On-Board Charger Connectors And Relays: Inrush, Arcing And Lifetime

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EV Charging Connector Technology Background and Objectives

Electric vehicle (EV) charging connector technology has evolved significantly over the past decade, driven by the rapid growth of the electric vehicle market. The development trajectory began with basic conductive charging systems in the early 2000s and has progressed toward more sophisticated solutions that address higher power requirements, safety concerns, and user convenience. This technological evolution reflects the industry's response to increasing consumer demand for faster charging times and greater reliability.

On-board chargers (OBCs) represent a critical component in the EV charging ecosystem, serving as the interface between external power sources and the vehicle's battery system. The connectors and relays within these systems face unique challenges related to electrical stress, thermal management, and mechanical wear. Historical data indicates that early OBC systems suffered from significant reliability issues, with connector failures accounting for approximately 15% of charging-related malfunctions.

The technological progression has been marked by several key milestones, including the introduction of standardized connector types (CCS, CHAdeMO, GB/T), the development of higher voltage systems capable of supporting fast charging, and the integration of advanced safety features. Recent innovations have focused on improving the durability and performance of connectors and relays under extreme conditions, with particular attention to managing inrush currents and minimizing arcing during connection and disconnection events.

Current research objectives in this field center on extending component lifetime while maintaining safety and reliability. Specifically, the industry aims to develop connectors and relays capable of withstanding thousands of charging cycles without degradation, managing peak inrush currents exceeding 100A, and preventing arc formation that can lead to contact erosion and eventual failure. These objectives align with broader industry goals of reducing maintenance requirements and enhancing the overall user experience.

The technical challenges associated with OBC connectors and relays are multifaceted, involving complex interactions between electrical, thermal, and mechanical factors. Inrush current management presents particular difficulties, as the initial connection to charging infrastructure can generate current spikes that stress components and potentially reduce their operational lifespan. Similarly, arcing during disconnection events can cause material transfer between contacts, gradually degrading performance over time.

Looking forward, the industry trajectory points toward integrated solutions that combine advanced materials science, intelligent control systems, and predictive maintenance capabilities. The ultimate goal is to develop OBC connector and relay technologies that deliver seamless, reliable performance throughout the vehicle's operational lifetime while supporting increasingly demanding charging requirements.

On-board chargers (OBCs) represent a critical component in the EV charging ecosystem, serving as the interface between external power sources and the vehicle's battery system. The connectors and relays within these systems face unique challenges related to electrical stress, thermal management, and mechanical wear. Historical data indicates that early OBC systems suffered from significant reliability issues, with connector failures accounting for approximately 15% of charging-related malfunctions.

The technological progression has been marked by several key milestones, including the introduction of standardized connector types (CCS, CHAdeMO, GB/T), the development of higher voltage systems capable of supporting fast charging, and the integration of advanced safety features. Recent innovations have focused on improving the durability and performance of connectors and relays under extreme conditions, with particular attention to managing inrush currents and minimizing arcing during connection and disconnection events.

Current research objectives in this field center on extending component lifetime while maintaining safety and reliability. Specifically, the industry aims to develop connectors and relays capable of withstanding thousands of charging cycles without degradation, managing peak inrush currents exceeding 100A, and preventing arc formation that can lead to contact erosion and eventual failure. These objectives align with broader industry goals of reducing maintenance requirements and enhancing the overall user experience.

The technical challenges associated with OBC connectors and relays are multifaceted, involving complex interactions between electrical, thermal, and mechanical factors. Inrush current management presents particular difficulties, as the initial connection to charging infrastructure can generate current spikes that stress components and potentially reduce their operational lifespan. Similarly, arcing during disconnection events can cause material transfer between contacts, gradually degrading performance over time.

Looking forward, the industry trajectory points toward integrated solutions that combine advanced materials science, intelligent control systems, and predictive maintenance capabilities. The ultimate goal is to develop OBC connector and relay technologies that deliver seamless, reliable performance throughout the vehicle's operational lifetime while supporting increasingly demanding charging requirements.

Market Analysis for On-Board Charger Components

The global market for On-Board Charger (OBC) components is experiencing robust growth, driven primarily by the accelerating adoption of electric vehicles (EVs) worldwide. Current market valuations place the OBC component sector at approximately 2.3 billion USD in 2023, with projections indicating a compound annual growth rate of 16.8% through 2030, potentially reaching 6.7 billion USD by the end of the decade.

