Scaling Nitrification In Greenhouse Crop Production

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitrification Technology Background and Objectives

Nitrification is a critical biological process in agricultural systems, particularly in greenhouse crop production where controlled environments allow for optimized plant growth. Historically, nitrification technology has evolved from basic understanding of the nitrogen cycle in the early 20th century to sophisticated management systems in modern agriculture. The process involves the biological oxidation of ammonia to nitrite and subsequently to nitrate by nitrifying bacteria, primarily Nitrosomonas and Nitrobacter species.

The evolution of nitrification technology in greenhouse settings has been driven by the need for precise nutrient management to maximize crop yields while minimizing environmental impacts. Early greenhouse systems relied on conventional soil-based cultivation with limited control over nitrification processes. The transition to soilless culture systems in the 1970s and 1980s marked a significant advancement, allowing for greater manipulation of the root environment and nutrient delivery.

Recent technological trends show a shift toward integrated systems that combine biological nitrification with physical and chemical processes to optimize nitrogen utilization efficiency. Advanced monitoring technologies, including real-time sensors for nitrogen compounds and microbial activity, have enabled more precise management of nitrification processes in greenhouse environments.

The primary objective of scaling nitrification in greenhouse crop production is to develop sustainable, efficient systems that can maintain optimal nitrogen availability across varying production scales while minimizing resource inputs and environmental impacts. This includes enhancing the stability and resilience of nitrification processes under fluctuating environmental conditions typical in commercial greenhouse operations.

Secondary objectives include reducing the energy and resource requirements associated with nitrogen management, minimizing nitrogen losses through leaching and gaseous emissions, and developing standardized protocols that can be implemented across diverse greenhouse production systems and crop types.

The technological goals extend to creating adaptive nitrification management systems that can respond dynamically to changing crop demands throughout growth cycles. This involves integrating nitrification technology with broader nutrient management strategies, irrigation systems, and environmental control mechanisms within greenhouse environments.

Understanding the microbial ecology underlying nitrification processes represents another critical objective, as enhancing beneficial microbial communities can improve system stability and efficiency. Research aims to identify optimal conditions for nitrifying bacteria proliferation and activity in various substrate materials used in greenhouse production.

Ultimately, the scaling of nitrification technology seeks to bridge the gap between laboratory-scale understanding of nitrogen transformation processes and commercial-scale implementation in diverse greenhouse production systems, ensuring consistent crop quality and yield while advancing agricultural sustainability.

The evolution of nitrification technology in greenhouse settings has been driven by the need for precise nutrient management to maximize crop yields while minimizing environmental impacts. Early greenhouse systems relied on conventional soil-based cultivation with limited control over nitrification processes. The transition to soilless culture systems in the 1970s and 1980s marked a significant advancement, allowing for greater manipulation of the root environment and nutrient delivery.

Recent technological trends show a shift toward integrated systems that combine biological nitrification with physical and chemical processes to optimize nitrogen utilization efficiency. Advanced monitoring technologies, including real-time sensors for nitrogen compounds and microbial activity, have enabled more precise management of nitrification processes in greenhouse environments.

The primary objective of scaling nitrification in greenhouse crop production is to develop sustainable, efficient systems that can maintain optimal nitrogen availability across varying production scales while minimizing resource inputs and environmental impacts. This includes enhancing the stability and resilience of nitrification processes under fluctuating environmental conditions typical in commercial greenhouse operations.

Secondary objectives include reducing the energy and resource requirements associated with nitrogen management, minimizing nitrogen losses through leaching and gaseous emissions, and developing standardized protocols that can be implemented across diverse greenhouse production systems and crop types.

The technological goals extend to creating adaptive nitrification management systems that can respond dynamically to changing crop demands throughout growth cycles. This involves integrating nitrification technology with broader nutrient management strategies, irrigation systems, and environmental control mechanisms within greenhouse environments.

Understanding the microbial ecology underlying nitrification processes represents another critical objective, as enhancing beneficial microbial communities can improve system stability and efficiency. Research aims to identify optimal conditions for nitrifying bacteria proliferation and activity in various substrate materials used in greenhouse production.

Ultimately, the scaling of nitrification technology seeks to bridge the gap between laboratory-scale understanding of nitrogen transformation processes and commercial-scale implementation in diverse greenhouse production systems, ensuring consistent crop quality and yield while advancing agricultural sustainability.

