Performance metrics for MSH-based adsorbents.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MSH Adsorbent Background

Magnesium silicate hydrate (MSH) adsorbents have emerged as a promising class of materials for various environmental and industrial applications. These adsorbents are derived from the reaction between magnesium-rich compounds and silica sources, resulting in a unique structure with high surface area and excellent adsorption properties.

The development of MSH-based adsorbents can be traced back to the early 2000s when researchers began exploring alternatives to conventional adsorbents. The initial focus was on utilizing MSH for wastewater treatment, particularly for the removal of heavy metals and organic pollutants. As research progressed, the potential applications of MSH adsorbents expanded to include gas purification, carbon dioxide capture, and even catalysis.

One of the key advantages of MSH adsorbents is their tunable properties, which can be tailored to specific adsorption requirements. By adjusting the synthesis conditions, such as pH, temperature, and precursor ratios, researchers can control the morphology, pore structure, and surface chemistry of MSH materials. This versatility has led to the development of a wide range of MSH-based adsorbents with varying characteristics and performance metrics.

The evolution of MSH adsorbents has been driven by the need for more efficient and cost-effective solutions in environmental remediation and industrial processes. As global concerns about water pollution, air quality, and greenhouse gas emissions continue to grow, the demand for high-performance adsorbents has intensified. MSH materials have shown great promise in addressing these challenges, offering a combination of high adsorption capacity, selectivity, and regeneration potential.

Recent advancements in MSH adsorbent technology have focused on enhancing their performance through various strategies. These include the incorporation of functional groups, doping with metal ions, and the creation of composite materials. Such modifications have led to improved adsorption kinetics, increased selectivity for target pollutants, and enhanced stability under diverse operating conditions.

The growing interest in MSH-based adsorbents is reflected in the increasing number of publications and patents in this field. Research efforts have expanded from fundamental studies on synthesis and characterization to more applied investigations, including pilot-scale trials and real-world applications. This progression has been crucial in bridging the gap between laboratory findings and practical implementation, paving the way for the commercialization of MSH adsorbent technologies.

As the field continues to evolve, researchers are exploring novel synthesis methods, such as green chemistry approaches and the use of waste materials as precursors, to make MSH adsorbent production more sustainable and economically viable. These developments align with the broader trends in materials science and environmental technology, emphasizing the importance of eco-friendly and resource-efficient solutions.

The development of MSH-based adsorbents can be traced back to the early 2000s when researchers began exploring alternatives to conventional adsorbents. The initial focus was on utilizing MSH for wastewater treatment, particularly for the removal of heavy metals and organic pollutants. As research progressed, the potential applications of MSH adsorbents expanded to include gas purification, carbon dioxide capture, and even catalysis.

One of the key advantages of MSH adsorbents is their tunable properties, which can be tailored to specific adsorption requirements. By adjusting the synthesis conditions, such as pH, temperature, and precursor ratios, researchers can control the morphology, pore structure, and surface chemistry of MSH materials. This versatility has led to the development of a wide range of MSH-based adsorbents with varying characteristics and performance metrics.

The evolution of MSH adsorbents has been driven by the need for more efficient and cost-effective solutions in environmental remediation and industrial processes. As global concerns about water pollution, air quality, and greenhouse gas emissions continue to grow, the demand for high-performance adsorbents has intensified. MSH materials have shown great promise in addressing these challenges, offering a combination of high adsorption capacity, selectivity, and regeneration potential.

Recent advancements in MSH adsorbent technology have focused on enhancing their performance through various strategies. These include the incorporation of functional groups, doping with metal ions, and the creation of composite materials. Such modifications have led to improved adsorption kinetics, increased selectivity for target pollutants, and enhanced stability under diverse operating conditions.

The growing interest in MSH-based adsorbents is reflected in the increasing number of publications and patents in this field. Research efforts have expanded from fundamental studies on synthesis and characterization to more applied investigations, including pilot-scale trials and real-world applications. This progression has been crucial in bridging the gap between laboratory findings and practical implementation, paving the way for the commercialization of MSH adsorbent technologies.

As the field continues to evolve, researchers are exploring novel synthesis methods, such as green chemistry approaches and the use of waste materials as precursors, to make MSH adsorbent production more sustainable and economically viable. These developments align with the broader trends in materials science and environmental technology, emphasizing the importance of eco-friendly and resource-efficient solutions.

Market Analysis

The market for MSH-based adsorbents has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations on pollutant removal. These advanced materials have found applications across various industries, including water treatment, air purification, and industrial waste management.

