On-Board Charger Topologies: Totem-Pole PFC + LLC/HB—Efficiency And EMI

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

On-Board Charger Technology Evolution and Objectives

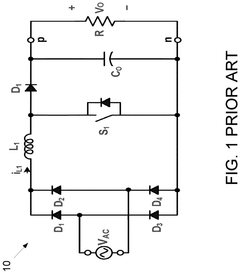

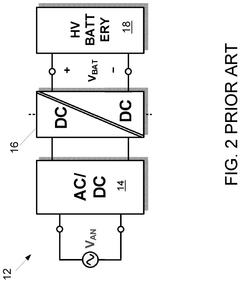

On-board chargers (OBCs) have undergone significant evolution since the early days of electric vehicles (EVs). Initially, OBCs were simple, low-power devices with limited efficiency, typically operating at power levels below 3.3 kW with efficiency rates of 85-88%. These early systems employed basic topologies such as conventional boost PFC followed by full-bridge converters, which were adequate for first-generation EVs with smaller battery packs.

The technological progression of OBCs has been driven by several key factors: increasing battery capacities, consumer demand for faster charging times, and stringent regulatory requirements for efficiency and electromagnetic interference (EMI). This evolution has led to a shift from single-phase to three-phase systems, enabling power levels to increase from 3.3 kW to current standards of 11-22 kW for premium EVs.

A pivotal advancement in OBC technology has been the transition from silicon-based power semiconductors to wide bandgap (WBG) materials, particularly silicon carbide (SiC) and gallium nitride (GaN). These materials have enabled higher switching frequencies, reduced switching losses, and improved thermal performance, collectively contributing to smaller form factors and higher power densities.

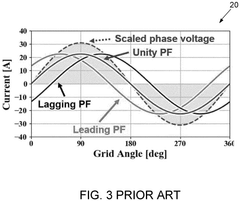

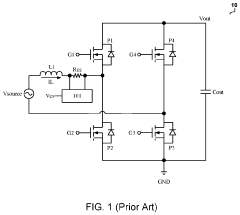

The Totem-Pole Power Factor Correction (PFC) topology represents a significant milestone in this evolution. Unlike traditional boost PFC circuits, the Totem-Pole configuration eliminates the need for a bridge rectifier, reducing conduction losses and improving efficiency. When paired with resonant converters like LLC (inductor-inductor-capacitor) or half-bridge (HB) topologies in the DC-DC stage, modern OBCs can achieve efficiency rates exceeding 95%.

Current technological objectives for OBC development focus on several critical areas. Efficiency optimization remains paramount, with targets now exceeding 97% for next-generation systems. Size and weight reduction is another key goal, with the industry pushing toward power densities above 4 kW/L. EMI management has become increasingly important as higher switching frequencies generate more electromagnetic noise, requiring sophisticated filtering and shielding solutions.

Bidirectional charging capability represents another significant objective, enabling vehicle-to-grid (V2G) and vehicle-to-home (V2H) functionalities. This requires symmetrical power flow capabilities in OBC topologies, with the Totem-Pole PFC + LLC/HB combination showing particular promise due to its inherent bidirectional potential when properly designed.

The integration of advanced digital control algorithms and smart charging features is also becoming essential, allowing OBCs to adapt to varying grid conditions, communicate with charging infrastructure, and optimize charging profiles based on battery state and user preferences.

The technological progression of OBCs has been driven by several key factors: increasing battery capacities, consumer demand for faster charging times, and stringent regulatory requirements for efficiency and electromagnetic interference (EMI). This evolution has led to a shift from single-phase to three-phase systems, enabling power levels to increase from 3.3 kW to current standards of 11-22 kW for premium EVs.

A pivotal advancement in OBC technology has been the transition from silicon-based power semiconductors to wide bandgap (WBG) materials, particularly silicon carbide (SiC) and gallium nitride (GaN). These materials have enabled higher switching frequencies, reduced switching losses, and improved thermal performance, collectively contributing to smaller form factors and higher power densities.