Connectors and relays represent critical segments within this market, collectively accounting for about 27% of the total OBC component value chain. These components face increasing demand for higher performance specifications as EV charging capabilities evolve toward higher power ratings and faster charging times.

Regional analysis reveals distinct market characteristics across different territories. Asia-Pacific currently dominates with approximately 45% market share, led by China's aggressive EV adoption policies and manufacturing capabilities. Europe follows at 32%, with particularly strong growth in countries with advanced electrification roadmaps such as Norway, Germany, and the Netherlands. North America represents about 20% of the market, with accelerating growth expected following recent policy initiatives supporting EV infrastructure.

The component supplier landscape is characterized by both specialized manufacturers and diversified electronics companies. Key players in the connector segment include TE Connectivity, Amphenol, and Yazaki, while the relay market is led by companies such as Panasonic, Omron, and Hongfa. These suppliers are increasingly focusing on developing components specifically engineered to address inrush current management, arc suppression, and extended operational lifetimes.

Demand drivers for advanced OBC connectors and relays include the industry-wide push toward higher voltage systems (800V architecture), bidirectional charging capabilities, and the need for components that can withstand more frequent connection/disconnection cycles in various usage scenarios. Vehicle manufacturers are particularly seeking components that can maintain performance integrity while reducing size and weight to optimize overall vehicle design.

Pricing trends indicate moderate pressure on margins as production volumes increase, though this is partially offset by the higher value proposition of advanced components designed specifically for next-generation charging systems. Components with enhanced thermal management, superior arc suppression, and documented longevity testing command premium pricing in the market.

Customer requirements are evolving toward more stringent specifications regarding operational lifetime, with many OEMs now demanding components rated for 10+ years of regular use under varying environmental conditions. This represents a significant engineering challenge for component manufacturers, particularly in managing the trade-offs between durability, performance, and cost.

Connectors and relays represent critical segments within this market, collectively accounting for about 27% of the total OBC component value chain. These components face increasing demand for higher performance specifications as EV charging capabilities evolve toward higher power ratings and faster charging times.

Regional analysis reveals distinct market characteristics across different territories. Asia-Pacific currently dominates with approximately 45% market share, led by China's aggressive EV adoption policies and manufacturing capabilities. Europe follows at 32%, with particularly strong growth in countries with advanced electrification roadmaps such as Norway, Germany, and the Netherlands. North America represents about 20% of the market, with accelerating growth expected following recent policy initiatives supporting EV infrastructure.

The component supplier landscape is characterized by both specialized manufacturers and diversified electronics companies. Key players in the connector segment include TE Connectivity, Amphenol, and Yazaki, while the relay market is led by companies such as Panasonic, Omron, and Hongfa. These suppliers are increasingly focusing on developing components specifically engineered to address inrush current management, arc suppression, and extended operational lifetimes.

Demand drivers for advanced OBC connectors and relays include the industry-wide push toward higher voltage systems (800V architecture), bidirectional charging capabilities, and the need for components that can withstand more frequent connection/disconnection cycles in various usage scenarios. Vehicle manufacturers are particularly seeking components that can maintain performance integrity while reducing size and weight to optimize overall vehicle design.

Pricing trends indicate moderate pressure on margins as production volumes increase, though this is partially offset by the higher value proposition of advanced components designed specifically for next-generation charging systems. Components with enhanced thermal management, superior arc suppression, and documented longevity testing command premium pricing in the market.

Customer requirements are evolving toward more stringent specifications regarding operational lifetime, with many OEMs now demanding components rated for 10+ years of regular use under varying environmental conditions. This represents a significant engineering challenge for component manufacturers, particularly in managing the trade-offs between durability, performance, and cost.

Technical Challenges in Connector and Relay Systems

The electric vehicle (EV) industry faces significant technical challenges in connector and relay systems, particularly for on-board chargers (OBCs). These challenges primarily revolve around managing inrush current, controlling arcing phenomena, and ensuring adequate service lifetime under demanding operational conditions.

Inrush current management presents a formidable challenge as it can reach magnitudes 10-20 times higher than steady-state current during initial connection. This momentary surge creates substantial thermal and mechanical stress on connector contacts and relay mechanisms. The challenge intensifies with higher voltage systems (800V architecture) becoming standard in modern EVs, where peak inrush currents can damage contact surfaces and compromise connection integrity.

