Scaling Nitrification Performance In Industrial Wastewater Plants

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitrification Technology Background and Objectives

Nitrification, a critical biological process in wastewater treatment, has evolved significantly over the past century. Initially recognized in the early 1900s as a natural phenomenon, engineered nitrification systems began emerging in the 1950s with the development of activated sludge processes. The technology has since progressed through several generations, from basic suspended growth systems to advanced integrated fixed-film activated sludge (IFAS) and moving bed biofilm reactor (MBBR) configurations.

The fundamental biochemical pathway involves the oxidation of ammonia (NH₃) to nitrite (NO₂⁻) by ammonia-oxidizing bacteria (AOB) such as Nitrosomonas, followed by the conversion of nitrite to nitrate (NO₃⁻) by nitrite-oxidizing bacteria (NOB) like Nitrobacter. This two-step process is essential for removing nitrogen compounds that would otherwise contribute to eutrophication and oxygen depletion in receiving water bodies.

Recent technological advancements have focused on enhancing nitrification efficiency while reducing energy consumption and spatial footprint. Innovations include granular sludge systems, membrane-aerated biofilm reactors (MABRs), and anammox-based processes that bypass traditional nitrification pathways. These developments reflect the industry's response to increasingly stringent discharge regulations and sustainability imperatives.

The primary objective of scaling nitrification performance in industrial wastewater treatment plants is to achieve consistent and reliable nitrogen removal across varying operational conditions and influent characteristics. This includes maintaining stable nitrification rates during temperature fluctuations, pH variations, and toxic shock loads that are common in industrial settings.

Secondary objectives encompass reducing energy requirements, particularly for aeration which typically accounts for 45-75% of wastewater treatment plant energy consumption. Minimizing the production of excess biomass and greenhouse gas emissions (notably N₂O) represents another crucial goal, aligning with broader environmental sustainability targets.

Long-term technological objectives include developing robust control systems capable of real-time process optimization, implementing energy-neutral or energy-positive treatment configurations, and creating modular solutions that can be readily scaled to accommodate industrial growth or changing regulatory requirements.

The trajectory of nitrification technology is increasingly influenced by digitalization trends, with advanced sensors, predictive analytics, and machine learning algorithms enabling more precise process control. These digital tools are expected to play a pivotal role in overcoming the inherent challenges of scaling nitrification processes, particularly in industrial applications where wastewater composition can be highly variable and complex.

The fundamental biochemical pathway involves the oxidation of ammonia (NH₃) to nitrite (NO₂⁻) by ammonia-oxidizing bacteria (AOB) such as Nitrosomonas, followed by the conversion of nitrite to nitrate (NO₃⁻) by nitrite-oxidizing bacteria (NOB) like Nitrobacter. This two-step process is essential for removing nitrogen compounds that would otherwise contribute to eutrophication and oxygen depletion in receiving water bodies.

Recent technological advancements have focused on enhancing nitrification efficiency while reducing energy consumption and spatial footprint. Innovations include granular sludge systems, membrane-aerated biofilm reactors (MABRs), and anammox-based processes that bypass traditional nitrification pathways. These developments reflect the industry's response to increasingly stringent discharge regulations and sustainability imperatives.

The primary objective of scaling nitrification performance in industrial wastewater treatment plants is to achieve consistent and reliable nitrogen removal across varying operational conditions and influent characteristics. This includes maintaining stable nitrification rates during temperature fluctuations, pH variations, and toxic shock loads that are common in industrial settings.

Secondary objectives encompass reducing energy requirements, particularly for aeration which typically accounts for 45-75% of wastewater treatment plant energy consumption. Minimizing the production of excess biomass and greenhouse gas emissions (notably N₂O) represents another crucial goal, aligning with broader environmental sustainability targets.

Long-term technological objectives include developing robust control systems capable of real-time process optimization, implementing energy-neutral or energy-positive treatment configurations, and creating modular solutions that can be readily scaled to accommodate industrial growth or changing regulatory requirements.

The trajectory of nitrification technology is increasingly influenced by digitalization trends, with advanced sensors, predictive analytics, and machine learning algorithms enabling more precise process control. These digital tools are expected to play a pivotal role in overcoming the inherent challenges of scaling nitrification processes, particularly in industrial applications where wastewater composition can be highly variable and complex.