The Totem-Pole Power Factor Correction (PFC) topology represents a significant milestone in this evolution. Unlike traditional boost PFC circuits, the Totem-Pole configuration eliminates the need for a bridge rectifier, reducing conduction losses and improving efficiency. When paired with resonant converters like LLC (inductor-inductor-capacitor) or half-bridge (HB) topologies in the DC-DC stage, modern OBCs can achieve efficiency rates exceeding 95%.

Current technological objectives for OBC development focus on several critical areas. Efficiency optimization remains paramount, with targets now exceeding 97% for next-generation systems. Size and weight reduction is another key goal, with the industry pushing toward power densities above 4 kW/L. EMI management has become increasingly important as higher switching frequencies generate more electromagnetic noise, requiring sophisticated filtering and shielding solutions.

Bidirectional charging capability represents another significant objective, enabling vehicle-to-grid (V2G) and vehicle-to-home (V2H) functionalities. This requires symmetrical power flow capabilities in OBC topologies, with the Totem-Pole PFC + LLC/HB combination showing particular promise due to its inherent bidirectional potential when properly designed.

The integration of advanced digital control algorithms and smart charging features is also becoming essential, allowing OBCs to adapt to varying grid conditions, communicate with charging infrastructure, and optimize charging profiles based on battery state and user preferences.

EV Charging Market Demand Analysis

The global electric vehicle (EV) market has experienced unprecedented growth in recent years, directly driving demand for efficient charging solutions. As of 2023, the global on-board charger (OBC) market was valued at approximately $7.8 billion, with projections indicating a compound annual growth rate of 15.2% through 2030. This growth is primarily fueled by increasing EV adoption rates across major automotive markets including China, Europe, and North America.

Consumer preferences are evolving rapidly, with charging speed and convenience emerging as critical factors influencing purchase decisions. Market research indicates that 78% of potential EV buyers consider charging capabilities a top-three decision factor when selecting a vehicle. This has created significant pressure on automotive manufacturers to develop more efficient on-board charging systems that can reduce charging times while maintaining safety and reliability.

The demand for higher power density in OBCs has become particularly pronounced, with automotive OEMs seeking solutions that minimize weight and space requirements while maximizing charging efficiency. Current market standards are pushing toward 11kW and 22kW on-board chargers, representing a substantial increase from the 3.3-6.6kW systems common just five years ago.

Regulatory frameworks are also shaping market demand significantly. Stringent electromagnetic interference (EMI) regulations in Europe and North America require OBC manufacturers to develop solutions with excellent EMI performance. Additionally, efficiency standards such as the European Commission's Ecodesign Directive are pushing manufacturers toward topologies that can achieve conversion efficiencies exceeding 95%.

From a regional perspective, China leads the global OBC market with approximately 42% market share, followed by Europe (31%) and North America (18%). The Chinese market particularly values cost-effective solutions with high power density, while European consumers demonstrate stronger preference for bidirectional charging capabilities that enable vehicle-to-grid (V2G) functionality.

The aftermarket segment for OBCs is also experiencing significant growth, with a 22% year-over-year increase in 2022. This indicates strong consumer interest in upgrading existing charging systems to achieve faster charging times and improved efficiency. Particularly, Totem-Pole PFC combined with LLC resonant converters has gained significant market attention due to its superior efficiency characteristics.

Industry forecasts suggest that by 2028, over 65% of new EVs will feature OBCs with efficiency ratings above 96%, with Totem-Pole PFC + LLC/HB topologies expected to capture a dominant market position due to their optimal balance of efficiency, power density, and EMI performance.

Consumer preferences are evolving rapidly, with charging speed and convenience emerging as critical factors influencing purchase decisions. Market research indicates that 78% of potential EV buyers consider charging capabilities a top-three decision factor when selecting a vehicle. This has created significant pressure on automotive manufacturers to develop more efficient on-board charging systems that can reduce charging times while maintaining safety and reliability.

The demand for higher power density in OBCs has become particularly pronounced, with automotive OEMs seeking solutions that minimize weight and space requirements while maximizing charging efficiency. Current market standards are pushing toward 11kW and 22kW on-board chargers, representing a substantial increase from the 3.3-6.6kW systems common just five years ago.

