PVDF in Advanced Computing: Boosting Memory Storage

PVDF Memory Evolution

PVDF (Polyvinylidene fluoride) has undergone a remarkable evolution in the field of advanced computing, particularly in memory storage applications. This evolution can be traced through several key stages, each marked by significant technological advancements and breakthroughs.

In the early stages, PVDF was primarily recognized for its piezoelectric properties, which allowed it to convert mechanical stress into electrical signals. This characteristic initially found applications in sensors and actuators rather than memory storage. However, researchers soon began to explore its potential in data storage due to its unique ferroelectric properties.

The 1980s marked a turning point in PVDF memory evolution with the discovery of its ferroelectric behavior. This property allowed PVDF to maintain a stable electrical polarization state even in the absence of an external electric field, making it a promising candidate for non-volatile memory applications. During this period, scientists focused on understanding and optimizing the ferroelectric properties of PVDF and its copolymers.

The 1990s and early 2000s saw significant advancements in PVDF thin film technology. Researchers developed methods to create ultra-thin PVDF films with enhanced ferroelectric properties, paving the way for higher density memory storage. This period also witnessed the emergence of PVDF-based ferroelectric random access memory (FRAM) prototypes, demonstrating the potential for fast, low-power, and non-volatile memory devices.

In the past decade, PVDF memory evolution has accelerated rapidly. The integration of nanotechnology has led to the development of PVDF nanocomposites and nanostructures with superior ferroelectric and piezoelectric properties. These advancements have significantly improved the storage density, switching speed, and energy efficiency of PVDF-based memory devices.

Recent years have seen a focus on flexible and wearable electronics, where PVDF's inherent flexibility gives it a distinct advantage. Researchers have successfully demonstrated PVDF-based flexible memory devices that can maintain performance under bending and stretching conditions, opening up new possibilities for wearable computing and Internet of Things (IoT) applications.

The latest frontier in PVDF memory evolution is the exploration of its potential in neuromorphic computing. Scientists are investigating PVDF-based memristive devices that can mimic the behavior of biological synapses, potentially leading to more efficient and brain-like computing architectures.

Market Demand Analysis

The market demand for PVDF (Polyvinylidene Fluoride) in advanced computing, particularly for boosting memory storage, has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for high-performance, reliable, and energy-efficient memory solutions in various computing applications.

The global demand for PVDF in electronic applications, including memory storage, is projected to grow steadily over the next decade. This growth is fueled by the rapid expansion of data centers, cloud computing, and the Internet of Things (IoT), all of which require advanced memory solutions to handle massive amounts of data efficiently.

In the realm of memory storage, PVDF-based ferroelectric random-access memory (FRAM) has emerged as a promising technology. FRAM offers several advantages over traditional memory types, including non-volatility, low power consumption, high endurance, and fast read/write speeds. These characteristics make PVDF-based FRAM particularly attractive for applications in wearable devices, IoT sensors, and embedded systems where energy efficiency and reliability are crucial.

The automotive industry is another significant driver of market demand for PVDF in memory applications. As vehicles become increasingly connected and autonomous, the need for reliable, high-performance memory solutions grows. PVDF-based memory technologies are well-suited for automotive applications due to their ability to withstand harsh environmental conditions and their long-term reliability.

The aerospace and defense sectors also contribute to the growing demand for PVDF in advanced computing. These industries require memory solutions that can operate in extreme conditions and offer high reliability, making PVDF-based technologies an attractive option.

In the consumer electronics market, the demand for PVDF in memory applications is driven by the need for faster, more energy-efficient devices with improved storage capabilities. Smartphones, tablets, and laptops are increasingly incorporating advanced memory technologies to enhance performance and user experience.

The healthcare industry is another emerging market for PVDF-based memory solutions. Medical devices, wearable health monitors, and diagnostic equipment require reliable, low-power memory technologies, creating new opportunities for PVDF applications.

As the demand for edge computing and artificial intelligence (AI) continues to grow, the market for PVDF in memory applications is expected to expand further. These technologies require high-performance, energy-efficient memory solutions to process and store large amounts of data in real-time, aligning well with the capabilities of PVDF-based memory technologies.