In the water treatment sector, MSH-based adsorbents have shown remarkable potential for removing heavy metals, organic pollutants, and emerging contaminants from wastewater. The global water treatment chemicals market, which includes adsorbents, is projected to reach $56.57 billion by 2030, with a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030. MSH-based adsorbents are expected to capture a significant portion of this market due to their superior performance and cost-effectiveness.

The air purification industry has also witnessed a surge in demand for MSH-based adsorbents, particularly in regions with high levels of air pollution. The global air purification market size was valued at $13.26 billion in 2022 and is anticipated to expand at a CAGR of 8.1% from 2023 to 2030. MSH-based adsorbents are gaining traction in this sector due to their high adsorption capacity and selectivity for various air pollutants.

In the industrial waste management sector, MSH-based adsorbents have shown promise in treating industrial effluents and removing hazardous substances. The global industrial waste management market size was valued at $1.47 trillion in 2022 and is expected to grow at a CAGR of 5.8% from 2023 to 2030. The increasing focus on sustainable industrial practices and circular economy principles is likely to drive the adoption of MSH-based adsorbents in this sector.

The pharmaceutical and food industries are emerging as potential growth areas for MSH-based adsorbents. These materials have demonstrated efficacy in removing impurities and contaminants from pharmaceutical products and food processing streams. As regulatory requirements become more stringent in these industries, the demand for high-performance adsorbents is expected to rise.

Geographically, Asia-Pacific is anticipated to be the fastest-growing market for MSH-based adsorbents, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India. North America and Europe are expected to maintain significant market shares due to their advanced environmental regulations and technological innovations in the field of adsorbent materials.

In the water treatment sector, MSH-based adsorbents have shown remarkable potential for removing heavy metals, organic pollutants, and emerging contaminants from wastewater. The global water treatment chemicals market, which includes adsorbents, is projected to reach $56.57 billion by 2030, with a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030. MSH-based adsorbents are expected to capture a significant portion of this market due to their superior performance and cost-effectiveness.

The air purification industry has also witnessed a surge in demand for MSH-based adsorbents, particularly in regions with high levels of air pollution. The global air purification market size was valued at $13.26 billion in 2022 and is anticipated to expand at a CAGR of 8.1% from 2023 to 2030. MSH-based adsorbents are gaining traction in this sector due to their high adsorption capacity and selectivity for various air pollutants.

In the industrial waste management sector, MSH-based adsorbents have shown promise in treating industrial effluents and removing hazardous substances. The global industrial waste management market size was valued at $1.47 trillion in 2022 and is expected to grow at a CAGR of 5.8% from 2023 to 2030. The increasing focus on sustainable industrial practices and circular economy principles is likely to drive the adoption of MSH-based adsorbents in this sector.

The pharmaceutical and food industries are emerging as potential growth areas for MSH-based adsorbents. These materials have demonstrated efficacy in removing impurities and contaminants from pharmaceutical products and food processing streams. As regulatory requirements become more stringent in these industries, the demand for high-performance adsorbents is expected to rise.

Geographically, Asia-Pacific is anticipated to be the fastest-growing market for MSH-based adsorbents, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India. North America and Europe are expected to maintain significant market shares due to their advanced environmental regulations and technological innovations in the field of adsorbent materials.

Technical Challenges

The development of Metal-Sulfur Hydride (MSH) based adsorbents for various applications faces several technical challenges that need to be addressed to enhance their performance and widespread adoption. One of the primary obstacles is the optimization of adsorption capacity and selectivity. While MSH-based materials have shown promising results, achieving consistently high adsorption capacities across a range of target molecules remains a significant challenge. This is particularly evident in applications such as gas separation and storage, where the ability to selectively adsorb specific molecules is crucial.

Another major technical hurdle is the stability of MSH-based adsorbents under diverse operating conditions. These materials often exhibit sensitivity to moisture and temperature fluctuations, which can lead to degradation of their performance over time. Enhancing the structural integrity and chemical stability of MSH adsorbents, especially in harsh environments or during repeated adsorption-desorption cycles, is a key area requiring further research and development.

The synthesis and scalability of MSH-based adsorbents present additional challenges. Current production methods often involve complex procedures or require expensive precursors, limiting their large-scale manufacturing potential. Developing cost-effective and scalable synthesis routes that maintain the desired properties of the adsorbents is crucial for their commercial viability.

