Optimizing Luteolin Bioavailability in Nanocapsules

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Luteolin Nanocapsule Technology Background and Objectives

Luteolin, a naturally occurring flavonoid found in various fruits, vegetables, and medicinal herbs, has garnered significant attention in recent years due to its diverse pharmacological properties. These include anti-inflammatory, antioxidant, anti-cancer, and neuroprotective effects. Despite these promising therapeutic potentials, the clinical application of luteolin faces a critical challenge: its poor bioavailability. This limitation stems from luteolin's low aqueous solubility, rapid metabolism, and extensive first-pass effect, resulting in minimal absorption and limited efficacy when administered conventionally.

The evolution of nanotechnology has opened new avenues for addressing bioavailability challenges in pharmaceutical compounds. Nanocapsules, specifically, represent a cutting-edge approach to drug delivery systems that can potentially revolutionize luteolin administration. These nano-sized vesicular systems consist of a polymeric membrane surrounding an oil or aqueous core where the active compound is dissolved or dispersed.

Historical developments in nanocapsule technology began in the 1970s with pioneering work on liposomes, followed by polymeric nanoparticles in the 1980s. The field has since expanded to include various types of nanocapsules with enhanced stability, targeting capabilities, and controlled release properties. Recent advancements in materials science and formulation techniques have further refined nanocapsule design, enabling more precise control over drug release kinetics and targeting specificity.

For luteolin specifically, nanocapsule technology has progressed from simple encapsulation methods to sophisticated systems incorporating surface modifications and stimuli-responsive elements. Early attempts focused primarily on improving solubility, while current research aims to optimize multiple parameters simultaneously: enhancing bioavailability, protecting against degradation, enabling targeted delivery, and controlling release profiles.

The primary technical objectives for optimizing luteolin bioavailability in nanocapsules include: increasing luteolin loading capacity within nanocapsules; enhancing stability during storage and in physiological conditions; improving intestinal absorption and cellular uptake; reducing systemic clearance; and enabling site-specific delivery to target tissues. Additionally, developing scalable and reproducible manufacturing processes represents a critical goal for translating laboratory success to clinical applications.

Future technological trajectories point toward smart nanocapsule systems capable of responding to biological cues, crossing biological barriers more effectively, and achieving precise spatiotemporal control over luteolin release. Integration with emerging technologies such as 3D printing, microfluidics, and artificial intelligence for formulation optimization presents exciting possibilities for next-generation luteolin delivery systems that could overcome current bioavailability limitations and maximize therapeutic efficacy.

The evolution of nanotechnology has opened new avenues for addressing bioavailability challenges in pharmaceutical compounds. Nanocapsules, specifically, represent a cutting-edge approach to drug delivery systems that can potentially revolutionize luteolin administration. These nano-sized vesicular systems consist of a polymeric membrane surrounding an oil or aqueous core where the active compound is dissolved or dispersed.

Historical developments in nanocapsule technology began in the 1970s with pioneering work on liposomes, followed by polymeric nanoparticles in the 1980s. The field has since expanded to include various types of nanocapsules with enhanced stability, targeting capabilities, and controlled release properties. Recent advancements in materials science and formulation techniques have further refined nanocapsule design, enabling more precise control over drug release kinetics and targeting specificity.

For luteolin specifically, nanocapsule technology has progressed from simple encapsulation methods to sophisticated systems incorporating surface modifications and stimuli-responsive elements. Early attempts focused primarily on improving solubility, while current research aims to optimize multiple parameters simultaneously: enhancing bioavailability, protecting against degradation, enabling targeted delivery, and controlling release profiles.

The primary technical objectives for optimizing luteolin bioavailability in nanocapsules include: increasing luteolin loading capacity within nanocapsules; enhancing stability during storage and in physiological conditions; improving intestinal absorption and cellular uptake; reducing systemic clearance; and enabling site-specific delivery to target tissues. Additionally, developing scalable and reproducible manufacturing processes represents a critical goal for translating laboratory success to clinical applications.

Future technological trajectories point toward smart nanocapsule systems capable of responding to biological cues, crossing biological barriers more effectively, and achieving precise spatiotemporal control over luteolin release. Integration with emerging technologies such as 3D printing, microfluidics, and artificial intelligence for formulation optimization presents exciting possibilities for next-generation luteolin delivery systems that could overcome current bioavailability limitations and maximize therapeutic efficacy.

