On-Board Charger Isolation: Reinforced Insulation, PD And Aging

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

On-Board Charger Isolation Technology Background and Objectives

On-board charger (OBC) isolation technology has evolved significantly over the past two decades, driven by the rapid growth of electric vehicles (EVs) and hybrid electric vehicles (HEVs). Initially developed as simple power conversion systems in the early 2000s, OBCs have transformed into sophisticated components that must meet stringent safety, efficiency, and reliability requirements. The evolution trajectory shows a clear shift from basic galvanic isolation methods to advanced reinforced insulation techniques that accommodate higher power densities and faster charging capabilities.

The technological progression of OBC isolation systems has been marked by several pivotal developments. The transition from traditional low-frequency transformers to high-frequency isolation barriers represented a significant leap forward, enabling substantial reductions in size and weight while maintaining essential safety features. Subsequently, the integration of wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), has pushed power densities to unprecedented levels while creating new challenges for isolation systems.

Current market trends indicate a growing demand for OBCs with higher power ratings (11-22 kW) for passenger vehicles and even higher ratings for commercial applications. This escalation in power requirements has intensified the focus on isolation technologies that can withstand higher voltages while maintaining long-term reliability under various environmental conditions. The industry is witnessing a convergence of reinforced insulation techniques with advanced partial discharge (PD) detection and prevention methodologies.

The primary objective of this research is to comprehensively analyze the state-of-the-art in OBC isolation technologies, with particular emphasis on reinforced insulation systems, partial discharge phenomena, and aging mechanisms. The investigation aims to identify optimal design approaches that balance safety, reliability, efficiency, and cost-effectiveness while meeting international standards such as IEC 60664, IEC 61851, and UL 2202.

Furthermore, this research seeks to establish a clear understanding of the correlation between isolation design parameters and long-term reliability under typical EV operating conditions. By examining the fundamental physics of insulation aging and partial discharge initiation in the context of OBC applications, the study aims to develop predictive models that can inform next-generation designs with enhanced durability and safety margins.

The ultimate goal is to formulate design guidelines and testing protocols that address the unique challenges of OBC isolation systems, particularly as the industry moves toward higher voltage platforms (800V+) and faster charging capabilities. These guidelines will serve as a foundation for future standardization efforts and technological innovations in the rapidly evolving EV charging infrastructure landscape.

The technological progression of OBC isolation systems has been marked by several pivotal developments. The transition from traditional low-frequency transformers to high-frequency isolation barriers represented a significant leap forward, enabling substantial reductions in size and weight while maintaining essential safety features. Subsequently, the integration of wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), has pushed power densities to unprecedented levels while creating new challenges for isolation systems.

Current market trends indicate a growing demand for OBCs with higher power ratings (11-22 kW) for passenger vehicles and even higher ratings for commercial applications. This escalation in power requirements has intensified the focus on isolation technologies that can withstand higher voltages while maintaining long-term reliability under various environmental conditions. The industry is witnessing a convergence of reinforced insulation techniques with advanced partial discharge (PD) detection and prevention methodologies.

The primary objective of this research is to comprehensively analyze the state-of-the-art in OBC isolation technologies, with particular emphasis on reinforced insulation systems, partial discharge phenomena, and aging mechanisms. The investigation aims to identify optimal design approaches that balance safety, reliability, efficiency, and cost-effectiveness while meeting international standards such as IEC 60664, IEC 61851, and UL 2202.

Furthermore, this research seeks to establish a clear understanding of the correlation between isolation design parameters and long-term reliability under typical EV operating conditions. By examining the fundamental physics of insulation aging and partial discharge initiation in the context of OBC applications, the study aims to develop predictive models that can inform next-generation designs with enhanced durability and safety margins.

The ultimate goal is to formulate design guidelines and testing protocols that address the unique challenges of OBC isolation systems, particularly as the industry moves toward higher voltage platforms (800V+) and faster charging capabilities. These guidelines will serve as a foundation for future standardization efforts and technological innovations in the rapidly evolving EV charging infrastructure landscape.

Market Demand Analysis for EV Charging Safety Solutions

The electric vehicle (EV) market is experiencing unprecedented growth globally, with annual sales projected to reach 14 million units by 2025. This rapid expansion has intensified focus on charging infrastructure safety, particularly regarding on-board chargers (OBCs) which represent a critical interface between high-voltage battery systems and external power sources.