Industrial Wastewater Treatment Market Analysis

The industrial wastewater treatment market is experiencing significant growth, driven by increasingly stringent environmental regulations and growing awareness of water scarcity issues. The global market was valued at approximately $26.7 billion in 2022 and is projected to reach $41.8 billion by 2030, representing a compound annual growth rate (CAGR) of 5.8% during the forecast period.

The nitrification segment specifically holds a substantial market share within industrial wastewater treatment, as industries such as food processing, chemical manufacturing, and municipal facilities face mounting pressure to reduce nitrogen compounds in their effluent. This segment is expected to grow at a CAGR of 6.2% through 2030, outpacing the overall market growth.

Geographically, Asia-Pacific dominates the industrial wastewater treatment market, accounting for nearly 40% of global revenue. This dominance is attributed to rapid industrialization in countries like China and India, coupled with increasingly strict discharge regulations. North America and Europe follow with mature markets characterized by advanced technology adoption and replacement demand.

By industry vertical, chemical manufacturing represents the largest end-user segment (28%), followed by food and beverage (22%), pharmaceuticals (15%), and pulp and paper (12%). The food and beverage sector is showing the fastest growth rate at 7.1% annually, driven by increasing production volumes and stricter quality requirements for water reuse.

Technology-wise, biological treatment methods, particularly those focused on nitrification processes, are gaining significant market share due to their effectiveness and relatively lower operational costs compared to chemical treatments. Advanced biological systems that enhance nitrification performance are projected to grow at 8.3% annually through 2030.

Key market drivers include regulatory pressures, particularly in developed economies where nitrogen discharge limits are becoming increasingly stringent. Water scarcity is another critical factor, with approximately 36% of industrial facilities now implementing water recycling systems that require effective nitrification processes.

Cost considerations remain significant, with the average installation cost for advanced nitrification systems ranging from $1.5-4 million depending on capacity and technology. However, the return on investment period has decreased from 7-8 years to 4-5 years due to improved technology efficiency and increasing costs of regulatory non-compliance.

Market challenges include high initial capital requirements, technical complexity in scaling nitrification processes, and variability in wastewater characteristics across different industries. These factors create significant barriers to entry for smaller players while providing competitive advantages to established technology providers with proven scaling capabilities.

The nitrification segment specifically holds a substantial market share within industrial wastewater treatment, as industries such as food processing, chemical manufacturing, and municipal facilities face mounting pressure to reduce nitrogen compounds in their effluent. This segment is expected to grow at a CAGR of 6.2% through 2030, outpacing the overall market growth.

Geographically, Asia-Pacific dominates the industrial wastewater treatment market, accounting for nearly 40% of global revenue. This dominance is attributed to rapid industrialization in countries like China and India, coupled with increasingly strict discharge regulations. North America and Europe follow with mature markets characterized by advanced technology adoption and replacement demand.

By industry vertical, chemical manufacturing represents the largest end-user segment (28%), followed by food and beverage (22%), pharmaceuticals (15%), and pulp and paper (12%). The food and beverage sector is showing the fastest growth rate at 7.1% annually, driven by increasing production volumes and stricter quality requirements for water reuse.

Technology-wise, biological treatment methods, particularly those focused on nitrification processes, are gaining significant market share due to their effectiveness and relatively lower operational costs compared to chemical treatments. Advanced biological systems that enhance nitrification performance are projected to grow at 8.3% annually through 2030.

Key market drivers include regulatory pressures, particularly in developed economies where nitrogen discharge limits are becoming increasingly stringent. Water scarcity is another critical factor, with approximately 36% of industrial facilities now implementing water recycling systems that require effective nitrification processes.

Cost considerations remain significant, with the average installation cost for advanced nitrification systems ranging from $1.5-4 million depending on capacity and technology. However, the return on investment period has decreased from 7-8 years to 4-5 years due to improved technology efficiency and increasing costs of regulatory non-compliance.

Market challenges include high initial capital requirements, technical complexity in scaling nitrification processes, and variability in wastewater characteristics across different industries. These factors create significant barriers to entry for smaller players while providing competitive advantages to established technology providers with proven scaling capabilities.

Current Nitrification Challenges in Industrial Applications

Industrial wastewater treatment facilities face significant challenges in maintaining efficient nitrification processes, particularly when dealing with variable influent compositions characteristic of industrial operations. The nitrification process, which converts ammonia to nitrite and subsequently to nitrate through biological oxidation, is highly sensitive to environmental conditions and inhibitory compounds commonly found in industrial wastewaters.