PVDF Tech Challenges

Polyvinylidene fluoride (PVDF) has emerged as a promising material for advanced computing applications, particularly in memory storage. However, its integration into high-performance computing systems faces several significant challenges that researchers and engineers must overcome.

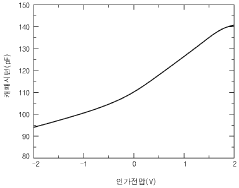

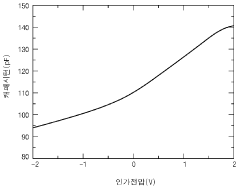

One of the primary technical hurdles is achieving consistent and reliable ferroelectric properties in PVDF thin films. The ferroelectric behavior of PVDF is crucial for its application in memory devices, but controlling the crystalline structure and orientation of PVDF molecules during the fabrication process remains difficult. This challenge is exacerbated when attempting to produce ultra-thin films required for high-density memory storage.

Another major obstacle is the integration of PVDF with existing semiconductor technologies. PVDF's processing temperature is typically lower than that of many standard semiconductor materials, which complicates its incorporation into conventional manufacturing processes. This incompatibility necessitates the development of new fabrication techniques and potentially entire new production lines, increasing costs and slowing adoption.

The scalability of PVDF-based memory devices presents another significant challenge. While PVDF shows promise in laboratory settings, scaling up production to meet the demands of the computing industry requires overcoming issues related to uniformity, yield, and cost-effectiveness. Ensuring consistent performance across large-scale production batches is crucial for commercial viability.

PVDF's switching speed and endurance also pose challenges for its use in high-performance computing applications. Although PVDF exhibits favorable properties for non-volatile memory, its switching speed is generally slower than that of traditional DRAM or SRAM. Improving the switching dynamics of PVDF-based memory cells without compromising their non-volatile nature is a key area of research.

Furthermore, the long-term stability and reliability of PVDF in computing environments need to be addressed. Factors such as temperature fluctuations, electrical stress, and mechanical strain can affect the performance and lifespan of PVDF-based memory devices. Developing robust solutions to ensure the longevity and consistent operation of these devices under various computing conditions is essential.

Lastly, the energy efficiency of PVDF-based memory systems requires optimization. While PVDF offers potential advantages in terms of non-volatility and low standby power consumption, the energy required for writing and reading operations must be minimized to make it competitive with existing memory technologies. This challenge involves not only improving the material properties of PVDF but also designing efficient circuitry and control systems.

Current PVDF Solutions

01 PVDF-based ferroelectric memory devices

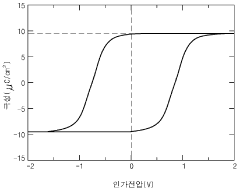

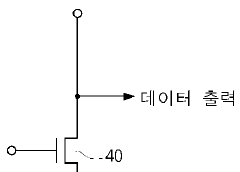

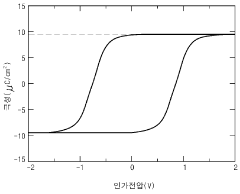

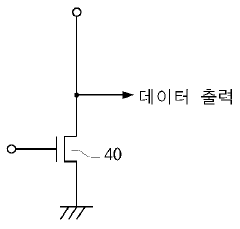

PVDF and its copolymers are used to create ferroelectric memory devices due to their excellent ferroelectric properties. These materials can be used in non-volatile memory applications, offering advantages such as low power consumption, high-speed operation, and long data retention times.- PVDF-based ferroelectric memory devices: PVDF and its copolymers are used to create ferroelectric memory devices due to their excellent ferroelectric properties. These materials can be used in non-volatile memory applications, offering advantages such as low power consumption, high-speed operation, and long data retention. The ferroelectric properties of PVDF allow for the storage and retrieval of data through polarization switching.

- Fabrication techniques for PVDF memory structures: Various fabrication techniques are employed to create PVDF-based memory structures. These may include spin coating, electrospinning, and nanoimprint lithography. The fabrication process often involves controlling the crystalline structure of PVDF to enhance its ferroelectric properties. Techniques such as annealing and stretching are used to promote the formation of the β-phase, which is crucial for ferroelectric behavior.