Furthermore, the kinetics of adsorption and desorption processes in MSH-based materials need improvement. While some MSH adsorbents demonstrate high equilibrium capacities, their rate of adsorption or desorption may be too slow for practical applications. Enhancing the kinetics without compromising other performance metrics is a delicate balance that researchers are striving to achieve.

The characterization and standardization of performance metrics for MSH-based adsorbents also pose challenges. There is a need for consistent and reliable methods to evaluate and compare the performance of different MSH materials across various applications. This includes developing standardized protocols for measuring adsorption capacities, selectivities, and kinetics under different conditions.

Lastly, the integration of MSH-based adsorbents into existing systems and processes presents engineering challenges. Designing efficient and cost-effective ways to incorporate these materials into adsorption columns, filters, or other separation units while maintaining their performance characteristics is an ongoing area of research. This includes addressing issues related to pressure drop, heat management, and regeneration processes in practical applications.

Another major technical hurdle is the stability of MSH-based adsorbents under diverse operating conditions. These materials often exhibit sensitivity to moisture and temperature fluctuations, which can lead to degradation of their performance over time. Enhancing the structural integrity and chemical stability of MSH adsorbents, especially in harsh environments or during repeated adsorption-desorption cycles, is a key area requiring further research and development.

The synthesis and scalability of MSH-based adsorbents present additional challenges. Current production methods often involve complex procedures or require expensive precursors, limiting their large-scale manufacturing potential. Developing cost-effective and scalable synthesis routes that maintain the desired properties of the adsorbents is crucial for their commercial viability.

Furthermore, the kinetics of adsorption and desorption processes in MSH-based materials need improvement. While some MSH adsorbents demonstrate high equilibrium capacities, their rate of adsorption or desorption may be too slow for practical applications. Enhancing the kinetics without compromising other performance metrics is a delicate balance that researchers are striving to achieve.

The characterization and standardization of performance metrics for MSH-based adsorbents also pose challenges. There is a need for consistent and reliable methods to evaluate and compare the performance of different MSH materials across various applications. This includes developing standardized protocols for measuring adsorption capacities, selectivities, and kinetics under different conditions.

Lastly, the integration of MSH-based adsorbents into existing systems and processes presents engineering challenges. Designing efficient and cost-effective ways to incorporate these materials into adsorption columns, filters, or other separation units while maintaining their performance characteristics is an ongoing area of research. This includes addressing issues related to pressure drop, heat management, and regeneration processes in practical applications.

Current Solutions

01 Adsorption capacity measurement

Performance metrics for MSH-based adsorbents often include adsorption capacity, which measures the amount of target substance that can be adsorbed per unit mass of the adsorbent. This metric is crucial for evaluating the efficiency and effectiveness of the adsorbent material in various applications.- Performance evaluation metrics for MSH-based adsorbents: Various metrics are used to evaluate the performance of MSH-based adsorbents, including adsorption capacity, selectivity, kinetics, and regeneration efficiency. These metrics help in assessing the effectiveness of the adsorbents in removing specific contaminants from water or gas streams.

- Modeling and simulation of MSH-based adsorbent systems: Advanced modeling and simulation techniques are employed to predict and optimize the performance of MSH-based adsorbent systems. These computational methods help in understanding the adsorption mechanisms, designing efficient adsorbent structures, and forecasting system behavior under various conditions.

- Real-time monitoring and data analysis for MSH-based adsorbents: Implementing real-time monitoring systems and data analysis techniques to track the performance of MSH-based adsorbents in industrial applications. This approach enables continuous assessment of adsorbent efficiency, early detection of performance degradation, and optimization of operational parameters.

- Economic and environmental impact assessment of MSH-based adsorbents: Evaluating the economic viability and environmental sustainability of MSH-based adsorbents in comparison to conventional adsorbent materials. This assessment includes factors such as production costs, energy consumption, waste generation, and overall lifecycle analysis.

- Integration of MSH-based adsorbents in smart water treatment systems: Incorporating MSH-based adsorbents into intelligent water treatment systems that utilize IoT sensors, machine learning algorithms, and automated control mechanisms. This integration aims to enhance the overall efficiency and adaptability of water purification processes.