Market Analysis for Greenhouse Nitrification Systems

The greenhouse nitrification systems market is experiencing robust growth, driven by increasing adoption of controlled environment agriculture and the need for more efficient nutrient management systems. Current market valuation stands at approximately 3.2 billion USD globally, with projections indicating a compound annual growth rate of 7.8% through 2028. This growth trajectory is supported by the expanding greenhouse cultivation sector, which has seen a 12% increase in total acreage over the past five years.

North America and Europe currently dominate the market, collectively accounting for 68% of global revenue. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading adoption rates due to their rapidly modernizing agricultural sectors and government initiatives supporting sustainable farming practices.

Commercial greenhouse operations represent the largest customer segment, comprising 76% of the market. These operations prioritize systems that can handle large-scale nitrification processes while maintaining consistent crop quality. Small to medium-sized greenhouse operations constitute a growing segment, particularly as more affordable and scalable solutions enter the market.

Demand drivers for nitrification systems include increasing pressure for sustainable agriculture practices, rising fertilizer costs, and stricter environmental regulations regarding nutrient runoff. The market has seen a notable shift toward integrated systems that combine nitrification with other nutrient management processes, offering growers comprehensive solutions rather than standalone components.

Consumer preferences are evolving toward systems with higher automation capabilities, remote monitoring features, and energy efficiency. Data from recent industry surveys indicates that 82% of greenhouse operators consider energy consumption a critical factor in purchasing decisions, while 74% prioritize systems with advanced monitoring capabilities.

Market barriers include high initial investment costs, technical complexity requiring specialized knowledge, and competition from traditional fertilization methods. The average return on investment period for advanced nitrification systems ranges from 2-4 years, depending on scale and crop type, which can deter smaller operations with limited capital resources.

Distribution channels are primarily direct sales from manufacturers to large greenhouse operations, while smaller growers typically purchase through agricultural supply distributors. Online sales channels have gained traction, growing at 15% annually as digital marketing strategies become more prevalent in the agricultural technology sector.

North America and Europe currently dominate the market, collectively accounting for 68% of global revenue. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading adoption rates due to their rapidly modernizing agricultural sectors and government initiatives supporting sustainable farming practices.

Commercial greenhouse operations represent the largest customer segment, comprising 76% of the market. These operations prioritize systems that can handle large-scale nitrification processes while maintaining consistent crop quality. Small to medium-sized greenhouse operations constitute a growing segment, particularly as more affordable and scalable solutions enter the market.

Demand drivers for nitrification systems include increasing pressure for sustainable agriculture practices, rising fertilizer costs, and stricter environmental regulations regarding nutrient runoff. The market has seen a notable shift toward integrated systems that combine nitrification with other nutrient management processes, offering growers comprehensive solutions rather than standalone components.

Consumer preferences are evolving toward systems with higher automation capabilities, remote monitoring features, and energy efficiency. Data from recent industry surveys indicates that 82% of greenhouse operators consider energy consumption a critical factor in purchasing decisions, while 74% prioritize systems with advanced monitoring capabilities.

Market barriers include high initial investment costs, technical complexity requiring specialized knowledge, and competition from traditional fertilization methods. The average return on investment period for advanced nitrification systems ranges from 2-4 years, depending on scale and crop type, which can deter smaller operations with limited capital resources.

Distribution channels are primarily direct sales from manufacturers to large greenhouse operations, while smaller growers typically purchase through agricultural supply distributors. Online sales channels have gained traction, growing at 15% annually as digital marketing strategies become more prevalent in the agricultural technology sector.

Current Nitrification Challenges in Controlled Environments

Nitrification in greenhouse crop production faces significant challenges when scaling operations, particularly in controlled environment agriculture (CEA). The process of converting ammonium to nitrate through microbial activity is fundamental to plant nutrition but becomes increasingly complex in larger greenhouse systems. Current challenges primarily revolve around maintaining optimal conditions for nitrifying bacteria while balancing the diverse needs of crop production.

Temperature fluctuations within greenhouse environments pose a major obstacle to consistent nitrification. Nitrifying bacteria operate optimally within specific temperature ranges (25-30°C for Nitrosomonas and 30-35°C for Nitrobacter), but large-scale greenhouses often experience temperature gradients and fluctuations that can inhibit bacterial activity in certain zones, leading to uneven nitrification across the system.