Market research indicates that safety concerns rank among the top three factors influencing consumer EV purchasing decisions. A recent industry survey revealed that 78% of potential EV buyers consider electrical safety features "extremely important" when evaluating vehicle options. This consumer sentiment is driving manufacturers to prioritize advanced isolation technologies in their OBC designs.

The regulatory landscape is simultaneously evolving to address these safety demands. Major automotive markets including the European Union, China, and the United States have implemented or announced stricter standards for electrical isolation in EV charging systems. The UN ECE R100 regulation and updated versions of IEC 61851 specifically address reinforced insulation requirements, creating substantial market pressure for compliant solutions.

Insurance data provides another compelling market indicator. EV models with documented charging-related electrical failures face premium increases averaging 15-20% compared to vehicles with superior safety records. This economic incentive further stimulates demand for robust isolation technologies including advanced partial discharge (PD) detection systems and aging-resistant insulation materials.

The aftermarket segment presents additional opportunities, with the retrofit safety solutions market for existing EVs valued at approximately $1.2 billion globally. This includes diagnostic tools for isolation monitoring and replacement components featuring enhanced insulation properties.

From a geographic perspective, demand patterns show regional variations. European markets demonstrate the highest willingness to pay premium prices for advanced safety features, while the rapidly expanding Chinese market prioritizes cost-effective solutions that meet minimum regulatory requirements. North American consumers fall between these positions, with particular emphasis on long-term reliability and aging resistance.

Industry forecasts project the global market for OBC isolation technologies to grow at a compound annual rate of 24% through 2028, outpacing the overall EV market growth. This acceleration reflects both regulatory pressure and increasing consumer awareness of electrical safety risks.

The service and maintenance sector also contributes to market demand, as diagnostic capabilities for isolation monitoring become essential components of EV service protocols. Fleet operators in particular seek predictive maintenance solutions that can identify insulation degradation before catastrophic failures occur.

Market research indicates that safety concerns rank among the top three factors influencing consumer EV purchasing decisions. A recent industry survey revealed that 78% of potential EV buyers consider electrical safety features "extremely important" when evaluating vehicle options. This consumer sentiment is driving manufacturers to prioritize advanced isolation technologies in their OBC designs.

The regulatory landscape is simultaneously evolving to address these safety demands. Major automotive markets including the European Union, China, and the United States have implemented or announced stricter standards for electrical isolation in EV charging systems. The UN ECE R100 regulation and updated versions of IEC 61851 specifically address reinforced insulation requirements, creating substantial market pressure for compliant solutions.

Insurance data provides another compelling market indicator. EV models with documented charging-related electrical failures face premium increases averaging 15-20% compared to vehicles with superior safety records. This economic incentive further stimulates demand for robust isolation technologies including advanced partial discharge (PD) detection systems and aging-resistant insulation materials.

The aftermarket segment presents additional opportunities, with the retrofit safety solutions market for existing EVs valued at approximately $1.2 billion globally. This includes diagnostic tools for isolation monitoring and replacement components featuring enhanced insulation properties.

From a geographic perspective, demand patterns show regional variations. European markets demonstrate the highest willingness to pay premium prices for advanced safety features, while the rapidly expanding Chinese market prioritizes cost-effective solutions that meet minimum regulatory requirements. North American consumers fall between these positions, with particular emphasis on long-term reliability and aging resistance.

Industry forecasts project the global market for OBC isolation technologies to grow at a compound annual rate of 24% through 2028, outpacing the overall EV market growth. This acceleration reflects both regulatory pressure and increasing consumer awareness of electrical safety risks.

The service and maintenance sector also contributes to market demand, as diagnostic capabilities for isolation monitoring become essential components of EV service protocols. Fleet operators in particular seek predictive maintenance solutions that can identify insulation degradation before catastrophic failures occur.

Current Isolation Technologies and Challenges in OBCs

On-board chargers (OBCs) in electric vehicles currently employ several isolation technologies to ensure safety and reliability. Galvanic isolation remains the predominant approach, implemented through transformers in both conventional and resonant topologies. High-frequency transformers have become standard, offering reduced size and weight while maintaining isolation integrity between high-voltage battery systems and low-voltage vehicle electronics.

