On-Board Charger Protection: OVP/OTP/Short-Circuit And Diagnostics

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OBC Protection Technology Background and Objectives

On-board chargers (OBCs) have evolved significantly since the early days of electric vehicles (EVs), transitioning from basic charging units to sophisticated power electronics systems. The protection mechanisms within OBCs have become increasingly critical as EV adoption accelerates globally. Historically, early OBC designs focused primarily on basic functionality with limited protection features, often relying on external systems for comprehensive safety measures.

The technological evolution of OBC protection systems has been driven by several factors, including higher power densities, faster charging requirements, and stringent automotive safety standards. From 2010 to 2015, OBC protection primarily centered on basic overvoltage protection (OVP) and rudimentary thermal management. The period from 2016 to 2020 saw significant advancements with integrated protection circuits and more sophisticated diagnostics capabilities.

Current industry trends indicate a shift toward comprehensive protection systems that address multiple failure modes simultaneously while maintaining optimal charging efficiency. The integration of wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), has introduced new protection challenges due to their unique electrical characteristics and higher operating temperatures.

The primary objective of modern OBC protection technology is to ensure safe and reliable operation under all charging conditions while preventing damage to the vehicle's battery system and electrical infrastructure. This includes rapid detection and response to overvoltage conditions (OVP), overtemperature events (OTP), and short-circuit scenarios, all while maintaining compliance with international safety standards such as ISO 26262 and IEC 61851.

Secondary objectives include minimizing system complexity and cost, reducing false triggers that interrupt the charging process, and implementing advanced diagnostics that can predict potential failures before they occur. These diagnostics capabilities are increasingly important as they enable predictive maintenance and enhance overall system reliability.

Looking forward, the industry aims to develop protection systems that can adapt to various charging environments and power quality conditions automatically. This adaptability will become crucial as EVs increasingly interact with diverse charging infrastructure and renewable energy sources with variable output characteristics.

The technological roadmap for OBC protection systems also includes enhanced communication protocols between protection circuits and vehicle management systems, allowing for more nuanced responses to detected anomalies and improved data collection for long-term reliability analysis. These advancements will be essential in supporting the next generation of ultra-fast charging technologies while maintaining the highest safety standards.

The technological evolution of OBC protection systems has been driven by several factors, including higher power densities, faster charging requirements, and stringent automotive safety standards. From 2010 to 2015, OBC protection primarily centered on basic overvoltage protection (OVP) and rudimentary thermal management. The period from 2016 to 2020 saw significant advancements with integrated protection circuits and more sophisticated diagnostics capabilities.

Current industry trends indicate a shift toward comprehensive protection systems that address multiple failure modes simultaneously while maintaining optimal charging efficiency. The integration of wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), has introduced new protection challenges due to their unique electrical characteristics and higher operating temperatures.

The primary objective of modern OBC protection technology is to ensure safe and reliable operation under all charging conditions while preventing damage to the vehicle's battery system and electrical infrastructure. This includes rapid detection and response to overvoltage conditions (OVP), overtemperature events (OTP), and short-circuit scenarios, all while maintaining compliance with international safety standards such as ISO 26262 and IEC 61851.

Secondary objectives include minimizing system complexity and cost, reducing false triggers that interrupt the charging process, and implementing advanced diagnostics that can predict potential failures before they occur. These diagnostics capabilities are increasingly important as they enable predictive maintenance and enhance overall system reliability.

Looking forward, the industry aims to develop protection systems that can adapt to various charging environments and power quality conditions automatically. This adaptability will become crucial as EVs increasingly interact with diverse charging infrastructure and renewable energy sources with variable output characteristics.

The technological roadmap for OBC protection systems also includes enhanced communication protocols between protection circuits and vehicle management systems, allowing for more nuanced responses to detected anomalies and improved data collection for long-term reliability analysis. These advancements will be essential in supporting the next generation of ultra-fast charging technologies while maintaining the highest safety standards.

Market Demand Analysis for Robust OBC Protection Systems

The electric vehicle (EV) market is experiencing unprecedented growth, with global sales surpassing 10 million units in 2022 and projected to reach 40 million by 2030. This rapid expansion has intensified demand for reliable On-Board Charger (OBC) protection systems that ensure safety, longevity, and performance of EV charging infrastructure.

Market research indicates that OBC protection systems addressing overvoltage protection (OVP), overtemperature protection (OTP), and short-circuit diagnostics are becoming critical differentiators for automotive manufacturers. The primary market drivers include increasingly stringent safety regulations, consumer demand for faster charging capabilities, and the need for extended battery life in EVs.

Safety regulations such as UN ECE R100, ISO 17409, and regional standards in North America, Europe, and Asia are mandating comprehensive protection mechanisms in charging systems. These regulations have created a compliance-driven demand segment estimated at $2.7 billion globally, with annual growth rates exceeding 25%.

Consumer expectations for charging speed have evolved dramatically, with 80% of potential EV buyers citing charging time as a decisive purchase factor. This has pushed OEMs to develop higher-power OBCs (increasing from 3.3kW to 22kW for standard vehicles), which consequently require more sophisticated protection systems to manage thermal loads and voltage fluctuations safely.

The aftermarket for OBC protection components is also expanding, with replacement and upgrade services growing at 18% annually. This is partly driven by early EV adopters seeking to extend vehicle lifespan through enhanced charging protection systems.