Arcing phenomena occur during both connection and disconnection events, particularly problematic in DC charging scenarios. When current-carrying contacts separate, the electrical potential difference can ionize the surrounding air, creating plasma arcs that reach temperatures exceeding 3000°C. These micro-arcs cause progressive material erosion, carbon deposition, and oxidation of contact surfaces. The technical difficulty lies in designing systems that can effectively suppress or redirect these arcs without compromising the connector's primary electrical functions.

Material degradation represents another critical challenge, as connector and relay materials must withstand thousands of connection cycles while exposed to temperature extremes, vibration, and environmental contaminants. Current copper alloys with silver or gold plating show limitations in high-power applications, necessitating research into advanced composite materials and coating technologies.

Miniaturization requirements further complicate these challenges, as OBC systems face continuous pressure for size and weight reduction. Engineers must balance the conflicting demands of compact design with adequate thermal management and electrical clearance requirements. This spatial constraint often limits the implementation of robust arc suppression mechanisms and heat dissipation solutions.

Thermal management presents particular difficulties as connectors and relays in OBC systems must handle current densities that generate significant heat. Inadequate thermal design leads to accelerated aging, increased contact resistance, and potential thermal runaway scenarios. The challenge involves creating effective thermal paths without adding substantial mass or volume to the system.

Standardization issues also persist across the industry, with multiple competing connector designs and communication protocols. This fragmentation complicates the development of universal solutions for inrush current limitation and arc suppression, forcing manufacturers to implement system-specific approaches rather than industry-wide standards.

Inrush current management presents a formidable challenge as it can reach magnitudes 10-20 times higher than steady-state current during initial connection. This momentary surge creates substantial thermal and mechanical stress on connector contacts and relay mechanisms. The challenge intensifies with higher voltage systems (800V architecture) becoming standard in modern EVs, where peak inrush currents can damage contact surfaces and compromise connection integrity.

Arcing phenomena occur during both connection and disconnection events, particularly problematic in DC charging scenarios. When current-carrying contacts separate, the electrical potential difference can ionize the surrounding air, creating plasma arcs that reach temperatures exceeding 3000°C. These micro-arcs cause progressive material erosion, carbon deposition, and oxidation of contact surfaces. The technical difficulty lies in designing systems that can effectively suppress or redirect these arcs without compromising the connector's primary electrical functions.

Material degradation represents another critical challenge, as connector and relay materials must withstand thousands of connection cycles while exposed to temperature extremes, vibration, and environmental contaminants. Current copper alloys with silver or gold plating show limitations in high-power applications, necessitating research into advanced composite materials and coating technologies.

Miniaturization requirements further complicate these challenges, as OBC systems face continuous pressure for size and weight reduction. Engineers must balance the conflicting demands of compact design with adequate thermal management and electrical clearance requirements. This spatial constraint often limits the implementation of robust arc suppression mechanisms and heat dissipation solutions.

Thermal management presents particular difficulties as connectors and relays in OBC systems must handle current densities that generate significant heat. Inadequate thermal design leads to accelerated aging, increased contact resistance, and potential thermal runaway scenarios. The challenge involves creating effective thermal paths without adding substantial mass or volume to the system.

Standardization issues also persist across the industry, with multiple competing connector designs and communication protocols. This fragmentation complicates the development of universal solutions for inrush current limitation and arc suppression, forcing manufacturers to implement system-specific approaches rather than industry-wide standards.

Current Solutions for Inrush Current and Arc Management

01 Inrush current protection mechanisms for on-board chargers

Various protection mechanisms are implemented in on-board chargers to mitigate inrush current during connection and operation. These include soft-start circuits, current limiting resistors, and specialized control algorithms that gradually increase power flow. These mechanisms help prevent damage to connectors and relays by reducing the initial current surge when the charger is connected to a power source or when the vehicle begins charging.- Inrush current mitigation techniques for on-board chargers: Various techniques are employed to mitigate inrush currents in on-board charger systems, which can damage connectors and relays. These include pre-charge circuits, soft-start mechanisms, and current limiting resistors that gradually charge capacitors before full power is applied. Such approaches help prevent voltage spikes and extend the lifetime of charging components by reducing thermal stress during connection events.

- Arc prevention and suppression in charging connectors: Arcing between charging connectors can significantly reduce component lifetime and pose safety hazards. Advanced designs incorporate arc suppression technologies such as snubber circuits, specialized contact materials, and optimized contact geometries. Some systems implement make-before-break connections or utilize electronic switching to ensure current is minimized before physical disconnection occurs, thereby reducing arc formation and extending connector lifespan.