Optocouplers represent another widely adopted isolation technology in OBCs, particularly for signal transmission across isolation barriers. These components utilize light for signal transfer, eliminating electrical connections between input and output circuits. Modern optocouplers feature enhanced common-mode transient immunity and longer operational lifespans, addressing historical reliability concerns.

Digital isolators have emerged as alternatives to optocouplers, employing capacitive or magnetic coupling mechanisms. These devices offer superior performance characteristics including faster data rates, lower power consumption, and enhanced reliability in high-temperature automotive environments. Their integration capabilities with other semiconductor components make them increasingly attractive for next-generation OBC designs.

Despite technological advancements, OBC isolation systems face significant challenges. Reinforced insulation requirements demand isolation barriers capable of withstanding voltage levels exceeding 4kV, while maintaining this performance throughout the vehicle's operational lifetime. This presents material science and design challenges, particularly as manufacturers pursue higher power density solutions.

Partial discharge (PD) phenomena represent a critical concern for isolation systems. These localized electrical discharges occur within insulation voids or at interfaces when electric field strength exceeds threshold values. PD activity, while initially minor, progressively degrades insulation materials, potentially leading to catastrophic failure. Detection and mitigation of PD in compact OBC designs remains technically challenging.

Insulation aging constitutes another major challenge. Automotive environments subject isolation materials to extreme temperature cycling, humidity variations, vibration, and electrical stress. These factors accelerate degradation mechanisms including thermal oxidation, moisture absorption, and electrical treeing. Current accelerated life testing protocols may inadequately predict real-world aging patterns, creating uncertainty in lifetime estimations.

Size and weight constraints further complicate isolation design. As vehicle manufacturers demand smaller, lighter OBCs with higher power capabilities, isolation components must maintain safety standards while occupying minimal space. This drives research toward novel materials and integration approaches that can satisfy competing requirements for compactness and isolation integrity.

Optocouplers represent another widely adopted isolation technology in OBCs, particularly for signal transmission across isolation barriers. These components utilize light for signal transfer, eliminating electrical connections between input and output circuits. Modern optocouplers feature enhanced common-mode transient immunity and longer operational lifespans, addressing historical reliability concerns.

Digital isolators have emerged as alternatives to optocouplers, employing capacitive or magnetic coupling mechanisms. These devices offer superior performance characteristics including faster data rates, lower power consumption, and enhanced reliability in high-temperature automotive environments. Their integration capabilities with other semiconductor components make them increasingly attractive for next-generation OBC designs.

Despite technological advancements, OBC isolation systems face significant challenges. Reinforced insulation requirements demand isolation barriers capable of withstanding voltage levels exceeding 4kV, while maintaining this performance throughout the vehicle's operational lifetime. This presents material science and design challenges, particularly as manufacturers pursue higher power density solutions.

Partial discharge (PD) phenomena represent a critical concern for isolation systems. These localized electrical discharges occur within insulation voids or at interfaces when electric field strength exceeds threshold values. PD activity, while initially minor, progressively degrades insulation materials, potentially leading to catastrophic failure. Detection and mitigation of PD in compact OBC designs remains technically challenging.

Insulation aging constitutes another major challenge. Automotive environments subject isolation materials to extreme temperature cycling, humidity variations, vibration, and electrical stress. These factors accelerate degradation mechanisms including thermal oxidation, moisture absorption, and electrical treeing. Current accelerated life testing protocols may inadequately predict real-world aging patterns, creating uncertainty in lifetime estimations.

Size and weight constraints further complicate isolation design. As vehicle manufacturers demand smaller, lighter OBCs with higher power capabilities, isolation components must maintain safety standards while occupying minimal space. This drives research toward novel materials and integration approaches that can satisfy competing requirements for compactness and isolation integrity.