Regional analysis reveals varying demand patterns: European markets prioritize comprehensive diagnostic capabilities due to stringent regulatory frameworks; North American consumers emphasize robust short-circuit protection given the varied quality of charging infrastructure; while Asian markets focus on cost-effective OTP solutions to address environmental challenges in densely populated urban centers.

Industry surveys indicate that automotive manufacturers are willing to invest 15-20% premium for OBC protection systems that offer advanced diagnostic capabilities, predictive failure analysis, and seamless integration with vehicle telematics. This represents a significant value-added opportunity for component suppliers and system integrators.

The market for OBC protection systems is expected to reach $5.8 billion by 2028, with the premium segment focusing on integrated protection solutions growing at twice the rate of basic compliance-oriented systems. This trend underscores the strategic importance of developing robust, intelligent protection technologies that can adapt to evolving charging standards and vehicle architectures.

Market research indicates that OBC protection systems addressing overvoltage protection (OVP), overtemperature protection (OTP), and short-circuit diagnostics are becoming critical differentiators for automotive manufacturers. The primary market drivers include increasingly stringent safety regulations, consumer demand for faster charging capabilities, and the need for extended battery life in EVs.

Safety regulations such as UN ECE R100, ISO 17409, and regional standards in North America, Europe, and Asia are mandating comprehensive protection mechanisms in charging systems. These regulations have created a compliance-driven demand segment estimated at $2.7 billion globally, with annual growth rates exceeding 25%.

Consumer expectations for charging speed have evolved dramatically, with 80% of potential EV buyers citing charging time as a decisive purchase factor. This has pushed OEMs to develop higher-power OBCs (increasing from 3.3kW to 22kW for standard vehicles), which consequently require more sophisticated protection systems to manage thermal loads and voltage fluctuations safely.

The aftermarket for OBC protection components is also expanding, with replacement and upgrade services growing at 18% annually. This is partly driven by early EV adopters seeking to extend vehicle lifespan through enhanced charging protection systems.

Regional analysis reveals varying demand patterns: European markets prioritize comprehensive diagnostic capabilities due to stringent regulatory frameworks; North American consumers emphasize robust short-circuit protection given the varied quality of charging infrastructure; while Asian markets focus on cost-effective OTP solutions to address environmental challenges in densely populated urban centers.

Industry surveys indicate that automotive manufacturers are willing to invest 15-20% premium for OBC protection systems that offer advanced diagnostic capabilities, predictive failure analysis, and seamless integration with vehicle telematics. This represents a significant value-added opportunity for component suppliers and system integrators.

The market for OBC protection systems is expected to reach $5.8 billion by 2028, with the premium segment focusing on integrated protection solutions growing at twice the rate of basic compliance-oriented systems. This trend underscores the strategic importance of developing robust, intelligent protection technologies that can adapt to evolving charging standards and vehicle architectures.

Current OBC Protection Challenges and Technical Limitations

On-board chargers (OBCs) face significant protection challenges in modern electric vehicle architectures. Current OBC protection systems struggle with the increasing power density requirements, which have escalated from 3.3kW to 22kW in recent years. This power escalation creates thermal management difficulties within the confined spaces of vehicle components, making traditional cooling solutions inadequate for maintaining safe operating temperatures.

Voltage protection mechanisms in current OBCs demonstrate limitations when handling grid voltage fluctuations, particularly in regions with unstable power infrastructure. The existing overvoltage protection (OVP) circuits often employ relatively slow response times, typically in the millisecond range, which may be insufficient to prevent damage to sensitive semiconductor components that require microsecond-level protection.

Thermal protection systems face challenges with sensor placement optimization. Current designs frequently utilize a limited number of temperature sensors, creating potential blind spots where thermal runaway could initiate undetected. The thermal gradients within compact OBC designs can vary significantly, making accurate temperature monitoring across all critical components technically challenging and cost-prohibitive.

Short-circuit protection mechanisms in contemporary OBCs predominantly rely on fuses and circuit breakers, which may not react quickly enough to prevent damage to power electronics components. The trade-off between nuisance tripping and adequate protection remains a significant engineering challenge, particularly as silicon carbide (SiC) and gallium nitride (GaN) components become more prevalent in OBC designs.

Diagnostic capabilities present another area of technical limitation. Current systems typically provide basic fault codes without detailed information about the nature or progression of failures. This hampers predictive maintenance capabilities and can lead to unnecessary component replacements or vehicle downtime. The communication protocols between the OBC and vehicle management systems often lack standardization, creating integration challenges across different vehicle platforms.

Electromagnetic interference (EMI) presents a growing challenge for OBC protection systems. As charging power levels increase, so does the potential for EMI to disrupt protection circuits or trigger false alarms. Current EMI shielding and filtering solutions add weight and cost to OBC designs, creating a difficult balance between protection, performance, and manufacturing economics.

Reliability testing methodologies for OBC protection systems have not fully evolved to address the complex failure modes in modern designs. Accelerated life testing protocols may not adequately simulate real-world conditions, particularly for vehicles operating in extreme environments or unusual duty cycles. This creates uncertainty in predicting long-term reliability and establishing appropriate maintenance intervals.

Voltage protection mechanisms in current OBCs demonstrate limitations when handling grid voltage fluctuations, particularly in regions with unstable power infrastructure. The existing overvoltage protection (OVP) circuits often employ relatively slow response times, typically in the millisecond range, which may be insufficient to prevent damage to sensitive semiconductor components that require microsecond-level protection.