Market Analysis for Bioavailable Luteolin Products

The global market for luteolin-based products has been experiencing significant growth, driven by increasing consumer awareness of its health benefits and the rising demand for natural bioactive compounds. The current market size for flavonoid-based nutraceuticals, including luteolin products, is estimated at $5.2 billion globally, with a compound annual growth rate of 7.8% projected through 2028. Luteolin-specific products currently represent approximately $890 million of this market, with enhanced bioavailability formulations commanding premium pricing.

Consumer demand for luteolin products is primarily concentrated in three major segments: dietary supplements, functional foods, and pharmaceutical applications. The dietary supplement sector dominates with 62% market share, followed by functional foods at 27% and pharmaceutical applications at 11%. This distribution reflects the current positioning of luteolin primarily as a wellness product rather than a therapeutic agent, despite its significant potential in disease prevention and treatment.

Regional analysis reveals that North America leads the market with 38% share, followed by Europe (29%), Asia-Pacific (24%), and rest of the world (9%). The Asia-Pacific region is expected to show the fastest growth rate of 9.6% annually, driven by traditional medicine practices and increasing health consciousness among the growing middle class in China, Japan, and South Korea.

Key market drivers include growing scientific evidence supporting luteolin's anti-inflammatory, antioxidant, and anti-cancer properties, alongside increasing consumer preference for plant-based health solutions. The aging global population and rising incidence of chronic diseases further fuel demand for preventive health products containing bioactive compounds like luteolin.

Market challenges primarily center around bioavailability limitations, which nanocapsule technology directly addresses. Traditional luteolin supplements exhibit poor absorption rates of 5-10%, significantly limiting their therapeutic potential. Products with enhanced bioavailability command price premiums of 40-85% over conventional formulations, indicating strong market willingness to pay for improved efficacy.

Consumer segmentation shows three distinct buyer groups: health-conscious preventive users (52%), condition-specific therapeutic users (31%), and performance-oriented athletic users (17%). Each segment demonstrates different price sensitivity and efficacy expectations, with therapeutic users showing the highest willingness to pay for bioavailability-enhanced formulations.

Market forecasts indicate that bioavailability-enhanced luteolin products could capture 38% of the total luteolin market by 2027, representing a significant opportunity for nanocapsule technology adoption. The projected value of this specific segment is expected to reach $520 million by 2027, with pharmaceutical applications showing the highest growth potential at 14.2% annually.

Consumer demand for luteolin products is primarily concentrated in three major segments: dietary supplements, functional foods, and pharmaceutical applications. The dietary supplement sector dominates with 62% market share, followed by functional foods at 27% and pharmaceutical applications at 11%. This distribution reflects the current positioning of luteolin primarily as a wellness product rather than a therapeutic agent, despite its significant potential in disease prevention and treatment.

Regional analysis reveals that North America leads the market with 38% share, followed by Europe (29%), Asia-Pacific (24%), and rest of the world (9%). The Asia-Pacific region is expected to show the fastest growth rate of 9.6% annually, driven by traditional medicine practices and increasing health consciousness among the growing middle class in China, Japan, and South Korea.

Key market drivers include growing scientific evidence supporting luteolin's anti-inflammatory, antioxidant, and anti-cancer properties, alongside increasing consumer preference for plant-based health solutions. The aging global population and rising incidence of chronic diseases further fuel demand for preventive health products containing bioactive compounds like luteolin.

Market challenges primarily center around bioavailability limitations, which nanocapsule technology directly addresses. Traditional luteolin supplements exhibit poor absorption rates of 5-10%, significantly limiting their therapeutic potential. Products with enhanced bioavailability command price premiums of 40-85% over conventional formulations, indicating strong market willingness to pay for improved efficacy.

Consumer segmentation shows three distinct buyer groups: health-conscious preventive users (52%), condition-specific therapeutic users (31%), and performance-oriented athletic users (17%). Each segment demonstrates different price sensitivity and efficacy expectations, with therapeutic users showing the highest willingness to pay for bioavailability-enhanced formulations.

Market forecasts indicate that bioavailability-enhanced luteolin products could capture 38% of the total luteolin market by 2027, representing a significant opportunity for nanocapsule technology adoption. The projected value of this specific segment is expected to reach $520 million by 2027, with pharmaceutical applications showing the highest growth potential at 14.2% annually.