Regulatory frameworks are also shaping market demand significantly. Stringent electromagnetic interference (EMI) regulations in Europe and North America require OBC manufacturers to develop solutions with excellent EMI performance. Additionally, efficiency standards such as the European Commission's Ecodesign Directive are pushing manufacturers toward topologies that can achieve conversion efficiencies exceeding 95%.

From a regional perspective, China leads the global OBC market with approximately 42% market share, followed by Europe (31%) and North America (18%). The Chinese market particularly values cost-effective solutions with high power density, while European consumers demonstrate stronger preference for bidirectional charging capabilities that enable vehicle-to-grid (V2G) functionality.

The aftermarket segment for OBCs is also experiencing significant growth, with a 22% year-over-year increase in 2022. This indicates strong consumer interest in upgrading existing charging systems to achieve faster charging times and improved efficiency. Particularly, Totem-Pole PFC combined with LLC resonant converters has gained significant market attention due to its superior efficiency characteristics.

Industry forecasts suggest that by 2028, over 65% of new EVs will feature OBCs with efficiency ratings above 96%, with Totem-Pole PFC + LLC/HB topologies expected to capture a dominant market position due to their optimal balance of efficiency, power density, and EMI performance.

Current OBC Topology Challenges and Limitations

On-board chargers (OBCs) in electric vehicles face several significant challenges that limit their performance and widespread adoption. Current OBC topologies predominantly utilize traditional boost PFC followed by isolated DC-DC converters, which struggle to meet the increasingly demanding requirements of modern electric vehicles.

Power density remains a critical limitation, with conventional OBC designs occupying substantial space and adding considerable weight to vehicles. This directly impacts vehicle range and efficiency, creating a challenging trade-off between charging capabilities and overall vehicle performance. As the automotive industry pushes for more compact and lightweight components, traditional OBC designs fall short of meeting these evolving requirements.

Efficiency losses present another major challenge, particularly at high power levels. Conventional topologies suffer from significant switching losses and conduction losses, especially during high-current charging operations. These losses manifest as heat generation, necessitating complex thermal management systems that further increase size, weight, and cost. Most current OBCs struggle to maintain efficiency above 92-94% across the full operating range.

EMI (Electromagnetic Interference) management represents a persistent challenge for existing OBC designs. The high-frequency switching operations in both PFC and DC-DC stages generate substantial electromagnetic noise that can interfere with vehicle electronics and nearby devices. Meeting stringent automotive EMC standards requires extensive filtering components that add complexity, size, and cost to the system.

Bidirectional power flow capabilities, increasingly important for vehicle-to-grid (V2G) applications, are limited in conventional OBC topologies. Most existing designs were optimized primarily for unidirectional charging, making bidirectional operation either impossible or highly inefficient without significant redesign.

Wide input voltage range adaptation presents another significant limitation. OBCs must operate efficiently across diverse global grid standards (85-265VAC), while also accommodating varying battery voltage levels. Traditional topologies struggle to maintain high efficiency across this broad operating range, often requiring complex control strategies or additional power stages.

Component stress and reliability concerns further complicate OBC design. High voltage and current stresses on semiconductor devices in conventional topologies lead to reliability issues and necessitate overdesigned components, increasing cost and size while reducing overall system reliability.

Cost optimization remains challenging, with traditional designs requiring numerous expensive components including magnetic elements, high-performance semiconductors, and extensive filtering networks. This cost structure limits mass-market adoption and presents barriers to scaling production.

Power density remains a critical limitation, with conventional OBC designs occupying substantial space and adding considerable weight to vehicles. This directly impacts vehicle range and efficiency, creating a challenging trade-off between charging capabilities and overall vehicle performance. As the automotive industry pushes for more compact and lightweight components, traditional OBC designs fall short of meeting these evolving requirements.