Thermal protection systems face challenges with sensor placement optimization. Current designs frequently utilize a limited number of temperature sensors, creating potential blind spots where thermal runaway could initiate undetected. The thermal gradients within compact OBC designs can vary significantly, making accurate temperature monitoring across all critical components technically challenging and cost-prohibitive.

Short-circuit protection mechanisms in contemporary OBCs predominantly rely on fuses and circuit breakers, which may not react quickly enough to prevent damage to power electronics components. The trade-off between nuisance tripping and adequate protection remains a significant engineering challenge, particularly as silicon carbide (SiC) and gallium nitride (GaN) components become more prevalent in OBC designs.

Diagnostic capabilities present another area of technical limitation. Current systems typically provide basic fault codes without detailed information about the nature or progression of failures. This hampers predictive maintenance capabilities and can lead to unnecessary component replacements or vehicle downtime. The communication protocols between the OBC and vehicle management systems often lack standardization, creating integration challenges across different vehicle platforms.

Electromagnetic interference (EMI) presents a growing challenge for OBC protection systems. As charging power levels increase, so does the potential for EMI to disrupt protection circuits or trigger false alarms. Current EMI shielding and filtering solutions add weight and cost to OBC designs, creating a difficult balance between protection, performance, and manufacturing economics.

Reliability testing methodologies for OBC protection systems have not fully evolved to address the complex failure modes in modern designs. Accelerated life testing protocols may not adequately simulate real-world conditions, particularly for vehicles operating in extreme environments or unusual duty cycles. This creates uncertainty in predicting long-term reliability and establishing appropriate maintenance intervals.

Current OVP/OTP/Short-Circuit Protection Implementation Approaches

01 Overvoltage protection (OVP) mechanisms for on-board chargers

On-board chargers incorporate overvoltage protection circuits to prevent damage to battery systems and charging components. These protection mechanisms monitor input and output voltage levels, automatically disconnecting or limiting current when voltage exceeds safe thresholds. Advanced OVP systems may include multiple detection stages, fast-response circuitry, and can communicate fault conditions to the vehicle's main control system for appropriate action.- Overvoltage protection (OVP) mechanisms for on-board chargers: On-board chargers implement overvoltage protection mechanisms to prevent damage to battery systems and charging components. These systems typically include voltage monitoring circuits that can detect when input or output voltages exceed safe thresholds. When overvoltage conditions are detected, protection circuits can disconnect power, activate clamping devices, or trigger controlled shutdown procedures to protect sensitive components and prevent catastrophic failures in electric vehicle charging systems.

- Over-temperature protection (OTP) systems for charging safety: Over-temperature protection systems are critical components in on-board chargers to prevent thermal damage. These systems utilize temperature sensors strategically placed near heat-generating components to continuously monitor thermal conditions. When temperatures exceed predetermined thresholds, the protection circuits can reduce charging current, activate cooling systems, or completely shut down the charging process. This protection is essential for preventing component degradation, thermal runaway, and potential fire hazards in electric vehicle charging systems.

- Short-circuit protection mechanisms and fault handling: On-board chargers incorporate short-circuit protection mechanisms to detect and respond to dangerous fault conditions. These systems typically include current sensing circuits that can identify abnormal current spikes indicative of short circuits. Upon detection, protection circuits rapidly disconnect power flow, isolate affected components, and prevent cascade failures. Advanced systems may include self-recovery features that attempt to restore normal operation after temporary faults or maintain partial functionality while isolating damaged sections.

- Diagnostic systems for on-board charger monitoring: Diagnostic systems in on-board chargers provide comprehensive monitoring and reporting capabilities for charging operations. These systems collect data from multiple sensors to track voltage, current, temperature, and other parameters throughout the charging process. Advanced diagnostic implementations include error logging, fault code generation, and communication interfaces that allow for remote monitoring and troubleshooting. These capabilities enable predictive maintenance, performance optimization, and enhanced safety through early detection of potential issues before they become critical failures.

- Integrated protection architectures for on-board charging systems: Integrated protection architectures combine multiple safety features into cohesive systems for comprehensive on-board charger protection. These designs incorporate overvoltage, over-temperature, and short-circuit protection along with diagnostic capabilities in unified control systems. The integration enables coordinated responses to complex fault scenarios, reduces component redundancy, and optimizes protection effectiveness. Advanced implementations may include adaptive protection parameters that adjust based on operating conditions, battery state, and charging profiles to maximize both safety and charging efficiency.