Current Challenges in Luteolin Bioavailability Enhancement

Despite the promising therapeutic potential of luteolin, a natural flavonoid with anti-inflammatory, antioxidant, and anticancer properties, its clinical application faces significant bioavailability challenges. The primary obstacle lies in luteolin's poor water solubility (less than 0.1 mg/mL), which severely limits its absorption in the gastrointestinal tract. This hydrophobic nature results in minimal systemic circulation, with bioavailability estimates below 5% in most clinical studies.

Metabolic instability presents another major challenge. Upon oral administration, luteolin undergoes extensive first-pass metabolism in the liver, where it is rapidly conjugated through glucuronidation and sulfation processes. These metabolic transformations significantly reduce the concentration of bioactive luteolin reaching target tissues, diminishing its therapeutic efficacy.

The compound's chemical structure, while responsible for its beneficial properties, contributes to its instability under physiological conditions. Luteolin is particularly susceptible to oxidation and degradation in the presence of light, heat, and certain pH environments found in the digestive system. This instability further compromises its bioavailability profile and shelf-life in pharmaceutical formulations.

Current nanocapsule delivery systems for luteolin face technical limitations that hinder optimal bioavailability. Conventional polymeric nanocapsules often demonstrate inadequate encapsulation efficiency, typically ranging from 45-70%, resulting in significant drug wastage during formulation. Additionally, many existing nanocapsule formulations exhibit premature release profiles in gastrointestinal conditions, releasing up to 60% of their payload before reaching absorption sites.

Scale-up manufacturing of luteolin nanocapsules presents considerable challenges. Batch-to-batch variability in particle size distribution (often exceeding 15% variation) and encapsulation efficiency compromises product consistency. Current production methods typically yield limited quantities suitable for laboratory research but insufficient for clinical application or commercial production.

Regulatory hurdles further complicate advancement in this field. The complex nature of nanocapsule formulations requires extensive characterization and stability studies to meet regulatory standards. Many current formulations lack comprehensive toxicological profiles, particularly regarding the long-term effects of nanomaterials used in the delivery system.

The cost-effectiveness of current approaches remains questionable. High-grade luteolin extraction and purification processes are expensive, and when combined with sophisticated nanocapsule formulation technologies, the resulting product often becomes economically unviable for widespread clinical application or commercialization.

Metabolic instability presents another major challenge. Upon oral administration, luteolin undergoes extensive first-pass metabolism in the liver, where it is rapidly conjugated through glucuronidation and sulfation processes. These metabolic transformations significantly reduce the concentration of bioactive luteolin reaching target tissues, diminishing its therapeutic efficacy.

The compound's chemical structure, while responsible for its beneficial properties, contributes to its instability under physiological conditions. Luteolin is particularly susceptible to oxidation and degradation in the presence of light, heat, and certain pH environments found in the digestive system. This instability further compromises its bioavailability profile and shelf-life in pharmaceutical formulations.

Current nanocapsule delivery systems for luteolin face technical limitations that hinder optimal bioavailability. Conventional polymeric nanocapsules often demonstrate inadequate encapsulation efficiency, typically ranging from 45-70%, resulting in significant drug wastage during formulation. Additionally, many existing nanocapsule formulations exhibit premature release profiles in gastrointestinal conditions, releasing up to 60% of their payload before reaching absorption sites.

Scale-up manufacturing of luteolin nanocapsules presents considerable challenges. Batch-to-batch variability in particle size distribution (often exceeding 15% variation) and encapsulation efficiency compromises product consistency. Current production methods typically yield limited quantities suitable for laboratory research but insufficient for clinical application or commercial production.

Regulatory hurdles further complicate advancement in this field. The complex nature of nanocapsule formulations requires extensive characterization and stability studies to meet regulatory standards. Many current formulations lack comprehensive toxicological profiles, particularly regarding the long-term effects of nanomaterials used in the delivery system.

The cost-effectiveness of current approaches remains questionable. High-grade luteolin extraction and purification processes are expensive, and when combined with sophisticated nanocapsule formulation technologies, the resulting product often becomes economically unviable for widespread clinical application or commercialization.