Current Reinforced Insulation and PD Detection Methods

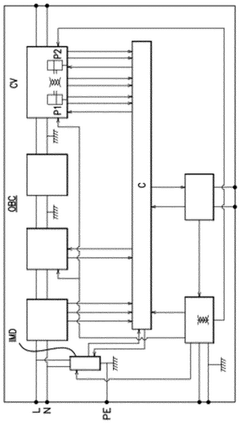

01 Transformer-based isolation for on-board chargers

Transformer-based isolation is a key method for ensuring electrical safety in on-board chargers. These designs use high-frequency transformers to provide galvanic isolation between the AC input and DC output, preventing dangerous current flow between the vehicle's electrical system and the power grid. Advanced transformer designs incorporate features like enhanced insulation materials, optimized winding configurations, and magnetic shielding to improve isolation performance while maintaining high efficiency and compact size.- Transformer-based isolation techniques: Transformer-based isolation is a key method for ensuring electrical isolation in on-board chargers. These designs utilize high-frequency transformers to provide galvanic isolation between the input and output circuits, effectively preventing current leakage while enabling power transfer. Advanced transformer designs incorporate specialized winding techniques, magnetic core materials, and shielding to enhance isolation performance while maintaining high efficiency and reducing electromagnetic interference.

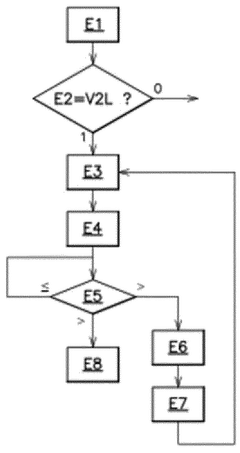

- Insulation monitoring and fault detection systems: On-board chargers incorporate sophisticated insulation monitoring systems to continuously assess isolation integrity and detect potential insulation failures. These systems measure insulation resistance between high-voltage circuits and vehicle chassis, providing real-time monitoring of isolation status. When insulation degradation is detected, the systems can trigger alerts or protective measures such as power reduction or shutdown to prevent safety hazards. Some advanced designs include predictive diagnostics to identify deteriorating insulation before critical failure occurs.

- Multi-layer insulation structures: Multi-layer insulation structures are employed in on-board chargers to enhance isolation reliability. These designs incorporate multiple layers of insulating materials with different electrical and thermal properties to create redundant barriers against voltage breakdown. Common configurations include combinations of air gaps, solid insulators, and specialized coatings. The multi-layer approach provides improved protection against environmental factors such as moisture, temperature fluctuations, and contaminants that could compromise single-layer insulation systems.

- Cooling systems for insulation protection: Thermal management systems are integrated into on-board chargers to protect insulation materials from degradation due to heat. These cooling solutions include liquid cooling channels, heat sinks, thermal interface materials, and forced air systems strategically positioned to dissipate heat from critical insulation components. By maintaining optimal operating temperatures, these systems extend the lifespan of insulation materials and prevent thermal breakdown that could compromise isolation integrity during high-power charging operations.

- PCB layout and creepage distance optimization: Specialized printed circuit board (PCB) design techniques are implemented to maintain isolation in on-board chargers. These include optimized creepage and clearance distances that exceed standard requirements, conformal coatings, and strategic component placement to prevent voltage arcing. Some designs incorporate isolation slots, barriers, and dedicated ground planes to segregate high and low voltage sections. Advanced PCB materials with superior dielectric properties and tracking resistance are selected to enhance long-term isolation reliability under various environmental conditions.

02 Insulation monitoring systems for electric vehicle chargers

Insulation monitoring systems continuously check the integrity of isolation barriers in on-board chargers. These systems detect insulation faults or breakdowns that could compromise safety by measuring resistance between high-voltage components and the vehicle chassis. When insulation degradation is detected, the system can trigger alerts, reduce charging power, or completely disconnect the charging circuit to prevent electrical hazards. Advanced monitoring systems incorporate self-diagnostic capabilities and can differentiate between temporary and permanent insulation failures.Expand Specific Solutions03 Multi-layer insulation structures for high-voltage components

Multi-layer insulation structures provide enhanced protection in on-board chargers by combining different materials with complementary properties. These designs typically include combinations of solid insulators, air gaps, and specialized coatings to achieve the required isolation voltage ratings. The layered approach creates redundancy in the insulation system, ensuring that a failure in one layer doesn't compromise overall safety. Advanced designs incorporate temperature-resistant materials that maintain their insulation properties under the thermal stress experienced during rapid charging cycles.Expand Specific Solutions04 Cooling systems integrated with isolation design

