PVDF in Energy Storage: Boosting Battery Performance

PVDF in Energy Storage: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a crucial material in the field of energy storage, particularly in enhancing battery performance. The evolution of PVDF in this domain traces back to the 1960s when its unique properties were first recognized. Since then, PVDF has undergone significant advancements, transforming from a simple polymer to a versatile component in various energy storage applications.

The primary objective of incorporating PVDF in energy storage systems is to improve the overall efficiency, durability, and performance of batteries. PVDF's exceptional properties, including its high dielectric constant, excellent thermal stability, and superior mechanical strength, make it an ideal candidate for addressing several challenges in battery technology.

In recent years, the focus has shifted towards developing advanced PVDF-based materials and composites to meet the growing demands of next-generation energy storage devices. These developments aim to enhance key battery parameters such as energy density, power output, cycle life, and safety.

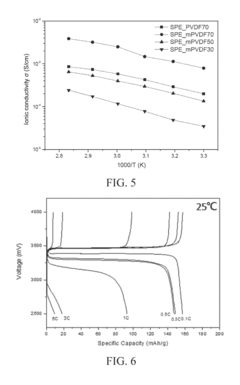

One of the most promising areas of research involves the use of PVDF as a binder material in lithium-ion batteries. The polymer's ability to form strong adhesive bonds between active materials and current collectors contributes to improved electrode stability and longevity. Additionally, PVDF's role in electrolyte systems has gained attention, with efforts directed towards creating novel PVDF-based gel polymer electrolytes that offer enhanced ionic conductivity and electrochemical stability.

The technological trajectory of PVDF in energy storage is closely aligned with the broader trends in sustainable energy solutions and electric mobility. As the demand for high-performance batteries continues to grow, driven by the electric vehicle market and renewable energy integration, the importance of PVDF in addressing these challenges becomes increasingly evident.

Looking ahead, the objectives for PVDF in energy storage extend beyond mere performance improvements. Researchers and industry players are exploring ways to leverage PVDF's properties to develop more environmentally friendly and cost-effective battery solutions. This includes investigating bio-based precursors for PVDF synthesis and optimizing manufacturing processes to reduce the environmental footprint of battery production.

In conclusion, the background and objectives of PVDF in energy storage reflect a dynamic and evolving field. From its initial recognition as a useful polymer to its current status as a key enabler of advanced battery technologies, PVDF continues to play a pivotal role in shaping the future of energy storage. The ongoing research and development efforts aim to unlock its full potential, paving the way for more efficient, durable, and sustainable energy storage solutions.

Market Analysis for PVDF-Enhanced Batteries

The market for PVDF-enhanced batteries is experiencing significant growth, driven by the increasing demand for high-performance energy storage solutions across various industries. PVDF (Polyvinylidene Fluoride) has emerged as a crucial material in improving battery performance, particularly in lithium-ion batteries, which dominate the rechargeable battery market.

The global lithium-ion battery market, where PVDF plays a vital role, is projected to expand rapidly in the coming years. This growth is primarily fueled by the rising adoption of electric vehicles (EVs), renewable energy systems, and portable electronic devices. The automotive sector, in particular, is a major driver for PVDF-enhanced batteries, as automakers seek to improve the range and performance of their electric vehicles.

In the EV market, PVDF-enhanced batteries offer several advantages, including higher energy density, improved thermal stability, and longer cycle life. These benefits are crucial for addressing consumer concerns about EV range and battery longevity. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for advanced battery technologies incorporating PVDF is expected to surge.

The renewable energy sector is another significant market for PVDF-enhanced batteries. As the world transitions towards cleaner energy sources, there is an increasing need for efficient and reliable energy storage systems. PVDF-based batteries are well-suited for grid-scale energy storage applications, helping to balance supply and demand in renewable energy systems and improve overall grid stability.

Consumer electronics represent another substantial market segment for PVDF-enhanced batteries. With the growing demand for longer-lasting and faster-charging devices, manufacturers are turning to advanced battery technologies to meet consumer expectations. PVDF's ability to enhance battery performance aligns well with these market requirements.

The Asia-Pacific region, particularly China, Japan, and South Korea, currently dominates the PVDF-enhanced battery market. These countries have established themselves as major players in battery manufacturing and are investing heavily in research and development to maintain their competitive edge. However, North America and Europe are also witnessing significant growth in this market, driven by increasing EV adoption and renewable energy initiatives.

Key market players in the PVDF-enhanced battery sector include major chemical companies that produce PVDF, such as Arkema, Solvay, and Kureha, as well as battery manufacturers like Panasonic, LG Chem, and Samsung SDI. These companies are actively investing in research and development to improve PVDF formulations and battery technologies, further driving market growth.

Current Challenges in PVDF Battery Integration

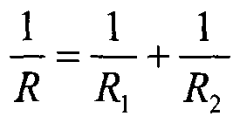

The integration of PVDF (Polyvinylidene Fluoride) in battery systems presents several significant challenges that researchers and manufacturers are actively working to overcome. One of the primary issues is the limited ionic conductivity of PVDF, which can hinder the overall performance of the battery. While PVDF offers excellent mechanical and chemical stability, its inherent insulating properties can impede the movement of ions, potentially reducing the battery's efficiency and power output.