One primary challenge is the presence of toxic compounds and heavy metals that inhibit nitrifying bacteria activity. Industries such as chemical manufacturing, pharmaceuticals, and metal processing release effluents containing substances that can severely impair nitrifier performance even at low concentrations. These inhibitory effects often manifest as reduced ammonia removal rates, extended startup periods, and process instability.

Temperature fluctuations represent another significant obstacle, as nitrification rates decrease substantially at temperatures below 15°C and above 35°C. Industrial facilities with seasonal production patterns or batch processing operations frequently experience temperature variations that can destabilize nitrifying bacterial communities, requiring constant process adjustments to maintain treatment efficiency.

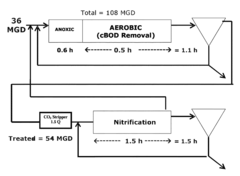

High organic loading rates characteristic of many industrial wastewaters create competition between heterotrophic and autotrophic nitrifying bacteria for oxygen and space. This competition typically favors faster-growing heterotrophs, resulting in reduced nitrification capacity unless careful process control is implemented. The oxygen demand for nitrification (4.57 g O₂ per g NH₄⁺-N oxidized) further complicates operations when combined with high BOD loads.

pH control presents another operational challenge, as nitrification optimally occurs within a narrow pH range of 7.5-8.5. Industrial wastewaters often exhibit extreme pH values or significant fluctuations that necessitate chemical addition systems and sophisticated control strategies to maintain suitable conditions for nitrifying organisms.

The slow growth rate of nitrifying bacteria (doubling time of 1-3 days compared to hours for heterotrophs) makes recovery from system upsets particularly challenging in industrial applications. Process disruptions due to toxic shock loads or operational failures can result in extended periods of non-compliance with discharge regulations while nitrifier populations re-establish.

Scaling nitrification performance also faces challenges related to biofilm management in attached growth systems. Excessive biofilm accumulation can lead to mass transfer limitations, while insufficient biofilm development results in inadequate treatment capacity. The balance is particularly difficult to maintain when treating industrial wastewaters with variable characteristics.

Finally, the energy intensity of nitrification processes presents economic challenges for industrial facilities seeking to scale treatment capacity. Aeration requirements for nitrification can account for 45-75% of wastewater treatment plant energy consumption, creating significant operational cost barriers to implementing robust nitrification systems at industrial scale.

One primary challenge is the presence of toxic compounds and heavy metals that inhibit nitrifying bacteria activity. Industries such as chemical manufacturing, pharmaceuticals, and metal processing release effluents containing substances that can severely impair nitrifier performance even at low concentrations. These inhibitory effects often manifest as reduced ammonia removal rates, extended startup periods, and process instability.

Temperature fluctuations represent another significant obstacle, as nitrification rates decrease substantially at temperatures below 15°C and above 35°C. Industrial facilities with seasonal production patterns or batch processing operations frequently experience temperature variations that can destabilize nitrifying bacterial communities, requiring constant process adjustments to maintain treatment efficiency.

High organic loading rates characteristic of many industrial wastewaters create competition between heterotrophic and autotrophic nitrifying bacteria for oxygen and space. This competition typically favors faster-growing heterotrophs, resulting in reduced nitrification capacity unless careful process control is implemented. The oxygen demand for nitrification (4.57 g O₂ per g NH₄⁺-N oxidized) further complicates operations when combined with high BOD loads.

pH control presents another operational challenge, as nitrification optimally occurs within a narrow pH range of 7.5-8.5. Industrial wastewaters often exhibit extreme pH values or significant fluctuations that necessitate chemical addition systems and sophisticated control strategies to maintain suitable conditions for nitrifying organisms.

The slow growth rate of nitrifying bacteria (doubling time of 1-3 days compared to hours for heterotrophs) makes recovery from system upsets particularly challenging in industrial applications. Process disruptions due to toxic shock loads or operational failures can result in extended periods of non-compliance with discharge regulations while nitrifier populations re-establish.

Scaling nitrification performance also faces challenges related to biofilm management in attached growth systems. Excessive biofilm accumulation can lead to mass transfer limitations, while insufficient biofilm development results in inadequate treatment capacity. The balance is particularly difficult to maintain when treating industrial wastewaters with variable characteristics.

