PVDF in Renewable Energy: Increasing Solar Panel Efficiency

PVDF in Solar Energy: Evolution and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a promising material in the field of renewable energy, particularly in enhancing solar panel efficiency. The evolution of PVDF in solar energy applications can be traced back to the 1960s when its piezoelectric properties were first discovered. Since then, researchers and engineers have been exploring its potential to improve the performance of photovoltaic systems.

The primary objective of incorporating PVDF in solar panels is to increase their overall efficiency by addressing key challenges in energy conversion and durability. One of the main goals is to enhance the light-trapping capabilities of solar cells, thereby maximizing the absorption of incident sunlight. PVDF's unique properties allow for the creation of nanostructured surfaces that can significantly reduce reflection and increase light scattering within the solar cell.

Another crucial objective is to improve the long-term stability and reliability of solar panels. PVDF's excellent weather resistance and UV stability make it an ideal candidate for protective coatings and encapsulation materials. By incorporating PVDF into the panel structure, researchers aim to extend the operational lifespan of solar modules and maintain their performance under harsh environmental conditions.

The evolution of PVDF in solar energy has been marked by continuous advancements in material science and manufacturing techniques. Early applications focused on using PVDF as a simple protective layer, but recent developments have led to more sophisticated implementations. These include the creation of PVDF-based nanocomposites, self-cleaning surfaces, and even flexible solar cells that can be integrated into various structures and devices.

As the renewable energy sector continues to grow, the objectives for PVDF in solar energy are becoming increasingly ambitious. Researchers are now exploring ways to combine PVDF with other advanced materials to create multi-functional components that can simultaneously harvest solar energy and perform additional tasks, such as energy storage or self-healing.

The future trajectory of PVDF in solar energy is likely to focus on further improving efficiency, reducing manufacturing costs, and developing more sustainable production methods. There is also a growing interest in exploring PVDF's potential in next-generation solar technologies, such as perovskite solar cells and tandem photovoltaic systems.

Market Analysis for PVDF-Enhanced Solar Panels

The market for PVDF-enhanced solar panels is experiencing significant growth, driven by the increasing demand for higher efficiency photovoltaic systems. As the global push for renewable energy intensifies, solar energy has emerged as a key player in the transition towards cleaner power sources. PVDF (Polyvinylidene fluoride) has gained attention in the solar industry due to its potential to enhance the performance and durability of solar panels.

The current market size for PVDF-enhanced solar panels is substantial and is expected to expand rapidly in the coming years. This growth is primarily attributed to the material's unique properties, including its high dielectric strength, excellent weatherability, and resistance to UV radiation. These characteristics make PVDF an ideal component for improving the longevity and efficiency of solar panels, addressing key challenges faced by traditional photovoltaic systems.

Market demand for PVDF-enhanced solar panels is particularly strong in regions with high solar irradiance and ambitious renewable energy targets. Countries like China, the United States, India, and several European nations are at the forefront of adopting this technology. The residential, commercial, and utility-scale solar sectors are all showing interest in PVDF-enhanced panels, with utility-scale installations leading in terms of volume.

The market is also being driven by stringent environmental regulations and government incentives promoting the adoption of more efficient solar technologies. As countries strive to meet their carbon reduction goals, there is a growing emphasis on maximizing the energy output from solar installations, making PVDF-enhanced panels an attractive option for both new projects and retrofitting existing ones.

Competitive dynamics in the PVDF-enhanced solar panel market are intensifying, with both established solar manufacturers and new entrants vying for market share. Major players are investing heavily in research and development to further improve the integration of PVDF in solar panel design, aiming to achieve even higher efficiency gains and cost reductions.

Despite the positive outlook, the market faces some challenges. The higher initial cost of PVDF-enhanced panels compared to standard modules remains a barrier to widespread adoption, particularly in price-sensitive markets. However, the long-term benefits of increased efficiency and durability are expected to outweigh the upfront costs, especially as production scales up and prices decrease.

