PVDF in Fuel Cells: Increasing Operational Longevity

PVDF in Fuel Cells: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a crucial material in fuel cell technology, particularly in the quest for enhancing operational longevity. The development of PVDF in fuel cells traces back to the early 2000s when researchers began exploring alternative materials to address the limitations of traditional membranes. As fuel cell technology progressed, the need for more durable and efficient components became increasingly apparent, leading to a focused interest in PVDF's unique properties.

The evolution of PVDF in fuel cells has been driven by the growing demand for clean energy solutions and the push towards sustainable transportation. Initially, PVDF was primarily used as a binder material in electrode fabrication. However, its potential as a membrane material soon became evident due to its excellent chemical stability, mechanical strength, and proton conductivity when properly modified.

Over the past two decades, significant advancements have been made in understanding the behavior of PVDF in fuel cell environments. Researchers have explored various modifications and composites to enhance its performance, including the incorporation of inorganic fillers, surface treatments, and the development of PVDF-based copolymers. These efforts have aimed to address key challenges such as membrane degradation, fuel crossover, and maintaining proton conductivity under varying operating conditions.

The primary objective in utilizing PVDF for fuel cells is to increase operational longevity while maintaining or improving overall cell performance. This goal encompasses several key aspects, including enhancing chemical and mechanical stability, improving proton conductivity, and reducing degradation rates under prolonged operation. Researchers are particularly focused on developing PVDF-based membranes that can withstand the harsh chemical environment of fuel cells, resist physical deformation, and maintain consistent performance over extended periods.

Another critical objective is to optimize the manufacturing processes for PVDF-based fuel cell components, ensuring scalability and cost-effectiveness. This involves refining techniques for membrane fabrication, electrode preparation, and assembly integration. Additionally, there is a growing emphasis on developing PVDF formulations that are compatible with high-volume production methods, which is essential for the widespread adoption of fuel cell technology.

As the field progresses, the research community is also exploring the potential of PVDF in next-generation fuel cell designs, such as high-temperature proton exchange membrane fuel cells (HT-PEMFCs) and direct methanol fuel cells (DMFCs). These applications present unique challenges and opportunities for PVDF, driving further innovation in material science and fuel cell engineering.

Market Analysis for PVDF-Enhanced Fuel Cells

The market for PVDF-enhanced fuel cells is experiencing significant growth, driven by the increasing demand for clean energy solutions and the push towards sustainable transportation. As governments worldwide implement stricter emissions regulations, the automotive industry is rapidly shifting towards fuel cell electric vehicles (FCEVs), particularly in the commercial and heavy-duty sectors. This transition is creating a robust market for advanced fuel cell technologies, with PVDF-enhanced membranes playing a crucial role in improving fuel cell performance and longevity.

The global fuel cell market is projected to expand at a compound annual growth rate (CAGR) of over 20% in the coming years, with the transportation sector expected to be the largest contributor to this growth. Within this market, PVDF-enhanced fuel cells are gaining traction due to their superior durability and efficiency compared to traditional membrane materials. The automotive industry, in particular, is showing keen interest in PVDF-based proton exchange membranes (PEMs) for their potential to extend the operational life of fuel cell stacks in vehicles.

In addition to the automotive sector, stationary power generation and portable electronics are emerging as promising markets for PVDF-enhanced fuel cells. The increasing need for reliable backup power systems in data centers, hospitals, and telecommunications infrastructure is driving demand for long-lasting fuel cell solutions. PVDF's excellent chemical stability and mechanical strength make it an attractive option for these applications, where extended operational life is critical.

The Asia-Pacific region, led by Japan, South Korea, and China, is at the forefront of fuel cell technology adoption and is expected to be the largest market for PVDF-enhanced fuel cells. These countries have implemented strong government support and incentives for fuel cell technology development and commercialization. Europe and North America are also showing significant growth potential, with several major automotive manufacturers investing heavily in fuel cell research and development.