Cooling systems that maintain insulation integrity are critical for on-board charger reliability. These designs address the challenge of removing heat from high-voltage components while maintaining electrical isolation. Solutions include dielectric cooling fluids, thermally conductive but electrically insulating materials, and isolated cooling channels. Advanced systems monitor temperature distribution across isolation barriers to prevent thermal degradation of insulation properties, ensuring long-term reliability even under high-power charging conditions.Expand Specific Solutions05 Digital isolation techniques for control and communication

Digital isolation techniques protect low-voltage control circuits from high-voltage power components in on-board chargers. These methods use optocouplers, capacitive isolators, or magnetic coupling to transmit control signals and data across isolation barriers without compromising safety. Advanced digital isolation solutions provide high-speed communication channels while maintaining isolation integrity, enabling sophisticated control algorithms and diagnostics. These techniques are essential for implementing features like adaptive charging profiles and remote monitoring while ensuring user safety.Expand Specific Solutions

Key Industry Players in OBC Isolation Solutions

The on-board charger isolation technology market is currently in a growth phase, with increasing adoption of electric vehicles driving demand for safer and more reliable charging solutions. The market is projected to expand significantly as automotive manufacturers like BMW, Volkswagen, Toyota, and BYD integrate advanced isolation technologies into their EV platforms. Leading technology providers including Samsung SDI, LG Energy Solution, and ABB E-mobility are developing reinforced insulation systems and partial discharge (PD) detection methods to address aging concerns in isolation materials. The competitive landscape shows automotive OEMs collaborating with specialized power electronics companies like Delta Electronics and Bosch to overcome technical challenges related to high-voltage isolation, thermal management, and long-term reliability in increasingly compact on-board charger designs.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an innovative on-board charger isolation system called "HI-GUARD" (Hyundai Integrated Ground-fault and Undervoltage Active Resistance Detection). This system implements reinforced insulation through a combination of physical barriers and specialized materials that maintain dielectric strength across extreme temperature ranges (-40°C to 105°C). Their OBCs feature double-layer isolation with independent monitoring for each layer, providing redundant protection between high and low voltage circuits. The isolation system incorporates specialized transformers with enhanced creepage distances (>12mm) that exceed automotive safety standards. Hyundai's Power Delivery (PD) system includes continuous isolation monitoring that measures insulation resistance in real-time and can detect degradation trends before safety thresholds are compromised. For aging management, Hyundai employs a comprehensive approach including accelerated life testing that simulates 15+ years of operational conditions with particular focus on thermal cycling and vibration stress. Their predictive maintenance algorithms analyze isolation resistance trends to forecast potential failures before they occur.

Strengths: Exceptional isolation reliability with documented performance after extensive environmental testing, including maintaining isolation integrity after water immersion tests. Their dual-layer monitoring provides redundant protection. Weaknesses: The sophisticated isolation system increases production costs compared to conventional designs, and the complex monitoring systems require additional computational resources that may impact overall efficiency.

BYD Co., Ltd.

Technical Solution: BYD has developed a comprehensive on-board charger isolation system featuring their patented "Blade Isolation" technology. This approach combines physical and electrical isolation methods with specialized high-temperature resistant materials that maintain dielectric strength even under extreme conditions. Their OBCs implement reinforced insulation through a multi-layer approach that exceeds IEC 60664 requirements with creepage distances of >10mm and clearance >8mm between primary and secondary circuits. BYD's Power Delivery (PD) system incorporates dynamic isolation monitoring that continuously measures insulation resistance across the full operating temperature range (-40°C to 85°C). For aging management, BYD employs a three-tier approach: preventive design using materials with minimal degradation characteristics, active monitoring through embedded sensors that track isolation parameters in real-time, and predictive algorithms that analyze trends to forecast potential isolation failures before they occur. Their testing protocols include accelerated aging under combined stress conditions (temperature, humidity, vibration) to validate 10+ year operational life.

Strengths: Superior thermal management that prevents isolation degradation even during rapid charging cycles, with documented isolation resistance stability after 10,000+ charge cycles. Their integrated cell-to-charger design optimizes isolation coordination. Weaknesses: Proprietary isolation technology creates dependency on BYD-specific components, potentially increasing service costs, and the comprehensive monitoring systems add complexity to the overall design.