Current Nanocapsule Formulation Approaches for Luteolin

01 Nanocapsule formulations enhancing luteolin bioavailability

Nanocapsule formulations can significantly enhance the bioavailability of luteolin by improving its solubility and absorption in the gastrointestinal tract. These formulations typically involve encapsulating luteolin within nano-sized carriers that protect it from degradation and facilitate its transport across biological membranes. The small size of nanocapsules increases the surface area available for absorption, leading to improved bioavailability compared to conventional formulations.- Nanocapsule formulation techniques for luteolin: Various techniques are employed to formulate luteolin into nanocapsules, including polymer-based encapsulation, lipid-based nanocarriers, and specialized coating methods. These formulation approaches help protect luteolin from degradation in the gastrointestinal tract and control its release profile. The nanocapsule size, surface properties, and composition are optimized to enhance stability and improve the overall bioavailability of luteolin.

- Surface modification of luteolin nanocapsules: Surface modification strategies for luteolin nanocapsules involve coating with specific polymers, attaching targeting ligands, or altering surface charge to improve their pharmacokinetic profile. These modifications enhance mucoadhesion, cellular uptake, and tissue penetration of the nanocapsules. By optimizing surface properties, the bioavailability of luteolin can be significantly increased through prolonged circulation time and targeted delivery to specific tissues.

- Bioavailability enhancement mechanisms for luteolin: Several mechanisms are employed to enhance luteolin bioavailability, including particle size reduction to nanoscale, solubility enhancement through complexation, and permeation enhancement across biological membranes. The nanocapsule formulations protect luteolin from first-pass metabolism and enzymatic degradation while facilitating controlled release at target sites. These mechanisms collectively contribute to improved absorption and higher systemic exposure of luteolin.

- Novel carrier systems for luteolin delivery: Innovative carrier systems for luteolin delivery include lipid-polymer hybrid nanocapsules, stimuli-responsive nanocarriers, and biomimetic delivery systems. These advanced carriers offer advantages such as improved stability, enhanced cellular uptake, and targeted release of luteolin. The novel delivery systems are designed to overcome biological barriers and enhance the bioavailability of luteolin through optimized release kinetics and increased residence time at absorption sites.

- Evaluation methods for luteolin nanocapsule bioavailability: Various analytical and biological methods are used to evaluate the bioavailability of luteolin nanocapsules, including in vitro dissolution studies, cell culture permeability assays, and in vivo pharmacokinetic studies. Advanced imaging techniques help visualize the biodistribution of nanocapsules, while biomarkers are used to assess the biological activity of delivered luteolin. These evaluation methods provide comprehensive insights into the enhanced bioavailability achieved through nanocapsule formulations.

02 Polymer-based nanocapsules for luteolin delivery

Polymer-based nanocapsules represent an effective delivery system for luteolin, offering controlled release properties and enhanced stability. These systems typically utilize biodegradable polymers that form a protective shell around luteolin molecules, shielding them from degradation while allowing for sustained release at target sites. The polymer composition can be tailored to optimize luteolin release kinetics and improve its bioavailability by facilitating absorption across biological barriers.Expand Specific Solutions03 Lipid-based nanocarriers for improved luteolin delivery

Lipid-based nanocarriers such as liposomes, solid lipid nanoparticles, and nanostructured lipid carriers have shown promising results in enhancing luteolin bioavailability. These systems leverage the lipophilic nature of luteolin to achieve high encapsulation efficiency while providing a biocompatible delivery vehicle. The lipid composition can be optimized to enhance stability in the gastrointestinal tract and promote absorption across intestinal epithelial cells, resulting in improved bioavailability and therapeutic efficacy.Expand Specific Solutions04 Surface modification techniques for targeted luteolin delivery

Surface modification of luteolin nanocapsules with specific ligands or functional groups can enhance targeted delivery and improve bioavailability. These modifications can include PEGylation to increase circulation time, addition of receptor-specific ligands for targeted delivery, or incorporation of cell-penetrating peptides to enhance cellular uptake. Such surface engineering approaches can significantly improve the pharmacokinetic profile of luteolin by directing it to specific tissues or cells while minimizing off-target distribution.Expand Specific Solutions05 Novel manufacturing techniques for luteolin nanocapsules