Another challenge lies in the compatibility of PVDF with other battery components, particularly electrolytes. The interaction between PVDF and certain electrolytes can lead to unwanted side reactions or degradation over time, affecting the long-term stability and cycle life of the battery. Researchers are exploring various modifications to PVDF or developing composite materials to enhance its compatibility and performance within the battery system.

The processing and manufacturing of PVDF for battery applications also present technical hurdles. Achieving the desired morphology and porosity in PVDF membranes or coatings is crucial for optimal battery performance. However, controlling these parameters consistently during large-scale production remains a challenge. The need for precise control over the crystalline structure of PVDF, which significantly influences its properties, adds another layer of complexity to the manufacturing process.

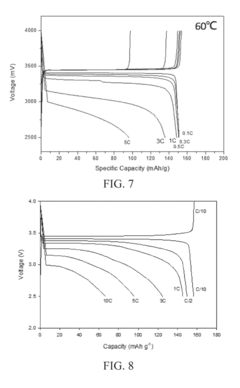

Temperature sensitivity is another concern in PVDF battery integration. The material's properties can change significantly with temperature fluctuations, potentially affecting battery performance and safety under extreme conditions. This necessitates careful design considerations and the development of strategies to maintain stable performance across a wide temperature range.

Furthermore, the cost-effectiveness of incorporating PVDF into battery systems poses an economic challenge. While PVDF offers numerous benefits, its production and processing can be more expensive compared to some alternative materials. Balancing the enhanced performance with the increased cost is a key consideration for widespread adoption in commercial battery applications.

Lastly, the environmental impact and recyclability of PVDF in batteries are growing concerns. As the demand for energy storage solutions increases, the end-of-life management of batteries containing PVDF becomes increasingly important. Developing efficient recycling processes for PVDF-containing batteries and exploring more sustainable alternatives are areas of ongoing research and development in the field.

Existing PVDF-Based Battery Solutions

01 PVDF binder composition for improved battery performance

Optimizing the PVDF binder composition can enhance battery performance. This includes modifying the molecular weight, crystallinity, and additives in the PVDF binder to improve adhesion, mechanical strength, and electrochemical stability of the electrode materials.- PVDF binder composition for improved battery performance: Optimizing the PVDF binder composition can enhance battery performance. This includes modifying the molecular weight, crystallinity, and additives in the PVDF formulation to improve adhesion, conductivity, and overall battery efficiency.

- PVDF-based separator membranes: Developing advanced PVDF-based separator membranes can significantly improve battery safety and performance. These membranes offer enhanced thermal stability, mechanical strength, and ion conductivity, leading to better overall battery characteristics.

- PVDF nanocomposites for electrode materials: Incorporating nanoparticles or nanostructures into PVDF-based electrode materials can enhance the electrochemical properties of batteries. This approach improves conductivity, capacity, and cycling stability of the electrodes.

- Surface modification of PVDF for improved battery performance: Modifying the surface of PVDF materials used in batteries can enhance their compatibility with electrolytes and active materials. This leads to improved interfacial properties, better ion transport, and increased overall battery efficiency.

- PVDF-based gel polymer electrolytes: Developing PVDF-based gel polymer electrolytes can improve the safety and performance of lithium-ion batteries. These electrolytes offer better thermal stability, higher ionic conductivity, and reduced electrolyte leakage compared to traditional liquid electrolytes.

02 PVDF-based composite separators

Developing PVDF-based composite separators can improve battery safety and performance. These separators often incorporate inorganic particles or other polymers to enhance thermal stability, mechanical strength, and ion conductivity while maintaining the excellent chemical stability of PVDF.Expand Specific Solutions03 Surface modification of PVDF for enhanced electrode properties

Modifying the surface of PVDF used in electrodes can improve its compatibility with active materials and electrolytes. Techniques such as plasma treatment, grafting, or coating can enhance wettability, adhesion, and electrochemical performance of PVDF-based electrodes.Expand Specific Solutions04 PVDF copolymers for battery applications

Developing PVDF copolymers by incorporating other monomers can tailor the properties of the resulting material for specific battery applications. These copolymers can offer improved flexibility, adhesion, or electrolyte uptake compared to pure PVDF.Expand Specific Solutions05 PVDF-based gel polymer electrolytes

Creating PVDF-based gel polymer electrolytes can enhance the safety and performance of lithium-ion batteries. These electrolytes combine the mechanical stability of PVDF with the high ionic conductivity of liquid electrolytes, potentially reducing the risk of leakage and improving cycle life.Expand Specific Solutions

Key Players in PVDF Battery Research

The PVDF in energy storage market is in a growth phase, driven by increasing demand for high-performance batteries. The market size is expanding rapidly, with major players like LG Energy Solution, BYD, and Nissan Motor Co. investing heavily in research and development. Technologically, PVDF applications in batteries are advancing, with companies such as DuPont, Zhejiang Juhua, and Daikin Industries leading innovations. The technology's maturity varies across different applications, with established uses in lithium-ion batteries and emerging potential in next-generation energy storage solutions. Collaborations between academic institutions like Nanyang Technological University and industry leaders are accelerating technological progress, indicating a competitive and dynamic landscape.