02 Over-temperature protection (OTP) systems for charging safety

Over-temperature protection systems are critical components in on-board chargers to prevent thermal damage and potential fire hazards. These systems utilize temperature sensors strategically placed near heat-generating components to continuously monitor thermal conditions. When temperatures exceed predetermined thresholds, the OTP system can reduce charging current, activate cooling systems, or completely shut down the charging process until safe operating temperatures are restored.Expand Specific Solutions03 Short-circuit protection mechanisms and fault handling

Short-circuit protection systems in on-board chargers detect abnormal current paths and rapidly interrupt power flow to prevent component damage and safety hazards. These systems typically employ current sensors, fuses, and electronic circuit breakers that can respond within milliseconds to fault conditions. Advanced implementations include self-recovery capabilities after temporary faults and isolation mechanisms to contain failures within specific charging modules.Expand Specific Solutions04 Diagnostic systems for on-board charger fault detection

Diagnostic systems in on-board chargers provide comprehensive monitoring and reporting of operational parameters and fault conditions. These systems collect data from multiple sensors throughout the charging circuit, analyze performance patterns, and can identify potential issues before they cause failures. Modern diagnostic implementations include self-test routines during startup, continuous monitoring during operation, and detailed fault logging with timestamp information for maintenance purposes.Expand Specific Solutions05 Integrated protection architectures with multiple safeguards

Integrated protection architectures combine multiple safeguard mechanisms into cohesive systems that provide comprehensive protection for on-board chargers. These architectures implement layered defense strategies with redundant protection for critical components, coordinated responses to various fault conditions, and intelligent power management during abnormal situations. The integration allows for optimized protection with minimal components while ensuring reliable charging operations under diverse environmental and electrical conditions.Expand Specific Solutions

Key OBC Protection Solution Providers and Competitive Landscape

The On-Board Charger (OBC) protection market is currently in a growth phase, driven by the rapid expansion of electric vehicle adoption worldwide. The market size is estimated to grow significantly as global EV sales continue to accelerate, with protection technologies becoming increasingly critical for safety and reliability. Leading automotive manufacturers like Tesla, BYD, Hyundai, and Stellantis are investing heavily in advanced OBC protection systems, while specialized semiconductor companies such as Richtek Technology, BCD Micro-Electronics, and Zgmicro are developing sophisticated protection ICs. The technology is maturing rapidly with innovations in over-voltage protection (OVP), over-temperature protection (OTP), and short-circuit diagnostics, though standardization remains in development. Battery manufacturers including Samsung SDI and LG Energy Solution are also contributing to advancements in this field to ensure seamless integration with their energy storage systems.

Richtek Technology Corp.

Technical Solution: Richtek Technology has developed specialized integrated circuits specifically designed for On-Board Charger protection applications. Their solution centers around highly integrated power management ICs that combine multiple protection functions in a single package. Richtek's RT9466/RT9467 series implements a comprehensive protection suite for OBCs with programmable overvoltage protection thresholds that can be customized for different battery chemistries and charging profiles. The OVP circuit features response times under 2ms and includes hysteresis to prevent oscillation around threshold points. For over-temperature protection, Richtek employs both internal die temperature sensing and external thermistor inputs, allowing for monitoring of both the controller IC and critical power components. Their short-circuit protection utilizes cycle-by-cycle current limiting with adjustable thresholds and response times, complemented by absolute maximum current cutoff for catastrophic failures. The diagnostic capabilities include I²C or SPI interface options for communication with the vehicle's main controller, providing detailed status reporting and fault codes. Richtek's solution also features built-in analog-to-digital converters for precise measurement of system parameters, enabling advanced functions like adaptive protection thresholds based on operating conditions and charging history. Their ICs include dedicated pins for fault signaling, allowing for rapid system response even without digital communication.

Strengths: Richtek's highly integrated solution reduces component count and PCB space requirements while improving reliability through fewer interconnections. Their programmable thresholds allow for optimization across different vehicle models and battery configurations. Weaknesses: As a component supplier rather than a complete system provider, Richtek's solutions require additional engineering by OEMs to integrate into full charging systems, and may not offer the same level of customization as fully proprietary solutions.

BYD Co., Ltd.

Technical Solution: BYD has engineered a comprehensive On-Board Charger protection system leveraging their expertise in both automotive and battery technologies. Their "Blade Battery" technology integration extends to their OBC protection architecture, which features a multi-level safety approach. BYD's system incorporates silicon carbide (SiC) power modules that provide higher efficiency and better thermal performance compared to traditional silicon-based components. For overvoltage protection (OVP), BYD implements a dual-monitoring system with independent voltage reference sources that can detect anomalies within 5ms and trigger protective actions. Their over-temperature protection (OTP) utilizes a distributed thermal management system with multiple temperature sensors and a liquid cooling solution for high-power charging scenarios. The short-circuit protection mechanism employs both hardware fuses and electronic current limiting, with specialized algorithms that can distinguish between momentary current spikes and genuine fault conditions. BYD's diagnostic system features comprehensive self-checking routines that run during startup and continuously during operation, with fault information stored in non-volatile memory for later analysis. The system also includes isolation monitoring to detect insulation failures between high-voltage and low-voltage circuits, providing an additional layer of safety against electrical hazards.

Strengths: BYD's vertical integration allows for optimized component matching and system-level efficiency. Their experience with battery technology translates to particularly robust protection against conditions that could damage battery cells. Weaknesses: The system's complexity requires sophisticated manufacturing processes and quality control, potentially limiting production scalability and increasing costs for lower-priced vehicle models.