Oxygen availability presents another critical challenge, as nitrification is an aerobic process requiring 4.57 mg of oxygen for every mg of ammonium-nitrogen oxidized. In scaled operations, maintaining adequate dissolved oxygen levels throughout irrigation systems becomes increasingly difficult, especially in recirculating nutrient solutions where oxygen demand can rapidly deplete available supply.

pH management becomes exponentially more complex in large-scale operations. Nitrification naturally produces acidity, decreasing solution pH over time. While small systems might require occasional pH adjustment, industrial-scale greenhouses need sophisticated automated monitoring and correction systems to maintain the optimal pH range of 7.5-8.0 for nitrifying bacteria while simultaneously addressing crop-specific pH requirements.

Biofilm management represents a significant operational challenge in scaled nitrification systems. While biofilms provide habitat for beneficial nitrifying bacteria, excessive growth can clog irrigation lines, emitters, and filters. Conversely, aggressive cleaning protocols may remove too much beneficial bacterial population, disrupting nitrification capacity. This delicate balance becomes harder to maintain as system size increases.

Nutrient solution composition variability across large systems impacts nitrification efficiency. Inconsistent concentrations of ammonium, competing ions, and potential inhibitory compounds can create "dead zones" where nitrification proceeds poorly. This heterogeneity increases with system scale, requiring more sophisticated monitoring and management approaches.

Microbial community stability faces greater threats in large-scale operations where contamination risks multiply with increased points of entry, more extensive plumbing systems, and higher volumes of materials moving through the facility. Maintaining a stable, beneficial microbial community becomes increasingly difficult, with potential for pathogen introduction or beneficial bacteria population crashes.

Energy and resource efficiency decline as nitrification systems scale up. Larger systems require proportionally more energy for pumping, aeration, and temperature control. This increased resource demand directly impacts operational costs and environmental sustainability, creating economic and ecological barriers to effective scaling.

Temperature fluctuations within greenhouse environments pose a major obstacle to consistent nitrification. Nitrifying bacteria operate optimally within specific temperature ranges (25-30°C for Nitrosomonas and 30-35°C for Nitrobacter), but large-scale greenhouses often experience temperature gradients and fluctuations that can inhibit bacterial activity in certain zones, leading to uneven nitrification across the system.

Oxygen availability presents another critical challenge, as nitrification is an aerobic process requiring 4.57 mg of oxygen for every mg of ammonium-nitrogen oxidized. In scaled operations, maintaining adequate dissolved oxygen levels throughout irrigation systems becomes increasingly difficult, especially in recirculating nutrient solutions where oxygen demand can rapidly deplete available supply.

pH management becomes exponentially more complex in large-scale operations. Nitrification naturally produces acidity, decreasing solution pH over time. While small systems might require occasional pH adjustment, industrial-scale greenhouses need sophisticated automated monitoring and correction systems to maintain the optimal pH range of 7.5-8.0 for nitrifying bacteria while simultaneously addressing crop-specific pH requirements.

Biofilm management represents a significant operational challenge in scaled nitrification systems. While biofilms provide habitat for beneficial nitrifying bacteria, excessive growth can clog irrigation lines, emitters, and filters. Conversely, aggressive cleaning protocols may remove too much beneficial bacterial population, disrupting nitrification capacity. This delicate balance becomes harder to maintain as system size increases.

Nutrient solution composition variability across large systems impacts nitrification efficiency. Inconsistent concentrations of ammonium, competing ions, and potential inhibitory compounds can create "dead zones" where nitrification proceeds poorly. This heterogeneity increases with system scale, requiring more sophisticated monitoring and management approaches.

Microbial community stability faces greater threats in large-scale operations where contamination risks multiply with increased points of entry, more extensive plumbing systems, and higher volumes of materials moving through the facility. Maintaining a stable, beneficial microbial community becomes increasingly difficult, with potential for pathogen introduction or beneficial bacteria population crashes.

Energy and resource efficiency decline as nitrification systems scale up. Larger systems require proportionally more energy for pumping, aeration, and temperature control. This increased resource demand directly impacts operational costs and environmental sustainability, creating economic and ecological barriers to effective scaling.

