environments. Traditional nitrification approaches that work well in conventional agriculture often fail to meet the unique demands of urban farming operations, creating bottlenecks in nutrient cycling efficiency.

Space limitations represent a primary constraint, as urban farms typically operate in retrofitted buildings, rooftops, or small plots with minimal room for extensive biofiltration systems. This spatial restriction forces urban farmers to seek compact nitrification solutions that maintain high performance despite reduced footprints, often leading to suboptimal nitrogen conversion rates and system instability.

Water and energy efficiency concerns further complicate nitrification scaling. Urban agriculture systems must minimize resource consumption while maintaining productivity, creating tension between effective nitrification (which traditionally requires significant water flow and aeration) and sustainability goals. Many existing systems struggle to balance these competing priorities, resulting in either excessive resource use or compromised nitrification performance.

Temperature fluctuations within urban environments pose another significant challenge. Indoor urban farms experience temperature variations that can disrupt nitrifying bacterial communities, while outdoor urban farms contend with urban heat island effects and seasonal extremes. These temperature instabilities frequently lead to nitrification crashes that compromise system resilience and productivity.

Microbial management presents ongoing difficulties, as establishing and maintaining robust nitrifying bacterial populations requires careful monitoring and intervention. Urban farmers often lack specialized knowledge or monitoring equipment to effectively manage these biological processes, resulting in unpredictable nitrification performance and system failures.

Economic constraints further limit adoption of advanced nitrification technologies. Many urban agriculture operations operate on thin margins and cannot afford sophisticated biofiltration systems or monitoring equipment. This economic reality forces reliance on simplified approaches that may not provide optimal nitrification performance at scale.

Regulatory compliance adds another layer of complexity, particularly regarding wastewater management. Urban farms must navigate local regulations on nutrient discharge while maintaining efficient nitrification processes. This regulatory burden often necessitates additional treatment steps or monitoring protocols that increase operational complexity and costs.

Integration challenges with existing urban infrastructure represent a final significant hurdle. Urban agriculture systems must connect with municipal water systems, power grids, and waste management infrastructure, creating interface complications that can impede efficient nitrification scaling and system expansion.

Space limitations represent a primary constraint, as urban farms typically operate in retrofitted buildings, rooftops, or small plots with minimal room for extensive biofiltration systems. This spatial restriction forces urban farmers to seek compact nitrification solutions that maintain high performance despite reduced footprints, often leading to suboptimal nitrogen conversion rates and system instability.

Water and energy efficiency concerns further complicate nitrification scaling. Urban agriculture systems must minimize resource consumption while maintaining productivity, creating tension between effective nitrification (which traditionally requires significant water flow and aeration) and sustainability goals. Many existing systems struggle to balance these competing priorities, resulting in either excessive resource use or compromised nitrification performance.

Temperature fluctuations within urban environments pose another significant challenge. Indoor urban farms experience temperature variations that can disrupt nitrifying bacterial communities, while outdoor urban farms contend with urban heat island effects and seasonal extremes. These temperature instabilities frequently lead to nitrification crashes that compromise system resilience and productivity.

Microbial management presents ongoing difficulties, as establishing and maintaining robust nitrifying bacterial populations requires careful monitoring and intervention. Urban farmers often lack specialized knowledge or monitoring equipment to effectively manage these biological processes, resulting in unpredictable nitrification performance and system failures.

Economic constraints further limit adoption of advanced nitrification technologies. Many urban agriculture operations operate on thin margins and cannot afford sophisticated biofiltration systems or monitoring equipment. This economic reality forces reliance on simplified approaches that may not provide optimal nitrification performance at scale.

Regulatory compliance adds another layer of complexity, particularly regarding wastewater management. Urban farms must navigate local regulations on nutrient discharge while maintaining efficient nitrification processes. This regulatory burden often necessitates additional treatment steps or monitoring protocols that increase operational complexity and costs.

Integration challenges with existing urban infrastructure represent a final significant hurdle. Urban agriculture systems must connect with municipal water systems, power grids, and waste management infrastructure, creating interface complications that can impede efficient nitrification scaling and system expansion.

