PVDF's Role in Sustainable Architecture: Building the Future

PVDF in Architecture: Evolution and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a revolutionary material in the field of sustainable architecture, marking a significant milestone in the evolution of building technologies. The journey of PVDF in architecture began in the late 1960s when its unique properties were first recognized for construction applications. Initially used primarily for its weather resistance and durability, PVDF has since evolved to become a cornerstone of sustainable building practices.

The evolution of PVDF in architecture has been driven by the growing demand for energy-efficient and environmentally friendly building materials. As global awareness of climate change and environmental issues increased, the construction industry sought innovative solutions to reduce the carbon footprint of buildings. PVDF coatings and membranes have played a crucial role in this transition, offering superior protection against UV radiation, chemical resistance, and thermal stability.

Over the decades, PVDF has undergone significant technological advancements. The development of new formulations and manufacturing processes has enhanced its performance characteristics, making it suitable for a wider range of architectural applications. From exterior cladding and roofing membranes to solar-reflective coatings, PVDF-based products have continuously adapted to meet the changing needs of the construction industry.

The objectives of PVDF in sustainable architecture are multifaceted. Primarily, it aims to improve the energy efficiency of buildings by providing excellent thermal insulation and reflective properties. This contributes to reduced heating and cooling costs, thereby lowering the overall energy consumption of structures. Additionally, PVDF's durability and resistance to weathering extend the lifespan of building components, reducing the need for frequent replacements and minimizing waste.

Another key objective is to enhance the aesthetic appeal of buildings while maintaining functionality. PVDF coatings offer a wide range of colors and finishes, allowing architects to create visually striking designs without compromising on performance. The material's ability to retain its appearance over time, resisting fading and chalking, ensures that buildings maintain their intended look for years to come.

Looking towards the future, the role of PVDF in sustainable architecture is set to expand further. Research and development efforts are focused on improving its recyclability and incorporating bio-based components to reduce its environmental impact. The integration of PVDF with smart building technologies, such as self-cleaning surfaces and energy-harvesting systems, represents an exciting frontier in architectural innovation.

As we move towards more stringent environmental regulations and sustainability standards, PVDF is positioned to play a pivotal role in meeting these challenges. Its continued evolution will likely focus on enhancing its eco-friendly properties while maintaining its superior performance characteristics, ultimately contributing to the creation of more sustainable, resilient, and energy-efficient buildings for future generations.

Market Demand for Sustainable Building Materials

The demand for sustainable building materials has been steadily increasing in recent years, driven by growing environmental awareness, stringent regulations, and the need for energy-efficient structures. PVDF (Polyvinylidene Fluoride) has emerged as a key player in this market, offering unique properties that align with the principles of sustainable architecture.

The global sustainable construction materials market is experiencing robust growth, with projections indicating a significant expansion in the coming years. This growth is fueled by factors such as urbanization, population growth, and the increasing adoption of green building practices. Governments worldwide are implementing policies and incentives to promote sustainable construction, further stimulating market demand.

PVDF-based materials have gained traction in the sustainable building sector due to their exceptional durability, weather resistance, and energy-saving properties. These materials are particularly sought after for exterior applications, such as facades and roofing, where longevity and low maintenance are crucial. The ability of PVDF coatings to reflect solar radiation and reduce heat absorption contributes to improved energy efficiency in buildings, aligning with the growing demand for materials that can help reduce carbon footprints.

In the commercial construction segment, there is a strong preference for sustainable materials that can enhance building performance while minimizing environmental impact. PVDF-coated metal panels and membranes are increasingly specified in high-performance building designs, driven by their ability to meet stringent sustainability certifications such as LEED (Leadership in Energy and Environmental Design).

The residential sector is also showing increased interest in sustainable building materials, with homeowners becoming more conscious of the long-term benefits of using durable, energy-efficient products. PVDF-based materials are gaining popularity in residential roofing and siding applications, offering homeowners aesthetically pleasing options that require minimal maintenance and contribute to energy savings.

Developing economies are presenting significant growth opportunities for sustainable building materials, including PVDF-based products. Rapid urbanization and infrastructure development in these regions are creating a substantial demand for materials that can withstand harsh environmental conditions while meeting sustainability criteria.