Looking ahead, the market for PVDF-enhanced solar panels is projected to grow substantially. Factors such as technological advancements, increasing awareness of the benefits of high-efficiency solar solutions, and the global shift towards sustainable energy sources are expected to drive this growth. As the technology matures and becomes more cost-effective, its market penetration is likely to accelerate, potentially reshaping the broader solar energy landscape.

PVDF Integration Challenges in Photovoltaics

The integration of PVDF (Polyvinylidene Fluoride) into photovoltaic systems presents several significant challenges that researchers and manufacturers must overcome to fully harness its potential for increasing solar panel efficiency. One of the primary obstacles is the complex process of incorporating PVDF into existing solar cell structures without compromising their performance or durability.

PVDF's unique piezoelectric and ferroelectric properties make it an attractive material for enhancing solar panel efficiency, but its integration requires precise control over film thickness, crystallinity, and orientation. Achieving the optimal PVDF layer thickness is crucial, as it directly impacts the material's ability to convert mechanical stress into electrical energy. Too thick a layer may impede light transmission to the underlying photovoltaic cells, while too thin a layer may not provide sufficient piezoelectric effect.

Another significant challenge lies in ensuring proper adhesion between the PVDF layer and the solar cell surface. Poor adhesion can lead to delamination over time, reducing the overall efficiency and lifespan of the solar panel. Developing effective bonding techniques that can withstand various environmental conditions, including temperature fluctuations and humidity, is essential for long-term stability.

The crystalline structure of PVDF plays a vital role in its piezoelectric properties. Controlling the formation of the desired β-phase crystal structure during the manufacturing process is challenging, as it requires specific processing conditions and can be sensitive to environmental factors. Achieving a high percentage of β-phase crystals is crucial for maximizing the piezoelectric response and, consequently, the energy harvesting capabilities of the PVDF layer.

Furthermore, integrating PVDF into large-scale solar panel production presents scalability challenges. Current laboratory-scale successes must be translated into commercially viable manufacturing processes that can maintain consistent quality and performance across large production volumes. This transition requires significant investment in research and development of new manufacturing techniques and equipment.

Electrical interfacing between the PVDF layer and the solar cell's existing circuitry is another area of concern. Designing efficient charge collection and management systems that can handle both the photovoltaic output and the additional piezoelectric contribution from PVDF is complex and requires innovative circuit designs.

Lastly, the long-term stability and degradation of PVDF under prolonged exposure to sunlight and environmental stressors need to be thoroughly investigated. Ensuring that the PVDF layer maintains its performance characteristics over the expected lifespan of solar panels (typically 25-30 years) is crucial for the technology's commercial viability and widespread adoption in the renewable energy sector.

Current PVDF-Based Solar Efficiency Solutions

01 PVDF membrane fabrication and modification

Various techniques are employed to fabricate and modify PVDF membranes to enhance their efficiency. These methods include blending with other polymers, surface modification, and incorporation of nanoparticles. Such modifications can improve the membrane's hydrophilicity, antifouling properties, and overall performance in applications like water treatment and separation processes.- PVDF membrane fabrication and modification: Various techniques are employed to fabricate and modify PVDF membranes to enhance their efficiency. These methods include blending with other polymers, surface modification, and incorporation of nanoparticles. Such modifications can improve the membrane's hydrophilicity, fouling resistance, and overall performance in applications like water treatment and separation processes.

- PVDF in energy storage applications: PVDF is utilized in energy storage devices, particularly in lithium-ion batteries and supercapacitors. Its high dielectric constant and excellent electrochemical stability make it an effective binder material for electrodes. Research focuses on optimizing PVDF formulations and processing techniques to enhance the performance and efficiency of these energy storage systems.

- PVDF-based piezoelectric materials: PVDF and its copolymers are explored for their piezoelectric properties. Research in this area aims to improve the efficiency of PVDF-based piezoelectric materials for applications in sensors, actuators, and energy harvesting devices. Techniques such as stretching, poling, and incorporation of fillers are investigated to enhance the piezoelectric response and overall performance.