Efficiency losses present another major challenge, particularly at high power levels. Conventional topologies suffer from significant switching losses and conduction losses, especially during high-current charging operations. These losses manifest as heat generation, necessitating complex thermal management systems that further increase size, weight, and cost. Most current OBCs struggle to maintain efficiency above 92-94% across the full operating range.

EMI (Electromagnetic Interference) management represents a persistent challenge for existing OBC designs. The high-frequency switching operations in both PFC and DC-DC stages generate substantial electromagnetic noise that can interfere with vehicle electronics and nearby devices. Meeting stringent automotive EMC standards requires extensive filtering components that add complexity, size, and cost to the system.

Bidirectional power flow capabilities, increasingly important for vehicle-to-grid (V2G) applications, are limited in conventional OBC topologies. Most existing designs were optimized primarily for unidirectional charging, making bidirectional operation either impossible or highly inefficient without significant redesign.

Wide input voltage range adaptation presents another significant limitation. OBCs must operate efficiently across diverse global grid standards (85-265VAC), while also accommodating varying battery voltage levels. Traditional topologies struggle to maintain high efficiency across this broad operating range, often requiring complex control strategies or additional power stages.

Component stress and reliability concerns further complicate OBC design. High voltage and current stresses on semiconductor devices in conventional topologies lead to reliability issues and necessitate overdesigned components, increasing cost and size while reducing overall system reliability.

Cost optimization remains challenging, with traditional designs requiring numerous expensive components including magnetic elements, high-performance semiconductors, and extensive filtering networks. This cost structure limits mass-market adoption and presents barriers to scaling production.

Existing Totem-Pole PFC + LLC/HB Implementation Approaches

01 Totem-Pole PFC Converter Design for High Efficiency

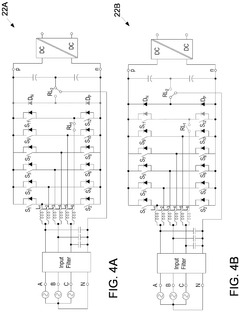

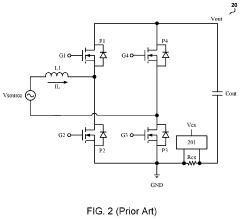

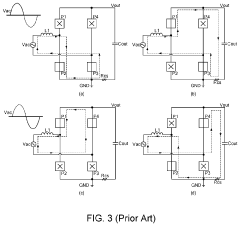

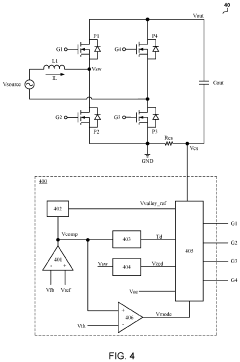

Totem-pole power factor correction (PFC) converters are designed to achieve high efficiency in on-board chargers for electric vehicles. These converters utilize advanced semiconductor devices such as GaN or SiC MOSFETs to reduce switching losses and improve power density. The design focuses on optimizing the bridgeless topology to minimize conduction losses and achieve near-unity power factor, making them ideal for high-power charging applications.- Totem-Pole PFC Converter Design for Efficiency Improvement: Totem-pole power factor correction (PFC) converters are designed with advanced switching techniques to improve efficiency in on-board chargers. These designs utilize GaN or SiC devices to reduce switching losses and achieve higher power density. The topology enables bidirectional power flow capability while maintaining high efficiency across wide load ranges, making it suitable for electric vehicle charging applications.

- LLC Resonant Converter Integration with PFC Stage: The integration of LLC resonant converters with PFC stages creates a highly efficient DC-DC conversion system for on-board chargers. This combination provides soft-switching operation, reducing electromagnetic interference and thermal stress on components. The LLC stage typically operates at high frequency to reduce the size of magnetic components while maintaining high efficiency through resonant operation.

- EMI Reduction Techniques in Totem-Pole PFC and LLC Topologies: Various EMI reduction techniques are implemented in totem-pole PFC and LLC converter combinations, including optimized PCB layout, common-mode noise suppression filters, and strategic placement of EMI filters. These techniques help meet electromagnetic compatibility standards while maintaining high power density and efficiency. Interleaving and phase-shifting strategies are also employed to reduce input and output ripple currents.