02 Kinetics and rate of adsorption

The kinetics and rate of adsorption are important performance metrics for MSH-based adsorbents. These parameters indicate how quickly the adsorbent can remove target substances from a solution or gas stream, which is critical for practical applications in industrial processes and environmental remediation.Expand Specific Solutions03 Selectivity and specificity

Selectivity and specificity are key performance metrics for MSH-based adsorbents, measuring the ability of the adsorbent to preferentially adsorb target substances in the presence of other competing species. High selectivity is crucial for applications in separation processes and purification technologies.Expand Specific Solutions04 Regeneration and reusability

The regeneration capacity and reusability of MSH-based adsorbents are important performance metrics that assess the economic viability and sustainability of the material. These metrics evaluate how well the adsorbent can be regenerated and reused without significant loss of adsorption capacity over multiple cycles.Expand Specific Solutions05 Stability and durability

Stability and durability are critical performance metrics for MSH-based adsorbents, measuring the material's resistance to degradation under various operating conditions such as temperature, pH, and chemical environment. These metrics are essential for determining the long-term performance and applicability of the adsorbent in real-world scenarios.Expand Specific Solutions

Key Industry Players

The performance metrics for MSH-based adsorbents market is in its growth stage, with increasing research and development activities. The market size is expanding due to rising demand for efficient adsorbents in various industries. Technologically, MSH-based adsorbents are advancing, with companies like BLÜCHER GmbH, Nippon Shokubai, and W. L. Gore & Associates leading innovation. These firms are developing novel formulations and applications, improving adsorption capacity and selectivity. However, the technology is not yet fully mature, presenting opportunities for further optimization and commercialization by key players such as Johnson Matthey and Praxair Technology.

BLÜCHER GmbH

Technical Solution: BLÜCHER GmbH has developed innovative MSH-based adsorbents with a focus on spherical activated carbon. Their technology utilizes a unique manufacturing process that results in highly uniform and mechanically stable adsorbent particles. BLÜCHER's MSH-based adsorbents demonstrate exceptional adsorption capacity, with reported values of up to 1200 mg/g for certain organic compounds [2]. The company has also optimized the pore size distribution of their adsorbents, achieving a balance between micropores and mesopores to enhance both adsorption capacity and kinetics. BLÜCHER's adsorbents show rapid adsorption rates, with equilibrium times as low as 30 minutes for some applications [4].

Strengths: High adsorption capacity, rapid kinetics, and excellent mechanical stability. Weaknesses: Potentially higher production costs compared to traditional activated carbons.

Nippon Shokubai Co., Ltd.

Technical Solution: Nippon Shokubai has developed MSH-based adsorbents with a focus on environmental applications, particularly water and air purification. Their adsorbents feature a hierarchical pore structure, combining micropores for high adsorption capacity and mesopores for improved mass transfer. Nippon Shokubai's MSH-based adsorbents have demonstrated removal efficiencies of over 95% for various organic pollutants in water treatment applications [5]. The company has also reported breakthrough capacities of up to 300 mg/g for volatile organic compounds (VOCs) in gas-phase adsorption [6]. Additionally, Nippon Shokubai has developed regeneration protocols that allow for multiple adsorption-desorption cycles without significant loss of performance.

Strengths: High removal efficiency, good regeneration capability, and versatility in both liquid and gas-phase applications. Weaknesses: Potential limitations in selectivity for complex mixtures.

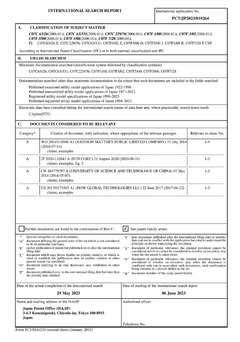

Core Innovations

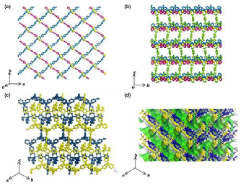

Metal organic framework

PatentPendingEP4495098A1

Innovation

- A metal organic framework with a structure S M-x, where two or more metal ions are bonded to one oxygen atom in a structure S x, and has a decomposition start temperature of 200°C or higher, along with specific ratios of oxygen species and cluster structures, is developed.

Metal-organic framework with stepwise and hysteretic gas sorption properties and its use for gas storage material and method for manufacturing the same

PatentActiveKR1020110005591A

Innovation

- Development of a doubly interpenetrated 3D metal-organic framework represented by [Formula 1] that adsorbs gases like nitrogen, oxygen, hydrogen, and carbon dioxide even at low pressures, exhibiting stepwise and hysteresis gas adsorption/desorption properties.

Performance Evaluation Methods

The evaluation of performance metrics for MSH-based adsorbents requires a comprehensive approach that encompasses various analytical techniques and standardized methods. These evaluation methods are crucial for assessing the efficiency, capacity, and selectivity of MSH-based adsorbents in different applications.