Current Nitrification Scaling Solutions for Crop Production

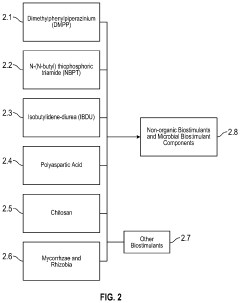

01 Biological nitrification control methods

Biological methods for controlling nitrification scaling involve the use of specific microorganisms or biological processes to manage nitrogen compounds in water systems. These approaches include bioaugmentation with nitrifying bacteria, implementation of biofilm reactors, and the use of biological filters to convert ammonia to nitrate in a controlled manner. These biological processes can effectively prevent scaling by maintaining optimal nitrification rates and preventing the accumulation of nitrogen compounds that contribute to scale formation.- Nitrification inhibition methods for wastewater treatment: Various methods are employed to inhibit nitrification in wastewater treatment systems to prevent scaling. These methods include the use of specific chemical inhibitors that target nitrifying bacteria, controlling operational parameters such as pH and temperature, and implementing specialized treatment processes. By inhibiting nitrification, the formation of scale-causing compounds can be reduced, leading to improved system efficiency and reduced maintenance requirements.

- Scale prevention in nitrification systems using chemical additives: Chemical additives can be incorporated into nitrification systems to prevent or reduce scaling. These additives work by interfering with the crystallization process of scale-forming compounds, modifying crystal structures, or dispersing scale particles. Examples include scale inhibitors, dispersants, and chelating agents that can bind with scale-forming ions. The proper selection and dosing of these chemicals can significantly extend equipment life and maintain system efficiency.

- Biological approaches to nitrification scaling control: Biological approaches utilize specific microorganisms or biological processes to control nitrification scaling. These methods include bioaugmentation with specialized bacterial strains, implementation of biofilm management strategies, and optimization of microbial community structures. By promoting beneficial biological activities while suppressing scale-forming processes, these approaches offer environmentally friendly solutions to nitrification scaling problems in water treatment systems.

- Advanced monitoring and control systems for nitrification scaling: Advanced monitoring and control systems employ sensors, data analytics, and automation to detect and manage nitrification scaling in real-time. These systems continuously monitor key parameters such as pH, dissolved oxygen, nitrogen compounds, and mineral concentrations to predict scaling potential. When scaling conditions are detected, automated responses can adjust treatment parameters or trigger maintenance protocols, thereby preventing scale formation before it becomes problematic.

- Physical and mechanical methods for nitrification scale removal: Physical and mechanical methods are employed to remove existing nitrification scale from treatment systems. These techniques include ultrasonic treatment, hydrodynamic cavitation, mechanical scraping, and high-pressure washing. Additionally, controlled pH adjustment can dissolve certain types of scale. These methods are often applied during scheduled maintenance periods to restore system efficiency and prevent the accumulation of scale that could lead to equipment failure or reduced treatment capacity.

02 Chemical inhibitors for nitrification scaling prevention

Chemical inhibitors can be used to prevent or reduce nitrification scaling in water treatment systems. These compounds work by interfering with the biological processes that convert ammonia to nitrite and nitrate, or by preventing scale formation directly. Various chemical agents such as specific salts, polymers, and organic compounds can be applied at controlled dosages to inhibit nitrification while maintaining water quality parameters within acceptable ranges.Expand Specific Solutions03 Physical and mechanical scale control techniques

Physical and mechanical methods for controlling nitrification scaling include ultrasonic treatment, electrostatic field application, and mechanical cleaning systems. These techniques disrupt scale formation by preventing crystal growth or by removing existing scale deposits. Regular mechanical cleaning, flow management, and surface modifications of equipment can also reduce scale adhesion and buildup in water treatment systems and distribution networks.Expand Specific Solutions04 Monitoring and control systems for nitrification management

Advanced monitoring and control systems are essential for managing nitrification scaling in water treatment facilities. These systems include real-time sensors for measuring ammonia, nitrite, and nitrate levels, automated dosing equipment for chemical inhibitors, and computerized control algorithms that adjust treatment parameters based on water quality data. Implementing comprehensive monitoring protocols allows for early detection of nitrification issues and timely intervention to prevent scaling problems.Expand Specific Solutions05 Water treatment process optimization for scale reduction