- Digital Control Strategies for Totem-Pole PFC and LLC Converters: Advanced digital control strategies are implemented to optimize the performance of totem-pole PFC and LLC converter combinations. These control methods include adaptive dead-time control, frequency modulation, and phase-shift control to improve efficiency across varying load conditions. Digital controllers enable features such as power factor optimization, harmonic reduction, and protection functions while facilitating communication with vehicle management systems.

- Bidirectional Operation and Vehicle-to-Grid Capability: On-board charger designs incorporating totem-pole PFC and LLC/HB converters enable bidirectional power flow for vehicle-to-grid (V2G) applications. These topologies support both charging (grid-to-vehicle) and discharging (vehicle-to-grid) modes with high efficiency in both directions. The bidirectional capability allows electric vehicles to serve as energy storage units that can support grid stability and provide emergency power when needed.

02 LLC Resonant Converter Integration with PFC Stage

The integration of LLC resonant converters with totem-pole PFC stages creates a highly efficient DC-DC conversion system for on-board chargers. This combination leverages soft-switching techniques to minimize switching losses and reduce electromagnetic interference. The LLC stage provides galvanic isolation and precise voltage regulation while maintaining high efficiency across wide input voltage ranges, which is crucial for battery charging applications.Expand Specific Solutions03 EMI Mitigation Techniques in Totem-Pole PFC and LLC Topologies

Various electromagnetic interference (EMI) mitigation techniques are implemented in totem-pole PFC and LLC converter topologies to meet stringent automotive EMC standards. These include optimized PCB layout design, common-mode noise suppression filters, spread spectrum frequency modulation, and strategic placement of EMI filters. Advanced gate driving techniques and careful component selection help reduce conducted and radiated emissions while maintaining high power conversion efficiency.Expand Specific Solutions04 Digital Control Strategies for Totem-Pole PFC and LLC Converters

Digital control strategies enhance the performance of totem-pole PFC and LLC converter combinations in on-board chargers. These control methods include adaptive dead-time control, phase-shift modulation, and predictive current control algorithms that optimize efficiency across various operating conditions. Digital controllers enable features such as burst mode operation at light loads, active thermal management, and seamless transition between operating modes, improving overall system reliability and efficiency.Expand Specific Solutions05 Compact Integration and Thermal Management for On-Board Chargers

Compact integration techniques and thermal management solutions are essential for high-power density on-board chargers using totem-pole PFC and LLC/HB topologies. These include 3D packaging methods, integrated cooling systems, and optimized component placement to manage heat dissipation effectively. Advanced thermal interface materials and cooling strategies ensure reliable operation under various environmental conditions while minimizing the overall size and weight of the charging system.Expand Specific Solutions

Key OBC Technology Manufacturers and Competitors

The On-Board Charger (OBC) market with Totem-Pole PFC + LLC/HB topologies is currently in a growth phase, with increasing adoption driven by electric vehicle proliferation. The market is projected to expand significantly as automotive electrification accelerates, with major players including established automotive manufacturers (Stellantis, GM, Hyundai, BYD, BMW, Volvo) and specialized power electronics companies (Delta Electronics, Huawei, Murata). The technology is approaching maturity with efficiency improvements and EMI reduction being key focus areas. Leading companies like BYD and Delta Electronics have made significant advancements in high-efficiency designs, while research institutions such as Zhejiang University and Virginia Tech are contributing to topology innovations. The competitive landscape shows automotive OEMs increasingly partnering with electronics specialists to develop proprietary solutions optimized for their specific vehicle platforms.

Delta Electronics, Inc.