Market analysis indicates that the demand for PVDF-enhanced fuel cells is closely tied to the overall growth of the hydrogen economy. As hydrogen production and distribution infrastructure expands, it is expected to further boost the adoption of fuel cell technologies across various sectors. This symbiotic relationship between hydrogen infrastructure development and fuel cell market growth presents both opportunities and challenges for PVDF-enhanced fuel cell manufacturers.

Current PVDF Technology and Challenges in Fuel Cells

Polyvinylidene fluoride (PVDF) has emerged as a crucial material in fuel cell technology, particularly in proton exchange membrane fuel cells (PEMFCs). Its unique properties, including excellent chemical stability, high mechanical strength, and good proton conductivity, make it an ideal candidate for various components within fuel cells. However, the current state of PVDF technology in fuel cells faces several challenges that limit its operational longevity and overall performance.

One of the primary challenges is the degradation of PVDF membranes under the harsh operating conditions of fuel cells. The high temperatures, acidic environment, and presence of reactive species can lead to chemical and mechanical degradation of PVDF over time. This degradation manifests as membrane thinning, pinhole formation, and loss of proton conductivity, ultimately reducing the fuel cell's efficiency and lifespan.

Another significant challenge is the water management within PVDF-based membranes. While PVDF exhibits good proton conductivity when properly hydrated, maintaining optimal water content throughout the membrane during fuel cell operation remains difficult. Excessive water can lead to flooding, while insufficient hydration results in decreased proton conductivity. Balancing these factors to ensure consistent performance across various operating conditions is an ongoing challenge.

The current PVDF technology also faces limitations in terms of its temperature resistance. Although PVDF has good thermal stability compared to many polymers, the extreme temperature fluctuations experienced in fuel cell systems can still cause structural changes and performance degradation over time. Improving the high-temperature stability of PVDF membranes without compromising other essential properties is a key area of focus for researchers.

Furthermore, the mechanical durability of PVDF membranes under cyclic stress conditions is a concern. The repeated swelling and shrinking of the membrane due to hydration changes, coupled with mechanical stresses from assembly and operation, can lead to fatigue and eventual failure. Enhancing the mechanical robustness of PVDF membranes while maintaining their flexibility and proton conductivity is crucial for increasing operational longevity.

The integration of PVDF with other materials to form composite membranes presents both opportunities and challenges. While composites can potentially address some of the limitations of pure PVDF membranes, issues such as phase separation, interfacial adhesion, and long-term stability of these multi-component systems need to be carefully managed.

Lastly, the scalability and cost-effectiveness of PVDF-based solutions for fuel cells remain significant hurdles. Developing manufacturing processes that can produce high-quality, defect-free PVDF membranes at scale, while keeping costs competitive, is essential for the widespread adoption of this technology in commercial fuel cell applications.

Existing PVDF Solutions for Fuel Cell Longevity

01 PVDF membrane modification for enhanced longevity

Various techniques are employed to modify PVDF membranes, improving their operational longevity. These modifications can include surface treatments, blending with other polymers, or incorporating additives. Such enhancements can lead to increased durability, improved chemical resistance, and better overall performance in long-term applications.- PVDF membrane modification for enhanced longevity: Various techniques are employed to modify PVDF membranes, improving their operational longevity. These modifications can include surface treatments, blending with other polymers, or incorporating additives. Such enhancements can lead to increased durability, chemical resistance, and overall performance of PVDF membranes in various applications.

- PVDF in energy storage applications: PVDF is utilized in energy storage devices, particularly in lithium-ion batteries and supercapacitors. Its use as a binder or separator material contributes to improved cycle life and operational longevity of these devices. The polymer's stability and electrochemical properties make it suitable for long-term energy storage applications.

- PVDF-based coatings for extended lifespan: PVDF-based coatings are developed to enhance the longevity of various substrates. These coatings provide excellent weather resistance, UV stability, and chemical resistance. The application of PVDF coatings can significantly extend the operational life of materials used in construction, automotive, and industrial sectors.

- PVDF in water treatment and filtration systems: PVDF membranes are widely used in water treatment and filtration systems due to their long operational life. The polymer's resistance to fouling, chemical stability, and mechanical strength contribute to its durability in these applications. Various modifications and treatments are employed to further enhance the longevity of PVDF membranes in water purification processes.