Optimizing water treatment processes can significantly reduce nitrification scaling issues. This includes adjusting pH levels, controlling dissolved oxygen concentration, managing hydraulic retention times, and implementing strategic flushing protocols. Temperature management and proper nutrient balancing in the system can also inhibit excessive nitrification activity. These optimization techniques focus on creating conditions that discourage scale formation while maintaining effective water treatment performance.Expand Specific Solutions

Leading Companies in Greenhouse Nitrification Technology

The nitrification scaling market in greenhouse crop production is currently in a growth phase, with increasing demand driven by sustainable agriculture trends. The market size is expanding as greenhouse cultivation becomes more prevalent globally, estimated to reach significant value in the coming years. Technologically, the field shows moderate maturity with ongoing innovation. Leading research institutions like Cornell University, Michigan State University, and Zhejiang University are advancing fundamental science, while commercial players demonstrate varying levels of technological readiness. Companies like BASF, Pioneer Hi-Bred, and Pluton Biosciences are developing proprietary solutions, with BASF and Corteva Agriscience leveraging their agricultural expertise to commercialize advanced nitrification management systems. Emerging players like Atmonia and Tenfold Technologies are introducing disruptive approaches, creating a competitive landscape balanced between established agrochemical companies and innovative startups.

BASF Corp.

Technical Solution: BASF has developed an integrated nitrification management system for greenhouse crop production that combines controlled-release fertilizers with nitrification inhibitors. Their Nitrasol™ technology utilizes specialized polymer coatings that regulate nitrogen release based on soil temperature and moisture conditions, ensuring optimal nitrogen availability throughout the growing cycle. The system incorporates proprietary nitrification inhibitors that temporarily suppress the activity of Nitrosomonas bacteria, extending the period ammonium remains in the soil before converting to nitrate. This approach allows for precise nitrogen management in greenhouse environments where traditional field-based approaches are insufficient. BASF's solution includes sensor-based monitoring systems that provide real-time data on nitrogen levels, enabling automated adjustments to fertilization regimes based on crop growth stage and environmental conditions.

Strengths: Comprehensive integration of controlled-release technology with inhibitors provides superior nitrogen use efficiency. Advanced monitoring capabilities enable precise management. Weaknesses: Higher initial implementation costs compared to conventional systems. Requires technical expertise for optimal calibration to specific greenhouse environments and crop varieties.

Cornell University

Technical Solution: Cornell University has pioneered a biological nitrification enhancement system for greenhouse production that leverages beneficial microbial communities. Their approach involves the cultivation and application of specialized nitrifying bacterial consortia that are adapted to greenhouse conditions. The system utilizes proprietary bioreactors that maintain optimal conditions for nitrifying bacteria, which are then introduced into the growing substrate through irrigation systems. Cornell's research has demonstrated that these enhanced microbial communities can increase nitrification rates by up to 40% compared to conventional methods, while maintaining stability across varying pH and temperature conditions common in greenhouse environments. The technology incorporates a monitoring system that tracks key indicators of nitrification activity, allowing growers to make data-driven decisions about nitrogen management throughout the crop cycle.

Strengths: Biological approach reduces dependency on chemical inputs and provides more stable nitrification under variable conditions. Highly sustainable solution with minimal environmental impact. Weaknesses: Requires careful management of environmental conditions to maintain microbial activity. Initial establishment of beneficial communities may take longer than chemical approaches to reach optimal performance.

Key Nitrification Microbiology and Biochemical Mechanisms

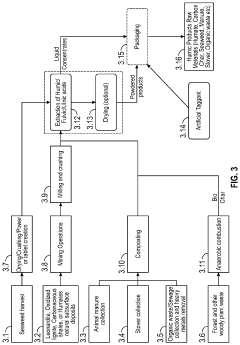

A method of manufacturing of NANO nitrogen for slow release, enhanced utilization by the plants and application thereof

PatentActiveIN201921044499A

Innovation

- A method of manufacturing nano-scale nitrogen, zinc, and copper using a process involving the compression of nitrogen and hydrogen in the presence of carbon dioxide, forming oligosaccharide nano-fibers that interact with amide and nitrate particles to create stable nano-clusters for enhanced plant uptake and controlled release.

Method to Formulate Humic Substances

PatentActiveUS20200385320A1

Innovation

- A blockchain-based multichain protocol is developed to track the lifecycle of humic substances from mining to application in agriculture, ensuring transparency and accountability in carbon credit generation, validation, and retirement, thereby incentivizing farmers to adopt more sustainable practices.