Technical Solution: Delta Electronics has developed a comprehensive on-board charger solution based on Totem-Pole PFC combined with an LLC resonant converter, optimized for both efficiency and EMI performance. Their design implements a hybrid switching strategy in the Totem-Pole PFC stage, using continuous conduction mode (CCM) at high power and transitioning to triangular current mode (TCM) at light loads to maintain high efficiency across the operating range. Delta's solution incorporates GaN power devices in the high-frequency switching legs, achieving switching frequencies up to 140 kHz while maintaining low switching losses. For EMI mitigation, Delta employs a multi-pronged approach including integrated common-mode chokes, optimized PCB layout with minimized loop areas, and careful placement of Y-capacitors to create low-impedance paths for high-frequency noise. Their LLC resonant converter design features variable frequency control with optimized magnetic components that maintain high efficiency across wide voltage ranges. Delta's thermal management system uses a combination of advanced materials and forced cooling to maintain optimal operating temperatures even under sustained high-power operation. The design also incorporates sophisticated protection features including input surge protection, output short circuit protection, and thermal monitoring with adaptive derating.

Strengths: Excellent full-load efficiency (>96%) and superior light-load efficiency; robust EMI performance meeting automotive standards with margin; proven reliability in field applications; comprehensive protection features. Weaknesses: Moderate power density compared to some competitors; complex control requirements for hybrid switching modes; thermal management challenges in compact automotive installations.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed a high-frequency Totem-Pole PFC with LLC resonant converter topology for on-board charging applications, leveraging their expertise in telecommunications power supplies. Their solution operates the Totem-Pole PFC at frequencies above 100 kHz using advanced SiC MOSFETs, achieving power factor correction exceeding 0.99 across wide input voltage ranges. The design implements digital adaptive control algorithms that optimize switching patterns based on load conditions and input voltage variations. For the DC-DC stage, Huawei employs an LLC resonant converter with planar magnetics to reduce size while maintaining high efficiency. Their EMI mitigation strategy includes multi-stage filtering with both passive and active components, careful power loop layout, and advanced shielding techniques. Huawei's design also features integrated communication capabilities that enable smart charging functions, including load balancing and scheduled charging based on grid conditions. The thermal management system uses a combination of forced air cooling and thermally conductive materials to maintain optimal operating temperatures even under sustained high-power operation.

Strengths: Exceptional efficiency (>96%) across wide operating conditions; compact design with high power density; advanced digital control enabling smart grid integration; robust EMI performance. Weaknesses: Complex control algorithms requiring significant computational resources; higher component costs; potential reliability issues in automotive environments with temperature extremes.

Critical Patents and Innovations in High-Efficiency OBC Design

Totem-pole power factor correction converter and control method thereof

PatentPendingEP4618392A1

Innovation

- A totem-pole power factor correction (PFC) converter with a T-type leg configuration, utilizing active switches and diodes, is designed to operate around AC zero crossings, enabling non-unity power factor operation by providing an additional current path and controlling the input current effectively.

Control circuit for a totem pole power factor correction circuit and the method thereof

PatentActiveUS20230163679A1

Innovation

- A constant on-time scheme is implemented to control the totem pole PFC circuit, where the main switch is kept on for specific periods based on current valley detection, allowing the detecting resistor to be placed at the low side, eliminating the need for high voltage devices and enabling operation in CCM.

EMI Mitigation Strategies for Advanced OBC Topologies

EMI mitigation in advanced On-Board Charger (OBC) topologies, particularly those utilizing Totem-Pole PFC and LLC/HB resonant converters, requires comprehensive strategies to ensure regulatory compliance while maintaining high efficiency. The electromagnetic interference generated by these high-frequency switching converters presents significant challenges in automotive applications where electromagnetic compatibility is critical.

Passive filtering techniques remain fundamental in EMI suppression for OBCs. Common-mode (CM) and differential-mode (DM) filters strategically placed at both AC and DC interfaces effectively attenuate conducted emissions. Advanced filter designs incorporating nanocrystalline cores and optimized capacitor arrangements have demonstrated superior attenuation characteristics while minimizing volume and weight constraints critical for automotive applications.

Soft-switching techniques have emerged as essential EMI mitigation approaches in modern OBC designs. Zero Voltage Switching (ZVS) and Zero Current Switching (ZCS) significantly reduce switching transients that contribute to EMI generation. For Totem-Pole PFC stages, critical conduction mode (CrCM) or triangular current mode (TCM) control schemes facilitate soft switching across wide operating ranges, substantially reducing high-frequency noise components.