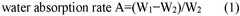

One of the primary performance evaluation methods is the determination of adsorption capacity. This is typically measured through adsorption isotherms, which provide information on the amount of adsorbate taken up by the adsorbent at different concentrations or pressures. Common isotherm models, such as Langmuir and Freundlich, are used to fit experimental data and extract key parameters like maximum adsorption capacity and adsorption affinity.

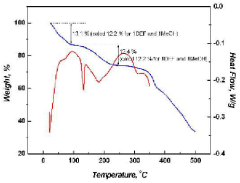

Kinetic studies form another essential aspect of performance evaluation. These studies involve measuring the rate of adsorption over time, which is crucial for understanding the speed and efficiency of the adsorption process. Various kinetic models, including pseudo-first-order and pseudo-second-order models, are employed to analyze the adsorption kinetics and determine rate constants.

The selectivity of MSH-based adsorbents is evaluated through competitive adsorption experiments, where multiple adsorbates are present simultaneously. This method helps in assessing the adsorbent's ability to preferentially adsorb specific compounds from complex mixtures, which is particularly important in applications such as water purification and gas separation.

Regeneration and reusability studies are critical for determining the long-term performance and economic viability of MSH-based adsorbents. These evaluations involve subjecting the adsorbent to multiple adsorption-desorption cycles and measuring any changes in adsorption capacity or efficiency over time. Various regeneration methods, including thermal treatment, chemical washing, and pressure swing, are employed depending on the specific adsorbent and application.

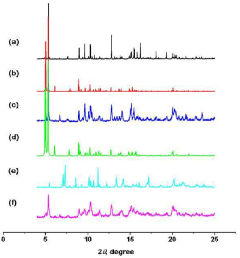

Surface characterization techniques play a vital role in understanding the performance of MSH-based adsorbents. Methods such as Brunauer-Emmett-Teller (BET) analysis for surface area determination, pore size distribution analysis, and X-ray diffraction (XRD) for crystal structure characterization provide valuable insights into the adsorbent's physical properties and their impact on adsorption performance.

Spectroscopic methods, including Fourier-transform infrared spectroscopy (FTIR) and X-ray photoelectron spectroscopy (XPS), are employed to investigate the surface chemistry and binding mechanisms of MSH-based adsorbents. These techniques help in elucidating the nature of interactions between the adsorbent and adsorbate, which is crucial for optimizing performance and designing more effective adsorbents.

In real-world applications, column studies and breakthrough curve analysis are often conducted to evaluate the performance of MSH-based adsorbents under dynamic flow conditions. These methods provide valuable information on the adsorbent's behavior in practical scenarios, including breakthrough time, saturation capacity, and mass transfer zone characteristics.

One of the primary performance evaluation methods is the determination of adsorption capacity. This is typically measured through adsorption isotherms, which provide information on the amount of adsorbate taken up by the adsorbent at different concentrations or pressures. Common isotherm models, such as Langmuir and Freundlich, are used to fit experimental data and extract key parameters like maximum adsorption capacity and adsorption affinity.

Kinetic studies form another essential aspect of performance evaluation. These studies involve measuring the rate of adsorption over time, which is crucial for understanding the speed and efficiency of the adsorption process. Various kinetic models, including pseudo-first-order and pseudo-second-order models, are employed to analyze the adsorption kinetics and determine rate constants.

The selectivity of MSH-based adsorbents is evaluated through competitive adsorption experiments, where multiple adsorbates are present simultaneously. This method helps in assessing the adsorbent's ability to preferentially adsorb specific compounds from complex mixtures, which is particularly important in applications such as water purification and gas separation.

Regeneration and reusability studies are critical for determining the long-term performance and economic viability of MSH-based adsorbents. These evaluations involve subjecting the adsorbent to multiple adsorption-desorption cycles and measuring any changes in adsorption capacity or efficiency over time. Various regeneration methods, including thermal treatment, chemical washing, and pressure swing, are employed depending on the specific adsorbent and application.

Surface characterization techniques play a vital role in understanding the performance of MSH-based adsorbents. Methods such as Brunauer-Emmett-Teller (BET) analysis for surface area determination, pore size distribution analysis, and X-ray diffraction (XRD) for crystal structure characterization provide valuable insights into the adsorbent's physical properties and their impact on adsorption performance.

Spectroscopic methods, including Fourier-transform infrared spectroscopy (FTIR) and X-ray photoelectron spectroscopy (XPS), are employed to investigate the surface chemistry and binding mechanisms of MSH-based adsorbents. These techniques help in elucidating the nature of interactions between the adsorbent and adsorbate, which is crucial for optimizing performance and designing more effective adsorbents.