Finally, the energy intensity of nitrification processes presents economic challenges for industrial facilities seeking to scale treatment capacity. Aeration requirements for nitrification can account for 45-75% of wastewater treatment plant energy consumption, creating significant operational cost barriers to implementing robust nitrification systems at industrial scale.

Current Scaling Methodologies for Nitrification Systems

01 Optimization of nitrification process parameters

Various parameters can be optimized to improve nitrification process performance and scaling. These include temperature, pH, dissolved oxygen levels, and hydraulic retention time. By carefully controlling these parameters, the efficiency of the nitrification process can be significantly enhanced, leading to better conversion of ammonia to nitrate and improved overall system performance.- Optimization of nitrification process parameters: Various parameters can be optimized to improve nitrification process performance and scaling. These include temperature, pH, dissolved oxygen levels, and hydraulic retention time. By carefully controlling these parameters, the efficiency of the nitrification process can be significantly enhanced, leading to better ammonia removal rates and overall system performance. Advanced monitoring systems can be implemented to maintain optimal conditions for nitrifying bacteria.

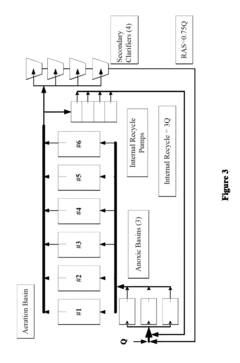

- Biofilm carrier technology for nitrification scaling: Biofilm carrier technology provides an effective solution for scaling up nitrification processes. By utilizing specialized carriers that support the growth of nitrifying bacteria, the active surface area for biological treatment can be significantly increased. This approach allows for higher treatment capacity within the same reactor volume, making it particularly valuable for upgrading existing facilities or designing new compact treatment systems. The carriers protect the slow-growing nitrifying bacteria from washout and environmental stresses.

- Performance monitoring and predictive analytics: Advanced monitoring systems and predictive analytics can be employed to optimize nitrification process scaling. These technologies enable real-time tracking of key performance indicators and early detection of potential issues. By analyzing operational data, predictive models can forecast system performance under various conditions, allowing operators to make proactive adjustments. This approach enhances process stability and facilitates efficient scaling of nitrification systems.

- Microbial community management for enhanced nitrification: Effective management of the microbial community is crucial for successful nitrification process scaling. This involves selecting and enriching specific nitrifying bacteria strains that demonstrate high efficiency and resilience. Techniques such as bioaugmentation, selective pressure, and optimized nutrient ratios can be employed to maintain a robust nitrifying population. Understanding the microbial ecology and interactions within the system enables better control over the nitrification process during scaling operations.

- Modular system design for scalable nitrification: Modular system designs offer an effective approach to scaling nitrification processes. By implementing standardized, interconnected treatment modules, capacity can be incrementally increased as needed. This approach provides flexibility in system configuration and facilitates phased implementation of nitrification capacity. Modular designs also enable more efficient resource allocation and simplified maintenance procedures, making them particularly suitable for applications where treatment demands may change over time.

02 Advanced monitoring and control systems

Implementation of advanced monitoring and control systems can help in scaling nitrification processes effectively. These systems use sensors and real-time data analysis to monitor key parameters and automatically adjust process conditions. This approach enables better process stability, reduces operational costs, and facilitates scaling up from laboratory to industrial applications.Expand Specific Solutions03 Biofilm and carrier media technologies

Utilizing biofilm and carrier media technologies can enhance nitrification process performance during scaling. These technologies provide surfaces for nitrifying bacteria to attach and grow, increasing the biomass concentration without increasing reactor volume. This approach allows for higher treatment capacity, improved resistance to shock loads, and more efficient nitrification in compact systems.Expand Specific Solutions04 Computational modeling for process scaling

Computational modeling and simulation techniques can be applied to predict and optimize nitrification process performance during scaling. These models can simulate various operating conditions and predict system behavior, allowing for efficient design and operation of scaled-up systems. By using these tools, potential issues can be identified and addressed before implementation, reducing the risk of scaling failures.Expand Specific Solutions05 Microbial community management