- Relay design and materials for extended lifetime: Specialized relay designs for on-board chargers focus on materials and structures that withstand repeated high-current switching operations. These include silver-cadmium oxide or silver-tin oxide contact materials that resist welding and erosion, hermetically sealed environments to prevent oxidation, and mechanical designs that ensure proper contact pressure. Some relays incorporate temperature compensation mechanisms to maintain consistent performance across operating conditions.

- Thermal management systems for charging components: Effective thermal management is crucial for extending the lifetime of on-board charger connectors and relays. Solutions include active cooling systems with liquid or forced air, thermally conductive materials to dissipate heat, temperature sensors for real-time monitoring, and intelligent power management algorithms that adjust charging rates based on component temperatures. These approaches prevent thermal degradation of connector materials and relay contacts.

- Diagnostic and protection systems for charging infrastructure: Advanced diagnostic and protection systems monitor the health and performance of on-board charger connectors and relays. These include real-time impedance monitoring to detect degradation, fault detection algorithms that identify abnormal operating conditions, isolation monitoring for safety, and predictive maintenance capabilities. Some systems implement automatic shutdown mechanisms when dangerous conditions are detected, preventing catastrophic failures and extending component lifetime.

02 Relay design and materials for extended lifetime in charging applications

Advanced relay designs incorporate specialized materials and contact configurations to withstand the repeated high-current switching operations in electric vehicle charging systems. These designs feature arc-resistant contact materials, optimized contact geometry, and enhanced thermal management to dissipate heat effectively. Some relays also incorporate mechanical reinforcement to maintain proper contact pressure over thousands of cycles, significantly extending operational lifetime in charging applications.Expand Specific Solutions03 Arc suppression techniques for charging connectors

Various arc suppression techniques are employed in charging connectors to minimize arcing during connection and disconnection events. These include snubber circuits with capacitors and resistors to absorb energy during switching, zero-crossing detection for timing relay operations, and specialized contact materials that resist arc-induced damage. Some designs incorporate mechanical features that ensure rapid make-or-break connections to minimize the duration of any potential arcing.Expand Specific Solutions04 Thermal management solutions for connector reliability

Effective thermal management is crucial for maintaining connector and relay reliability in on-board charging systems. Solutions include active cooling systems, heat-dissipating materials, and thermal sensors integrated into connector assemblies. Advanced designs feature optimized current paths to minimize resistance heating and incorporate materials with superior thermal conductivity. These thermal management approaches help prevent overheating that can lead to premature connector and relay failure.Expand Specific Solutions05 Diagnostic and monitoring systems for connector health

Sophisticated diagnostic and monitoring systems are implemented to track the health and performance of charging connectors and relays. These systems monitor parameters such as contact resistance, temperature, and switching performance to detect early signs of degradation. Some designs incorporate predictive maintenance algorithms that analyze trends in these parameters to forecast potential failures before they occur, allowing for scheduled maintenance rather than emergency repairs.Expand Specific Solutions

Key Industry Players in Automotive Charging Components

The On-Board Charger (OBC) connectors and relays market is currently in a growth phase, driven by the expanding electric vehicle (EV) industry. The market is projected to reach significant scale as global EV adoption accelerates, with particular focus on improving component reliability and longevity. Leading automotive manufacturers like Porsche, Toyota, and BYD are investing heavily in advanced OBC technologies, while specialized component suppliers such as Schaltbau, Arc Suppression Technologies, and ABB E-mobility are developing innovative solutions addressing inrush current management and arc suppression. Tier-1 suppliers including Bosch, Lear, and Vitesco Technologies have achieved moderate technical maturity in this space, though challenges remain in extending connector and relay lifetimes under high-voltage, high-current conditions typical in modern EV charging systems.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced on-board charger (OBC) connector systems with integrated arc detection and suppression technology. Their solution employs a combination of mechanical and electronic approaches to manage inrush current and arcing. The system features pre-insertion detection circuits that monitor connection status before full power engagement, allowing controlled ramp-up of current to minimize inrush effects. For arc suppression, Bosch implements specialized contact materials with high thermal conductivity and erosion resistance, coupled with electronic monitoring that can detect arc formation within microseconds. Their relay designs incorporate silver-tin oxide composites with tungsten additives that significantly extend contact life under high-current switching conditions. Bosch's technology also includes predictive maintenance capabilities through continuous monitoring of contact resistance changes over time, enabling early identification of potential failure points before they impact charging performance.