Spread spectrum frequency modulation (SSFM) represents an increasingly adopted technique for EMI reduction in OBCs. By deliberately varying the switching frequency around a central value, SSFM distributes EMI energy across a wider frequency band, effectively reducing peak emission levels. Implementation in digital controllers allows adaptive modulation profiles that optimize EMI reduction without significantly compromising conversion efficiency.

Layout optimization plays a crucial role in EMI mitigation that is often underestimated. Careful placement of power components to minimize loop areas, strategic routing of high dv/dt and di/dt traces, and proper implementation of ground planes significantly reduce radiated emissions. Advanced multi-layer PCB designs with embedded shielding layers have demonstrated substantial improvements in EMI performance for high-density OBC implementations.

Active EMI cancellation techniques represent the cutting edge of interference suppression. These systems sense EMI in real-time and generate counter-signals to neutralize the interference. While more complex than passive approaches, they offer significant advantages in size and weight reduction compared to traditional filtering solutions, making them particularly attractive for next-generation OBCs where power density is paramount.

Shielding and enclosure design considerations complete the comprehensive EMI mitigation strategy. Proper shielding of magnetic components, strategic placement of shield layers between power and control circuits, and careful design of enclosure apertures all contribute to reduced radiated emissions. Advanced materials including ferrite-loaded polymers and nano-composite shields offer improved attenuation with reduced weight penalties.

Passive filtering techniques remain fundamental in EMI suppression for OBCs. Common-mode (CM) and differential-mode (DM) filters strategically placed at both AC and DC interfaces effectively attenuate conducted emissions. Advanced filter designs incorporating nanocrystalline cores and optimized capacitor arrangements have demonstrated superior attenuation characteristics while minimizing volume and weight constraints critical for automotive applications.

Soft-switching techniques have emerged as essential EMI mitigation approaches in modern OBC designs. Zero Voltage Switching (ZVS) and Zero Current Switching (ZCS) significantly reduce switching transients that contribute to EMI generation. For Totem-Pole PFC stages, critical conduction mode (CrCM) or triangular current mode (TCM) control schemes facilitate soft switching across wide operating ranges, substantially reducing high-frequency noise components.

Spread spectrum frequency modulation (SSFM) represents an increasingly adopted technique for EMI reduction in OBCs. By deliberately varying the switching frequency around a central value, SSFM distributes EMI energy across a wider frequency band, effectively reducing peak emission levels. Implementation in digital controllers allows adaptive modulation profiles that optimize EMI reduction without significantly compromising conversion efficiency.

Layout optimization plays a crucial role in EMI mitigation that is often underestimated. Careful placement of power components to minimize loop areas, strategic routing of high dv/dt and di/dt traces, and proper implementation of ground planes significantly reduce radiated emissions. Advanced multi-layer PCB designs with embedded shielding layers have demonstrated substantial improvements in EMI performance for high-density OBC implementations.

Active EMI cancellation techniques represent the cutting edge of interference suppression. These systems sense EMI in real-time and generate counter-signals to neutralize the interference. While more complex than passive approaches, they offer significant advantages in size and weight reduction compared to traditional filtering solutions, making them particularly attractive for next-generation OBCs where power density is paramount.

Shielding and enclosure design considerations complete the comprehensive EMI mitigation strategy. Proper shielding of magnetic components, strategic placement of shield layers between power and control circuits, and careful design of enclosure apertures all contribute to reduced radiated emissions. Advanced materials including ferrite-loaded polymers and nano-composite shields offer improved attenuation with reduced weight penalties.

Thermal Management Solutions for High-Power OBC Systems

Thermal management has become a critical challenge in high-power On-Board Charger (OBC) systems, particularly those utilizing Totem-Pole PFC and LLC/HB topologies. As power densities increase to meet market demands for faster charging capabilities, thermal issues directly impact both efficiency and electromagnetic interference (EMI) performance. Current high-power OBCs operating at 11kW and above generate significant heat during operation, with power semiconductor devices being the primary heat sources.