Effective management of the microbial community is crucial for successful nitrification process scaling. This includes selecting and enriching specific nitrifying bacteria, maintaining appropriate microbial diversity, and preventing the growth of competing or inhibitory organisms. Strategies such as bioaugmentation, selective pressure, and careful inoculation can be employed to establish and maintain an efficient nitrifying community across different scales.Expand Specific Solutions

Leading Industrial Wastewater Treatment Solution Providers

The industrial wastewater nitrification market is currently in a growth phase, with increasing regulatory pressures driving adoption of advanced treatment technologies. The global market size for industrial wastewater treatment is expanding rapidly, expected to reach significant valuation as industries prioritize environmental compliance. Technology maturity varies across solutions, with established players like ChemTreat, Yara International, and Sumitomo Heavy Industries offering proven conventional nitrification systems, while innovative approaches are emerging from research institutions including University of South Florida, Jiangsu University, and North Carolina State University. Companies like Bayer Technology Services and Voltea are developing next-generation solutions focused on energy efficiency and process intensification. China Petroleum & Chemical Corporation and Hitachi are leveraging their industrial scale to implement large-scale nitrification systems, while specialized firms such as Osmoflo and Wehrle-Werk focus on niche applications requiring customized solutions.

ChemTreat, Inc.

Technical Solution: ChemTreat has developed advanced biological nutrient removal (BNR) systems specifically designed for industrial wastewater nitrification scaling. Their approach combines specialized nitrifying bacteria consortia with proprietary chemical additives that enhance biofilm development and protect nitrifiers from inhibitory compounds commonly found in industrial effluents. The technology employs a multi-stage process with segregated aerobic zones maintaining optimal dissolved oxygen gradients (4-6 mg/L) for different nitrifier populations. ChemTreat's system incorporates real-time monitoring with automated chemical dosing to maintain optimal alkalinity (7.5-8.5 pH range) and nutrient ratios, critical for sustained nitrification performance at industrial scales. Their moving bed biofilm reactor (MBBR) configuration allows for higher nitrifier retention and resilience against toxic shock loads, enabling treatment of high-strength industrial wastewaters with ammonia concentrations exceeding 500 mg/L while maintaining removal efficiencies above 95% even during variable loading conditions.

Strengths: Highly adaptable to various industrial wastewater compositions with robust performance under variable loading conditions. The proprietary chemical additives provide protection against industrial inhibitors that typically challenge nitrification processes. Weaknesses: Higher operational costs compared to conventional systems due to chemical additives and intensive monitoring requirements. System requires specialized expertise for optimization and troubleshooting.

Yara International ASA

Technical Solution: Yara has pioneered an integrated nitrification enhancement system for industrial applications called "N-Optimizer" that combines their expertise in nitrogen chemistry with advanced process control. Their technology utilizes specialized suspended carrier media with optimized surface area-to-volume ratios that support dense nitrifying biofilms while minimizing clogging issues common in scaled industrial operations. The system incorporates Yara's proprietary nutrient formulations that provide precise micronutrient supplementation (including copper, molybdenum and iron) critical for ammonia monooxygenase enzyme function in nitrifying bacteria. Their approach includes a patented alkalinity management system that automatically adjusts inorganic carbon availability based on real-time nitrification rates, maintaining optimal conditions even during peak loading events. Yara's technology employs advanced aeration systems with fine-bubble diffusers and automated DO control algorithms that maintain oxygen transfer efficiency while reducing energy consumption by up to 30% compared to conventional systems. The N-Optimizer includes specialized bioaugmentation protocols using acclimated nitrifier populations that significantly reduce startup times for new installations or recovery after system upsets.

Strengths: Comprehensive solution addressing multiple aspects of nitrification including microbial ecology, nutrient requirements, and process control. Excellent energy efficiency through optimized aeration control. Weaknesses: Relatively high capital investment required for full implementation. System performance heavily dependent on proper maintenance of the specialized carrier media, which can be challenging in some industrial environments with high solids loading.

Key Patents and Innovations in Nitrification Technology

Biological nitrification/denitrification water treatment plant and method

PatentInactiveEP0583349A1

Innovation

- A biological nitrification/denitrification system using fluidized bed reactors with porous particles of specific density, porosity, and size range for optimal bacterial attachment and growth conditions, including baked clay as the support material, to regulate pH, oxygen levels, and fluidization for enhanced nitrogen removal.