- PVDF composites for improved durability: PVDF is combined with other materials to create composites with enhanced properties and extended operational life. These composites may incorporate nanoparticles, fibers, or other polymers to improve mechanical strength, thermal stability, and chemical resistance. The resulting materials find applications in various industries where long-term performance is crucial.

02 PVDF in energy storage applications

PVDF is utilized in energy storage devices, particularly in lithium-ion batteries and supercapacitors. Its use as a binder or separator material contributes to improved cycle life and overall operational longevity of these devices. The polymer's stability and electrochemical properties make it suitable for long-term energy storage applications.Expand Specific Solutions03 PVDF-based coatings for extended lifespan

PVDF-based coatings are developed to enhance the longevity of various surfaces and materials. These coatings provide excellent weather resistance, UV stability, and chemical resistance, making them suitable for long-term outdoor applications. The coatings can be applied to metals, plastics, and other substrates to extend their operational life.Expand Specific Solutions04 PVDF in water treatment and filtration systems

PVDF membranes are widely used in water treatment and filtration systems due to their long operational life. The polymer's resistance to fouling, chemical stability, and mechanical strength contribute to its durability in these applications. Various modifications and treatments are employed to further enhance the longevity of PVDF membranes in water purification processes.Expand Specific Solutions05 PVDF composites for improved durability

PVDF is combined with other materials to create composites with enhanced properties and extended operational life. These composites can incorporate nanoparticles, fibers, or other polymers to improve mechanical strength, thermal stability, and chemical resistance. The resulting materials find applications in various industries where long-term performance is crucial.Expand Specific Solutions

Key Players in PVDF and Fuel Cell Industries

The PVDF in fuel cells market is in a growth phase, driven by increasing demand for sustainable energy solutions. The market size is expanding, with major automotive players like Toyota, Nissan, and Hyundai investing heavily in fuel cell technology. Technical maturity varies, with established companies like Panasonic and Samsung SDI leading in PVDF membrane development. Research institutions such as Dalian Institute of Chemical Physics and Forschungszentrum Jülich are advancing the technology, while specialized firms like Intelligent Energy and Plug Power focus on commercialization. The competitive landscape is diverse, including chemical companies like Arkema and automotive suppliers such as DENSO, indicating a complex ecosystem working towards improving fuel cell longevity and performance.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Samsung SDI Co., Ltd.

Core Innovations in PVDF for Fuel Cells

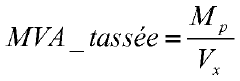

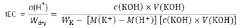

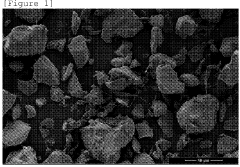

- A proton exchange membrane based on irradiated PVDF in the form of cryocrushed granules, where the PVDF powder is grafted with vinyl monomers and sulfonated, resulting in a dense powder with enhanced ion exchange capacity and improved thermal resistance, mechanical flexibility, and conductivity.

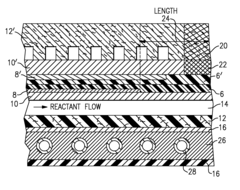

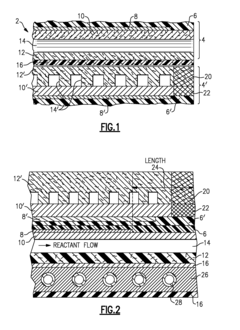

- The fuel cell assembly incorporates non-porous and hydrophobic flow field layers, an electrolyte retaining matrix with silicon carbide powder, hydrophilic substrates as catalyst layer reservoirs, and a condensation zone that cools vapor to less than 140°C, reducing acid loss and enhancing acid absorption rates.

Environmental Impact of PVDF in Fuel Cells

The environmental impact of PVDF (Polyvinylidene fluoride) in fuel cells is a critical consideration as the technology advances towards increasing operational longevity. PVDF, widely used as a membrane material in fuel cells, offers excellent chemical stability and mechanical strength. However, its production, use, and disposal present several environmental challenges that must be addressed.