- PVDF in water treatment and purification: PVDF membranes are widely used in water treatment and purification processes. Research focuses on improving the efficiency of PVDF-based filtration systems by enhancing membrane properties such as flux, selectivity, and fouling resistance. Novel membrane designs, surface modifications, and hybrid systems are explored to optimize the performance of PVDF membranes in various water treatment applications.

- PVDF in coating and protective applications: PVDF is utilized in coating and protective applications due to its excellent chemical resistance and weatherability. Research in this area aims to improve the efficiency of PVDF-based coatings by enhancing properties such as adhesion, durability, and UV resistance. Novel formulations and processing techniques are explored to optimize the performance of PVDF coatings in various industrial and architectural applications.

02 PVDF in energy storage applications

PVDF is utilized in energy storage devices, particularly in lithium-ion batteries and supercapacitors. Its high dielectric constant and excellent thermal stability make it an efficient binder material for electrodes. Research focuses on optimizing PVDF formulations and processing methods to enhance the performance and longevity of energy storage devices.Expand Specific Solutions03 PVDF-based piezoelectric materials

PVDF and its copolymers exhibit piezoelectric properties, making them suitable for various sensing and energy harvesting applications. Research in this area focuses on improving the piezoelectric efficiency of PVDF materials through methods such as stretching, poling, and incorporation of fillers. These materials find applications in sensors, actuators, and energy harvesting devices.Expand Specific Solutions04 PVDF in filtration and separation processes

PVDF membranes are widely used in filtration and separation processes due to their chemical resistance and mechanical strength. Research focuses on improving the efficiency of PVDF membranes in applications such as water treatment, gas separation, and oil-water separation. This includes developing novel membrane structures and surface modifications to enhance selectivity and flux.Expand Specific Solutions05 PVDF composites for enhanced properties

PVDF is often combined with other materials to create composites with enhanced properties. These composites can exhibit improved mechanical strength, thermal stability, and electrical properties. Research in this area focuses on developing new PVDF-based composites for applications in electronics, aerospace, and automotive industries, among others.Expand Specific Solutions

Key PVDF and Solar Panel Manufacturers

The PVDF in renewable energy sector, specifically for increasing solar panel efficiency, is in a growth phase with expanding market size and evolving technological maturity. The competitive landscape is diverse, featuring established players and innovative startups. Companies like Arkema France SA and 3M Innovative Properties Co. are leveraging their expertise in materials science to develop advanced PVDF formulations. Solar panel manufacturers such as Jinko Solar Co., Ltd. and LONGi Green Energy Technology Co., Ltd. are integrating PVDF technologies to enhance panel performance. Research institutions like King Abdullah University of Science & Technology and the University of California are driving fundamental advancements. The involvement of diverse players, from material suppliers to end-product manufacturers, indicates a growing recognition of PVDF's potential in solar energy efficiency improvements.

Arkema France SA

Jinko Solar Co., Ltd.