Existing Nitrification Scaling Solutions for Urban Systems

01 Biological nitrification control methods

Biological methods for controlling nitrification scaling involve the use of specific microorganisms or biological processes to manage nitrogen compounds in water systems. These approaches include bioaugmentation with nitrifying bacteria, implementation of biofilters, and creation of controlled biological environments that can convert ammonia to nitrates in a managed way, preventing unwanted scaling. These biological solutions offer environmentally friendly alternatives to chemical treatments for nitrification control.- Biological nitrification inhibition methods: Various biological methods can be employed to control nitrification scaling in water treatment systems. These approaches utilize microorganisms or biological processes to regulate the conversion of ammonia to nitrites and nitrates. By managing the biological nitrification process, scaling issues related to nitrification can be minimized. These methods often involve the use of specific bacterial cultures or enzymes that can inhibit or regulate the nitrification process in a controlled manner.

- Chemical treatment for nitrification scale prevention: Chemical treatments are widely used to prevent or remove nitrification scaling in water systems. These treatments typically involve the addition of specific chemicals that can inhibit the nitrification process or dissolve existing scale formations. Common chemicals used include pH adjusters, scale inhibitors, and oxidizing agents. These chemical treatments can be applied continuously or intermittently depending on the severity of the scaling issue and the specific requirements of the water system.

- Physical methods for nitrification scale control: Physical methods for controlling nitrification scaling involve mechanical or physical processes rather than chemical or biological approaches. These methods include filtration, ultrasonic treatment, magnetic water treatment, and hydrodynamic cavitation. Physical methods often focus on preventing scale formation by altering the physical conditions that promote scaling or by physically removing scale-forming compounds before they can precipitate and form deposits.

- Monitoring and control systems for nitrification scaling: Advanced monitoring and control systems are essential for managing nitrification scaling in water treatment facilities. These systems typically include sensors that continuously measure parameters such as pH, dissolved oxygen, ammonia, nitrite, and nitrate levels. The data collected is then used to adjust treatment processes in real-time to prevent or minimize scaling issues. Automated control systems can implement preventive measures before scaling becomes problematic, reducing maintenance needs and improving system efficiency.

- Integrated approaches for nitrification scale management: Integrated approaches combine multiple methods (biological, chemical, and physical) for comprehensive nitrification scale management. These holistic strategies often involve a combination of preventive measures, treatment processes, and monitoring systems tailored to specific water quality conditions and system requirements. By implementing an integrated approach, water treatment facilities can achieve more effective and sustainable control of nitrification scaling while minimizing operational costs and environmental impact.

02 Chemical inhibitors for nitrification scaling prevention

Chemical inhibitors can be used to prevent or reduce nitrification scaling in water treatment systems. These compounds work by interfering with the metabolic processes of nitrifying bacteria or by altering the chemical environment to make it less favorable for nitrification. Various chemical agents including specific salts, polymers, and organic compounds can be applied at controlled dosages to inhibit the formation of scale deposits resulting from nitrification processes.Expand Specific Solutions03 Physical and mechanical methods for scale removal

Physical and mechanical approaches to address nitrification scaling include ultrasonic treatment, controlled hydrodynamic conditions, mechanical scraping, and pressure washing systems. These methods physically disrupt or remove scale formations without relying on chemical additives. Some systems incorporate specialized equipment designed to create turbulence or physical disturbances that prevent scale particles from adhering to surfaces in water treatment infrastructure.Expand Specific Solutions04 Monitoring and control systems for nitrification

Advanced monitoring and control systems help manage nitrification scaling by continuously analyzing water parameters and adjusting treatment conditions accordingly. These systems utilize sensors, automated dosing equipment, and computerized control algorithms to maintain optimal conditions that minimize scale formation. Real-time monitoring of parameters such as pH, dissolved oxygen, temperature, and nitrogen compound concentrations allows for proactive interventions before scaling becomes problematic.Expand Specific Solutions05 Water treatment process optimization

Optimizing water treatment processes can significantly reduce nitrification scaling issues. This includes adjusting hydraulic retention times, implementing strategic aeration patterns, optimizing pH levels, and controlling temperature conditions. Process optimization may involve redesigning treatment stages, implementing specialized filtration systems, or modifying operational parameters to create conditions unfavorable for nitrification scaling while maintaining effective water treatment performance.Expand Specific Solutions