Reduction and control of pH and soluble CO<sub>2 </sub>for optimal nitrification for domestic, industrial and municipal wastewater

PatentInactiveUS8940159B1

Innovation

- Optimizing the soluble CO2 concentration in aeration basins through CO2 stripping technology to improve the specific growth rate of nitrifying bacteria, thereby reducing capital and energy costs for municipalities.

Environmental Regulations Impact on Nitrification Requirements

Environmental regulations governing industrial wastewater treatment have evolved significantly over the past decades, creating increasingly stringent requirements for nitrification processes. The Clean Water Act amendments and subsequent regulatory frameworks have progressively lowered permissible ammonia discharge limits, compelling industrial facilities to enhance their nitrification capabilities. Current regulations in many jurisdictions mandate ammonia-nitrogen concentrations below 5 mg/L, with some environmentally sensitive areas requiring levels as low as 1-2 mg/L.

These tightening regulations have directly influenced the design parameters and operational strategies of industrial wastewater treatment plants. Facilities must now implement more sophisticated nitrification systems capable of consistent performance under varying influent conditions. The regulatory landscape has shifted from simple end-of-pipe compliance to comprehensive watershed management approaches, necessitating more reliable nitrification processes that can withstand seasonal variations and industrial production fluctuations.

Regulatory compliance costs have become a significant economic factor for industries with ammonia-rich wastewater streams. Non-compliance penalties, which can reach tens of thousands of dollars per violation day in some jurisdictions, have created strong financial incentives for optimizing nitrification performance. This economic pressure has accelerated innovation in treatment technologies and process control systems specifically designed to enhance nitrification reliability and efficiency.

The geographical variation in regulatory requirements presents additional challenges for multinational corporations. European regulations under the Water Framework Directive generally impose stricter nitrification requirements than those in North America, while rapidly industrializing nations are implementing increasingly rigorous standards. This regulatory heterogeneity necessitates adaptable nitrification solutions that can be calibrated to meet diverse compliance thresholds across global operations.

Future regulatory trends indicate continued tightening of ammonia discharge limits, with emerging concerns about nitrification by-products and greenhouse gas emissions from treatment processes. Regulatory frameworks are evolving to address not only ammonia removal but also nitrous oxide emissions and total nitrogen management. This holistic regulatory approach is driving research into advanced nitrification technologies that can simultaneously address multiple environmental objectives while maintaining scalability for industrial applications.

The regulatory push toward digitalization and continuous monitoring is transforming compliance verification for nitrification processes. Real-time monitoring requirements are becoming more common, compelling industries to implement sophisticated instrumentation and control systems that can demonstrate consistent nitrification performance and rapid response to potential upsets or exceedances.

These tightening regulations have directly influenced the design parameters and operational strategies of industrial wastewater treatment plants. Facilities must now implement more sophisticated nitrification systems capable of consistent performance under varying influent conditions. The regulatory landscape has shifted from simple end-of-pipe compliance to comprehensive watershed management approaches, necessitating more reliable nitrification processes that can withstand seasonal variations and industrial production fluctuations.

Regulatory compliance costs have become a significant economic factor for industries with ammonia-rich wastewater streams. Non-compliance penalties, which can reach tens of thousands of dollars per violation day in some jurisdictions, have created strong financial incentives for optimizing nitrification performance. This economic pressure has accelerated innovation in treatment technologies and process control systems specifically designed to enhance nitrification reliability and efficiency.

The geographical variation in regulatory requirements presents additional challenges for multinational corporations. European regulations under the Water Framework Directive generally impose stricter nitrification requirements than those in North America, while rapidly industrializing nations are implementing increasingly rigorous standards. This regulatory heterogeneity necessitates adaptable nitrification solutions that can be calibrated to meet diverse compliance thresholds across global operations.

Future regulatory trends indicate continued tightening of ammonia discharge limits, with emerging concerns about nitrification by-products and greenhouse gas emissions from treatment processes. Regulatory frameworks are evolving to address not only ammonia removal but also nitrous oxide emissions and total nitrogen management. This holistic regulatory approach is driving research into advanced nitrification technologies that can simultaneously address multiple environmental objectives while maintaining scalability for industrial applications.

The regulatory push toward digitalization and continuous monitoring is transforming compliance verification for nitrification processes. Real-time monitoring requirements are becoming more common, compelling industries to implement sophisticated instrumentation and control systems that can demonstrate consistent nitrification performance and rapid response to potential upsets or exceedances.