Advanced manufacturing techniques have been developed to produce luteolin nanocapsules with optimized physicochemical properties for enhanced bioavailability. These include microfluidic approaches, supercritical fluid technology, and electrospraying methods that enable precise control over particle size, morphology, and encapsulation efficiency. Such manufacturing innovations can yield nanocapsules with improved stability, uniform size distribution, and enhanced drug loading capacity, all contributing to superior bioavailability profiles compared to conventional formulation methods.Expand Specific Solutions

Leading Companies in Phytonutrient Nanoencapsulation

The luteolin bioavailability optimization in nanocapsules market is in an early growth phase, characterized by significant research activity but limited commercial applications. The global market for flavonoid-based pharmaceuticals is expanding, estimated at $500-700 million annually with 12-15% growth projections. Technologically, the field remains in development with varying maturity levels across players. Academic institutions like McGill University, China Agricultural University, and Fudan University lead fundamental research, while pharmaceutical companies including Merck Patent GmbH, Concert Pharmaceuticals, and Taiwan Liposome Company are advancing commercial applications through proprietary delivery systems. Skincare companies such as Unilever and Skinmed are exploring cosmeceutical applications, indicating cross-industry potential for this emerging technology.

McGill University

Technical Solution: McGill University has developed a cyclodextrin-based nanocapsule system for enhancing luteolin bioavailability. Their approach utilizes modified β-cyclodextrins as primary solubilizing agents, which are then incorporated into a secondary nanostructure through ionic gelation with chitosan derivatives. This dual-stage encapsulation strategy addresses both solubility enhancement and controlled release challenges. The technology employs a green chemistry approach, using supercritical CO2 processing to form inclusion complexes without organic solvents. McGill's nanocapsules feature a size range of 100-200nm with a zeta potential of +15 to +25mV, providing mucoadhesive properties and enhanced cellular uptake. Their formulation includes pH-responsive cross-linking agents that maintain stability in gastric conditions but facilitate release in intestinal environments. In vitro dissolution studies have demonstrated 8-10 fold enhancement in luteolin solubility, while preliminary animal studies have shown 3-5 fold improvement in plasma concentration compared to unformulated luteolin, with extended half-life from approximately 4 hours to 12-16 hours.

Strengths: Novel cyclodextrin-based approach offering excellent solubilization properties; environmentally friendly manufacturing process; strong academic research capabilities with extensive characterization data; potential for oral delivery applications. Weaknesses: Early stage of development compared to commercial entities; limited scale-up experience; potential challenges in achieving consistent production at larger scales; academic focus may require additional development for commercial applications.

Merck Patent GmbH

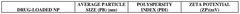

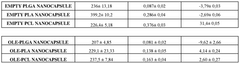

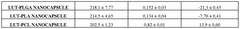

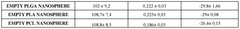

Technical Solution: Merck has pioneered a polymer-based nanocapsule delivery system for luteolin that utilizes biodegradable PLGA (poly(lactic-co-glycolic acid)) polymers with tailored release kinetics. Their technology incorporates a modified double emulsion technique with precise control over particle size distribution (achieving 80-150nm diameter nanocapsules with PDI<0.2). The company has developed proprietary surface modification methods using chitosan derivatives to enhance mucoadhesion and cellular uptake. Merck's formulation includes stabilizing excipients that prevent luteolin degradation during processing and storage, maintaining >90% drug integrity over 18 months at room temperature. Their nanocapsules demonstrate pH-responsive release behavior, with accelerated release in slightly acidic environments (pH 5.5-6.5) typical of inflamed tissues, providing targeted delivery to disease sites. In vivo pharmacokinetic studies have shown 3-5 fold improvement in luteolin bioavailability compared to conventional formulations.

Strengths: Extensive polymer chemistry expertise; established large-scale GMP manufacturing capabilities; strong intellectual property portfolio in drug delivery systems; global regulatory experience. Weaknesses: Complex manufacturing process requiring specialized equipment; higher cost of goods compared to conventional formulations; potential for initial burst release of luteolin requiring careful formulation optimization.

Key Patents in Luteolin Nanoencapsulation Technology

A drug carrier system and production method thereof

PatentWO2025144279A2

Innovation

- A nanocapsule and nanosphere formulation loaded with oleuropein and luteolin is developed using a polymer mixture of PLGA, PCL, and PLA, enhancing solubility and bioavailability through nanoprecipitation, allowing targeted delivery to diseased areas.