PVDF Innovations for Photovoltaic Performance

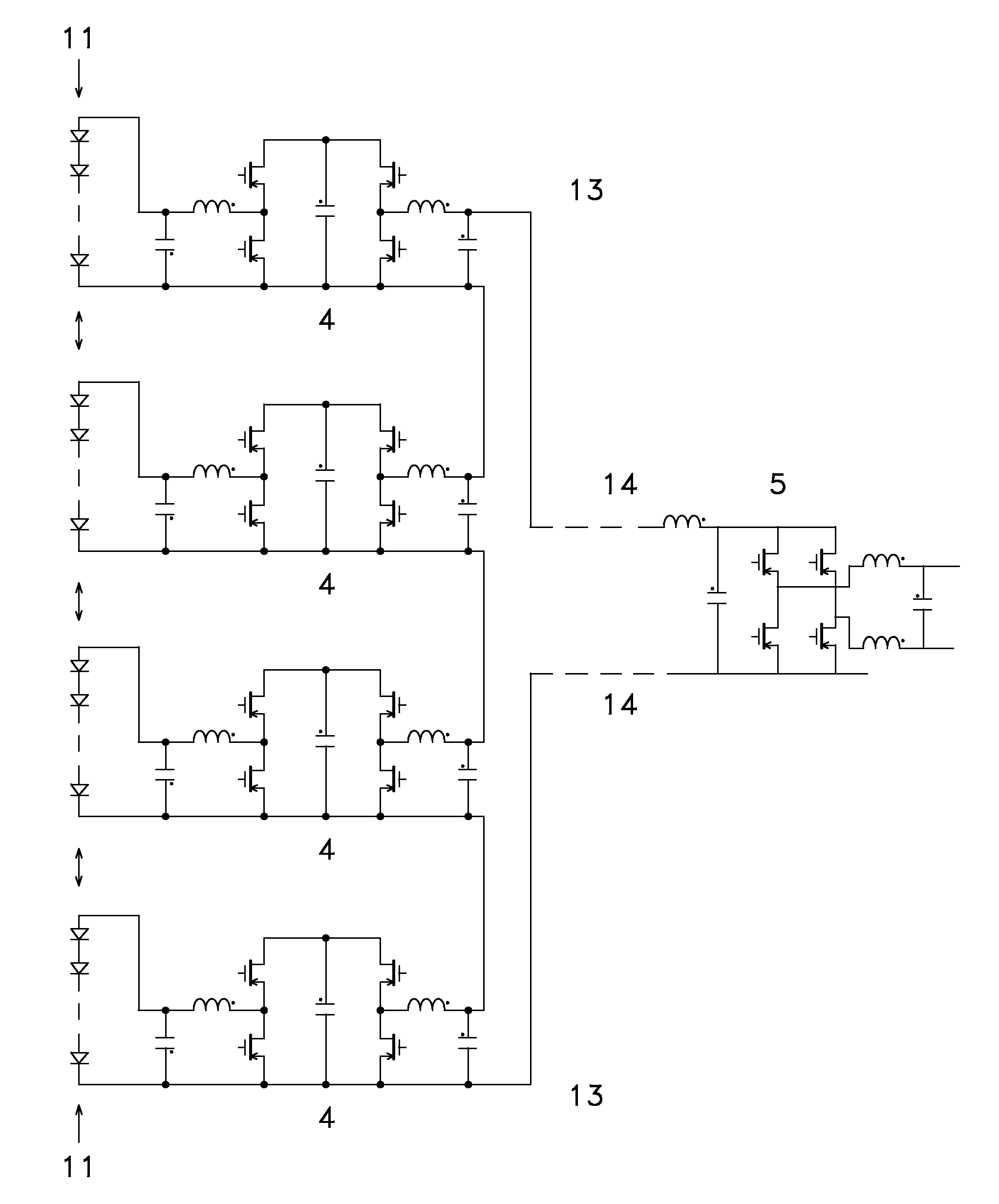

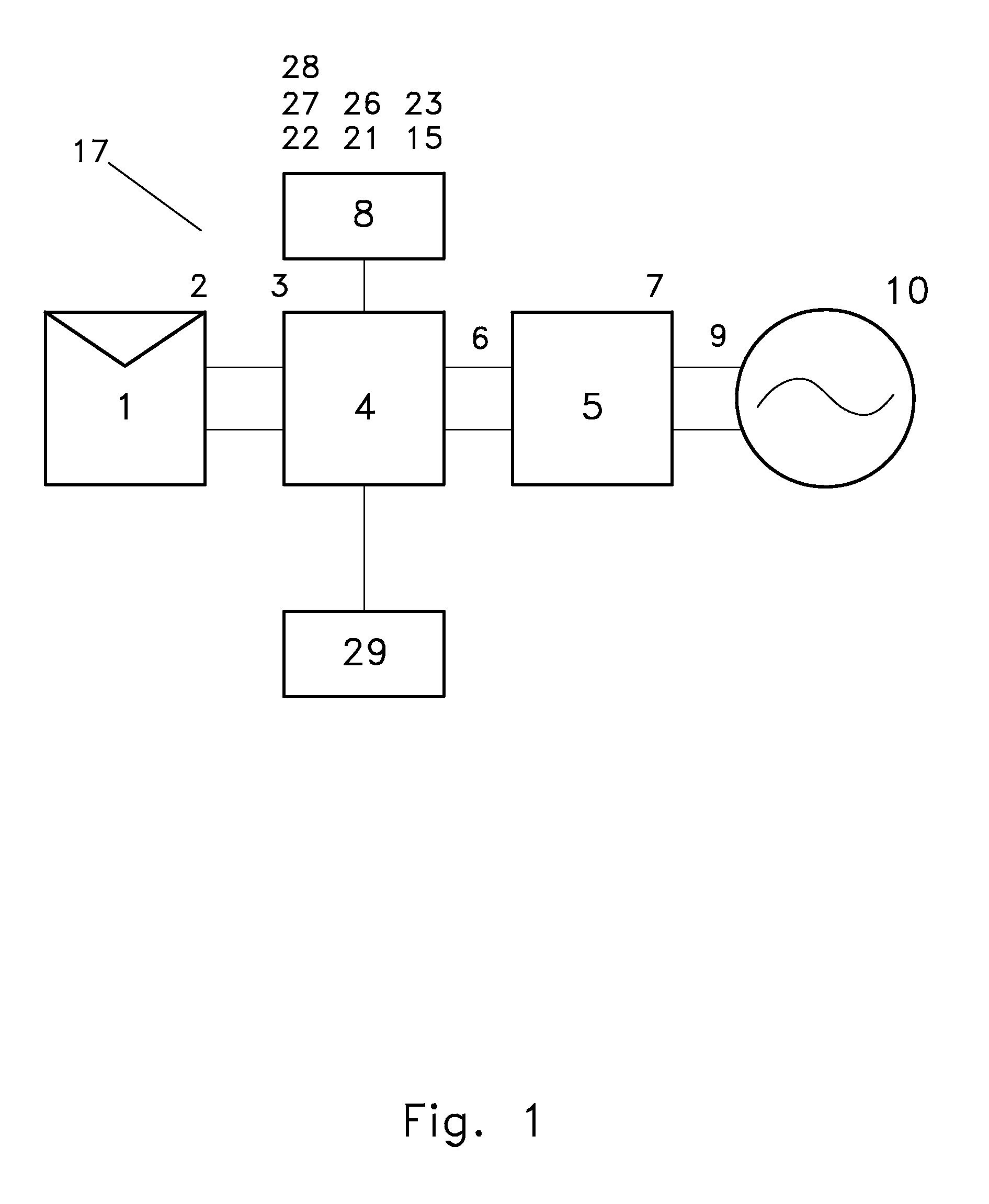

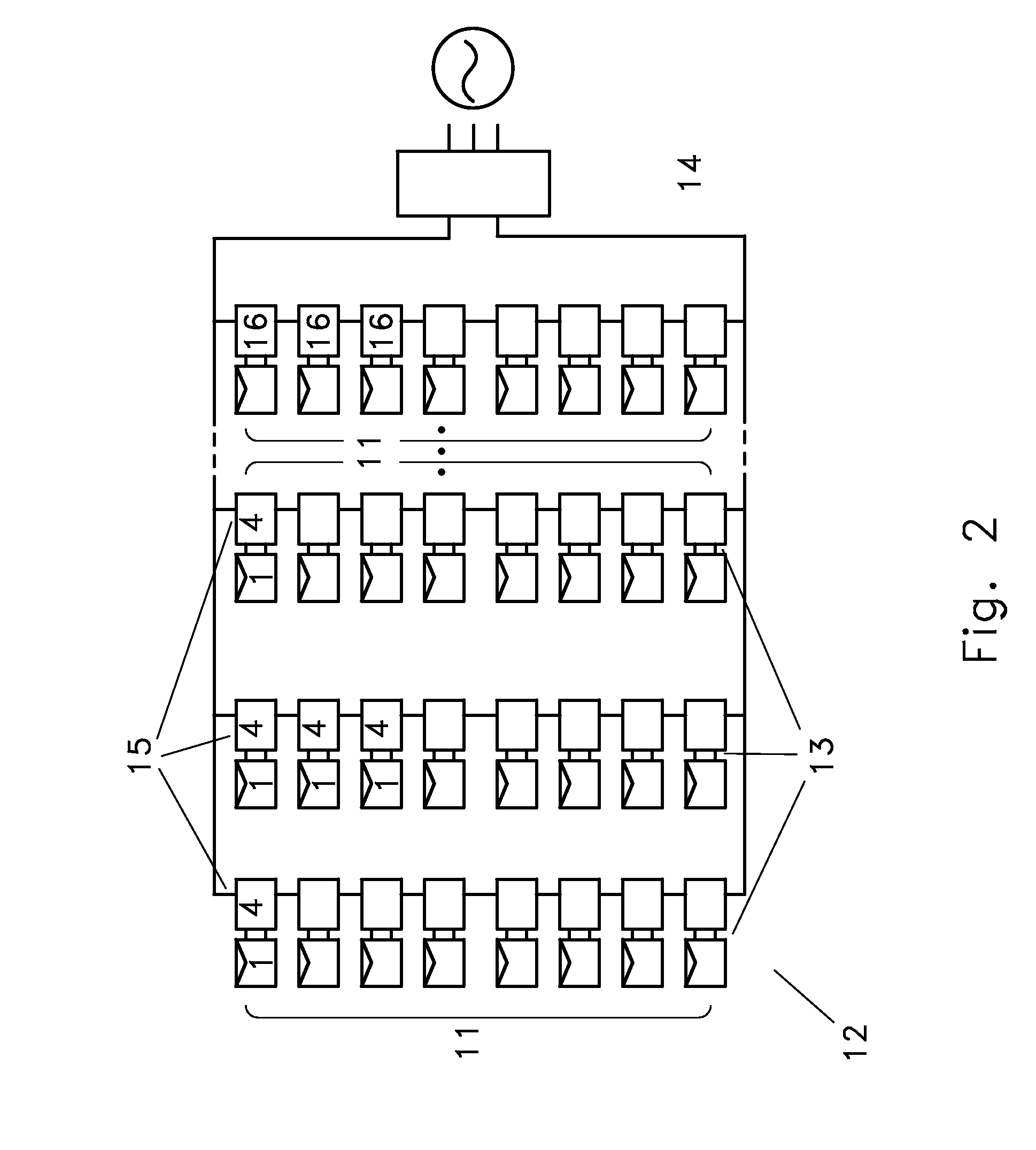

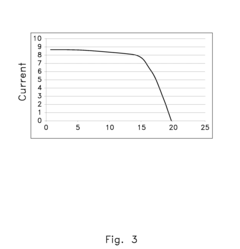

- The implementation of high-efficiency photovoltaic DC-DC power converters with individual maximum power point tracking (MPPT) circuits for each panel, allowing for optimal power extraction and conversion, even in series or parallel configurations, and enabling the combination of different panel types to achieve maximum power output while minimizing losses.

- A photovoltaic module with a transparent thermoplastic glazing covered by a thin layer of polyvinylidene fluoride (PVDF), which provides a chemical-resistant and dirt-shedding surface, often with a tie or adhesive layer for improved adhesion, to minimize dirt accumulation and maintain optimal performance.

Environmental Impact of PVDF in Solar Panels

The environmental impact of PVDF (Polyvinylidene Fluoride) in solar panels is a crucial consideration as the renewable energy sector continues to expand. PVDF plays a significant role in enhancing the efficiency and durability of solar panels, but its production and use also have environmental implications that must be carefully evaluated.