The manufacturing process of PVDF involves the use of fluorine-containing compounds, which can contribute to greenhouse gas emissions if not properly managed. The production of PVDF monomers and subsequent polymerization require energy-intensive processes, potentially increasing the carbon footprint of fuel cell production. Additionally, the use of solvents in PVDF membrane fabrication may lead to air and water pollution if appropriate containment and treatment measures are not implemented.

During the operational life of fuel cells, PVDF membranes demonstrate remarkable durability, which indirectly benefits the environment by reducing the frequency of replacements and associated waste. However, the degradation of PVDF over extended periods can release small amounts of fluoride ions into the fuel cell system, potentially impacting the overall efficiency and lifespan of the cell.

End-of-life considerations for PVDF membranes pose significant environmental challenges. PVDF is not biodegradable and can persist in the environment for extended periods if not properly disposed of or recycled. Incineration of PVDF-containing components can release harmful fluorine compounds into the atmosphere, necessitating specialized waste management protocols.

On the positive side, the increased operational longevity of fuel cells using PVDF membranes contributes to resource conservation by reducing the need for frequent replacements. This extended lifespan translates to fewer raw materials extracted, less energy consumed in manufacturing, and reduced waste generation over the fuel cell's lifecycle.

Efforts to mitigate the environmental impact of PVDF in fuel cells focus on several areas. Research into green synthesis methods for PVDF aims to reduce the use of harmful solvents and minimize energy consumption during production. Advanced recycling technologies are being developed to recover and reuse PVDF from decommissioned fuel cells, closing the loop on material usage and reducing waste.

Furthermore, ongoing studies explore the potential of bio-based or hybrid materials that could partially or fully replace PVDF in fuel cell membranes, offering improved environmental profiles without compromising performance. These alternatives may provide a pathway to more sustainable fuel cell technologies in the future, balancing the need for increased operational longevity with reduced environmental impact.

Cost-Benefit Analysis of PVDF Integration

The integration of PVDF (Polyvinylidene Fluoride) in fuel cells presents a complex cost-benefit scenario that requires careful analysis. On the cost side, PVDF is generally more expensive than traditional materials used in fuel cell components. The initial investment in PVDF-based materials can be significantly higher, potentially increasing the overall production costs of fuel cells.

However, the benefits of PVDF integration often outweigh these upfront costs. PVDF's exceptional chemical resistance and thermal stability contribute to increased operational longevity of fuel cells. This extended lifespan translates to reduced maintenance and replacement costs over the fuel cell's operational lifetime. The durability of PVDF components also leads to improved reliability, minimizing downtime and associated economic losses.

PVDF's unique properties allow for enhanced performance in fuel cell systems. Its low gas permeability helps maintain the integrity of gas separation within the cell, improving overall efficiency. This increased efficiency can result in higher power output and lower fuel consumption, providing long-term cost savings for end-users.

The environmental benefits of PVDF integration also factor into the cost-benefit analysis. The extended lifespan of PVDF-enhanced fuel cells reduces the frequency of replacements, thereby decreasing the environmental impact associated with manufacturing and disposal. This aligns with growing environmental regulations and can potentially lead to cost savings through reduced environmental compliance expenses.

From a manufacturing perspective, while initial tooling and process adjustments may be required, the integration of PVDF can lead to streamlined production processes in the long run. PVDF's versatility allows for the potential consolidation of components, reducing assembly complexity and associated labor costs.

Market differentiation is another crucial factor to consider. Fuel cells with PVDF components can command premium pricing due to their superior performance and longevity. This price premium can offset the higher initial costs and potentially increase profit margins for manufacturers.

In conclusion, while the upfront costs of PVDF integration in fuel cells are higher, the long-term benefits in terms of durability, performance, and reduced lifecycle costs present a compelling value proposition. As the fuel cell market continues to grow and mature, the cost-benefit ratio of PVDF integration is likely to improve further, driven by economies of scale and advancements in manufacturing technologies.