Critical Patents and Technical Literature in OBC Protection

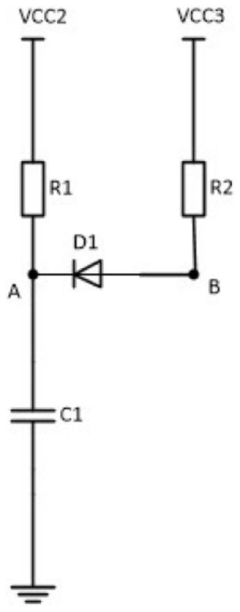

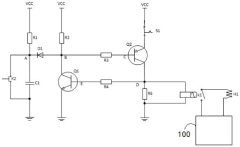

Over-temperature protection circuit and in-vitro diagnosis medical equipment

PatentActiveCN220401420U

Innovation

- Using a design that combines an interlock circuit and a temperature probe, the temperature probe cuts off the power connection and disconnects the relay to isolate the heating circuit and automatically stop heating, and restore the interlocked state through manual reset of the relay to meet non-automatic reset requirements.

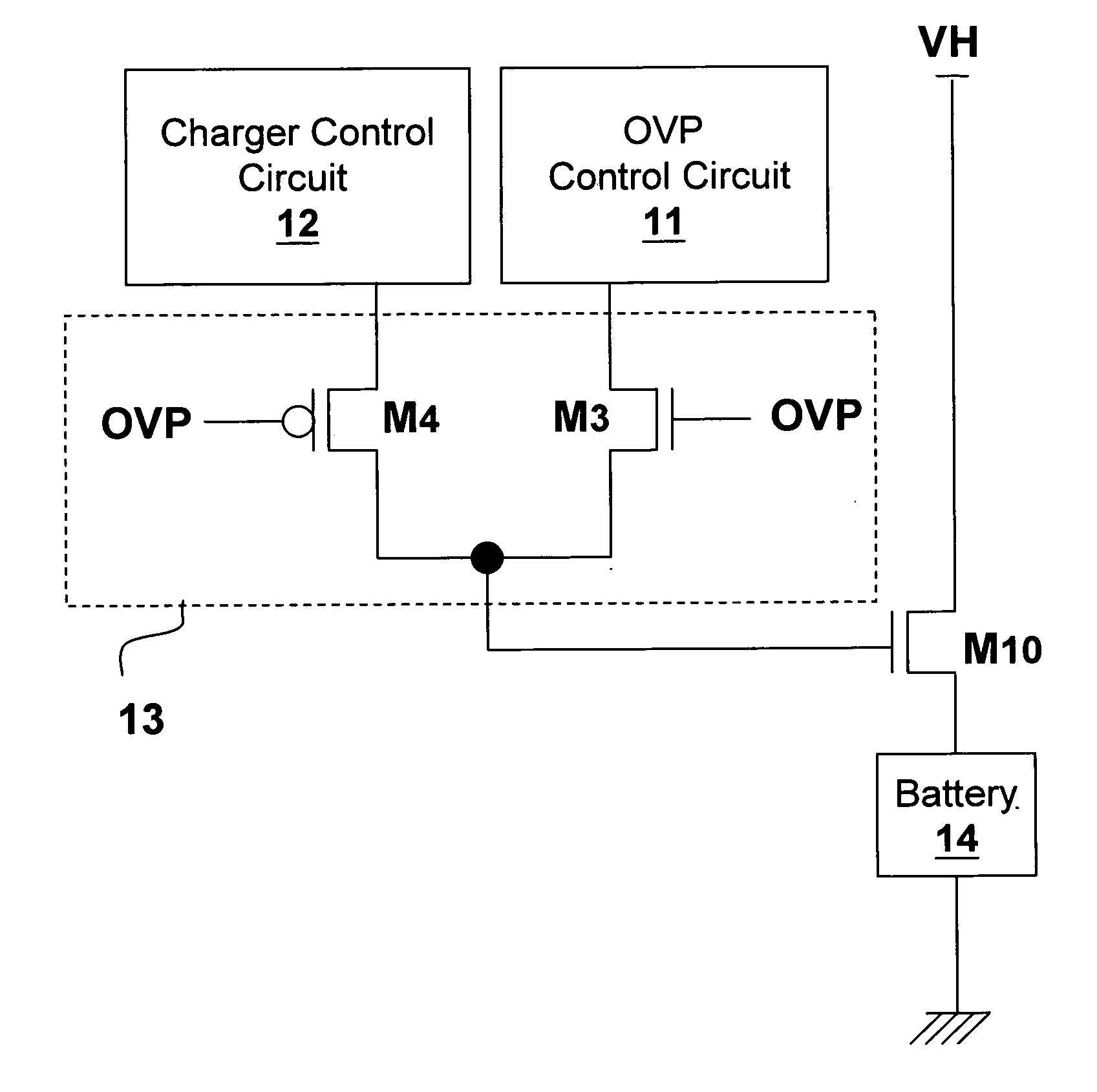

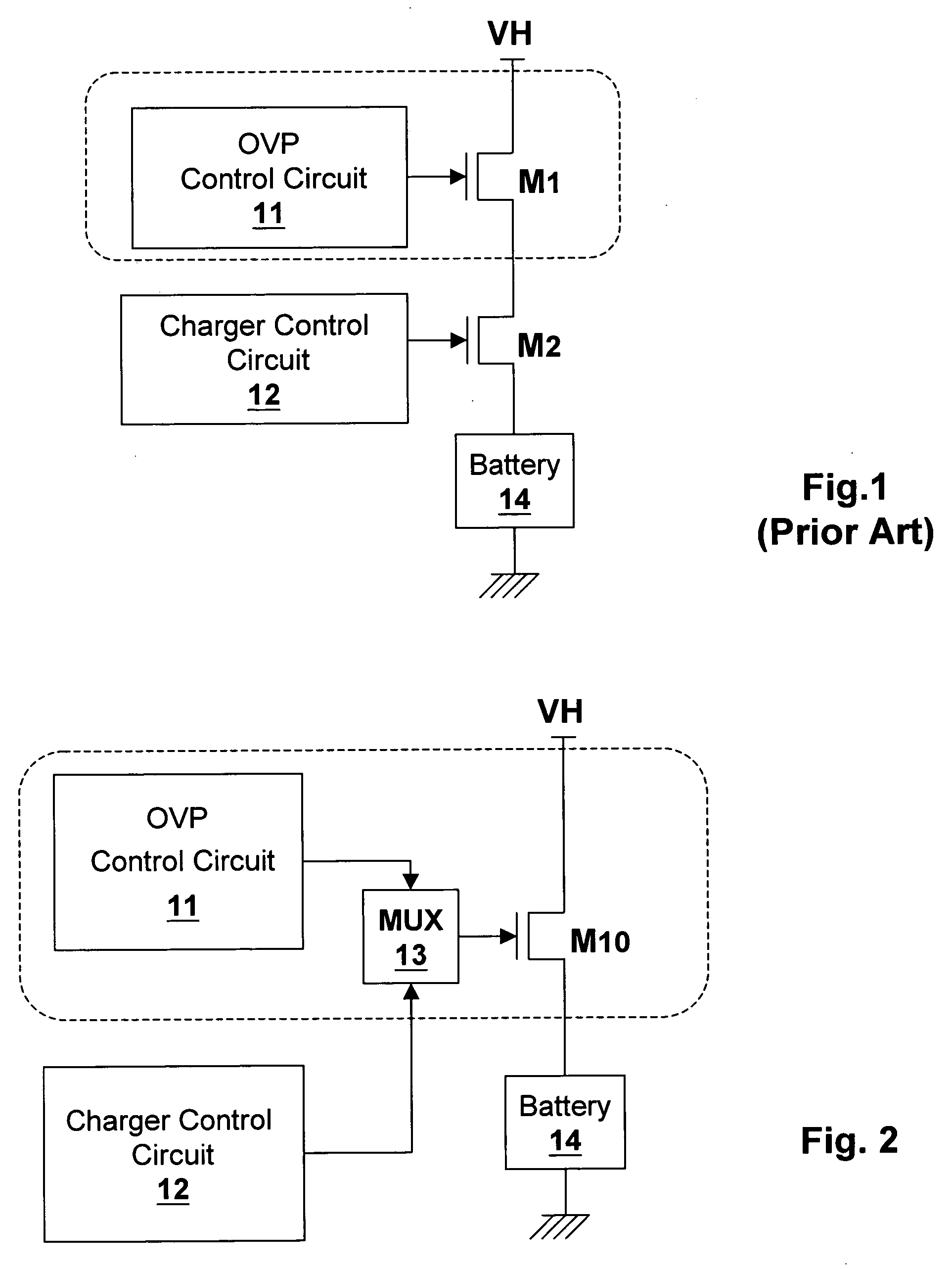

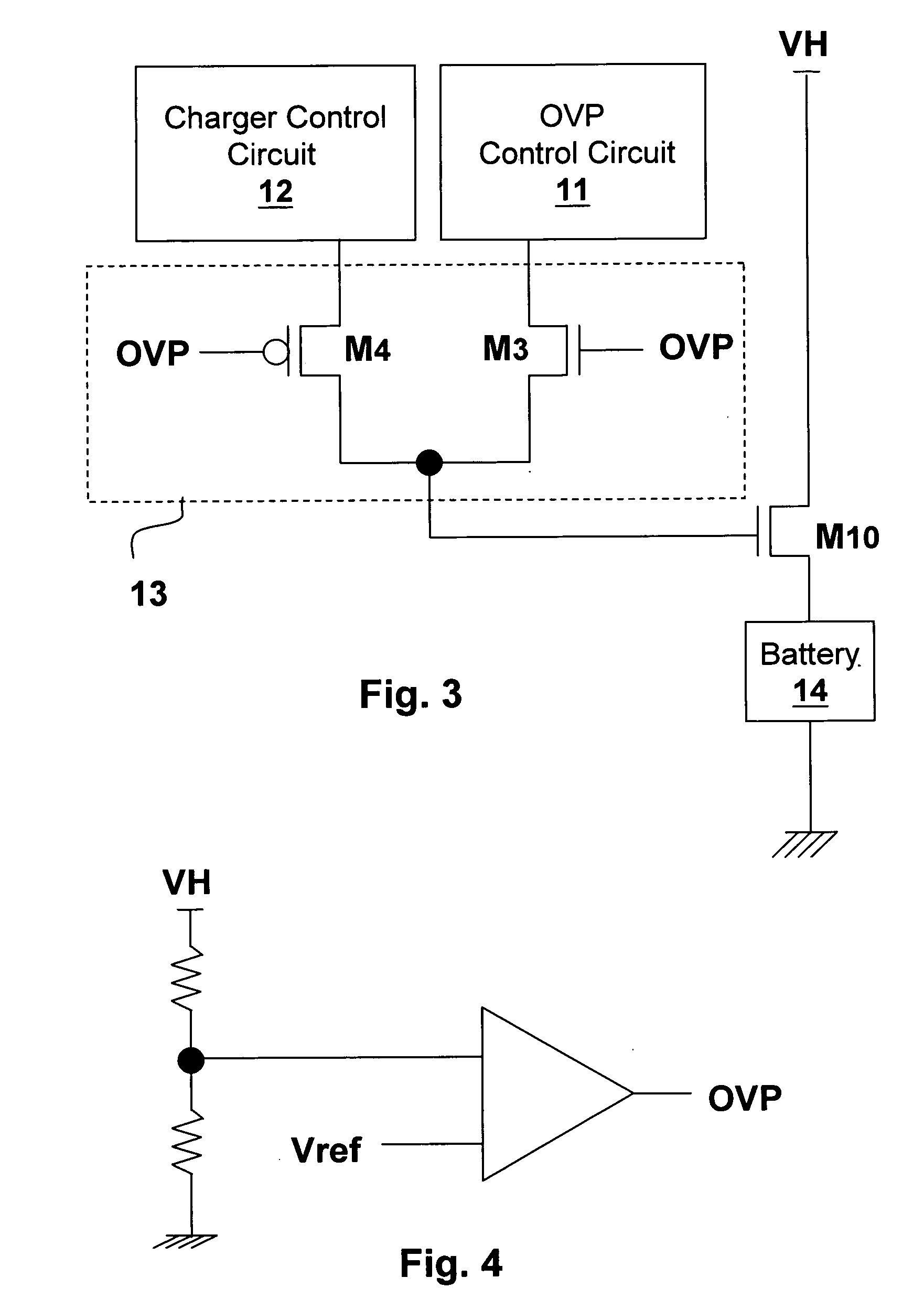

Overvoltage protection circuit for use in charger circuit system and charge circuit with overvoltage protection function

PatentInactiveUS20100066312A1

Innovation

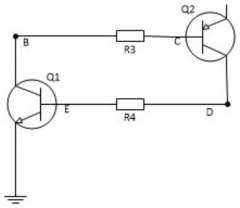

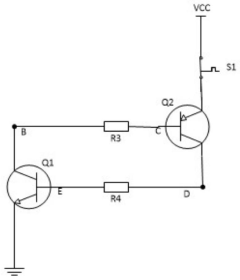

- A single power transistor with an integrated OVP control circuit and a multiplexing circuit that controls the transistor's gate, replacing the need for additional transistors by using the OVP control circuit to turn off the transistor when voltage exceeds a threshold and the charger control circuit to manage charge current within safe voltage ranges.

Safety Standards and Regulatory Requirements for OBC Systems