PVDF is primarily used as a protective backsheet material in solar panels, offering excellent weather resistance and durability. This application helps extend the lifespan of solar panels, potentially reducing the overall environmental impact associated with panel replacement and disposal. The material's resistance to UV radiation, moisture, and chemical degradation contributes to maintaining the panel's performance over time, ensuring a more consistent energy output throughout its operational life.

However, the production of PVDF involves energy-intensive processes and the use of fluorine-based chemicals, which can have negative environmental consequences if not properly managed. The synthesis of PVDF typically requires high temperatures and pressures, leading to increased energy consumption and associated greenhouse gas emissions. Additionally, the use of fluorinated compounds in PVDF production raises concerns about potential releases of these substances into the environment, which could contribute to air and water pollution if not adequately controlled.

On the positive side, the use of PVDF in solar panels contributes to the overall sustainability of renewable energy systems. By improving panel efficiency and longevity, PVDF indirectly supports the reduction of carbon emissions associated with energy production. The extended lifespan of solar panels also means fewer replacements are needed over time, potentially reducing the environmental impact related to panel manufacturing and disposal.

End-of-life considerations for PVDF-containing solar panels are an important aspect of their environmental impact. While PVDF itself is not biodegradable, research is ongoing to develop effective recycling methods for solar panels, including the separation and recovery of PVDF components. Successful implementation of these recycling technologies could significantly mitigate the long-term environmental impact of PVDF use in solar energy systems.

The environmental trade-offs associated with PVDF in solar panels highlight the complexity of sustainable technology development. While the material contributes to improved solar panel performance and longevity, its production and end-of-life management present challenges that require ongoing research and innovation. As the renewable energy sector continues to grow, balancing the benefits of PVDF use against its potential environmental impacts will be crucial in developing truly sustainable solar energy solutions.

Cost-Benefit Analysis of PVDF Solar Integration

The integration of PVDF (Polyvinylidene Fluoride) into solar panel technology presents a compelling case for enhancing renewable energy efficiency. To fully understand the economic implications of this innovation, a comprehensive cost-benefit analysis is essential.

From a cost perspective, the incorporation of PVDF into solar panels involves several factors. The primary expense lies in the material itself, as PVDF is a specialized polymer that requires precise manufacturing processes. This initial investment in PVDF production and integration may lead to higher upfront costs for solar panel manufacturers. Additionally, the modification of existing production lines to accommodate PVDF integration could result in temporary disruptions and associated expenses.

However, these costs must be weighed against the potential long-term benefits. The most significant advantage of PVDF integration is the anticipated increase in solar panel efficiency. Studies have shown that PVDF can enhance light absorption and electron transport within solar cells, potentially increasing energy conversion rates by 5-10%. This improvement in efficiency translates directly into increased energy output over the lifespan of the solar panel.

The durability of PVDF also contributes to the cost-benefit equation. PVDF's resistance to UV radiation, chemicals, and extreme temperatures can extend the operational life of solar panels. This longevity reduces the frequency of panel replacements, leading to substantial savings in maintenance and replacement costs over time.

Energy market dynamics play a crucial role in this analysis. As global demand for renewable energy continues to rise, even marginal improvements in solar panel efficiency can yield significant economic benefits. The increased energy output from PVDF-enhanced panels could result in higher returns on investment for solar farm operators and individual consumers alike.

Environmental considerations further bolster the case for PVDF integration. The improved efficiency and durability of solar panels contribute to a reduction in the overall carbon footprint of solar energy production. This aligns with global sustainability goals and may provide additional economic incentives through carbon credits or government subsidies for clean energy initiatives.

In conclusion, while the initial costs of PVDF integration in solar panels may be substantial, the long-term benefits in terms of increased efficiency, durability, and environmental impact present a strong economic case. As production scales up and technology matures, the cost-benefit ratio is likely to improve further, making PVDF-enhanced solar panels an increasingly attractive option for the renewable energy sector.