Critical Patents and Research on OBC Isolation Technologies

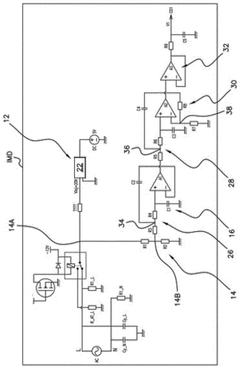

Method for monitoring the insulation of an on-board charger in order to detect an insulation fault between the primary and secondary circuits of a power conversion stage of the charger

PatentWO2025132098A1

Innovation

- A method involving an insulation monitoring device that injects a DC current into a voltage divider, filters out AC components, and compares the resulting voltage signal with a threshold, triggering deactivation of the power conversion stage if an insulation fault is detected.

Safety Standards and Regulatory Requirements for OBCs

On-board chargers (OBCs) in electric vehicles must comply with stringent safety standards and regulatory requirements to ensure user safety and system reliability. The International Electrotechnical Commission (IEC) has established several key standards, including IEC 61851 for electric vehicle charging systems and IEC 62196 for plugs, socket-outlets, and vehicle connectors. These standards define essential safety parameters for isolation, insulation, and protection against electric shock.

In the United States, UL 2202 specifically addresses electric vehicle charging system equipment, while SAE J1772 standardizes the electrical connector interface. The European Union enforces compliance with the Low Voltage Directive (2014/35/EU) and Electromagnetic Compatibility Directive (2014/30/EU), which establish fundamental safety requirements for electrical equipment operating within certain voltage limits.

For reinforced insulation in OBCs, IEC 60664-1 provides guidelines on insulation coordination, specifying clearance and creepage distances based on working voltage, pollution degree, and material group. The standard IEC 60950-1 (being replaced by IEC 62368-1) establishes requirements for double and reinforced insulation in information technology equipment, which has been adapted for automotive applications.

Partial discharge (PD) testing requirements are outlined in IEC 61851-21-2, which mandates specific test procedures to verify the absence of significant partial discharge activity under normal operating conditions. The standard specifies measurement techniques, acceptance criteria, and test voltage levels that OBCs must meet to ensure long-term reliability.

Regarding aging and reliability, automotive-grade components must comply with AEC-Q200 for passive components and AEC-Q100 for integrated circuits. These standards define stress test qualifications that ensure components can withstand harsh automotive environments over the vehicle's lifetime. Additionally, ISO 16750 specifies environmental conditions and testing for electrical and electronic equipment in road vehicles.

China's GB/T 18487 and GB/T 20234 standards govern electric vehicle conductive charging systems and connection requirements, respectively, while Japan follows their own standards set by JARI (Japan Automobile Research Institute) and JSAE (Society of Automotive Engineers of Japan).

The regulatory landscape continues to evolve with the rapid advancement of electric vehicle technology. Recent updates include enhanced requirements for cybersecurity (UN Regulation No. 155) and software updates (UN Regulation No. 156), which indirectly impact OBC design and implementation. Manufacturers must continuously monitor these evolving standards to ensure compliance throughout the product lifecycle.

In the United States, UL 2202 specifically addresses electric vehicle charging system equipment, while SAE J1772 standardizes the electrical connector interface. The European Union enforces compliance with the Low Voltage Directive (2014/35/EU) and Electromagnetic Compatibility Directive (2014/30/EU), which establish fundamental safety requirements for electrical equipment operating within certain voltage limits.

For reinforced insulation in OBCs, IEC 60664-1 provides guidelines on insulation coordination, specifying clearance and creepage distances based on working voltage, pollution degree, and material group. The standard IEC 60950-1 (being replaced by IEC 62368-1) establishes requirements for double and reinforced insulation in information technology equipment, which has been adapted for automotive applications.

Partial discharge (PD) testing requirements are outlined in IEC 61851-21-2, which mandates specific test procedures to verify the absence of significant partial discharge activity under normal operating conditions. The standard specifies measurement techniques, acceptance criteria, and test voltage levels that OBCs must meet to ensure long-term reliability.

Regarding aging and reliability, automotive-grade components must comply with AEC-Q200 for passive components and AEC-Q100 for integrated circuits. These standards define stress test qualifications that ensure components can withstand harsh automotive environments over the vehicle's lifetime. Additionally, ISO 16750 specifies environmental conditions and testing for electrical and electronic equipment in road vehicles.