On-Board Charger (OBC) systems must comply with a comprehensive framework of safety standards and regulatory requirements to ensure safe operation in electric vehicles. The International Electrotechnical Commission (IEC) has established several key standards, including IEC 61851 for electric vehicle conductive charging systems and IEC 62196 for plugs, socket-outlets, and vehicle connectors. These standards define essential safety parameters for voltage protection, thermal management, and short-circuit prevention.

In the United States, UL 2202 (Electric Vehicle Charging System Equipment) provides detailed requirements for OBC protection mechanisms, mandating specific overvoltage protection thresholds and response times. Similarly, the Society of Automotive Engineers (SAE) has developed J1772, which outlines safety protocols for charging interfaces and protection systems, including diagnostic communication requirements between vehicles and charging infrastructure.

The European market is governed by ECE R100, which specifically addresses battery electric vehicle safety, including requirements for OBC systems. This regulation mandates comprehensive protection against electrical hazards, with particular emphasis on isolation monitoring and fault detection capabilities. Additionally, ISO 26262 (Road Vehicles - Functional Safety) classifies OBC protection systems under Automotive Safety Integrity Level (ASIL) requirements, typically at ASIL C or D levels due to their critical safety functions.

China's GB/T 18487 standard series establishes requirements for conductive charging systems, with GB/T 18487.1-2015 specifically addressing protection mechanisms and diagnostic capabilities for on-board charging equipment. These standards align with international frameworks while incorporating specific requirements for the Chinese market.

Electromagnetic compatibility (EMC) requirements are covered by CISPR 25 and IEC 61000 series, which define limits for electromagnetic emissions and immunity. OBC protection systems must demonstrate resilience against electromagnetic interference while not generating disruptive emissions themselves.

Recent regulatory trends show increasing emphasis on cybersecurity aspects of OBC systems, with standards like ISO/SAE 21434 addressing potential vulnerabilities in connected charging systems. Protection mechanisms must now incorporate secure communication protocols and intrusion detection capabilities to prevent malicious manipulation of charging parameters.

Compliance with these standards requires comprehensive testing regimes, including accelerated life testing, environmental stress screening, and fault injection testing. Manufacturers must document test results and maintain traceability throughout the development process to demonstrate regulatory compliance and obtain necessary certifications for market access.

In the United States, UL 2202 (Electric Vehicle Charging System Equipment) provides detailed requirements for OBC protection mechanisms, mandating specific overvoltage protection thresholds and response times. Similarly, the Society of Automotive Engineers (SAE) has developed J1772, which outlines safety protocols for charging interfaces and protection systems, including diagnostic communication requirements between vehicles and charging infrastructure.