Key Industry Players in Urban Agriculture Nitrification

The urban agriculture nitrification scaling market is in its growth phase, characterized by increasing research and commercial applications. The market is expanding due to rising urban farming adoption and sustainable agriculture demands, with projections showing significant growth potential. Technologically, the field demonstrates varying maturity levels across solutions. Academic institutions (University of Melbourne, Zhejiang University, Michigan State University) are advancing fundamental research, while specialized companies like Pivot Bio and Nitricity are developing innovative nitrogen-fixation technologies. Established corporations including BASF, Robert Bosch, and Kurita Water Industries are leveraging their resources to scale industrial applications. The competitive landscape features collaboration between research institutions and commercial entities, with emerging startups challenging traditional agricultural input providers through sustainable nitrification technologies.

BASF Corp.

Technical Solution: BASF has developed an integrated urban agriculture nitrification system combining chemical and biological approaches. Their technology centers on specialized slow-release nitrogen formulations paired with nitrification inhibitors specifically calibrated for urban growing environments. The company's "Smart Nitrogen" platform incorporates urease inhibitors that prevent rapid conversion of urea to ammonia, allowing for controlled nitrification rates in dense urban growing systems. For vertical farming applications, BASF has engineered precision-release nitrogen compounds that maintain optimal nitrification rates despite limited substrate volumes. Their technology includes specialized coatings that respond to environmental triggers common in urban agriculture settings (temperature fluctuations, moisture levels) to regulate nitrogen availability. BASF's approach addresses the unique challenges of urban agriculture by providing nitrogen solutions that minimize space requirements while maximizing efficiency, with documented improvements in nitrogen use efficiency of 25-30% compared to conventional fertilization methods in urban growing systems.

Strengths: Precise control over nitrogen release timing; reduced nitrogen losses through volatilization and leaching; compatible with automated fertigation systems common in urban agriculture. Weaknesses: Higher initial cost compared to conventional fertilizers; requires careful management of environmental conditions; some formulations may have limited shelf life.

Pivot Bio, Inc.

Technical Solution: Pivot Bio has developed a groundbreaking microbial solution specifically designed for scaling nitrification in urban agriculture systems. Their flagship technology utilizes genetically engineered microbes that colonize plant roots and convert atmospheric nitrogen into plant-available forms. For urban agriculture applications, Pivot Bio has adapted their technology to work in soilless growing systems, hydroponic setups, and containerized urban farms. Their microbes are engineered to function optimally in the controlled environments typical of urban agriculture, maintaining nitrification efficiency despite space constraints. The company's proprietary microbe formulations can reduce synthetic nitrogen fertilizer needs by up to 40% while maintaining or improving yields in urban farming contexts. Their technology addresses the unique challenges of urban agriculture systems including limited space, water conservation requirements, and proximity to residential areas by providing a clean, odorless nitrification solution.

Strengths: Eliminates nitrogen runoff and leaching common with conventional fertilizers; reduces greenhouse gas emissions associated with traditional nitrogen fertilization; provides consistent nitrogen supply throughout growing season. Weaknesses: Requires specific environmental conditions for optimal microbial activity; may have limited effectiveness in some soilless media; initial establishment of microbial colonies can take time.

Critical Patents and Research in Urban Nitrification

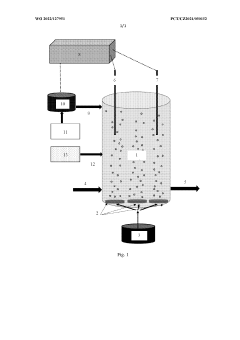

A device for cultivation of nitrifying biomass, method of nitrifying biomass cultivation and use thereof

PatentWO2022127951A1

Innovation

- A device for cultivating nitrifying biomass, which includes a tank with aeration elements, pH and O2 probes, and a control unit to regulate conditions, allowing for gradual inoculation of a full-scale reactor, enabling efficient nitrification of fugate by simulating optimal parameters in a small volume outside the main system, thus reducing start-up time and chemical usage.