Strengths: Comprehensive integration with vehicle systems, excellent reliability metrics with demonstrated 100,000+ cycle durability, and advanced diagnostic capabilities. Weaknesses: Higher cost implementation compared to standard solutions, requires sophisticated control electronics, and may have compatibility limitations with some older charging infrastructure.

Schaltbau GmbH

Technical Solution: Schaltbau has developed specialized DC switching technology specifically optimized for electric vehicle charging applications. Their connector and relay systems feature patented bi-directional arc quenching chambers that effectively contain and extinguish arcs through controlled magnetic field manipulation. This technology directs the arc into a series of splitter plates that divide and cool it, reducing contact erosion by up to 80% compared to conventional designs. For inrush current management, Schaltbau implements pre-charging circuits with precise timing control that limits initial current flow to predetermined safe levels before engaging main contacts. Their connector designs utilize silver-tungsten composite materials with optimized contact geometry that maintains consistent contact pressure throughout thermal cycling. Schaltbau's relays incorporate permanent magnet blow-out systems that accelerate arc extinction, particularly effective in high-voltage DC applications typical in modern electric vehicles. Their testing protocols simulate accelerated aging under extreme conditions, validating performance for over 100,000 operation cycles while maintaining contact resistance within tight tolerances.

Strengths: Exceptional performance in high-voltage DC switching applications, proven reliability in harsh environmental conditions, and compact design optimized for space-constrained vehicle integration. Weaknesses: Higher manufacturing complexity leading to increased unit costs, requires specific mounting orientations for optimal arc quenching performance, and limited compatibility with some charging protocols.

Critical Patents in Connector and Relay Durability

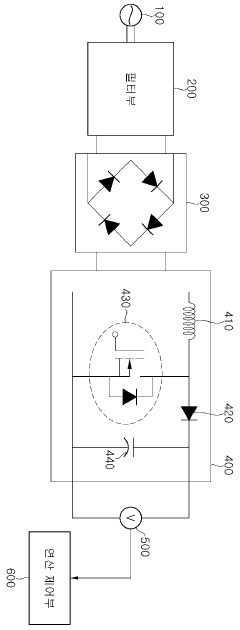

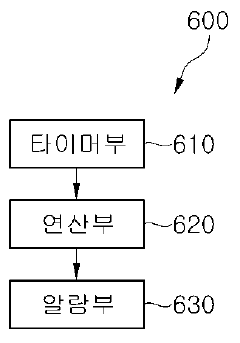

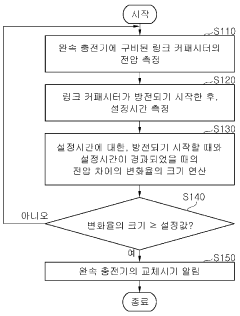

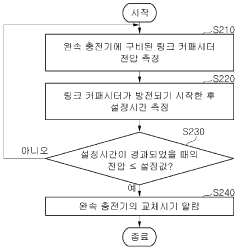

Life expecting system of on board charger and life expecting method thereof

PatentActiveKR1020140134024A

Innovation

- A system and method that includes a voltage measurement unit, a timer unit, a calculation unit, and an alarm unit to monitor the voltage of the link capacitor, calculating the voltage change rate or comparing the voltage to a set value, and generating an alarm when the capacitor needs replacement.