The market for PVDF in sustainable architecture is also being driven by technological advancements. Innovations in PVDF formulations and application techniques are expanding the material's capabilities, making it suitable for a wider range of architectural applications. This includes the development of self-cleaning PVDF coatings and improved color retention properties, which are highly valued in sustainable building design.

Despite the positive market outlook, challenges such as the higher initial costs of PVDF-based materials compared to traditional alternatives persist. However, the long-term benefits in terms of durability, energy savings, and reduced maintenance are increasingly recognized by architects, builders, and property owners, contributing to the growing acceptance and demand for these materials in sustainable architecture.

Current PVDF Applications and Challenges

PVDF (Polyvinylidene fluoride) has gained significant traction in sustainable architecture due to its unique properties and versatile applications. Currently, PVDF is widely used in building facades, roofing systems, and protective coatings, offering excellent durability, weather resistance, and energy efficiency.

In facade applications, PVDF-based coatings and films are applied to metal panels, providing long-lasting protection against UV radiation, corrosion, and chemical exposure. These coatings maintain their color and gloss for extended periods, reducing the need for frequent maintenance and replacement. Additionally, PVDF-coated panels contribute to improved thermal performance by reflecting solar radiation, thus reducing cooling loads in buildings.

Roofing systems incorporating PVDF membranes have become increasingly popular due to their superior weatherability and resistance to environmental pollutants. These membranes offer excellent water resistance and can withstand extreme temperature fluctuations, making them ideal for various climatic conditions. PVDF roofing solutions also contribute to energy efficiency by reflecting solar heat and reducing the urban heat island effect.

Despite its numerous advantages, PVDF faces several challenges in the context of sustainable architecture. One primary concern is the environmental impact of PVDF production, which involves the use of fluorine-based chemicals. While PVDF itself is considered relatively inert and non-toxic, the manufacturing process raises questions about its overall sustainability footprint.

Another challenge lies in the recyclability of PVDF-based materials. While theoretically recyclable, the complex nature of PVDF composites and coatings often makes the recycling process difficult and economically unfeasible. This limitation poses a significant hurdle in achieving closed-loop material cycles in the construction industry.

The high initial cost of PVDF-based products compared to conventional alternatives remains a barrier to widespread adoption, particularly in cost-sensitive markets. Although the long-term benefits often outweigh the upfront investment, convincing stakeholders to prioritize life-cycle costs over initial expenses can be challenging.

Furthermore, the integration of PVDF materials with other sustainable building technologies, such as photovoltaic systems or green roofs, presents both opportunities and challenges. While PVDF's durability and chemical resistance make it compatible with various technologies, optimizing these integrations for maximum performance and sustainability requires ongoing research and development.

As the construction industry increasingly focuses on sustainable practices, addressing these challenges will be crucial for expanding PVDF's role in building the future of sustainable architecture. Innovations in production processes, recycling technologies, and cost-effective applications will be key to unlocking the full potential of PVDF in creating resilient, energy-efficient, and environmentally friendly buildings.

Existing PVDF-based Sustainable Building Systems

01 PVDF membrane fabrication and modification

Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance in applications such as filtration, separation, and energy storage. This includes methods for improving membrane porosity, hydrophilicity, and mechanical strength through the use of additives, surface treatments, or novel processing techniques.- PVDF membrane fabrication and modification: Various techniques for fabricating and modifying PVDF membranes are explored, including blending with other polymers, surface treatments, and incorporation of nanoparticles. These methods aim to enhance the membrane's properties such as hydrophilicity, fouling resistance, and mechanical strength for applications in water treatment and filtration.

- PVDF-based piezoelectric and energy harvesting devices: PVDF's piezoelectric properties are utilized in the development of energy harvesting devices and sensors. Research focuses on improving the piezoelectric performance through various processing techniques, electrode designs, and composite formations for applications in wearable electronics and self-powered systems.

- PVDF in battery separators and electrolytes: PVDF is extensively used in lithium-ion battery components, particularly as a binder for electrodes and in separator membranes. Research explores ways to enhance the electrochemical stability, ionic conductivity, and mechanical properties of PVDF-based materials for improved battery performance and safety.