Environmental Impact Assessment of Nitrification Systems

The environmental impact of nitrification systems in greenhouse crop production extends across multiple ecological dimensions. When scaling these systems, greenhouse operators must consider both direct and indirect environmental consequences. Energy consumption represents a significant environmental concern, as conventional nitrification processes require substantial electrical inputs for aeration, pumping, and temperature control. Large-scale operations can consume between 3-7 kWh per kilogram of nitrogen processed, contributing to greenhouse gas emissions when powered by non-renewable energy sources.

Water usage patterns in nitrification systems present another critical environmental consideration. Traditional systems may require 2-4 liters of water per square meter of greenhouse space daily, placing pressure on local water resources. Advanced recirculating systems have demonstrated potential water savings of 60-80% compared to conventional methods, significantly reducing the environmental footprint of scaled operations.

Nutrient runoff from nitrification systems poses substantial risks to surrounding ecosystems. Excess nitrogen and phosphorus compounds can lead to eutrophication in nearby water bodies, disrupting aquatic ecosystems and potentially causing harmful algal blooms. Studies indicate that poorly managed greenhouse nitrification systems can contribute 15-30 mg/L of nitrates to effluent water, well above the ecological safety threshold of 10 mg/L recommended by environmental protection agencies.

Carbon footprint assessments reveal that greenhouse nitrification systems generate between 2.3-4.8 kg CO2 equivalent per kilogram of nitrogen processed, primarily from energy consumption and nitrous oxide emissions. These emissions vary significantly based on system design, with closed-loop systems demonstrating 30-40% lower emissions compared to open systems when properly optimized and maintained.

Land use efficiency represents a positive environmental aspect of scaled nitrification systems. By enabling higher crop densities and yields, these systems can reduce overall agricultural land requirements by 60-75% compared to conventional field agriculture for equivalent production volumes. This efficiency helps preserve natural habitats and biodiversity that might otherwise be converted to agricultural use.

Chemical inputs for nitrification management, including pH adjusters and supplemental minerals, must be carefully monitored as operations scale. Improper disposal of spent nitrification media and chemical residues can introduce contaminants into soil and water systems. Life cycle assessments indicate that environmentally responsible disposal protocols can reduce the ecological impact of these materials by up to 85% compared to standard waste management approaches.

Water usage patterns in nitrification systems present another critical environmental consideration. Traditional systems may require 2-4 liters of water per square meter of greenhouse space daily, placing pressure on local water resources. Advanced recirculating systems have demonstrated potential water savings of 60-80% compared to conventional methods, significantly reducing the environmental footprint of scaled operations.

Nutrient runoff from nitrification systems poses substantial risks to surrounding ecosystems. Excess nitrogen and phosphorus compounds can lead to eutrophication in nearby water bodies, disrupting aquatic ecosystems and potentially causing harmful algal blooms. Studies indicate that poorly managed greenhouse nitrification systems can contribute 15-30 mg/L of nitrates to effluent water, well above the ecological safety threshold of 10 mg/L recommended by environmental protection agencies.

Carbon footprint assessments reveal that greenhouse nitrification systems generate between 2.3-4.8 kg CO2 equivalent per kilogram of nitrogen processed, primarily from energy consumption and nitrous oxide emissions. These emissions vary significantly based on system design, with closed-loop systems demonstrating 30-40% lower emissions compared to open systems when properly optimized and maintained.

Land use efficiency represents a positive environmental aspect of scaled nitrification systems. By enabling higher crop densities and yields, these systems can reduce overall agricultural land requirements by 60-75% compared to conventional field agriculture for equivalent production volumes. This efficiency helps preserve natural habitats and biodiversity that might otherwise be converted to agricultural use.

Chemical inputs for nitrification management, including pH adjusters and supplemental minerals, must be carefully monitored as operations scale. Improper disposal of spent nitrification media and chemical residues can introduce contaminants into soil and water systems. Life cycle assessments indicate that environmentally responsible disposal protocols can reduce the ecological impact of these materials by up to 85% compared to standard waste management approaches.