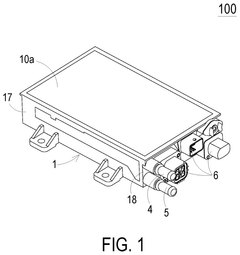

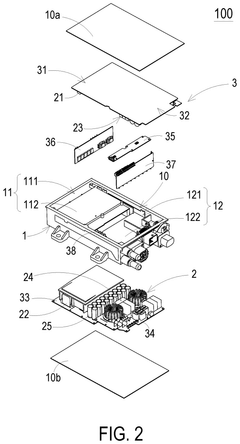

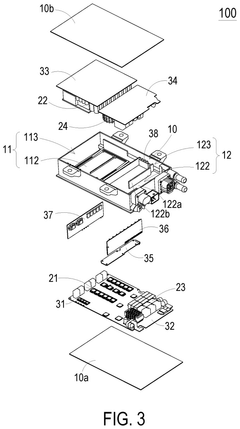

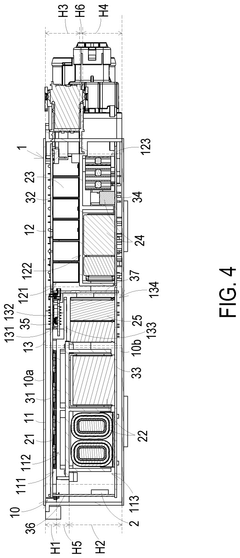

On-board charger

PatentPendingUS20240407081A1

Innovation

- The design incorporates a housing with a multi-layer structure for electronic components and fluid channels, allowing for efficient heat dissipation and compact layout, with fluid channels integrated into the sidewalls to reduce width and enhance power density.

Safety Standards and Compliance Requirements

Safety standards and compliance requirements for on-board charger connectors and relays are critical to ensure the safe operation of electric vehicle charging systems. These standards address the specific challenges of inrush current management, arc prevention, and component lifetime reliability. The International Electrotechnical Commission (IEC) has established IEC 61851 as the primary standard governing EV charging equipment, with specific provisions for connector design and safety mechanisms.

For connectors, the UL 2251 and IEC 62196 standards define rigorous testing protocols that simulate extreme operating conditions, including temperature cycling, moisture exposure, and mechanical stress. These standards mandate that connectors must withstand a minimum of 10,000 connection/disconnection cycles while maintaining electrical integrity. Additionally, SAE J1772 in North America and GB/T 20234 in China establish region-specific requirements for connector design, focusing on arc prevention during connection and disconnection events.

Relay safety standards, including IEC 61810 and UL 508, specify performance requirements under inrush current conditions. These standards require relays in on-board chargers to withstand inrush currents up to 10 times their nominal rating without contact welding or significant degradation. The IEC 60947 standard specifically addresses the arc extinguishing capabilities of relays, mandating minimum performance levels for breaking capacity under various load conditions.

Electromagnetic compatibility (EMC) requirements, governed by IEC 61000 series standards, ensure that connectors and relays do not generate electromagnetic interference that could affect vehicle systems or nearby electronic devices. These standards establish limits for conducted and radiated emissions during normal operation and switching events.

Temperature rise limitations are another critical aspect of safety standards. UL 2202 specifies that temperature increases at connection points must not exceed 30°C above ambient temperature under maximum rated current. This requirement helps prevent thermal degradation of insulating materials and reduces fire risks associated with overheating.

Ingress protection standards (IEC 60529) define the required environmental protection levels for connectors and relays. For on-board chargers, a minimum rating of IP67 is typically required for connectors exposed to external environments, ensuring protection against dust and temporary immersion in water.

Compliance with these standards is verified through rigorous testing procedures, including accelerated aging tests, high-potential insulation tests, and thermal cycling. Certification bodies such as UL, TÜV, and CQC conduct independent verification to ensure products meet all applicable requirements before market approval.

For connectors, the UL 2251 and IEC 62196 standards define rigorous testing protocols that simulate extreme operating conditions, including temperature cycling, moisture exposure, and mechanical stress. These standards mandate that connectors must withstand a minimum of 10,000 connection/disconnection cycles while maintaining electrical integrity. Additionally, SAE J1772 in North America and GB/T 20234 in China establish region-specific requirements for connector design, focusing on arc prevention during connection and disconnection events.

Relay safety standards, including IEC 61810 and UL 508, specify performance requirements under inrush current conditions. These standards require relays in on-board chargers to withstand inrush currents up to 10 times their nominal rating without contact welding or significant degradation. The IEC 60947 standard specifically addresses the arc extinguishing capabilities of relays, mandating minimum performance levels for breaking capacity under various load conditions.

Electromagnetic compatibility (EMC) requirements, governed by IEC 61000 series standards, ensure that connectors and relays do not generate electromagnetic interference that could affect vehicle systems or nearby electronic devices. These standards establish limits for conducted and radiated emissions during normal operation and switching events.

Temperature rise limitations are another critical aspect of safety standards. UL 2202 specifies that temperature increases at connection points must not exceed 30°C above ambient temperature under maximum rated current. This requirement helps prevent thermal degradation of insulating materials and reduces fire risks associated with overheating.