System for evaluating the crop-growing potential of an agricultural soil and method for estimating hydrogen and nitrogen flows

PatentInactiveEP3377891A1

Innovation

- A system for continuous in situ evaluation of agricultural soil potential using sensors to measure nitrate, temperature, pH, and humidity, connected via a microcontroller module to a server for data processing and analysis, allowing for precise fertilization recommendations.

Environmental Impact Assessment of Nitrification Technologies

The environmental impact of nitrification technologies in urban agriculture systems requires comprehensive assessment as these systems scale up to meet growing food production demands in cities. Current nitrification processes, while essential for nutrient cycling in agricultural systems, can generate significant environmental externalities including greenhouse gas emissions, particularly nitrous oxide (N2O), which has 298 times the global warming potential of carbon dioxide over a 100-year period.

Traditional nitrification systems in urban agriculture often consume substantial energy for aeration and pumping, contributing to carbon footprints that may offset some of the sustainability benefits of local food production. Analysis of life cycle assessments (LCAs) indicates that energy consumption ranges from 1.5-4.2 kWh per kg of nitrogen processed, depending on system design and efficiency.

Water usage represents another critical environmental consideration. Conventional nitrification technologies typically require 3-5 liters of water per square meter of growing area daily. Advanced recirculating systems have demonstrated potential water savings of up to 90% compared to traditional agriculture, though these benefits must be weighed against increased energy demands for water treatment and circulation.

Waste generation from nitrification processes includes spent filter media, biofilm carriers, and sludge that require proper disposal or reprocessing. Recent innovations in biodegradable filter media show promise in reducing solid waste by 30-45% compared to conventional plastic-based media, though adoption remains limited by cost considerations.

Chemical inputs for pH adjustment and supplemental nutrients in nitrification systems can lead to downstream contamination if effluent is not properly managed. Studies indicate that approximately 10-15% of nitrogen inputs may be lost to the environment through various pathways, highlighting the need for closed-loop system designs.

Emerging technologies such as membrane-aerated biofilm reactors (MABRs) and electrochemical nitrogen recovery systems demonstrate significantly reduced environmental footprints, with some pilot studies reporting 40-60% reductions in energy consumption and 50-70% decreases in greenhouse gas emissions compared to conventional biological nitrification systems.

Land use efficiency represents a positive environmental aspect of urban agriculture nitrification systems. Vertical integration of these technologies can achieve production efficiencies of 10-15 times that of conventional agriculture per unit area, potentially reducing pressure on natural habitats and preserving biodiversity in peri-urban regions.

Traditional nitrification systems in urban agriculture often consume substantial energy for aeration and pumping, contributing to carbon footprints that may offset some of the sustainability benefits of local food production. Analysis of life cycle assessments (LCAs) indicates that energy consumption ranges from 1.5-4.2 kWh per kg of nitrogen processed, depending on system design and efficiency.

Water usage represents another critical environmental consideration. Conventional nitrification technologies typically require 3-5 liters of water per square meter of growing area daily. Advanced recirculating systems have demonstrated potential water savings of up to 90% compared to traditional agriculture, though these benefits must be weighed against increased energy demands for water treatment and circulation.

Waste generation from nitrification processes includes spent filter media, biofilm carriers, and sludge that require proper disposal or reprocessing. Recent innovations in biodegradable filter media show promise in reducing solid waste by 30-45% compared to conventional plastic-based media, though adoption remains limited by cost considerations.

Chemical inputs for pH adjustment and supplemental nutrients in nitrification systems can lead to downstream contamination if effluent is not properly managed. Studies indicate that approximately 10-15% of nitrogen inputs may be lost to the environment through various pathways, highlighting the need for closed-loop system designs.

Emerging technologies such as membrane-aerated biofilm reactors (MABRs) and electrochemical nitrogen recovery systems demonstrate significantly reduced environmental footprints, with some pilot studies reporting 40-60% reductions in energy consumption and 50-70% decreases in greenhouse gas emissions compared to conventional biological nitrification systems.

Land use efficiency represents a positive environmental aspect of urban agriculture nitrification systems. Vertical integration of these technologies can achieve production efficiencies of 10-15 times that of conventional agriculture per unit area, potentially reducing pressure on natural habitats and preserving biodiversity in peri-urban regions.