Energy Efficiency Considerations in Scaled Nitrification Systems

Energy efficiency represents a critical factor in the scaling of nitrification systems for industrial wastewater treatment, directly impacting both operational costs and environmental sustainability. As nitrification processes are scaled up to handle larger volumes of industrial effluent, energy consumption typically increases disproportionately, creating significant economic and ecological challenges for facility operators.

The aeration systems required for nitrification typically account for 45-75% of a wastewater treatment plant's total energy consumption. When scaling up operations, conventional approaches often simply multiply existing aeration capacity, resulting in diminishing energy efficiency returns. Recent technological innovations have demonstrated that optimized diffuser placement and advanced bubble size control can reduce energy requirements by 15-30% in large-scale applications compared to traditional scaling methods.

Variable frequency drives (VFDs) for blowers have emerged as a transformative technology for scaled nitrification systems, allowing precise matching of oxygen supply to biological demand. Implementation data from industrial facilities indicates energy savings of 25-40% compared to fixed-speed alternatives, with particularly impressive results in facilities processing variable influent loads. The initial capital investment for VFD technology typically achieves return on investment within 12-24 months through operational savings.

Advanced process control systems utilizing real-time monitoring of dissolved oxygen, ammonia, and nitrate levels enable dynamic adjustment of aeration intensity. These systems have demonstrated energy efficiency improvements of 20-35% in large-scale industrial applications while maintaining or improving effluent quality standards. The integration of machine learning algorithms for predictive control represents the cutting edge of this approach, with pilot studies showing potential for additional 10-15% energy reductions.

Heat recovery systems present another significant opportunity for energy optimization in scaled nitrification operations. The biological processes involved in nitrification generate considerable thermal energy, which can be captured and repurposed for facility heating or other processes. Innovative heat exchanger designs specifically developed for wastewater applications have shown efficiency rates of 60-75% in large-scale installations, substantially reducing external energy requirements.

The physical configuration of scaled nitrification systems also significantly impacts energy efficiency. Plug-flow designs with tapered aeration have demonstrated 15-25% lower energy requirements compared to completely mixed systems of equivalent capacity. Additionally, innovative reactor designs incorporating strategic baffling and improved hydraulic flow patterns can reduce short-circuiting and dead zones, enhancing treatment efficiency while decreasing energy inputs by 10-20%.

The aeration systems required for nitrification typically account for 45-75% of a wastewater treatment plant's total energy consumption. When scaling up operations, conventional approaches often simply multiply existing aeration capacity, resulting in diminishing energy efficiency returns. Recent technological innovations have demonstrated that optimized diffuser placement and advanced bubble size control can reduce energy requirements by 15-30% in large-scale applications compared to traditional scaling methods.

Variable frequency drives (VFDs) for blowers have emerged as a transformative technology for scaled nitrification systems, allowing precise matching of oxygen supply to biological demand. Implementation data from industrial facilities indicates energy savings of 25-40% compared to fixed-speed alternatives, with particularly impressive results in facilities processing variable influent loads. The initial capital investment for VFD technology typically achieves return on investment within 12-24 months through operational savings.

Advanced process control systems utilizing real-time monitoring of dissolved oxygen, ammonia, and nitrate levels enable dynamic adjustment of aeration intensity. These systems have demonstrated energy efficiency improvements of 20-35% in large-scale industrial applications while maintaining or improving effluent quality standards. The integration of machine learning algorithms for predictive control represents the cutting edge of this approach, with pilot studies showing potential for additional 10-15% energy reductions.

Heat recovery systems present another significant opportunity for energy optimization in scaled nitrification operations. The biological processes involved in nitrification generate considerable thermal energy, which can be captured and repurposed for facility heating or other processes. Innovative heat exchanger designs specifically developed for wastewater applications have shown efficiency rates of 60-75% in large-scale installations, substantially reducing external energy requirements.

The physical configuration of scaled nitrification systems also significantly impacts energy efficiency. Plug-flow designs with tapered aeration have demonstrated 15-25% lower energy requirements compared to completely mixed systems of equivalent capacity. Additionally, innovative reactor designs incorporating strategic baffling and improved hydraulic flow patterns can reduce short-circuiting and dead zones, enhancing treatment efficiency while decreasing energy inputs by 10-20%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!