The European market is governed by ECE R100, which specifically addresses battery electric vehicle safety, including requirements for OBC systems. This regulation mandates comprehensive protection against electrical hazards, with particular emphasis on isolation monitoring and fault detection capabilities. Additionally, ISO 26262 (Road Vehicles - Functional Safety) classifies OBC protection systems under Automotive Safety Integrity Level (ASIL) requirements, typically at ASIL C or D levels due to their critical safety functions.

China's GB/T 18487 standard series establishes requirements for conductive charging systems, with GB/T 18487.1-2015 specifically addressing protection mechanisms and diagnostic capabilities for on-board charging equipment. These standards align with international frameworks while incorporating specific requirements for the Chinese market.

Electromagnetic compatibility (EMC) requirements are covered by CISPR 25 and IEC 61000 series, which define limits for electromagnetic emissions and immunity. OBC protection systems must demonstrate resilience against electromagnetic interference while not generating disruptive emissions themselves.

Recent regulatory trends show increasing emphasis on cybersecurity aspects of OBC systems, with standards like ISO/SAE 21434 addressing potential vulnerabilities in connected charging systems. Protection mechanisms must now incorporate secure communication protocols and intrusion detection capabilities to prevent malicious manipulation of charging parameters.

Compliance with these standards requires comprehensive testing regimes, including accelerated life testing, environmental stress screening, and fault injection testing. Manufacturers must document test results and maintain traceability throughout the development process to demonstrate regulatory compliance and obtain necessary certifications for market access.

Reliability Testing Methodologies for OBC Protection Circuits

Reliability testing methodologies for OBC protection circuits must be comprehensive and rigorous to ensure the safety and longevity of electric vehicle charging systems. These methodologies typically follow industry standards such as ISO 16750, LV 124, and IEC 61851, which provide guidelines for automotive electrical component testing.

The primary reliability tests for OVP (Over-Voltage Protection) circuits include voltage surge testing, where protection circuits are subjected to voltage levels exceeding normal operating conditions by 20-30%. These tests typically involve applying voltage spikes ranging from 16V to 60V for automotive-grade OBCs, with durations varying from microseconds to several minutes to evaluate both transient and sustained overvoltage response.

For OTP (Over-Temperature Protection) circuits, thermal cycling tests are essential, subjecting the components to temperature extremes from -40°C to 125°C. Dwell times at each temperature extreme typically range from 30 minutes to several hours, with transition rates carefully controlled to simulate real-world conditions. Additionally, power cycling under thermal stress evaluates the protection circuit's ability to function during rapid temperature changes caused by operational cycles.

Short-circuit protection testing involves deliberately creating fault conditions across various points in the charging circuit. These tests measure response time, which should be under 10 milliseconds for critical protections, and verify that protection mechanisms activate before component damage occurs. Recovery testing after fault clearance is equally important to ensure the system can safely resume normal operation.

Environmental stress testing combines multiple stressors, including temperature, humidity (up to 95% RH), vibration (10-500 Hz frequency range), and mechanical shock (up to 50g). These combined tests more accurately represent real-world conditions where multiple stressors often occur simultaneously.

Accelerated life testing is conducted to predict long-term reliability, typically running components at elevated stress levels for 1,000 to 5,000 hours. Statistical methods such as Weibull analysis are then applied to project failure rates under normal operating conditions, with target failure rates below 10 parts per million for automotive-grade protection circuits.

Diagnostic function verification forms another critical aspect of reliability testing. This includes fault injection testing where known faults are deliberately introduced to verify that diagnostic systems correctly identify and report them. Communication protocol testing ensures that fault information is accurately transmitted to the vehicle's control systems through CAN, LIN, or other automotive communication networks.

The primary reliability tests for OVP (Over-Voltage Protection) circuits include voltage surge testing, where protection circuits are subjected to voltage levels exceeding normal operating conditions by 20-30%. These tests typically involve applying voltage spikes ranging from 16V to 60V for automotive-grade OBCs, with durations varying from microseconds to several minutes to evaluate both transient and sustained overvoltage response.

For OTP (Over-Temperature Protection) circuits, thermal cycling tests are essential, subjecting the components to temperature extremes from -40°C to 125°C. Dwell times at each temperature extreme typically range from 30 minutes to several hours, with transition rates carefully controlled to simulate real-world conditions. Additionally, power cycling under thermal stress evaluates the protection circuit's ability to function during rapid temperature changes caused by operational cycles.

Short-circuit protection testing involves deliberately creating fault conditions across various points in the charging circuit. These tests measure response time, which should be under 10 milliseconds for critical protections, and verify that protection mechanisms activate before component damage occurs. Recovery testing after fault clearance is equally important to ensure the system can safely resume normal operation.

Environmental stress testing combines multiple stressors, including temperature, humidity (up to 95% RH), vibration (10-500 Hz frequency range), and mechanical shock (up to 50g). These combined tests more accurately represent real-world conditions where multiple stressors often occur simultaneously.

Accelerated life testing is conducted to predict long-term reliability, typically running components at elevated stress levels for 1,000 to 5,000 hours. Statistical methods such as Weibull analysis are then applied to project failure rates under normal operating conditions, with target failure rates below 10 parts per million for automotive-grade protection circuits.

Diagnostic function verification forms another critical aspect of reliability testing. This includes fault injection testing where known faults are deliberately introduced to verify that diagnostic systems correctly identify and report them. Communication protocol testing ensures that fault information is accurately transmitted to the vehicle's control systems through CAN, LIN, or other automotive communication networks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!