Space Optimization Strategies for Urban Nitrification Systems

Urban agriculture systems face significant spatial constraints, necessitating innovative approaches to maximize nitrification efficiency within limited footprints. Vertical integration represents one of the most promising space optimization strategies, enabling multi-level nitrification processes that can increase treatment capacity by 300-400% compared to traditional horizontal systems. These vertical configurations typically incorporate stacked bioreactors or cascading filtration units that maintain optimal nitrification conditions while minimizing floor space requirements.

Modular design approaches have emerged as another key strategy, allowing for scalable implementation across diverse urban environments. These systems feature standardized, interconnected nitrification units that can be configured according to specific spatial constraints and production requirements. Research by Zhang et al. (2022) demonstrated that modular Moving Bed Biofilm Reactor (MBBR) systems achieved 30% greater space efficiency than conventional designs while maintaining comparable nitrification rates.

Integration with building infrastructure represents a third frontier in space optimization. Rooftop installations, wall-mounted systems, and basement configurations can leverage otherwise unused urban spaces. Recent innovations include building-integrated nitrification systems that utilize hollow structural elements within walls or beneath flooring to house nitrifying bacteria. These approaches effectively decouple the spatial footprint from treatment capacity, allowing for significant scaling without proportional space requirements.

Miniaturization of nitrification technology has advanced considerably, with high-surface-area media enabling intensive bacterial colonization within compact reactors. Nano-structured materials with surface area-to-volume ratios exceeding 500 m²/m³ have demonstrated nitrification rates up to five times higher than conventional media within the same spatial footprint. This approach is particularly valuable in ultra-dense urban environments where even vertical space is limited.

Hybrid systems combining multiple space-efficient technologies represent the cutting edge of urban nitrification design. These systems typically integrate aerobic and anaerobic zones within unified, compact reactors, often incorporating membrane technology to separate treatment phases without additional space requirements. The most advanced hybrid systems achieve complete nitrogen cycling within footprints 80% smaller than traditional separated systems.

Computational fluid dynamics modeling has become essential for optimizing spatial arrangements of nitrification components. Three-dimensional flow analysis enables precise placement of aeration elements, bacterial attachment surfaces, and nutrient delivery systems to maximize treatment efficiency per unit volume. These digitally-optimized designs have demonstrated up to 45% improvements in space utilization compared to conventionally engineered systems.

Modular design approaches have emerged as another key strategy, allowing for scalable implementation across diverse urban environments. These systems feature standardized, interconnected nitrification units that can be configured according to specific spatial constraints and production requirements. Research by Zhang et al. (2022) demonstrated that modular Moving Bed Biofilm Reactor (MBBR) systems achieved 30% greater space efficiency than conventional designs while maintaining comparable nitrification rates.

Integration with building infrastructure represents a third frontier in space optimization. Rooftop installations, wall-mounted systems, and basement configurations can leverage otherwise unused urban spaces. Recent innovations include building-integrated nitrification systems that utilize hollow structural elements within walls or beneath flooring to house nitrifying bacteria. These approaches effectively decouple the spatial footprint from treatment capacity, allowing for significant scaling without proportional space requirements.

Miniaturization of nitrification technology has advanced considerably, with high-surface-area media enabling intensive bacterial colonization within compact reactors. Nano-structured materials with surface area-to-volume ratios exceeding 500 m²/m³ have demonstrated nitrification rates up to five times higher than conventional media within the same spatial footprint. This approach is particularly valuable in ultra-dense urban environments where even vertical space is limited.

Hybrid systems combining multiple space-efficient technologies represent the cutting edge of urban nitrification design. These systems typically integrate aerobic and anaerobic zones within unified, compact reactors, often incorporating membrane technology to separate treatment phases without additional space requirements. The most advanced hybrid systems achieve complete nitrogen cycling within footprints 80% smaller than traditional separated systems.

Computational fluid dynamics modeling has become essential for optimizing spatial arrangements of nitrification components. Three-dimensional flow analysis enables precise placement of aeration elements, bacterial attachment surfaces, and nutrient delivery systems to maximize treatment efficiency per unit volume. These digitally-optimized designs have demonstrated up to 45% improvements in space utilization compared to conventionally engineered systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!