China's GB/T 18487 and GB/T 20234 standards govern electric vehicle conductive charging systems and connection requirements, respectively, while Japan follows their own standards set by JARI (Japan Automobile Research Institute) and JSAE (Society of Automotive Engineers of Japan).

The regulatory landscape continues to evolve with the rapid advancement of electric vehicle technology. Recent updates include enhanced requirements for cybersecurity (UN Regulation No. 155) and software updates (UN Regulation No. 156), which indirectly impact OBC design and implementation. Manufacturers must continuously monitor these evolving standards to ensure compliance throughout the product lifecycle.

Thermal Management Impact on Isolation Aging Performance

Thermal management plays a critical role in the aging performance of isolation systems within on-board chargers (OBCs). The thermal stress experienced by insulation materials directly impacts their long-term reliability and safety performance. Research indicates that continuous operation at elevated temperatures accelerates the degradation of insulation properties, potentially leading to premature failure of the isolation barrier.

Temperature cycling, a common condition in automotive applications, creates additional mechanical stress on insulation materials due to differential thermal expansion coefficients between conductors and insulation. This cyclical stress can lead to microscopic cracks and delamination at material interfaces, compromising the isolation integrity over time. Studies have shown that the rate of insulation aging approximately doubles for every 10°C increase in operating temperature, following the Arrhenius relationship.

Advanced thermal management strategies have demonstrated significant improvements in isolation longevity. Techniques such as strategic component placement, optimized heat sink design, and the implementation of thermal interface materials with superior conductivity can effectively reduce hotspots within the OBC. Computational fluid dynamics (CFD) simulations have become essential tools for predicting thermal behavior and optimizing cooling solutions before physical prototyping.

The selection of insulation materials with superior thermal stability characteristics represents another critical aspect of thermal management. High-temperature resistant materials such as polyimide, silicon dioxide, and certain ceramic-based insulators exhibit significantly better aging performance under thermal stress compared to conventional options. However, these materials often present trade-offs in terms of cost, processability, and other electrical properties.

Active cooling solutions, including forced air and liquid cooling systems, have shown promising results in maintaining isolation integrity in high-power OBC applications. These systems can maintain insulation materials within their optimal temperature range even under peak load conditions, significantly extending the expected service life of the isolation barrier. However, the additional complexity, weight, and power consumption of active cooling systems must be carefully balanced against the benefits.

Thermal cycling qualification testing has become increasingly important in evaluating isolation aging performance. Accelerated aging tests that simulate years of thermal cycling in compressed timeframes help manufacturers predict long-term reliability. The development of more accurate acceleration factors and test methodologies continues to be an active area of research to better correlate laboratory results with real-world performance.

Temperature cycling, a common condition in automotive applications, creates additional mechanical stress on insulation materials due to differential thermal expansion coefficients between conductors and insulation. This cyclical stress can lead to microscopic cracks and delamination at material interfaces, compromising the isolation integrity over time. Studies have shown that the rate of insulation aging approximately doubles for every 10°C increase in operating temperature, following the Arrhenius relationship.

Advanced thermal management strategies have demonstrated significant improvements in isolation longevity. Techniques such as strategic component placement, optimized heat sink design, and the implementation of thermal interface materials with superior conductivity can effectively reduce hotspots within the OBC. Computational fluid dynamics (CFD) simulations have become essential tools for predicting thermal behavior and optimizing cooling solutions before physical prototyping.

The selection of insulation materials with superior thermal stability characteristics represents another critical aspect of thermal management. High-temperature resistant materials such as polyimide, silicon dioxide, and certain ceramic-based insulators exhibit significantly better aging performance under thermal stress compared to conventional options. However, these materials often present trade-offs in terms of cost, processability, and other electrical properties.

Active cooling solutions, including forced air and liquid cooling systems, have shown promising results in maintaining isolation integrity in high-power OBC applications. These systems can maintain insulation materials within their optimal temperature range even under peak load conditions, significantly extending the expected service life of the isolation barrier. However, the additional complexity, weight, and power consumption of active cooling systems must be carefully balanced against the benefits.

Thermal cycling qualification testing has become increasingly important in evaluating isolation aging performance. Accelerated aging tests that simulate years of thermal cycling in compressed timeframes help manufacturers predict long-term reliability. The development of more accurate acceleration factors and test methodologies continues to be an active area of research to better correlate laboratory results with real-world performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!