- PVDF-based coatings and surface treatments: PVDF is employed in various coating applications due to its excellent chemical resistance and weatherability. Research focuses on developing PVDF-based coatings with enhanced properties such as self-cleaning, anti-corrosion, and flame retardancy for use in construction materials, automotive parts, and industrial equipment.

- PVDF in composite materials and blends: PVDF is combined with other materials to create composites and blends with enhanced properties. Research explores the incorporation of nanofillers, other polymers, and functional additives to improve mechanical strength, thermal stability, and electrical properties for applications in aerospace, automotive, and electronics industries.

02 PVDF-based composites and blends

Development of PVDF-based composite materials and polymer blends to combine the unique properties of PVDF with other materials. These composites often exhibit improved mechanical, thermal, or electrical properties, making them suitable for a wide range of applications in electronics, energy, and advanced materials.Expand Specific Solutions03 PVDF in energy storage applications

Utilization of PVDF in energy storage devices, particularly in lithium-ion batteries and supercapacitors. PVDF is used as a binder material for electrode fabrication, as well as in the development of solid electrolytes and separator membranes, contributing to improved battery performance and safety.Expand Specific Solutions04 PVDF in sensor and actuator technologies

Application of PVDF in the development of sensors and actuators, leveraging its piezoelectric and pyroelectric properties. This includes the fabrication of flexible sensors, pressure-sensitive devices, and energy harvesting systems for various industrial and consumer applications.Expand Specific Solutions05 PVDF processing and manufacturing techniques

Innovative methods for processing and manufacturing PVDF materials, including extrusion, electrospinning, and 3D printing techniques. These processes aim to optimize the production of PVDF-based products with specific morphologies, structures, or properties tailored for particular applications.Expand Specific Solutions

Key Players in PVDF Architectural Solutions

The PVDF market in sustainable architecture is experiencing rapid growth, driven by increasing demand for energy-efficient and environmentally friendly building materials. The industry is in a transitional phase, moving from niche applications to mainstream adoption. Market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, PVDF is reaching maturity, with companies like Arkema, Inc., Kureha Corp., and Solvay leading innovation. These firms, along with emerging players such as Mitrex, Inc. and Shanghai HIUV New Materials Co., Ltd., are developing advanced PVDF formulations for improved durability, weather resistance, and energy efficiency in architectural applications. Research institutions like Zhejiang University and Beijing University of Chemical Technology are contributing to technological advancements, further solidifying PVDF's role in sustainable architecture.

Arkema, Inc.

Denka Corp.

Innovative PVDF Formulations for Construction

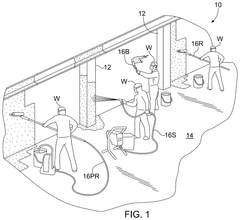

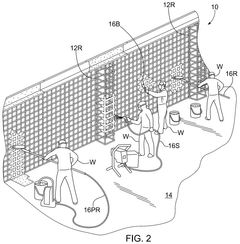

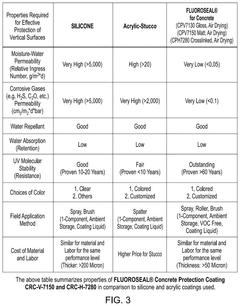

- A polyvinylidene fluoride (PVDF) dispersion coating is applied to architectural substrates, including backsheets, using a solvent-based or aqueous-based dispersion coating with hydrophobic solvents and non-reactive acrylic co-resins, which enhances adhesion and allows for lower curing temperatures to prevent shrinkage and embrittlement, and can be functionalized for improved adhesion without the need for cross-linking additives.

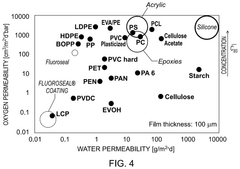

- A method involving the application of a liquidous coating of modified polyvinylidene fluoride (PVDF) or polyvinylidene difluoride (PVDF) material in an air dryable solution, which forms a blend with compatible acrylic and/or other polymers, providing a robust barrier against moisture and corrosive gases, and can be applied in the field without controlled conditions.

Environmental Impact Assessment of PVDF Use

The environmental impact assessment of PVDF (Polyvinylidene Fluoride) use in sustainable architecture is a critical aspect of evaluating its role in building the future. PVDF, a fluoropolymer known for its durability and resistance to various environmental factors, has gained significant attention in the construction industry. However, its widespread adoption necessitates a comprehensive analysis of its environmental footprint throughout its lifecycle.