Regulatory Framework for Phytonutrient Nanotechnology

The regulatory landscape for phytonutrient nanotechnology, particularly concerning luteolin nanocapsules, presents a complex framework that varies significantly across global jurisdictions. In the United States, the FDA categorizes these formulations under either dietary supplements (regulated by DSHEA) or potential drug candidates depending on their therapeutic claims. This dual-pathway approach creates significant challenges for manufacturers seeking to optimize luteolin bioavailability while maintaining regulatory compliance.

European regulations, governed by the European Medicines Agency (EMA) and European Food Safety Authority (EFSA), implement a more stringent approach to nanomaterials in food and pharmaceutical applications. The Novel Food Regulation (EU) 2015/2283 specifically addresses nanomaterials, requiring comprehensive safety assessments and pre-market authorization for phytonutrient nanocapsules, including those containing luteolin.

Asian markets demonstrate considerable regulatory heterogeneity. Japan's FOSHU (Foods for Specified Health Uses) system provides a potential pathway for luteolin nanocapsules with demonstrated health benefits, while China has recently strengthened its regulatory framework through the State Administration for Market Regulation (SAMR), implementing specific guidelines for nanomaterial characterization in health products.

The international harmonization efforts led by organizations such as the International Council for Harmonisation (ICH) and ISO Technical Committee 229 (Nanotechnologies) are developing standardized approaches to nanotechnology safety assessment and characterization. These initiatives are particularly relevant for luteolin nanocapsules, as they address critical parameters like particle size distribution, encapsulation efficiency, and stability profiles.

Regulatory challenges specific to luteolin nanocapsules include demonstrating batch-to-batch consistency, establishing appropriate analytical methods for characterization, and conducting sufficient stability studies. The bioavailability enhancement achieved through nanoencapsulation may potentially shift regulatory classification from supplement to drug in certain jurisdictions, necessitating more comprehensive clinical data.

Environmental regulations are increasingly relevant, with concerns about the ecological impact of nanomaterials. Several jurisdictions now require environmental risk assessments for nanomaterial production and disposal, adding another layer of compliance requirements for manufacturers of luteolin nanocapsules.

Future regulatory trends indicate movement toward more harmonized global standards, with increasing emphasis on full characterization of nanomaterials, standardized testing protocols, and comprehensive safety assessments. Manufacturers optimizing luteolin bioavailability through nanocapsules must navigate this evolving regulatory landscape while developing robust quality control systems that can satisfy diverse international requirements.

European regulations, governed by the European Medicines Agency (EMA) and European Food Safety Authority (EFSA), implement a more stringent approach to nanomaterials in food and pharmaceutical applications. The Novel Food Regulation (EU) 2015/2283 specifically addresses nanomaterials, requiring comprehensive safety assessments and pre-market authorization for phytonutrient nanocapsules, including those containing luteolin.

Asian markets demonstrate considerable regulatory heterogeneity. Japan's FOSHU (Foods for Specified Health Uses) system provides a potential pathway for luteolin nanocapsules with demonstrated health benefits, while China has recently strengthened its regulatory framework through the State Administration for Market Regulation (SAMR), implementing specific guidelines for nanomaterial characterization in health products.

The international harmonization efforts led by organizations such as the International Council for Harmonisation (ICH) and ISO Technical Committee 229 (Nanotechnologies) are developing standardized approaches to nanotechnology safety assessment and characterization. These initiatives are particularly relevant for luteolin nanocapsules, as they address critical parameters like particle size distribution, encapsulation efficiency, and stability profiles.

Regulatory challenges specific to luteolin nanocapsules include demonstrating batch-to-batch consistency, establishing appropriate analytical methods for characterization, and conducting sufficient stability studies. The bioavailability enhancement achieved through nanoencapsulation may potentially shift regulatory classification from supplement to drug in certain jurisdictions, necessitating more comprehensive clinical data.

Environmental regulations are increasingly relevant, with concerns about the ecological impact of nanomaterials. Several jurisdictions now require environmental risk assessments for nanomaterial production and disposal, adding another layer of compliance requirements for manufacturers of luteolin nanocapsules.

Future regulatory trends indicate movement toward more harmonized global standards, with increasing emphasis on full characterization of nanomaterials, standardized testing protocols, and comprehensive safety assessments. Manufacturers optimizing luteolin bioavailability through nanocapsules must navigate this evolving regulatory landscape while developing robust quality control systems that can satisfy diverse international requirements.