Ingress protection standards (IEC 60529) define the required environmental protection levels for connectors and relays. For on-board chargers, a minimum rating of IP67 is typically required for connectors exposed to external environments, ensuring protection against dust and temporary immersion in water.

Compliance with these standards is verified through rigorous testing procedures, including accelerated aging tests, high-potential insulation tests, and thermal cycling. Certification bodies such as UL, TÜV, and CQC conduct independent verification to ensure products meet all applicable requirements before market approval.

Thermal Management Strategies for High-Power Connections

Thermal management is a critical aspect of on-board charger (OBC) connector and relay design, particularly when dealing with high-power connections that experience significant current flow. As electric vehicle charging power levels continue to increase, from 3.3kW to now commonly 11kW or even 22kW for residential applications, the thermal challenges have grown exponentially.

The primary heat generation mechanisms in connectors and relays stem from contact resistance, which follows Joule's heating principle where power dissipation equals I²R. During inrush current events, which can reach 3-5 times nominal current levels, momentary temperature spikes occur that accelerate degradation of contact materials and surrounding insulation components.

Advanced thermal management strategies employ multiple approaches working in concert. Material selection represents the foundation, with copper alloys containing small percentages of chromium, zirconium, or beryllium offering superior conductivity while maintaining mechanical strength at elevated temperatures. Silver or gold plating further reduces contact resistance while providing oxidation resistance.

Geometric optimization of contact surfaces has evolved significantly, with manufacturers implementing multi-point contact designs that distribute current more evenly and increase effective contact area. Finite element analysis has enabled precise modeling of current density distribution, allowing designers to eliminate hotspots that previously led to premature failure.

Active cooling solutions are increasingly being integrated into high-power OBC systems. These range from thermally conductive potting compounds that efficiently transfer heat to the connector housing, to more sophisticated forced-air cooling channels. Some premium electric vehicle models now incorporate liquid cooling loops that extend to the charging interface components.

Temperature monitoring has become standard practice, with embedded thermistors providing real-time feedback to the battery management system. This enables dynamic current limiting algorithms that can reduce charging rates when thermal thresholds are approached, protecting components while maximizing charging speed under favorable conditions.

Thermal cycling presents a particular challenge for connection reliability. The repeated expansion and contraction of materials with different thermal coefficients creates micro-movement at contact interfaces, potentially leading to fretting corrosion. Advanced connector designs now incorporate floating contact mechanisms with calibrated spring pressure maintenance across the operational temperature range.

These thermal management strategies collectively contribute to extending connector and relay lifetime, with modern designs targeting 10,000+ connection cycles and relay operations while maintaining performance within specification throughout the vehicle's service life.

The primary heat generation mechanisms in connectors and relays stem from contact resistance, which follows Joule's heating principle where power dissipation equals I²R. During inrush current events, which can reach 3-5 times nominal current levels, momentary temperature spikes occur that accelerate degradation of contact materials and surrounding insulation components.

Advanced thermal management strategies employ multiple approaches working in concert. Material selection represents the foundation, with copper alloys containing small percentages of chromium, zirconium, or beryllium offering superior conductivity while maintaining mechanical strength at elevated temperatures. Silver or gold plating further reduces contact resistance while providing oxidation resistance.

Geometric optimization of contact surfaces has evolved significantly, with manufacturers implementing multi-point contact designs that distribute current more evenly and increase effective contact area. Finite element analysis has enabled precise modeling of current density distribution, allowing designers to eliminate hotspots that previously led to premature failure.

Active cooling solutions are increasingly being integrated into high-power OBC systems. These range from thermally conductive potting compounds that efficiently transfer heat to the connector housing, to more sophisticated forced-air cooling channels. Some premium electric vehicle models now incorporate liquid cooling loops that extend to the charging interface components.

Temperature monitoring has become standard practice, with embedded thermistors providing real-time feedback to the battery management system. This enables dynamic current limiting algorithms that can reduce charging rates when thermal thresholds are approached, protecting components while maximizing charging speed under favorable conditions.

Thermal cycling presents a particular challenge for connection reliability. The repeated expansion and contraction of materials with different thermal coefficients creates micro-movement at contact interfaces, potentially leading to fretting corrosion. Advanced connector designs now incorporate floating contact mechanisms with calibrated spring pressure maintenance across the operational temperature range.

These thermal management strategies collectively contribute to extending connector and relay lifetime, with modern designs targeting 10,000+ connection cycles and relay operations while maintaining performance within specification throughout the vehicle's service life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!