Advanced cooling strategies have evolved from simple passive cooling to sophisticated hybrid approaches. Liquid cooling systems offer superior thermal performance for high-power applications, achieving thermal resistances below 0.1°C/W compared to 0.3-0.5°C/W for forced-air solutions. This improvement directly translates to better efficiency by reducing conduction losses in power semiconductors, which increase approximately 0.3% per degree Celsius rise in junction temperature.

Phase-change materials (PCMs) represent an emerging solution for transient thermal management, absorbing heat during peak loads and releasing it during lower power operation. These materials can buffer temperature fluctuations by 15-20°C in typical automotive charging cycles, extending component lifetimes and maintaining optimal operating conditions for GaN and SiC devices used in modern Totem-Pole PFC stages.

Thermal interface materials (TIMs) have also advanced significantly, with metal-based TIMs achieving thermal conductivities exceeding 25 W/m·K, compared to traditional gap fillers at 3-5 W/m·K. This improvement reduces thermal resistance at critical interfaces by up to 40%, directly enhancing the thermal pathway from semiconductor junctions to cooling systems.

Integrated thermal-electrical design approaches have demonstrated efficiency improvements of 0.5-1.2% in Totem-Pole PFC stages by optimizing component placement and thermal pathways. These approaches utilize computational fluid dynamics (CFD) simulations to predict hotspots and optimize cooling channel designs, reducing temperature gradients across power modules.

EMI performance benefits significantly from improved thermal management, as lower operating temperatures reduce parasitic capacitance variations in semiconductor devices. Studies have shown a 3-5 dB reduction in conducted EMI when junction temperatures are maintained below 80°C versus operations at 120°C or higher, directly impacting filter requirements and overall system cost.

Future thermal management solutions are trending toward embedded cooling technologies, where cooling structures are integrated directly into power modules and PCB substrates. These approaches promise to reduce thermal resistance by an additional 30-40% while enabling even higher power densities for next-generation OBC systems utilizing wide-bandgap semiconductors.

Advanced cooling strategies have evolved from simple passive cooling to sophisticated hybrid approaches. Liquid cooling systems offer superior thermal performance for high-power applications, achieving thermal resistances below 0.1°C/W compared to 0.3-0.5°C/W for forced-air solutions. This improvement directly translates to better efficiency by reducing conduction losses in power semiconductors, which increase approximately 0.3% per degree Celsius rise in junction temperature.

Phase-change materials (PCMs) represent an emerging solution for transient thermal management, absorbing heat during peak loads and releasing it during lower power operation. These materials can buffer temperature fluctuations by 15-20°C in typical automotive charging cycles, extending component lifetimes and maintaining optimal operating conditions for GaN and SiC devices used in modern Totem-Pole PFC stages.

Thermal interface materials (TIMs) have also advanced significantly, with metal-based TIMs achieving thermal conductivities exceeding 25 W/m·K, compared to traditional gap fillers at 3-5 W/m·K. This improvement reduces thermal resistance at critical interfaces by up to 40%, directly enhancing the thermal pathway from semiconductor junctions to cooling systems.

Integrated thermal-electrical design approaches have demonstrated efficiency improvements of 0.5-1.2% in Totem-Pole PFC stages by optimizing component placement and thermal pathways. These approaches utilize computational fluid dynamics (CFD) simulations to predict hotspots and optimize cooling channel designs, reducing temperature gradients across power modules.

EMI performance benefits significantly from improved thermal management, as lower operating temperatures reduce parasitic capacitance variations in semiconductor devices. Studies have shown a 3-5 dB reduction in conducted EMI when junction temperatures are maintained below 80°C versus operations at 120°C or higher, directly impacting filter requirements and overall system cost.

Future thermal management solutions are trending toward embedded cooling technologies, where cooling structures are integrated directly into power modules and PCB substrates. These approaches promise to reduce thermal resistance by an additional 30-40% while enabling even higher power densities for next-generation OBC systems utilizing wide-bandgap semiconductors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!