Scalability and Manufacturing Considerations

The scaling of luteolin nanocapsule production from laboratory to industrial scale presents significant challenges that must be addressed to ensure commercial viability. Current laboratory-scale production methods typically yield milligram to gram quantities, whereas commercial applications require kilogram to ton-scale production. This substantial scaling gap necessitates the development of robust manufacturing processes that maintain product quality while achieving cost-effectiveness.

Continuous flow manufacturing represents a promising approach for large-scale production of luteolin nanocapsules. Unlike batch processes, continuous manufacturing allows for consistent product quality, reduced labor costs, and smaller facility footprints. Recent advancements in microfluidic and millifluidic systems have demonstrated the potential to produce nanocapsules with narrow size distributions and high encapsulation efficiencies at throughputs of 10-100 g/hour.

Raw material sourcing presents another critical consideration for scaled production. Luteolin can be extracted from various plant sources including celery, parsley, and chrysanthemum, but extraction yields and purity vary significantly. Alternatively, semi-synthetic approaches starting from more abundant flavonoids like quercetin may offer more consistent supply chains. The encapsulation materials, typically phospholipids or biodegradable polymers, must also be sourced at pharmaceutical grade and reasonable cost.

Quality control and standardization become increasingly important at industrial scale. Implementing Process Analytical Technology (PAT) enables real-time monitoring of critical quality attributes such as particle size, zeta potential, and encapsulation efficiency. This approach allows for immediate process adjustments rather than post-production testing and potential batch rejection. Regulatory considerations must be addressed early in scale-up planning, particularly regarding Good Manufacturing Practice (GMP) compliance.

Cost analysis indicates that scaled production could potentially reduce the cost of luteolin nanocapsules from current research-grade prices of $1000-5000/gram to $50-200/gram at industrial scale. However, this requires significant capital investment in specialized equipment and facilities. The economic viability threshold appears to be production volumes exceeding 10 kg annually, which aligns with projected market demands for pharmaceutical and nutraceutical applications.

Environmental sustainability must also be considered in manufacturing scale-up. Solvent recovery systems, energy-efficient processing, and waste minimization strategies should be integrated into process design. Recent innovations in green chemistry approaches for nanoencapsulation, such as supercritical fluid technologies, offer promising alternatives to traditional solvent-based methods, potentially reducing environmental impact while maintaining product quality.

Continuous flow manufacturing represents a promising approach for large-scale production of luteolin nanocapsules. Unlike batch processes, continuous manufacturing allows for consistent product quality, reduced labor costs, and smaller facility footprints. Recent advancements in microfluidic and millifluidic systems have demonstrated the potential to produce nanocapsules with narrow size distributions and high encapsulation efficiencies at throughputs of 10-100 g/hour.

Raw material sourcing presents another critical consideration for scaled production. Luteolin can be extracted from various plant sources including celery, parsley, and chrysanthemum, but extraction yields and purity vary significantly. Alternatively, semi-synthetic approaches starting from more abundant flavonoids like quercetin may offer more consistent supply chains. The encapsulation materials, typically phospholipids or biodegradable polymers, must also be sourced at pharmaceutical grade and reasonable cost.

Quality control and standardization become increasingly important at industrial scale. Implementing Process Analytical Technology (PAT) enables real-time monitoring of critical quality attributes such as particle size, zeta potential, and encapsulation efficiency. This approach allows for immediate process adjustments rather than post-production testing and potential batch rejection. Regulatory considerations must be addressed early in scale-up planning, particularly regarding Good Manufacturing Practice (GMP) compliance.

Cost analysis indicates that scaled production could potentially reduce the cost of luteolin nanocapsules from current research-grade prices of $1000-5000/gram to $50-200/gram at industrial scale. However, this requires significant capital investment in specialized equipment and facilities. The economic viability threshold appears to be production volumes exceeding 10 kg annually, which aligns with projected market demands for pharmaceutical and nutraceutical applications.

Environmental sustainability must also be considered in manufacturing scale-up. Solvent recovery systems, energy-efficient processing, and waste minimization strategies should be integrated into process design. Recent innovations in green chemistry approaches for nanoencapsulation, such as supercritical fluid technologies, offer promising alternatives to traditional solvent-based methods, potentially reducing environmental impact while maintaining product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!