- Integration of PVDF in flexible and wearable memory devices: PVDF's flexibility and biocompatibility make it suitable for use in flexible and wearable memory devices. These applications leverage PVDF's ability to maintain its ferroelectric properties under mechanical stress. The development of such devices often involves combining PVDF with other materials to create composite structures that offer both flexibility and reliable memory storage capabilities.

- PVDF nanocomposites for enhanced memory performance: Researchers are exploring PVDF nanocomposites to enhance memory performance. By incorporating nanoparticles or other nanomaterials into the PVDF matrix, the ferroelectric properties and overall performance of the memory devices can be improved. These nanocomposites often exhibit enhanced polarization, lower operating voltages, and improved data retention compared to pure PVDF.

- Multi-level storage capabilities in PVDF memory devices: PVDF-based memory devices are being developed with multi-level storage capabilities. This approach allows for storing multiple bits of information in a single memory cell, increasing data density. The multi-level storage is achieved by controlling the degree of polarization in the PVDF material, enabling the device to distinguish between multiple states and thus store more information in the same physical space.

02 Fabrication techniques for PVDF memory structures

Various fabrication techniques are employed to create PVDF-based memory structures, including spin coating, electrospinning, and nanoimprint lithography. These methods allow for the precise control of film thickness, crystallinity, and orientation, which are crucial for optimizing memory performance.Expand Specific Solutions03 Integration of PVDF in flexible and wearable memory devices

PVDF's flexibility and biocompatibility make it an ideal candidate for flexible and wearable memory devices. These applications include electronic skin, smart textiles, and implantable medical devices that require bendable and stretchable memory components.Expand Specific Solutions04 Enhancing PVDF memory performance through nanocomposites

Researchers are exploring the use of nanocomposites to enhance the memory performance of PVDF-based devices. By incorporating nanoparticles or other nanomaterials into the PVDF matrix, the ferroelectric properties and overall memory characteristics can be significantly improved.Expand Specific Solutions05 Multi-functional PVDF memory devices

PVDF-based memory devices are being developed with multi-functional capabilities, combining memory storage with other functionalities such as energy harvesting, sensing, or actuation. This approach leads to more integrated and efficient systems for various applications in electronics and IoT devices.Expand Specific Solutions

Key PVDF Players

The PVDF technology in advanced computing for memory storage is in a nascent stage of development, with significant potential for market growth. The industry is transitioning from research to early commercialization, attracting major players like Samsung Electronics, Micron Technology, and Intel. These companies are investing heavily in R&D to overcome technical challenges and improve PVDF's performance in memory applications. The market size is expected to expand rapidly as the technology matures, driven by increasing demand for high-density, energy-efficient storage solutions. While PVDF technology shows promise, it is still in the early stages of technological maturity, with companies like IBM and Huawei Technologies also contributing to its advancement through patent filings and research collaborations.

Samsung Electronics Co., Ltd.

Micron Technology, Inc.

PVDF Innovations

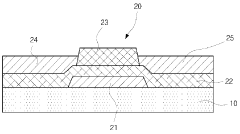

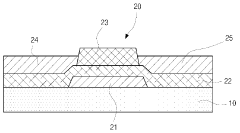

- A ferroelectric memory device utilizing a PVDF layer with a β-phase crystal structure, integrated with a channel formation layer and electrodes, is manufactured through controlled temperature transitions to maintain hysteresis polarity characteristics.

- A ferroelectric memory device utilizing a PVDF layer with a β-phase crystal structure as the ferroelectric layer, integrated with a channel formation layer and electrodes on a substrate, which can be made of organic materials like polyimide or flexible plastics, enabling low-voltage operation and simplified manufacturing.

PVDF Manufacturing

The manufacturing process of Polyvinylidene Fluoride (PVDF) for advanced computing applications, particularly in memory storage, involves several critical steps and considerations. The process typically begins with the polymerization of vinylidene fluoride monomers, which can be achieved through various methods such as suspension, emulsion, or solution polymerization. The choice of polymerization technique significantly impacts the final properties of the PVDF, including its crystallinity, molecular weight, and purity.