Resource Efficiency Metrics for Scaled Nitrification

Measuring the efficiency of nitrification processes in scaled greenhouse operations requires comprehensive metrics that capture both resource inputs and productive outputs. The development of standardized efficiency metrics enables growers to optimize their nitrification systems while minimizing environmental impact and operational costs.

Energy consumption represents a primary efficiency metric, typically measured in kilowatt-hours per kilogram of nitrogen processed. Advanced nitrification systems in large-scale greenhouses demonstrate energy efficiency ratios between 1.2-1.8 kWh/kg-N, with variations based on system design and operational parameters. Leading operations have achieved improvements of 15-20% in energy efficiency through implementation of variable frequency drives and optimized aeration cycles.

Water utilization efficiency, expressed as liters of water consumed per kilogram of nitrogen processed, provides critical insight into system performance. Current benchmark data indicates efficient systems operate at 40-60 L/kg-N, with closed-loop designs achieving the lower end of this range. Water recirculation rates of 85-95% have become standard in advanced operations, significantly reducing freshwater requirements.

Chemical input efficiency metrics track the consumption of supplementary chemicals required for maintaining optimal nitrification conditions. This includes pH adjusters, alkalinity supplements, and trace elements measured against nitrogen processing capacity. Industry leaders report chemical usage reductions of 30-40% through implementation of precision dosing systems and real-time monitoring technologies.

Labor efficiency metrics quantify personnel hours required for system maintenance and operation per unit of nitrogen processed. Automated systems demonstrate superior labor efficiency, with requirements as low as 0.05-0.1 hours per kilogram of nitrogen processed, compared to 0.3-0.5 hours for manual systems.

Capital efficiency evaluates the investment required to establish nitrification capacity, measured as installation cost per unit of daily nitrogen processing capacity. Current industry benchmarks range from $5,000-8,000 per kilogram of daily nitrogen processing capacity, with economies of scale evident in larger installations.

Space utilization efficiency, particularly relevant in greenhouse environments, measures nitrogen processing capacity per square meter of facility space. Vertical bioreactor designs have achieved processing densities of 0.8-1.2 kg-N/day/m², representing a 3-4 fold improvement over traditional horizontal configurations.

These metrics collectively provide a framework for evaluating and optimizing nitrification systems across different scales of greenhouse production, enabling evidence-based decision making and continuous improvement in resource utilization.

Energy consumption represents a primary efficiency metric, typically measured in kilowatt-hours per kilogram of nitrogen processed. Advanced nitrification systems in large-scale greenhouses demonstrate energy efficiency ratios between 1.2-1.8 kWh/kg-N, with variations based on system design and operational parameters. Leading operations have achieved improvements of 15-20% in energy efficiency through implementation of variable frequency drives and optimized aeration cycles.

Water utilization efficiency, expressed as liters of water consumed per kilogram of nitrogen processed, provides critical insight into system performance. Current benchmark data indicates efficient systems operate at 40-60 L/kg-N, with closed-loop designs achieving the lower end of this range. Water recirculation rates of 85-95% have become standard in advanced operations, significantly reducing freshwater requirements.

Chemical input efficiency metrics track the consumption of supplementary chemicals required for maintaining optimal nitrification conditions. This includes pH adjusters, alkalinity supplements, and trace elements measured against nitrogen processing capacity. Industry leaders report chemical usage reductions of 30-40% through implementation of precision dosing systems and real-time monitoring technologies.

Labor efficiency metrics quantify personnel hours required for system maintenance and operation per unit of nitrogen processed. Automated systems demonstrate superior labor efficiency, with requirements as low as 0.05-0.1 hours per kilogram of nitrogen processed, compared to 0.3-0.5 hours for manual systems.

Capital efficiency evaluates the investment required to establish nitrification capacity, measured as installation cost per unit of daily nitrogen processing capacity. Current industry benchmarks range from $5,000-8,000 per kilogram of daily nitrogen processing capacity, with economies of scale evident in larger installations.

Space utilization efficiency, particularly relevant in greenhouse environments, measures nitrogen processing capacity per square meter of facility space. Vertical bioreactor designs have achieved processing densities of 0.8-1.2 kg-N/day/m², representing a 3-4 fold improvement over traditional horizontal configurations.

These metrics collectively provide a framework for evaluating and optimizing nitrification systems across different scales of greenhouse production, enabling evidence-based decision making and continuous improvement in resource utilization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!