In real-world applications, column studies and breakthrough curve analysis are often conducted to evaluate the performance of MSH-based adsorbents under dynamic flow conditions. These methods provide valuable information on the adsorbent's behavior in practical scenarios, including breakthrough time, saturation capacity, and mass transfer zone characteristics.

Environmental Impact

The environmental impact of MSH-based adsorbents is a critical consideration in their development and application. These materials, derived from magnesium silicate hydrate (MSH), have shown promising potential for various adsorption processes, particularly in water treatment and environmental remediation. However, their widespread adoption necessitates a comprehensive assessment of their ecological footprint throughout their lifecycle.

One of the primary environmental benefits of MSH-based adsorbents is their potential to reduce water pollution. By effectively removing contaminants such as heavy metals, organic pollutants, and emerging micropollutants from water sources, these materials contribute to improved water quality and ecosystem health. This can lead to reduced stress on aquatic ecosystems and potentially lower the need for more energy-intensive water treatment processes.

The production of MSH-based adsorbents generally involves less energy-intensive processes compared to some conventional adsorbents, such as activated carbon. This can result in lower greenhouse gas emissions associated with their manufacture. Additionally, the raw materials used in MSH synthesis are often abundant and can be sourced from industrial by-products or waste materials, promoting circular economy principles and reducing the demand for virgin resources.

However, the environmental impact of MSH-based adsorbents extends beyond their production and use phases. The disposal or regeneration of spent adsorbents must be carefully considered. While some MSH-based materials show potential for regeneration and reuse, others may require disposal after a single use. The environmental implications of these end-of-life scenarios, including potential leaching of adsorbed contaminants, need thorough evaluation.

The scalability of MSH-based adsorbents also plays a role in their overall environmental impact. As production scales up to meet potential demand, it is crucial to assess and mitigate any negative environmental consequences associated with large-scale manufacturing, transportation, and application of these materials.

Furthermore, the long-term stability and potential release of nanoparticles from MSH-based adsorbents in the environment require careful study. While these materials show promise for environmental remediation, ensuring they do not introduce new environmental risks is paramount.

In conclusion, while MSH-based adsorbents offer significant potential for environmental benefits, particularly in water treatment, a holistic approach to assessing their environmental impact is essential. This includes considering their entire lifecycle, from raw material sourcing to end-of-life management, and evaluating both direct and indirect environmental effects. Ongoing research and development should focus on optimizing the environmental performance of these materials to ensure their sustainable application in addressing global environmental challenges.

One of the primary environmental benefits of MSH-based adsorbents is their potential to reduce water pollution. By effectively removing contaminants such as heavy metals, organic pollutants, and emerging micropollutants from water sources, these materials contribute to improved water quality and ecosystem health. This can lead to reduced stress on aquatic ecosystems and potentially lower the need for more energy-intensive water treatment processes.

The production of MSH-based adsorbents generally involves less energy-intensive processes compared to some conventional adsorbents, such as activated carbon. This can result in lower greenhouse gas emissions associated with their manufacture. Additionally, the raw materials used in MSH synthesis are often abundant and can be sourced from industrial by-products or waste materials, promoting circular economy principles and reducing the demand for virgin resources.

However, the environmental impact of MSH-based adsorbents extends beyond their production and use phases. The disposal or regeneration of spent adsorbents must be carefully considered. While some MSH-based materials show potential for regeneration and reuse, others may require disposal after a single use. The environmental implications of these end-of-life scenarios, including potential leaching of adsorbed contaminants, need thorough evaluation.

The scalability of MSH-based adsorbents also plays a role in their overall environmental impact. As production scales up to meet potential demand, it is crucial to assess and mitigate any negative environmental consequences associated with large-scale manufacturing, transportation, and application of these materials.

Furthermore, the long-term stability and potential release of nanoparticles from MSH-based adsorbents in the environment require careful study. While these materials show promise for environmental remediation, ensuring they do not introduce new environmental risks is paramount.

In conclusion, while MSH-based adsorbents offer significant potential for environmental benefits, particularly in water treatment, a holistic approach to assessing their environmental impact is essential. This includes considering their entire lifecycle, from raw material sourcing to end-of-life management, and evaluating both direct and indirect environmental effects. Ongoing research and development should focus on optimizing the environmental performance of these materials to ensure their sustainable application in addressing global environmental challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!