Following polymerization, the PVDF undergoes a series of post-processing steps to enhance its properties for memory storage applications. These steps may include purification, drying, and pelletization. The purification process is crucial to remove any residual monomers, catalysts, or impurities that could affect the performance of the material in advanced computing devices.

One of the key aspects of PVDF manufacturing for memory storage is the control of the polymer's crystalline structure. PVDF can exist in multiple crystalline phases, with the β-phase being particularly desirable for its ferroelectric properties. To promote the formation of the β-phase, specific processing techniques are employed, such as mechanical stretching, electrical poling, or the addition of nucleating agents during the manufacturing process.

The next stage in PVDF manufacturing involves the formation of thin films or nanostructures, which are essential for integration into memory storage devices. Advanced techniques like electrospinning, solution casting, or melt extrusion are utilized to create PVDF films with precise thickness and uniformity. These processes require careful control of parameters such as temperature, pressure, and cooling rates to achieve the desired microstructure and properties.

Surface modification and functionalization of PVDF films are often performed to enhance their compatibility with other materials in the memory storage device stack. This may involve plasma treatment, chemical grafting, or the deposition of additional layers to improve adhesion, electrical properties, or durability.

Quality control is a critical aspect of PVDF manufacturing for advanced computing applications. Rigorous testing and characterization techniques are employed throughout the production process to ensure consistency and reliability. These may include spectroscopic analysis, thermal analysis, and electrical property measurements to verify the material's suitability for memory storage devices.

The final stages of PVDF manufacturing for memory storage applications involve packaging and integration into device structures. This may include cutting, shaping, and electrode deposition processes, all of which must be performed under stringent cleanroom conditions to prevent contamination that could compromise device performance.

PVDF Sustainability

The sustainability of PVDF (Polyvinylidene Fluoride) in advanced computing applications, particularly in memory storage, is a critical consideration as the technology continues to evolve. PVDF's unique properties, including its ferroelectric behavior and high dielectric constant, make it an attractive material for next-generation memory devices. However, its long-term viability must be assessed from various sustainability perspectives.

From an environmental standpoint, PVDF production involves fluorine-based chemicals, which can have significant ecological impacts if not properly managed. The manufacturing process requires careful control to minimize emissions and waste. However, PVDF's durability and long lifespan in electronic applications can potentially offset some of these environmental concerns by reducing the need for frequent device replacements.

In terms of resource sustainability, PVDF relies on petrochemical feedstocks, which are finite resources. As global efforts to reduce dependence on fossil fuels intensify, alternative production methods or precursors for PVDF may need to be explored. Research into bio-based or recycled precursors for PVDF synthesis could potentially address this challenge in the future.

The energy efficiency of PVDF-based memory devices is a key factor in their sustainability profile. These devices typically operate at lower voltages compared to conventional memory technologies, potentially reducing power consumption in computing systems. This energy efficiency can contribute to the overall sustainability of data centers and personal computing devices, aligning with global efforts to reduce energy consumption in the IT sector.

Recyclability and end-of-life management of PVDF-based electronic components present both challenges and opportunities. While PVDF itself is recyclable, its integration into complex electronic devices can make separation and recovery difficult. Developing efficient recycling processes for PVDF-containing electronics will be crucial for closing the loop in the material's lifecycle and minimizing electronic waste.

The longevity and reliability of PVDF in memory applications also contribute to its sustainability profile. If PVDF-based memory devices can demonstrate superior endurance and retention characteristics compared to existing technologies, they could significantly extend the useful life of computing hardware, reducing electronic waste and the need for frequent replacements.

As the demand for advanced computing and data storage continues to grow, the scalability of PVDF production becomes a critical sustainability factor. Ensuring a stable and sustainable supply chain for PVDF and its precursors will be essential for its long-term viability in the memory storage market. This may involve developing more efficient synthesis methods or exploring alternative sources for raw materials.