One of the primary considerations in assessing PVDF's environmental impact is its production process. The manufacturing of PVDF involves the use of fluorine-based chemicals, which can have potential environmental implications if not properly managed. The energy-intensive nature of PVDF production also contributes to its carbon footprint. However, advancements in manufacturing technologies and the implementation of more efficient processes have led to reduced environmental impacts in recent years.

When evaluating the use phase of PVDF in buildings, several positive environmental aspects emerge. PVDF coatings and membranes contribute to improved energy efficiency by reflecting solar radiation and reducing heat absorption. This property can lead to decreased cooling loads in buildings, resulting in lower energy consumption and reduced greenhouse gas emissions over the structure's lifetime. Additionally, PVDF's resistance to weathering, UV radiation, and chemical degradation extends the lifespan of building components, reducing the need for frequent replacements and associated resource consumption.

The end-of-life considerations for PVDF-based materials are an essential component of their environmental impact assessment. While PVDF is not biodegradable, it is recyclable, which presents opportunities for reducing waste and conserving resources. However, the recycling process for PVDF can be complex due to its chemical properties, and the availability of recycling facilities may vary across regions. This aspect highlights the importance of developing more efficient recycling technologies and establishing comprehensive recycling programs to maximize the material's circularity.

In terms of indoor environmental quality, PVDF coatings have demonstrated low volatile organic compound (VOC) emissions, contributing to healthier indoor air quality. This characteristic aligns with sustainable building practices and can positively impact occupant health and well-being. Furthermore, PVDF's resistance to microbial growth can reduce the need for chemical treatments in buildings, potentially decreasing the overall environmental impact associated with maintenance activities.

When comparing PVDF to alternative materials used in sustainable architecture, a holistic approach is necessary. While PVDF may have a higher initial environmental impact due to its production process, its long-term benefits in terms of durability, energy efficiency, and reduced maintenance requirements can offset these initial costs over the building's lifecycle. However, this balance varies depending on specific applications, local climate conditions, and the availability of alternative sustainable materials.

Regulatory Framework for PVDF in Construction

The regulatory framework for PVDF in construction is a complex and evolving landscape that plays a crucial role in shaping the adoption and implementation of this material in sustainable architecture. As PVDF gains prominence in building applications, governments and industry bodies worldwide are developing and refining regulations to ensure its safe and effective use.

In the United States, the International Building Code (IBC) and the American Society for Testing and Materials (ASTM) have established standards for PVDF coatings and materials in construction. These standards address factors such as fire resistance, weatherability, and durability. The National Fire Protection Association (NFPA) also provides guidelines for the use of PVDF in building materials, particularly concerning fire safety.

The European Union has implemented the Construction Products Regulation (CPR), which includes provisions for PVDF-based products. This regulation ensures that construction materials, including those containing PVDF, meet specific performance requirements related to mechanical resistance, fire safety, and environmental impact. The European Committee for Standardization (CEN) has developed harmonized standards for PVDF-coated materials used in construction.

In Asia, countries like China and Japan have their own regulatory frameworks for PVDF in construction. China's GB standards and Japan's JIS standards provide guidelines for the use of PVDF in building materials, focusing on quality control, performance, and environmental considerations.

Environmental regulations also play a significant role in shaping the use of PVDF in sustainable architecture. Many countries have implemented green building codes and certification systems, such as LEED in the United States and BREEAM in the UK, which indirectly influence the use of PVDF by promoting materials with long lifespans and low environmental impact.

As concerns about sustainability and climate change grow, regulations are increasingly focusing on the lifecycle assessment of building materials. This trend is likely to benefit PVDF, given its durability and potential for recycling. However, it also puts pressure on manufacturers to develop more environmentally friendly production processes and end-of-life solutions for PVDF products.

The regulatory landscape for PVDF in construction is not static. Ongoing research into the material's properties and environmental impact continues to inform policy decisions. As a result, manufacturers, architects, and builders must stay informed about evolving regulations to ensure compliance and maximize the benefits of PVDF in sustainable architecture.