BYD Co., Ltd.

DuPont de Nemours, Inc.

Innovative PVDF Formulations for Batteries

- The energy storage device incorporates a copolymer derived from polyvinylidene difluoride (PVDF) with a functional group such as quaternary ammonium, phosphonium, sulfonato, cyano, or polyether, used in the anode, cathode, or electrolyte membrane, specifically synthesized through grafting processes like atom-transfer radical-polymerization, to enhance ionic conductivity.

- Formation of graft copolymers by irradiating PVDF with electrically charged particles, followed by grafting electrically conductive polymers like polyaniline, which improves compatibility and prevents aggregation, leading to enhanced dielectric properties and flexibility.

Environmental Impact of PVDF in Batteries

The environmental impact of PVDF (Polyvinylidene fluoride) in batteries is a critical consideration as the demand for energy storage solutions continues to grow. PVDF plays a crucial role in enhancing battery performance, particularly in lithium-ion batteries, but its production and disposal processes raise important environmental concerns.

The manufacturing of PVDF involves the use of fluorine-based chemicals, which can have significant environmental implications. The production process releases greenhouse gases, including hydrofluorocarbons (HFCs) and perfluorocarbons (PFCs), which contribute to global warming. These emissions have a high global warming potential, sometimes thousands of times more potent than carbon dioxide. Additionally, the synthesis of PVDF requires substantial energy inputs, further increasing its carbon footprint.

Water pollution is another environmental challenge associated with PVDF production. The manufacturing process can result in the release of fluorinated compounds into water systems, potentially affecting aquatic ecosystems and human health. These persistent organic pollutants can bioaccumulate in the food chain, posing long-term risks to the environment.

At the end of a battery's life cycle, the presence of PVDF complicates recycling efforts. The polymer's stability, while beneficial for battery performance, makes it resistant to degradation. This characteristic hinders the separation and recovery of other valuable battery components, such as lithium and cobalt. Consequently, the recycling process becomes more energy-intensive and less efficient, potentially leading to increased waste and resource depletion.

However, it's important to note that the use of PVDF in batteries also contributes to positive environmental outcomes. By improving battery performance and longevity, PVDF indirectly reduces the overall environmental impact of energy storage systems. Longer-lasting batteries mean fewer replacements, less frequent manufacturing, and reduced waste generation over time.

Efforts are underway to mitigate the environmental impact of PVDF in batteries. Research is focused on developing more environmentally friendly synthesis methods, exploring bio-based alternatives, and improving recycling technologies. Some studies are investigating the potential of water-based PVDF binders, which could significantly reduce the use of toxic solvents in battery production.

In conclusion, while PVDF plays a vital role in advancing battery technology, its environmental impact remains a complex issue. Balancing the benefits of improved battery performance against the environmental costs of production and disposal is an ongoing challenge for the energy storage industry. Future developments in green chemistry and circular economy principles will be crucial in addressing these environmental concerns and ensuring the sustainable growth of battery technology.

Cost-Benefit Analysis of PVDF Battery Implementation

The implementation of PVDF (Polyvinylidene Fluoride) in battery technology presents a complex cost-benefit scenario that requires careful analysis. On the cost side, PVDF is generally more expensive than traditional binder materials used in battery production. This higher material cost can significantly impact the overall manufacturing expenses, potentially increasing the price point of PVDF-enhanced batteries.

However, the benefits of PVDF implementation in batteries are substantial and may outweigh the initial cost increase. PVDF's superior electrochemical stability and adhesion properties contribute to enhanced battery performance and longevity. Batteries utilizing PVDF binders typically demonstrate improved capacity retention over multiple charge-discharge cycles, effectively extending the usable life of the battery.

The increased durability and performance of PVDF-enhanced batteries can lead to reduced replacement frequency, resulting in long-term cost savings for end-users. This is particularly relevant in applications where battery replacement is challenging or expensive, such as in electric vehicles or large-scale energy storage systems.

From an environmental perspective, the extended lifespan of PVDF batteries contributes to reduced electronic waste, aligning with sustainability goals and potentially offering economic benefits through reduced disposal costs and compliance with environmental regulations.

The manufacturing process for PVDF batteries may require initial investments in equipment and process modifications. However, these upfront costs can be offset by the potential for streamlined production processes and reduced material waste due to PVDF's excellent processing characteristics.

Market analysis suggests that consumers are increasingly willing to pay a premium for high-performance, long-lasting batteries, particularly in sectors like electric vehicles and portable electronics. This trend could justify the higher initial costs associated with PVDF implementation, as the perceived value of improved battery performance may drive market acceptance and sales.

In conclusion, while the implementation of PVDF in battery technology does incur higher initial costs, the long-term benefits in terms of performance, durability, and potential market advantages present a compelling case for its adoption. As production scales and technology advances, it is likely that the cost-benefit ratio will continue to improve, further solidifying PVDF's position as a valuable component in next-generation energy storage solutions.